Preparation method and application of prussian blue complex/carbon composite material

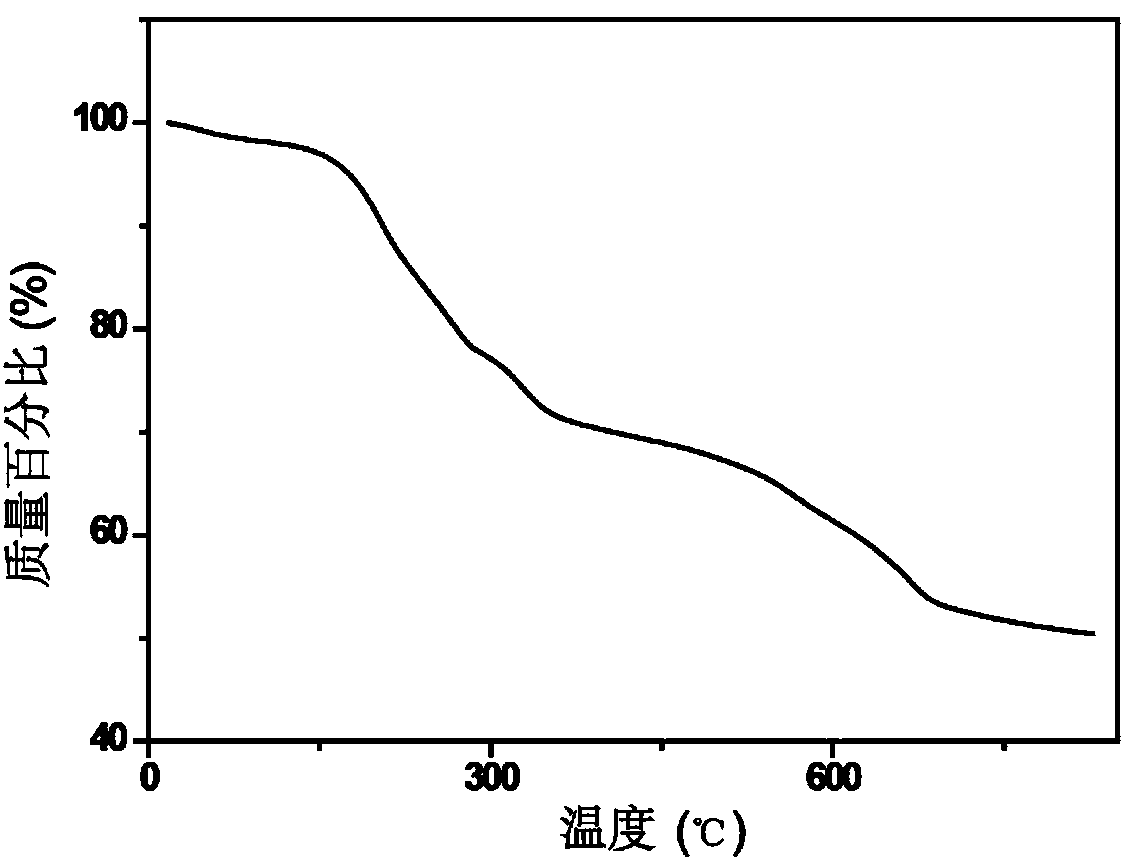

A technology of carbon composite materials and Prussian blue, which is applied in the field of energy material preparation and electrochemistry, can solve the problems of high content of internal vacancies, crystal water and coordination water, poor contact, and restrictions on large-scale applications, and achieve suitable Large-scale production, excellent cycle stability, and the effect of low content of crystallization water and coordination water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation Prussian blue complex compound / carbon composite material

[0027] Press Na 4 Fe(CN) 6 : HCl: Ketjen black = 1:0.1:5 mole fraction weighed, adding water as a solvent, heating at 60°C for 16h. After the reaction is completed, it is separated and dried to obtain the Prussian blue complex / carbon composite material provided by the present invention.

[0028] Use powder X-ray diffractometer (Rigaku DmaxrB, CuK ray) to analyze and confirm the crystal structure of the product, the results are as follows figure 1 As shown, it can be seen from the X-ray diffraction spectrum that there is no impurity peak, indicating that the product is of high purity. Since the obtained carbon has a non-crystalline structure, there is no diffraction peak.

