Aggressive agent for displaying metallographic structure of casting magnesium alloy and preparation method and application of aggressive agent

A casting magnesium alloy, metallographic structure technology, applied in the field of casting magnesium alloy metallographic inspection, can solve the problems of long erosion time, etc., achieve the effect of short erosion time, clearly visible grain boundaries, and easy observation of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment shows that the etchant for the metallographic structure of cast magnesium alloys consists of the following volume components: 6ml of lactic acid with a purity of 99%, 2ml of phosphoric acid with a mass fraction of 85%, 10ml of glycerin with a purity of 99.7%, and a mass fraction of 75ml of 99.7% absolute ethanol, 7ml of distilled water with a purity of 99.99%.

[0031] This embodiment shows the preparation method of the etchant for the metallographic structure of cast magnesium alloy, comprising the following steps:

[0032] 1) Mix 10ml of glycerin and 75ml of absolute ethanol, stir evenly to obtain the mixture A;

[0033] 2) Add 6ml of lactic acid and 2ml of phosphoric acid to mixture A in sequence, and stir evenly to obtain mixture B;

[0034] 3) Add 7ml of distilled water to the mixed solution B to dilute it.

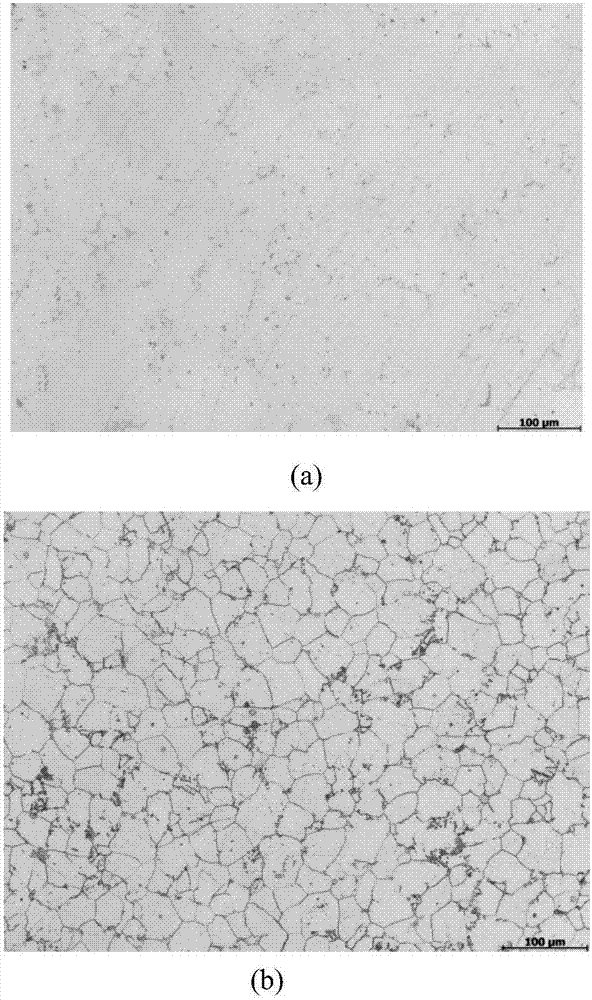

[0035] The application of the above-mentioned etchant in this embodiment in displaying the metallographic structure of cast magnesium alloys...

Embodiment 2

[0042] This embodiment shows that the etchant for the metallographic structure of cast magnesium alloys consists of the following volume components: 4 ml of lactic acid with a purity of 99%, 4 ml of phosphoric acid with a mass fraction of 85%, 5 ml of glycerin with a purity of 99.7%, and a mass fraction of 99.7 80ml of absolute ethanol, 7ml of distilled water with a purity of 99.99%.

[0043] This embodiment shows the preparation method of the etchant for the metallographic structure of cast magnesium alloy, comprising the following steps:

[0044] 1) Mix 5ml of glycerin and 80ml of absolute ethanol and stir evenly to obtain a mixture A;

[0045] 2) Add 4ml of lactic acid and 4ml of phosphoric acid to mixture A in sequence, and stir evenly to obtain mixture B;

[0046] 3) Add 7ml of distilled water to the mixed solution B to dilute it.

[0047] The application of the above-mentioned etchant obtained in this embodiment in displaying the metallographic structure of cast magnes...

Embodiment 3

[0054] This embodiment shows that the etchant for the metallographic structure of cast magnesium alloys consists of the following volume components: 2 ml of lactic acid with a purity of 99%, 6 ml of phosphoric acid with a mass fraction of 85%, 15 ml of glycerin with a purity of 99.7%, and a mass fraction of 70ml of 99.7% absolute ethanol, 7ml of distilled water with a purity of 99.99%.

[0055] This embodiment shows the preparation method of the etchant for the metallographic structure of cast magnesium alloy, comprising the following steps:

[0056] 1) Mix 15ml of glycerin and 70ml of absolute ethanol and stir evenly to obtain a mixture A;

[0057] 2) Add 2ml of lactic acid and 6ml of phosphoric acid to mixture A in sequence, and stir evenly to obtain mixture B;

[0058]3) Add 7ml of distilled water to the mixed solution B to dilute it.

