Sulfonated polymer applied to lithium battery electrode as binder

A technology for sulfonated polymers and lithium batteries, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as hindering electrode active materials, conductive media, and weak conductivity, so as to improve cycle performance, The effect of improving the magnification characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Preparation of Sulfonated PEEK

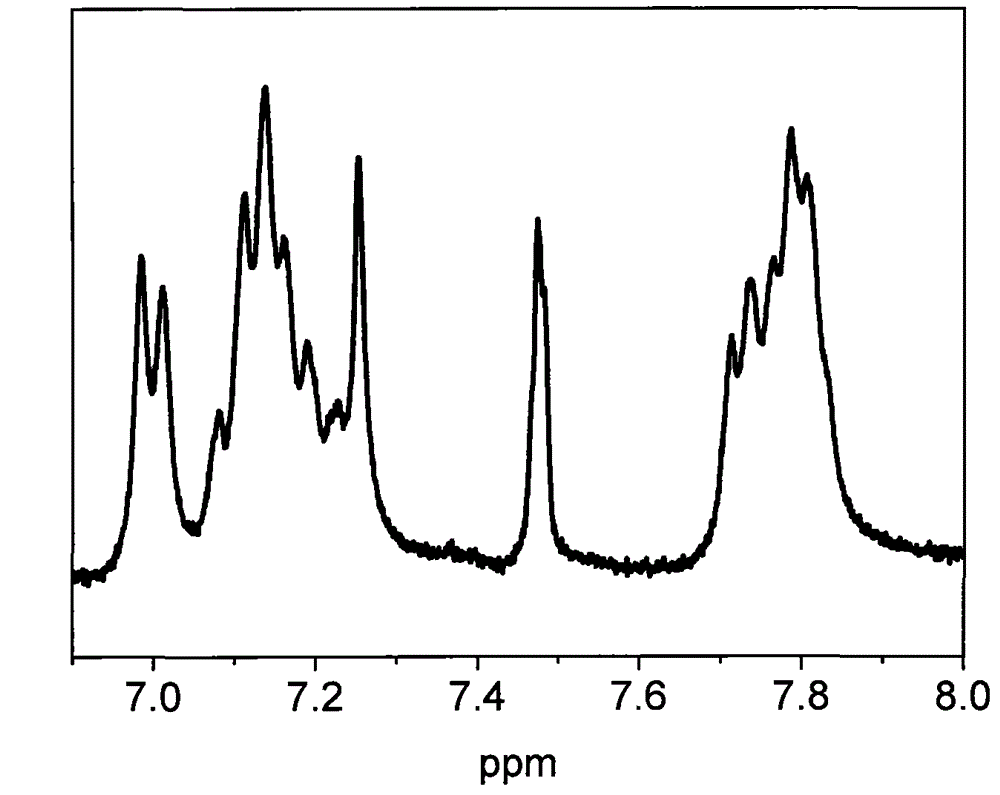

[0029] Dissolve 2g of polyetheretherketone in 60mL of sulfuric acid (mass concentration: 95% to 98%), heat in a water bath at 40°C, stir vigorously for 20 hours, then pour the solution into water, filter it with suction, wash with water until neutral; heat in an oven After drying, a solid product was obtained, which was sulfonated polyether ether ketone with a sulfonation degree of 75%. See figure 1 Sulfonated polyether ether ketone with a sulfonation degree of 75% 1 H-NMR spectrum. Based on the spectrum and the number of hydrogen atoms in different chemical environments in the sulfonated polyether ether ketone molecule, it can be calculated that the degree of sulfonation is 75%, that is, sulfonic acid groups are attached to 75% of the repeating units.

[0030] Synthetic Reaction Equation for Preparation of Sulfonated Polyetheretherketone

[0031]

[0032] Step 2: Preparation of lithium battery electrodes

[0033] 2-1. Pr...

Embodiment 2

[0038] Step 1: Preparation of Sulfonated PEEK

[0039]Dissolve 2g of polyetheretherketone in 60mL of sulfuric acid (mass concentration: 95% to 98%), heat in a water bath at 40°C, stir vigorously for 5 hours, then pour the solution into water, filter it with suction, wash with water until neutral; heat in an oven After drying, a solid product was obtained, which was sulfonated polyether ether ketone with a sulfonation degree of 56%.

[0040] Step 2: Preparation of lithium battery electrodes

[0041] Same as step 2 in Example 1.