[0029] The morphology of the product was analyzed with a scanning electron microscope (SEM, Japan Electron Scanning Electron Microscope JEOL-6701F), such as figure 2 As shown, the Prussian blue is in the form of ...

Embodiment 2

[0037] Embodiment 2, preparation Prussian blue complex compound / carbon composite material

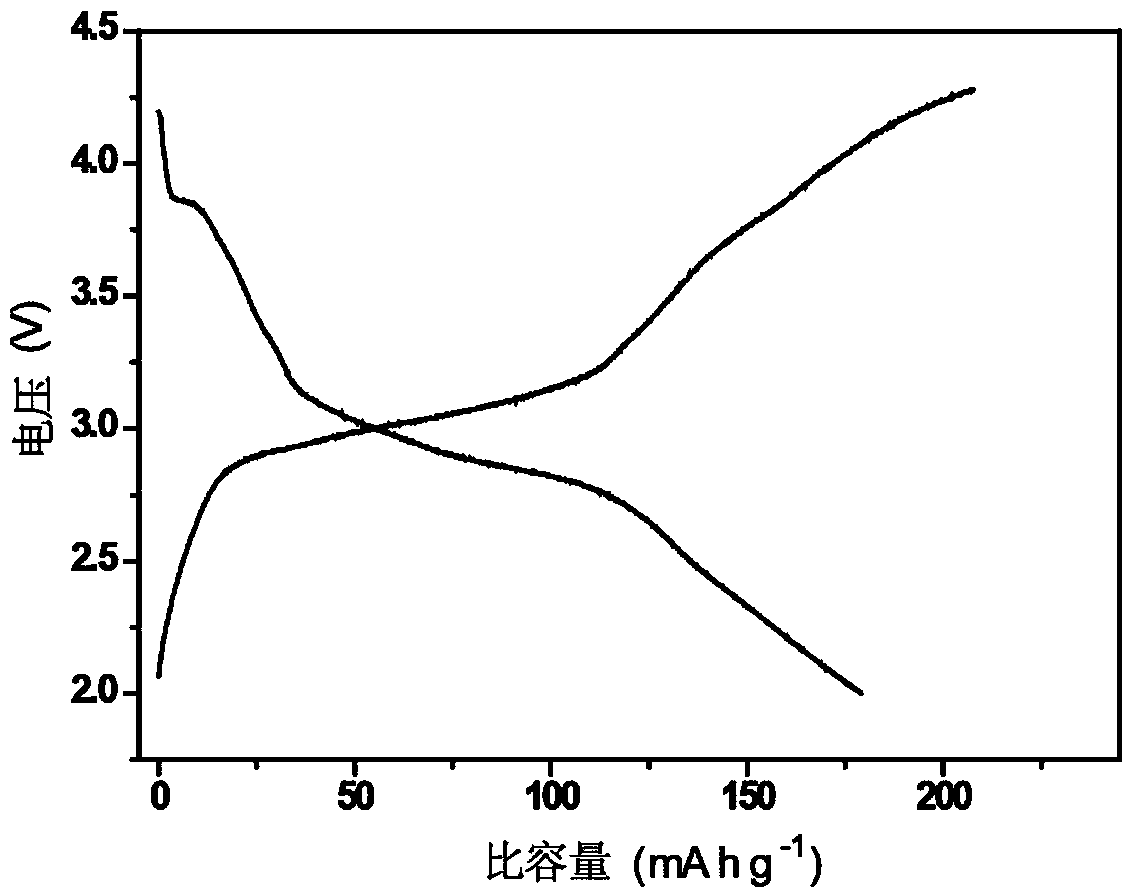

[0038] press K 4 Fe(CN) 6 : HNO 3 : Weigh the mole fraction of carbon nanotubes=1:0.1:0.1, add water as a solvent, and heat at room temperature for 24 hours. After the reaction is completed, it is separated and dried to obtain the Prussian blue complex / carbon composite material provided by the present invention. The composition of the obtained Prussian blue complex / carbon and the test results in the simulated battery are listed in Table 1, and the molecular formula and corresponding defects and water content are listed in Table 2.