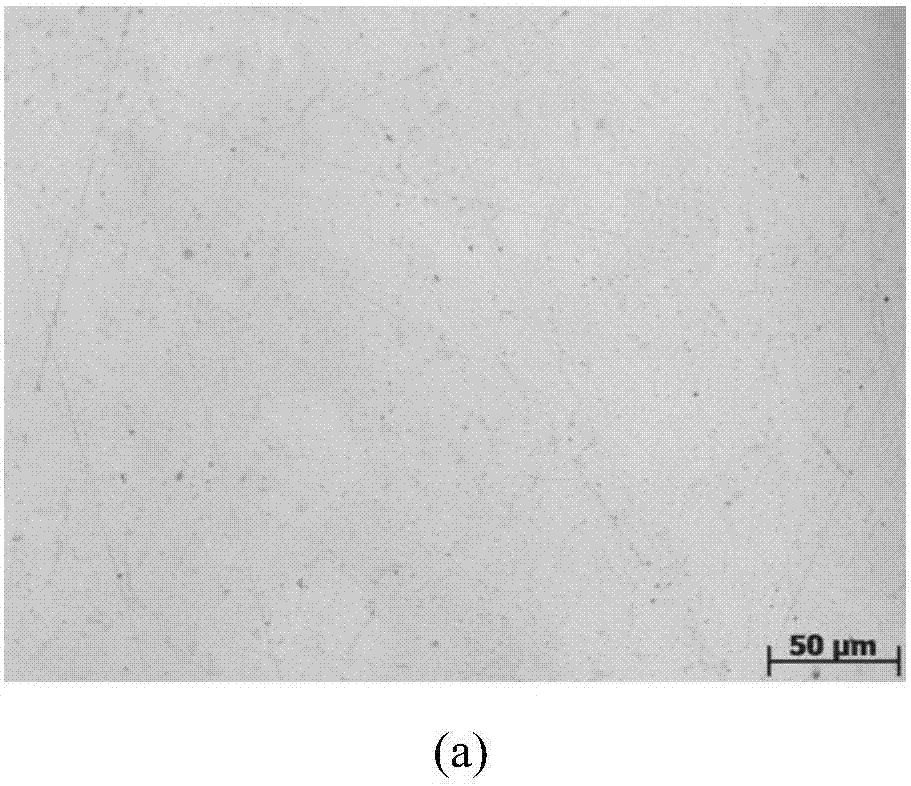

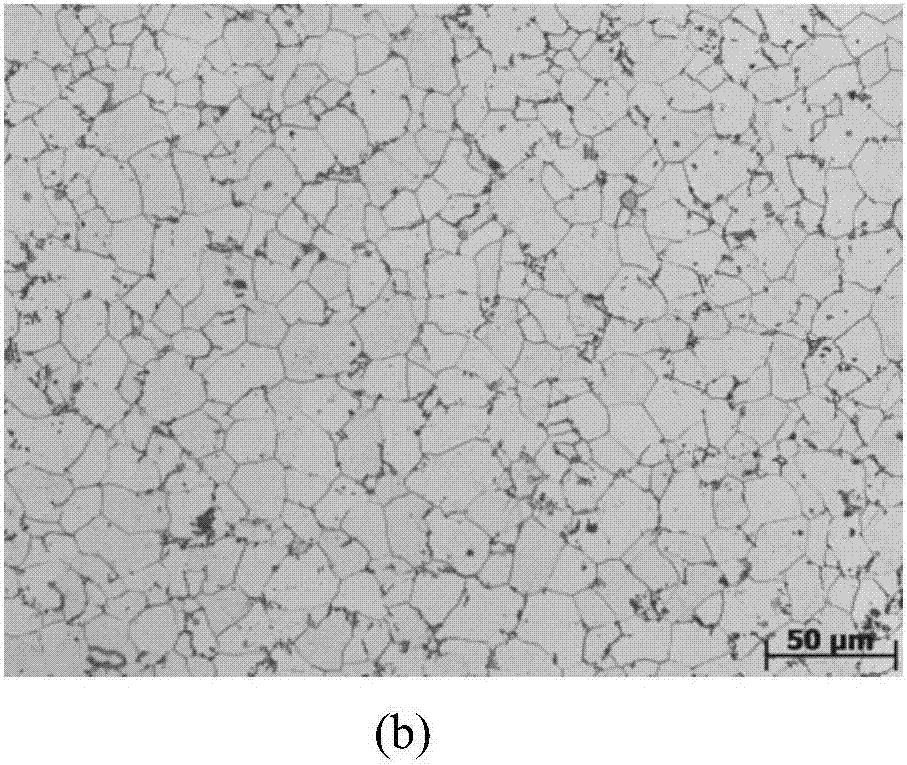

[0059] The application of the above-mentioned etchant obtained in this embodiment in displaying the metallographic structure of cast magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com