Preparation of high-safety ceramic-coated separator and application of ceramic-coated separator in lithium ion battery

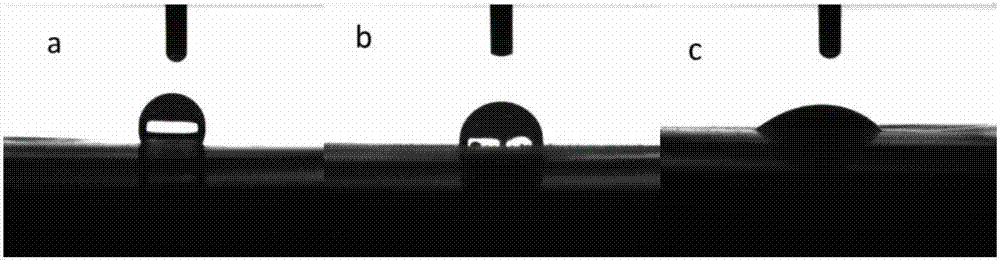

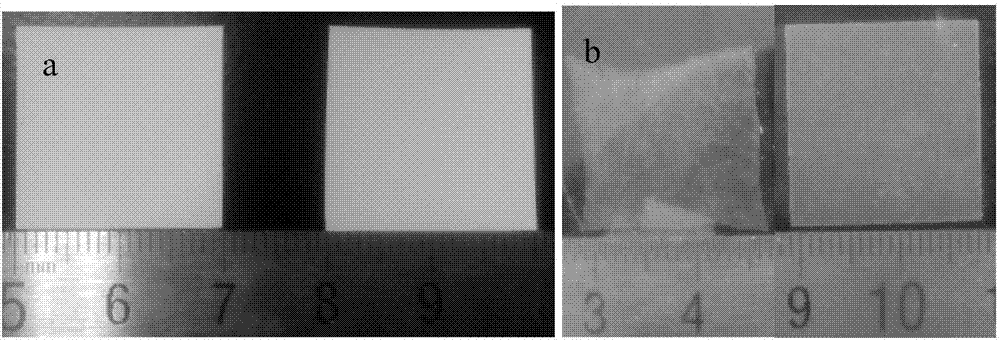

A technology of lithium-ion batteries and ceramic diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of limited thermal stability of ceramic diaphragms, aggravated heat accumulation, high battery pressure, etc., to improve strength and thermal stability performance, improve security performance, and improve the effect of interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

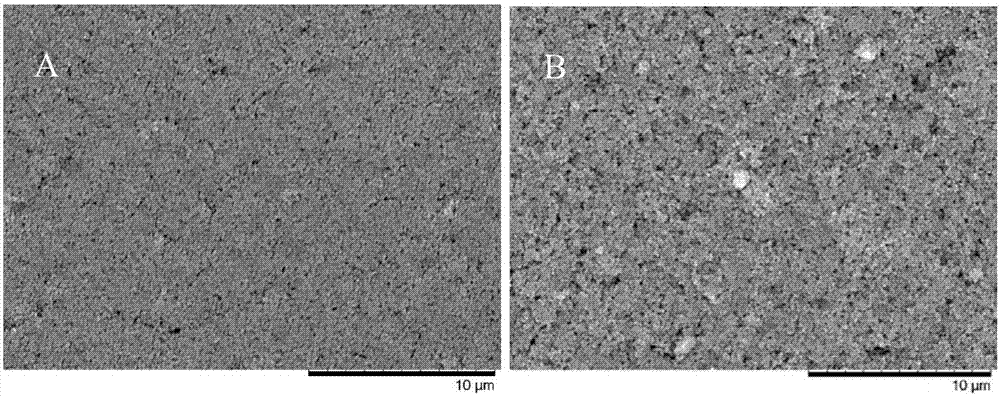

[0045] Put 1g of alumina nanoparticles, lignin, sodium carboxymethylcellulose (CMC) and styrene-butadiene rubber (SBR) in a mass ratio of 75:20:2:3 into deionized water and ethanol (1: 1, volume ratio) mixed solution 10ml, mix evenly, the obtained slurry is evenly coated on the monolayer surface of commercial polyethylene (PE) separator. Dry to remove the solvent to obtain a modified ceramic diaphragm.

Embodiment 2

[0051] Silica nanoparticles, sodium lignosulfonate, sodium carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) with a mass ratio of 80: 15: 2: 3 mixed powder 1g, put into deionized water and Propanol (1:2, volume ratio) mixed solution 10ml, mixed evenly, and the obtained slurry was uniformly coated on the surface of a single layer of commercial polypropylene (PP) separator. Dry to remove the solvent to obtain a modified ceramic diaphragm.

Embodiment 3

[0054] Put titanium dioxide nanoparticles, calcium lignosulfonate, and polyacrylate terpolymer latex (LA132, LA133) in a mass ratio of 70:25:3:2 into 1g of mixed powder, put it into deionized water and acetone (2: 1, volume ratio) mixed solution 10ml, mix evenly, the obtained slurry is evenly coated on the double-layer surface of commercial polyethylene (PE) diaphragm. Dry to remove the solvent to obtain a modified ceramic diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com