Halogen-free resin composition and low-fluidity prepreg thereof

A resin composition and composition technology, applied in the field of halogen-free resin composition and its low fluidity prepreg, can solve the problems of poor heat resistance, poor film bonding force, lower glass transition temperature, etc., and achieve excellent heat resistance , good wettability, high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

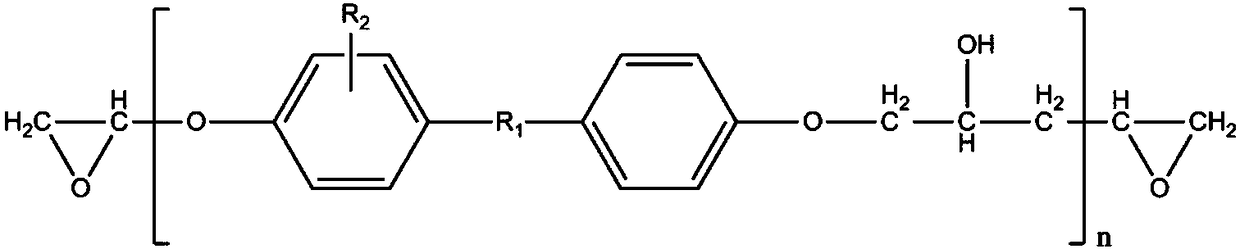

Image

Examples

Embodiment 1-7

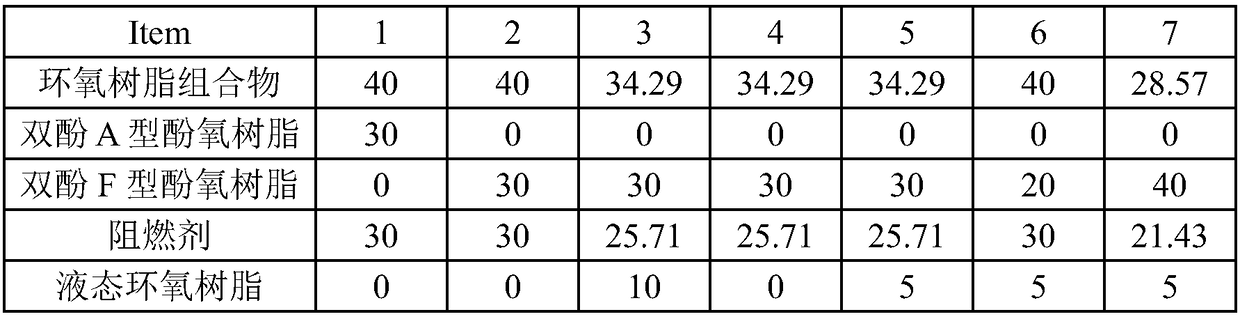

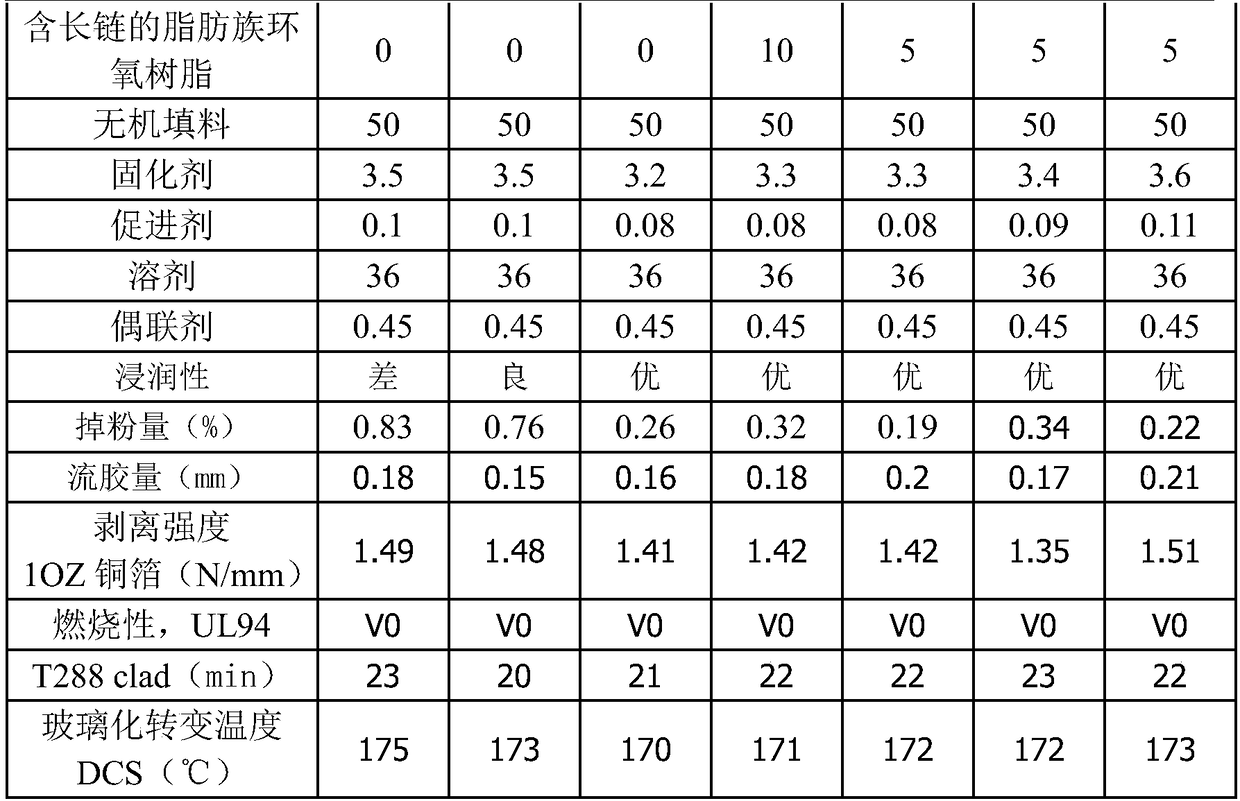

[0040] Examples 1-7: Prepare halogen-free resin compositions, corresponding low-fluidity prepregs and copper-clad laminates according to the content of each component in Table 1 and referring to the above steps. The corresponding performance results are listed in Table 1.

[0041] Table 1

[0042]

[0043]

[0044] In summary, the present invention improves the wettability of the resin system by introducing the bisphenol F type phenolic resin with better wettability, and simultaneously introduces liquid epoxy resin and aliphatic epoxy resin containing long chains to normal epoxy resin Toughening modification further improves the wettability of the glue, and at the same time makes the prepreg have better fluidity and does not drop resin dust, which can effectively improve the flexibility and Tg of the prepreg, and has good processability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com