Method for forming lithium manganese power cells

A technology of power battery and formation method, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery charging/discharging, etc. It can solve problems such as incomplete exhaust, poor battery consistency, and battery safety hazards, and achieve simple operation , high reliability, and the effect of improving available capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

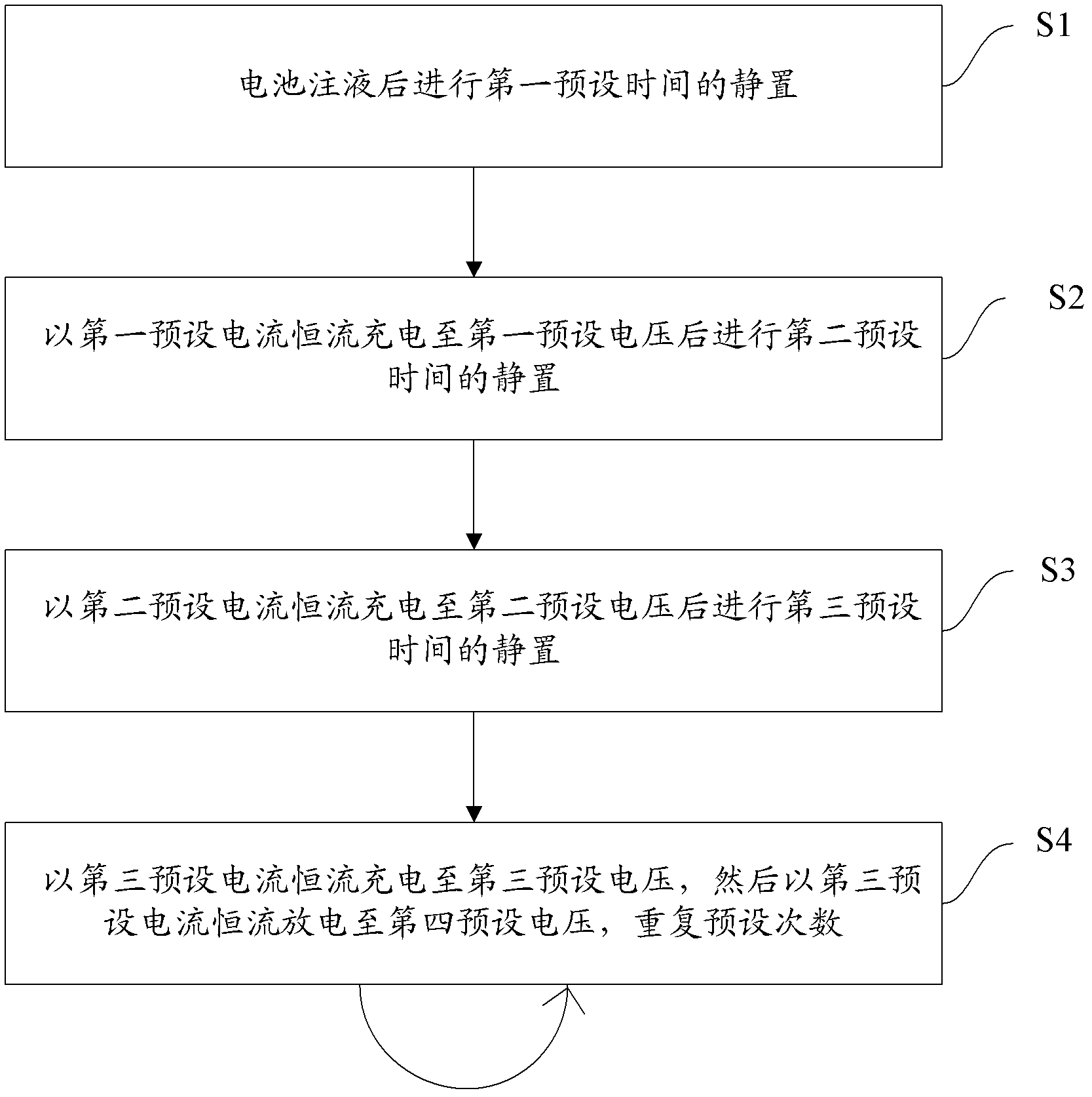

[0046] Take 1000 lithium manganese oxide batteries numbered S80200235MP after liquid injection, and let them stand for a first preset time t1 of 24 hours. Firstly, the battery cell is charged with the first preset current I1 at a constant current of 0.4A to the first preset voltage V1 of 3.45V, and the second preset time t2 is 10 minutes. Then charge the cell to a second preset voltage V2 of 3.9V with a second preset current I2 of 2A constant current, and let it stand for a third preset time t3 of 10 minutes. Finally, use the third preset current I3 as a constant current of 10A to charge the cell to the third preset voltage V3 as 4.2V, and then use the third preset current I3 as a constant current of 10A to discharge the cell to the fourth preset voltage V4 2.75V, repeat the last step once to complete the battery formation process.

no. 2 example

[0048] Take 1000 lithium manganese oxide batteries numbered S80200235MP after liquid injection, and let them stand for a first preset time t1 of 16 hours. Firstly, the battery cell is charged with the first preset current I1 at a constant current of 0.8A to the first preset voltage V1 of 3.4V, and the second preset time t2 is 20 minutes. Then charge the cell to a second preset voltage V2 of 3.95V with a second preset current I2 of 4A constant current, and let it stand for a third preset time t3 of 20 minutes. Finally, use the third preset current I3 as a constant current of 10A to charge the cell to the third preset voltage V3 as 4.2V, and then use the third preset current I3 as a constant current of 10A to discharge the cell to the fourth preset voltage V4 2.75V, repeat the last step 2 times to complete the battery formation process.

no. 3 example

[0050] Take 1000 lithium manganese oxide batteries numbered S80200235MP after liquid injection, and let them stand for the first preset time t1 of 20 hours. Firstly, the battery cell is charged with the first preset current I1 at a constant current of 1A to a first preset voltage V1 of 3.4V, and the second preset time t2 is 30 minutes. Then charge the cell to a second preset voltage V2 of 3.9V with a second preset current I2 of 2A constant current, and let it stand for a third preset time t3 of 30 minutes. Finally, use the third preset current I3 as a constant current of 16A to charge the cell to the third preset voltage V3 as 4.2V, and then use the third preset current I3 as a constant current of 16A to discharge the cell to the fourth preset voltage V4 2.75V, repeat the last step 5 times to complete the battery formation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com