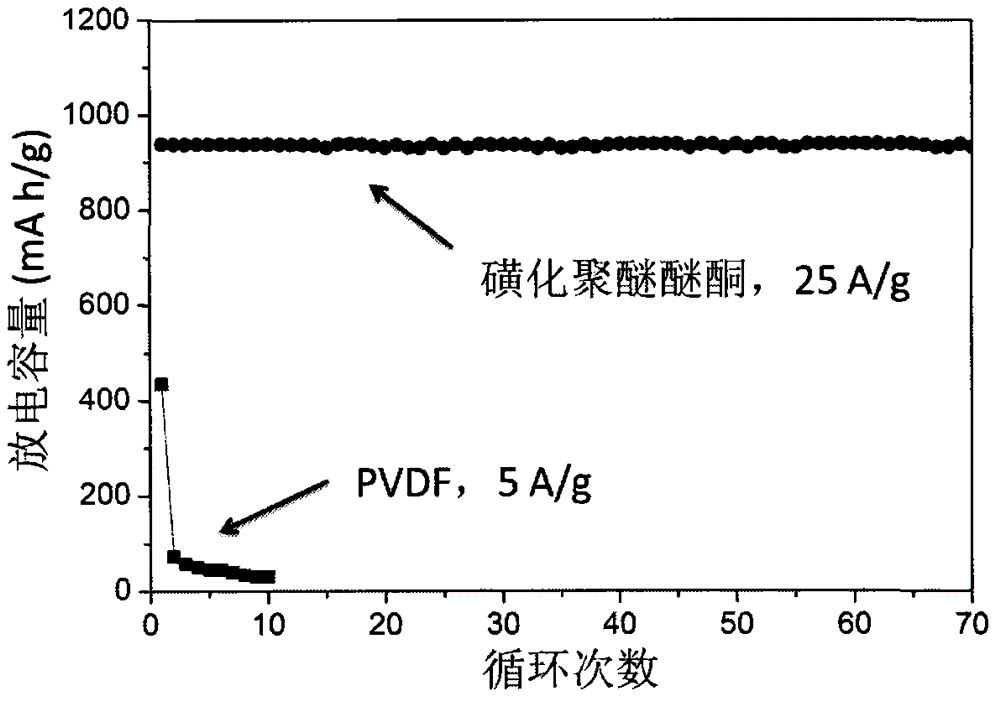

[0042] Step 3: Battery Performance Test Comparison

[0043] The sulfonated polyether ether ketone obtained in step 2-1 is used as a binder in the electrode slurry to use the obtained sulfur positive electrode for assembling a lithium battery, compared to using PVDF as a binder in the electrode slurry to use the obtained The sulfur cathode is used to assemble lithium batteries, and its battery cycle performance and rate performance are greatly improv...

Embodiment 3

[0045] Step 1: Preparation of Sulfonated PEEK

[0046] Same as step 1 in Example 1.

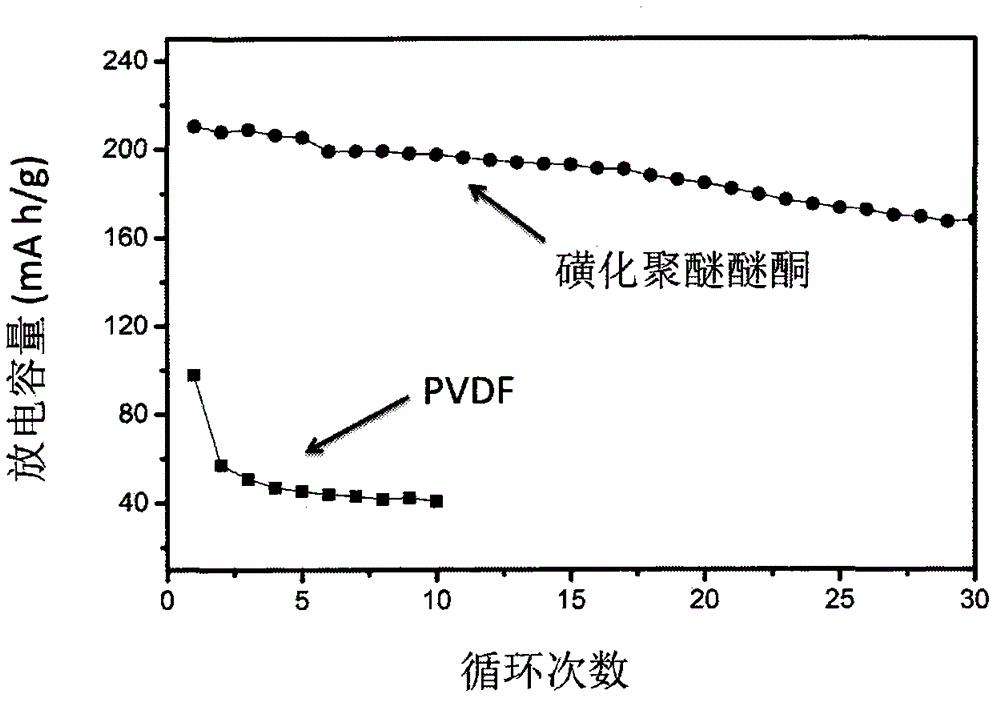

[0047] Step 2: Preparation of lithium battery electrodes

[0048] 2-1. Preparation of lithium battery electrodes containing sulfonates: mix sulfur and mesoporous carbon at a mass ratio of 3:1, heat in a closed container at 155°C for 24 hours to obtain active materials, and use conductive graphite as the conductive medium. 1 The obtained sulfonated polymer sulfonated polyetheretherketone is used as a binding agent, according to the mass ratio of active material: conductive graphite: sulfonated polyether ether ketone is 90:5:5 and then dispersed in N-formaldehyde The electrode slurry was obtained in a base pyrrolidone solvent, the electrode slurry was coated on an aluminum foil, and dried in vacuum at 70° C. for 24 hours to obtain a sulfur positive electrode used as a positive electrode of a lithium battery.

[0049] 2-2. Prepare a lithium battery electrode containing a traditional binder: as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com