Lignosulfonic acid-reinforced polypyrrole conductive paper and preparation method thereof

A technology of lignosulfonic acid and lignosulfonate, which is applied in special paper, natural cellulose pulp/paper, non-woody plant/crop pulp, etc. Powder and other problems, to achieve the effect of improving the strength of the paper, increasing the adsorption point and adsorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

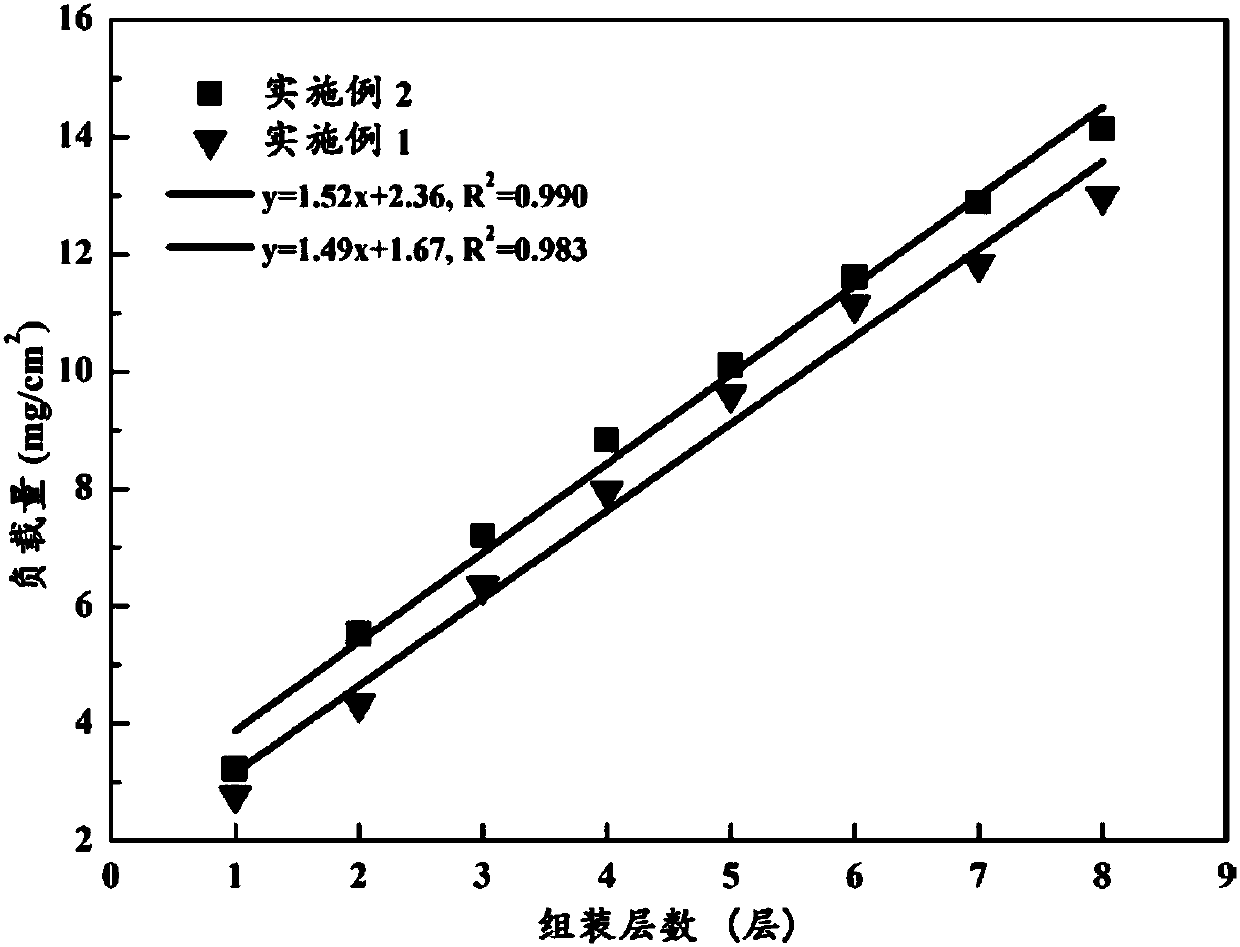

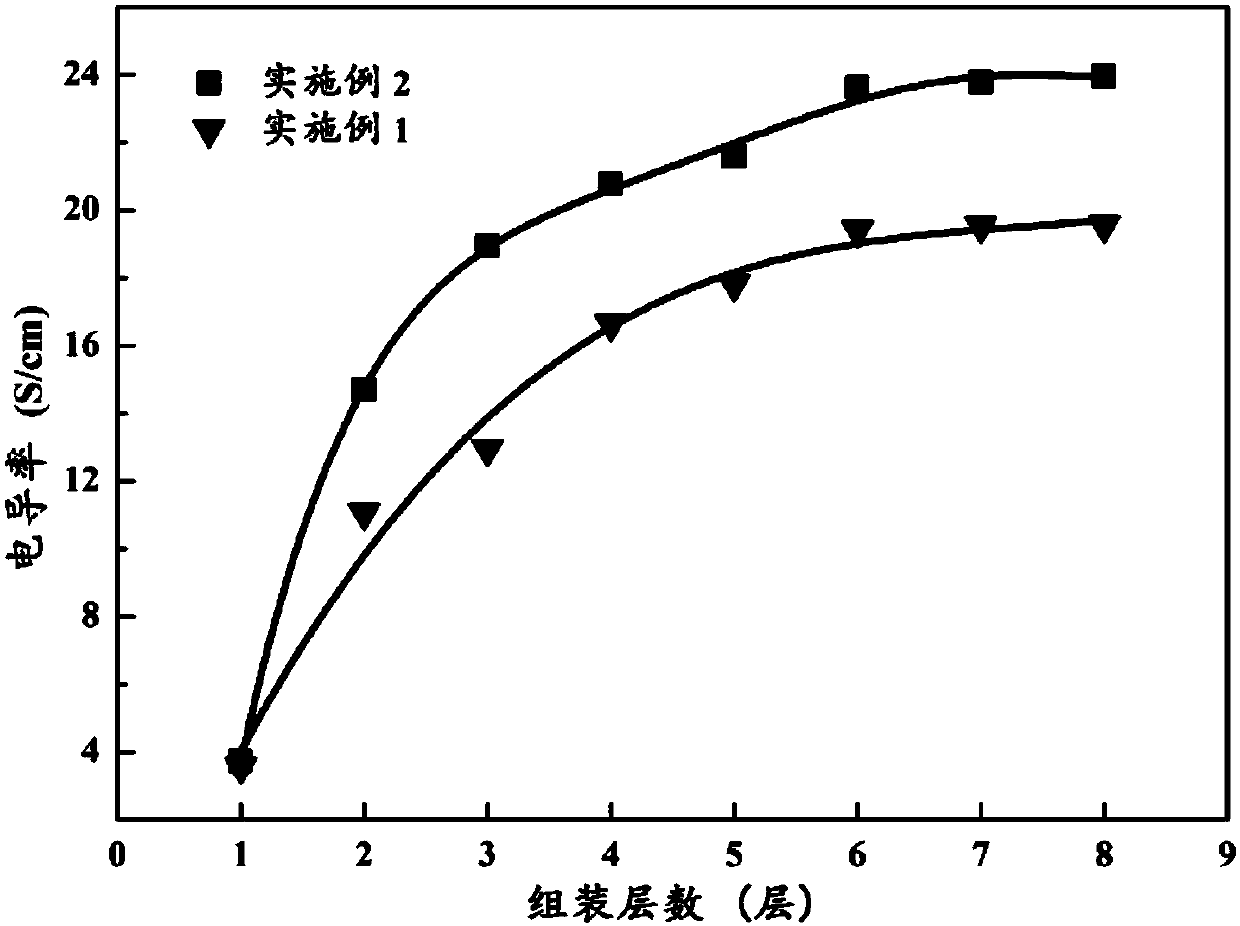

Embodiment 1

[0059] Straw pulp sulfonated alkali lignin (obtained from straw pulp alkali pulping black liquor through sulfonation reaction) is separated by an ultrafiltration membrane with a molecular weight cut-off of 10,000 to 50,000, and then purified by a cation exchange resin to obtain lignosulfonic acid (mass Percent = 20%, pH = 1.58). Soak 18cm qualitative filter paper in the above lignosulfonic acid for 10min, transfer to 0.5% formaldehyde aqueous solution (adjust pH=3 with hydrochloric acid) and soak for 10min, heat to 100°C for 2h, take out, wash with deionized water and dry. Then soak 10min in the mixed solution of pyrrole and ethanol of 20mL, the volume percentage of pyrrole and ethanol is 20%, take out and transfer to the mixed solution of 20mL hydrochloric acid and ferric chloride and react for 40min, the concentration of hydrochloric acid is 0.3M, hydrochloric acid and three The molar ratio of ferric chloride is 1:1. The paper loaded with the reaction product was taken out,...

