Polydopamine-coated bacterial cellulose membrane and preparation method thereof

A technology of bacterial cellulose membrane and bacterial cellulose, which is applied in the field of electrochemistry, can solve problems such as difficult wetting of electrolyte, large interface resistance, and decreased battery safety, and achieves simple preparation methods, low equipment requirements, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

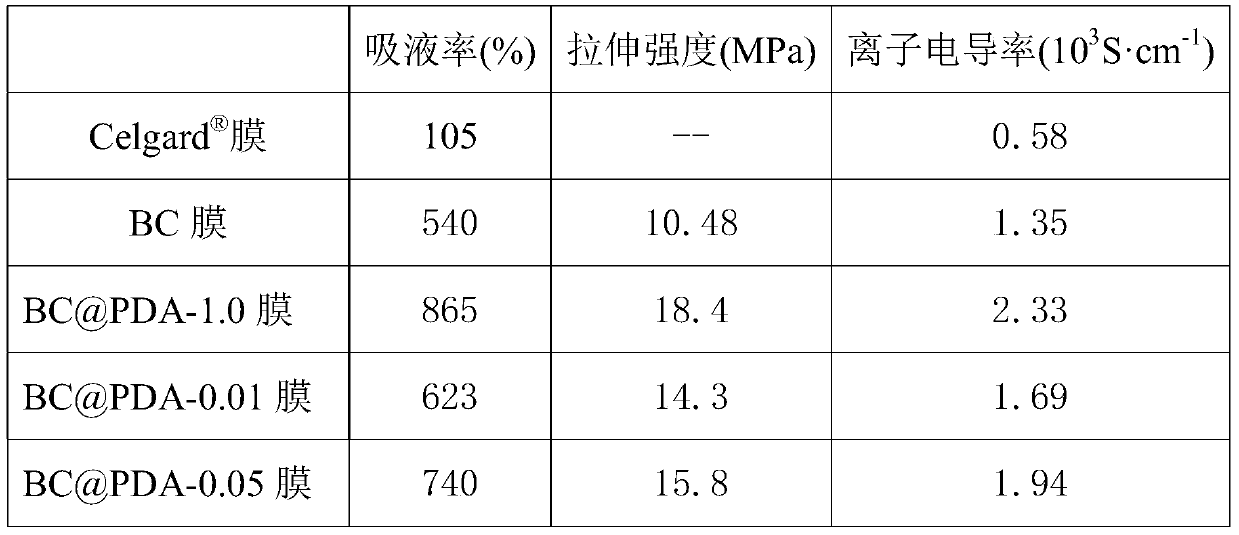

[0042] Prepare 100mL dopamine aqueous solution with a concentration of 1.0w / v%, put 5g bacterial cellulose membrane (gel membrane) in the solution and soak for 24h, stir slowly (it is beneficial for dopamine to diffuse into the bacterial cellulose membrane), take it out and place Soak in 100mL of ammonia solution with pH=8.0 for 24h, take it out, wash the surface with deionized water, then soak in 50mL of acetone (solvent exchange) for 24h, take it out and filter it first, and finally use a hot press at 60°C to dry the wet The membrane was pressed thin and dried at 80°C for 24 hours to obtain a bacterial cellulose membrane coated with polydopamine, which was denoted as BC@PDA-1.0 membrane.

Embodiment 2

[0044] Prepare 100mL dopamine aqueous solution with a concentration of 0.01w / v%, put 2g bacterial cellulose membrane (gel membrane) in the solution and soak for 12h, stir slowly (it is beneficial for dopamine to diffuse into the bacterial cellulose membrane), take it out and place Soak in 100mL pH=8.5 Tris aqueous solution for 12h, take it out, wash the surface with deionized water, then soak in 50mL methanol ketone (solvent exchange) for 20h, take it out and filter it first, and finally use a hot press The wet film was pressed thin at 70°C and dried at 80°C for 24 hours to obtain a bacterial cellulose film coated with polydopamine, which was designated as BC@PDA-0.01 film.

Embodiment 3

[0046] Prepare 100mL dopamine aqueous solution with a concentration of 0.05w / v%, put 3g bacterial cellulose membrane (gel membrane) in the solution and soak for 18h, stir slowly, (it is beneficial for dopamine to diffuse into the bacterial cellulose membrane), after taking it out Soak in 100mL pH=8.2 sodium bicarbonate aqueous solution for 12h, take it out, wash the surface with deionized water, then soak in 50mL isopropanol alcohol (solvent exchange) for 15h, take it out and filter it first, and finally use a hot press The wet film was pressed thin at 80°C and dried at 80°C for 24 hours to obtain a bacterial cellulose film coated with polydopamine, which was denoted as BC@PDA-0.05 film.

[0047] We scanned the BC@PDA-1.0 film prepared in Example 1 and the BC@PDA-0.01 film prepared in Example 2 respectively, and the obtained scanning electron micrographs are as follows: figure 1 and figure 2 shown.

[0048] Depend on figure 1 and figure 2 It can be seen that a layer of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com