Embodiment 3

[0045] Embodiment 3, preparation Prussian blue complex compound / carbon composite material

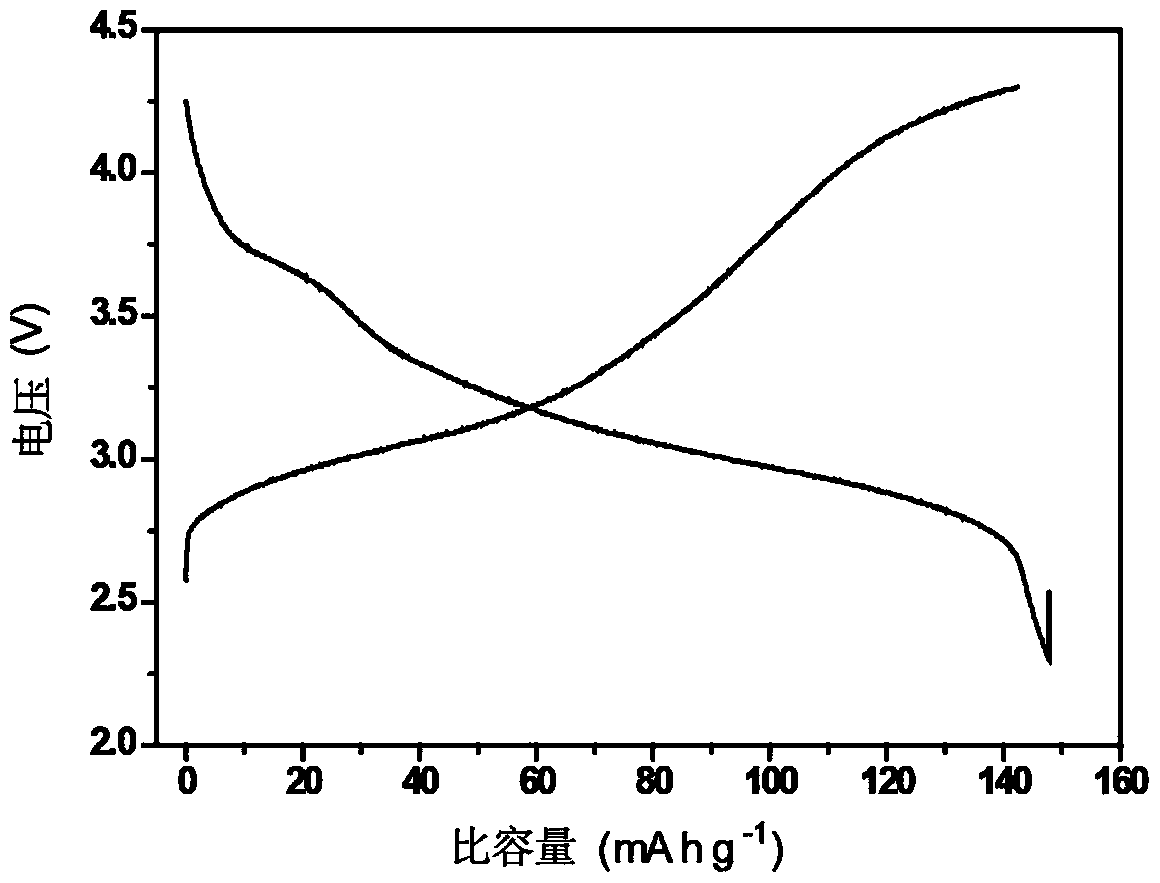

[0046] Press Na 3 Co(CN) 6 :H 2 SO 4 : Weigh the mole fraction of carbon black=1:0.5:5, add water as a solvent, and heat at 40°C for 18h. After the reaction is completed, it is separated and dried to obtain the Prussian blue complex / carbon composite material provided by the present invention. The composition of the obtained Prussian blue complex / carbon and the test results in the simulated battery are listed in Table 1, and the molecular formula and corresponding defects and water content are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com