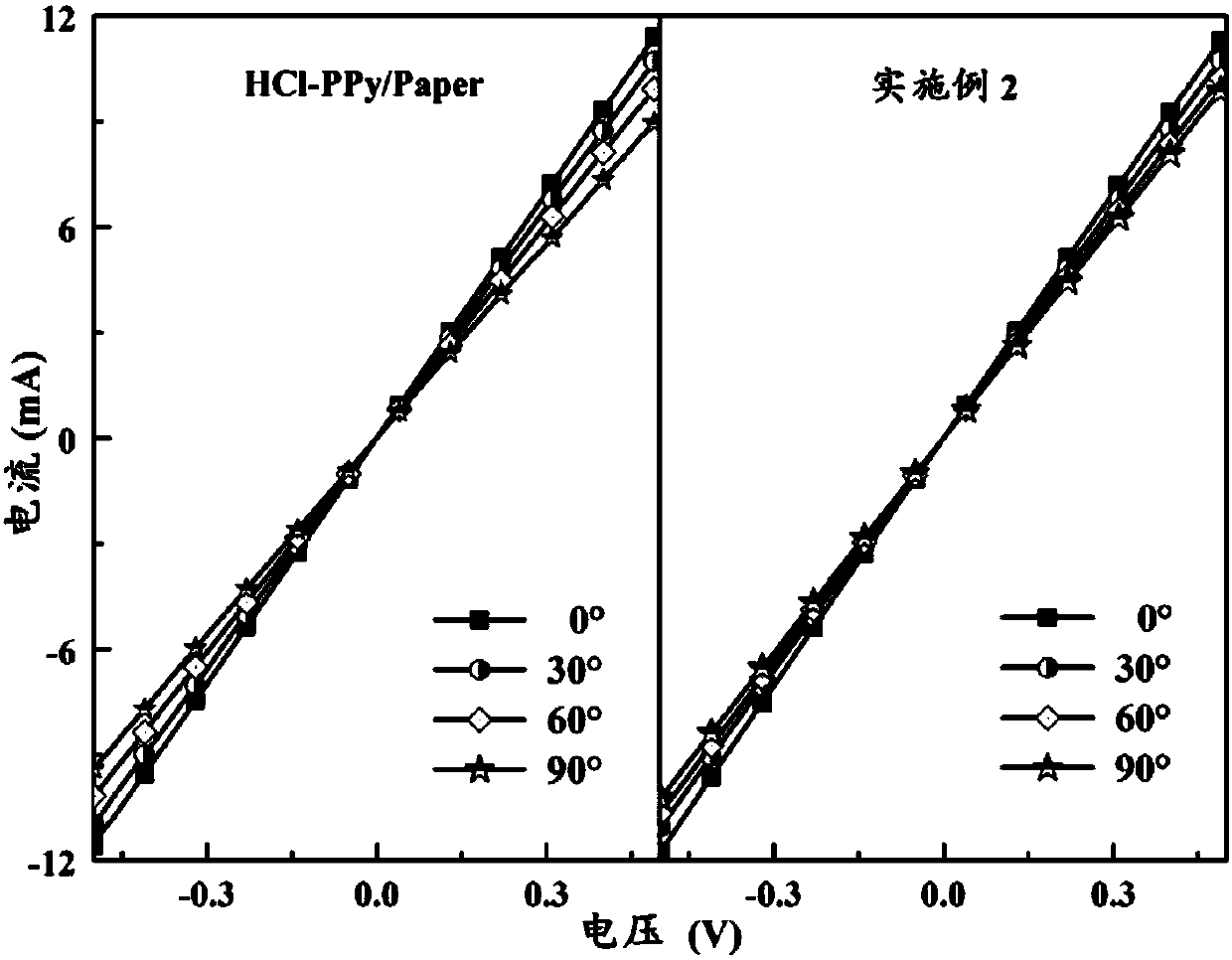

Embodiment 2

[0061] Wood pulp sodium lignosulfonate (for wood pulp acid pulping red liquor) is separated by an ultrafiltration membrane with a molecular weight cut-off of 10,000 to 50,000, and then purified by a cation exchange resin to obtain lignosulfonic acid (mass percentage=20%, pH = 1.65). Soak 18cm qualitative filter paper in the above lignosulfonic acid for 10min, transfer to 0.5% formaldehyde aqueous solution (adjust pH=3 with hydrochloric acid) and soak for 10min, heat to 100°C for 2h, take out, wash with deionized water and dry. Then soak 10min in the mixed solution of pyrrole and ethanol of 20mL, the volume percentage of pyrrole and ethanol is 20%, take out and transfer to the mixed solution of 20mL hydrochloric acid and ferric chloride and react for 40min, the concentration of hydrochloric acid is 0.3M, hydrochloric acid and three The molar ratio of ferric chloride is 1:1. The paper loaded with the reaction product was taken out, washed with deionized water and dried. Repeat...

Embodiment 3

[0062] Embodiment 3: comparative example

[0063] The qualitative filter paper of 18cm is soaked 10min in the mixed solution of pyrrole and ethanol of 20mL, and the volume percentage of pyrrole and ethanol is 20%, take out and transfer to the mixed solution of 20mL hydrochloric acid and ferric chloride and react for 40min, and the concentration of hydrochloric acid is 0.3M, The molar ratio of hydrochloric acid and ferric chloride is 1:1. The paper loaded with the reaction product was taken out, washed with deionized water and dried. Repeat the above steps to prepare hydrochloric acid-doped polypyrrole conductive paper (HCl-PPy / Paper).

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com