Self-assembly coating cloth or paper for treating VOCs (volatile organic compounds) like formaldehyde and preparation method thereof

A technology of self-assembly and coated cloth, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of limited amount of adsorption material and contact area, occupying indoor and car space, affecting adsorption efficiency, etc., to achieve Not easy to pulverize and fall off, not easy to drop powder, high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

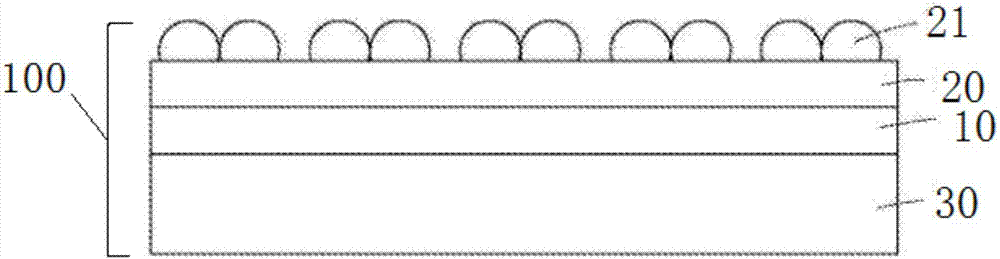

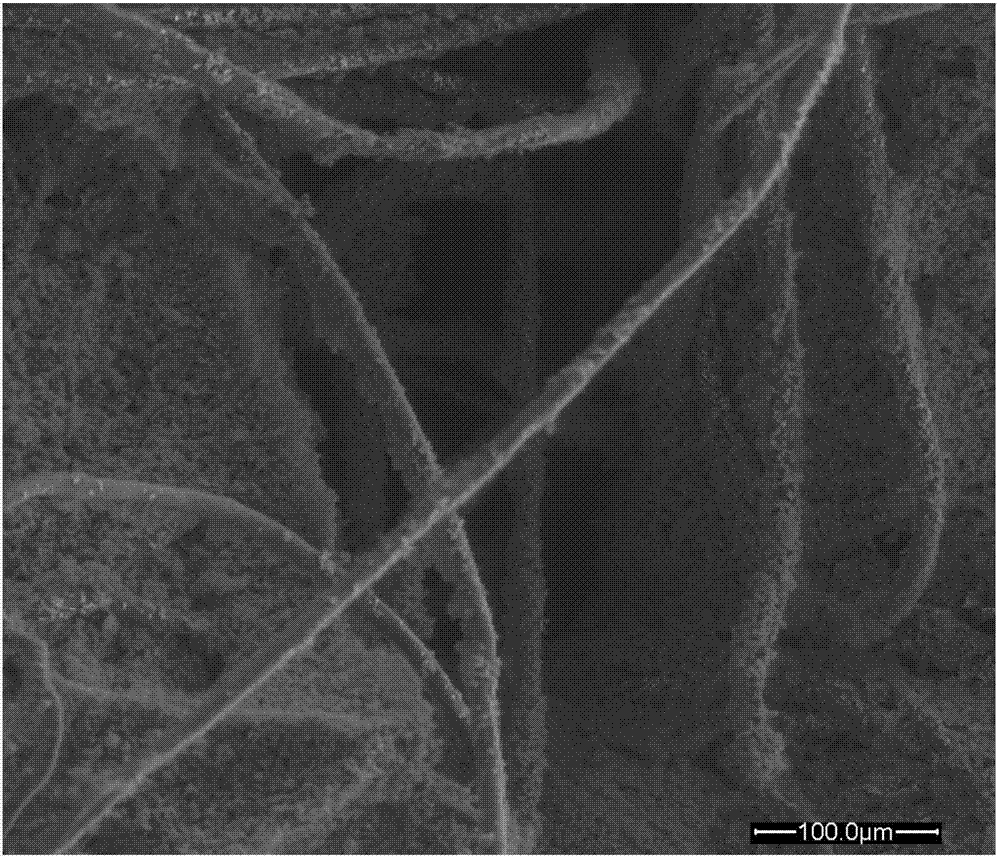

[0047] A kind of preparation method of the self-assembled coating furniture cloth that is used for the VOCs treatment such as formaldehyde, comprises the steps:

[0048] Prepare mixed solution a so that it contains 10g / L cationic polyelectrolyte (a mixed solution composed of polyallylamine hydrochloride and polyvinylamine in a volume ratio of 3:1), 0.1mol / L inorganic salt (sodium chloride) ; The 0.2mm thick polyester-cotton furniture cloth is completely submerged in the mixed solution a and deposited for 15 minutes; the mixed solution b is prepared so that it contains 5% zeolite by mass fraction, 1% nano-titanium dioxide, and 3% dodecane Sodium alkylbenzenesulfonate, 5% polyvinylpyrrolidone, and fully stirred and dispersed, the particle size of the zeolite nanoparticles is 50-200nm, and the particle size of the nano-titanium dioxide particles is 10-20nm; the polyester-cotton furniture cloth is mixed Take it out from solution a, and dry thoroughly in hot air at 50°C; immerse th...

Embodiment 2

[0050] A kind of preparation method of the self-assembled coating furniture cloth that is used for the VOCs treatment such as formaldehyde, comprises the steps:

[0051] Prepare mixed solution a so that it contains 20g / L anionic polyelectrolyte (polystyrene sulfonic acid), 0.05mol / L inorganic salt (ammonium chloride); 0.3mm thick linen furniture cloth is completely immersed in this mixed solution a In, deposition 15 minutes; Preparation mixed liquid b, make it contain the diatomite that mass fraction is 10%, the nanometer zinc oxide of 1%, the sodium dodecyl sulfonate of 2%, the curing agent of 4% (polyethylene The mass ratio of pyrrolidone to polyethylene oxide is 1:1), and fully stirred and dispersed, the particle diameter of the diatomaceous earth nanoparticles is 100-500nm, and the particle diameter of the nano-zinc oxide particles is 20nm; Take it out of the mixture a, and dry it in hot air at 50°C; immerse the dried linen furniture in the mixture b, let it stand for 15 m...

Embodiment 3

[0053] A kind of preparation method of self-assembled coating wallpaper that is used for VOCs control such as formaldehyde, comprises the steps:

[0054] Prepare mixed solution a, make it comprise the cationic polyelectrolyte (polyethylene amine) of 15g / L, the inorganic salt (potassium chloride) of 0.15mol / L; The polyester non-woven fabric wallpaper is fully immersed in this mixed solution a, deposits 15 minutes; Prepare mixed solution b, make it comprise the attapulgite of 15% massfraction, the catalyst nanoparticle of 2% (nano-titanium dioxide and nano-manganese dioxide mass ratio are 9:1), 3% sodium laurate , 8% polyethylene glycol, and fully stirred and dispersed, the particle size of the attapulgite particle is 200-500nm, and the particle size of the catalyst nanoparticle is 10-20nm; the polyester non-woven paper is taken out from the mixed solution a , dry in hot air at 50°C; immerse the dried polyester non-woven fabric wallpaper in the mixture b, let it stand for 15 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com