Waste heat recovery system of liquid cooling data center

A waste heat recovery system and data center technology, applied in heating systems, solar heating systems, cooling/ventilation/heating transformation, etc., can solve the problem of long-term waste heat recovery efficiency not reaching the practical level, high investment in recovery equipment, and low economic benefits Obvious problems, to achieve the effect of improving energy utilization efficiency, reducing operating costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

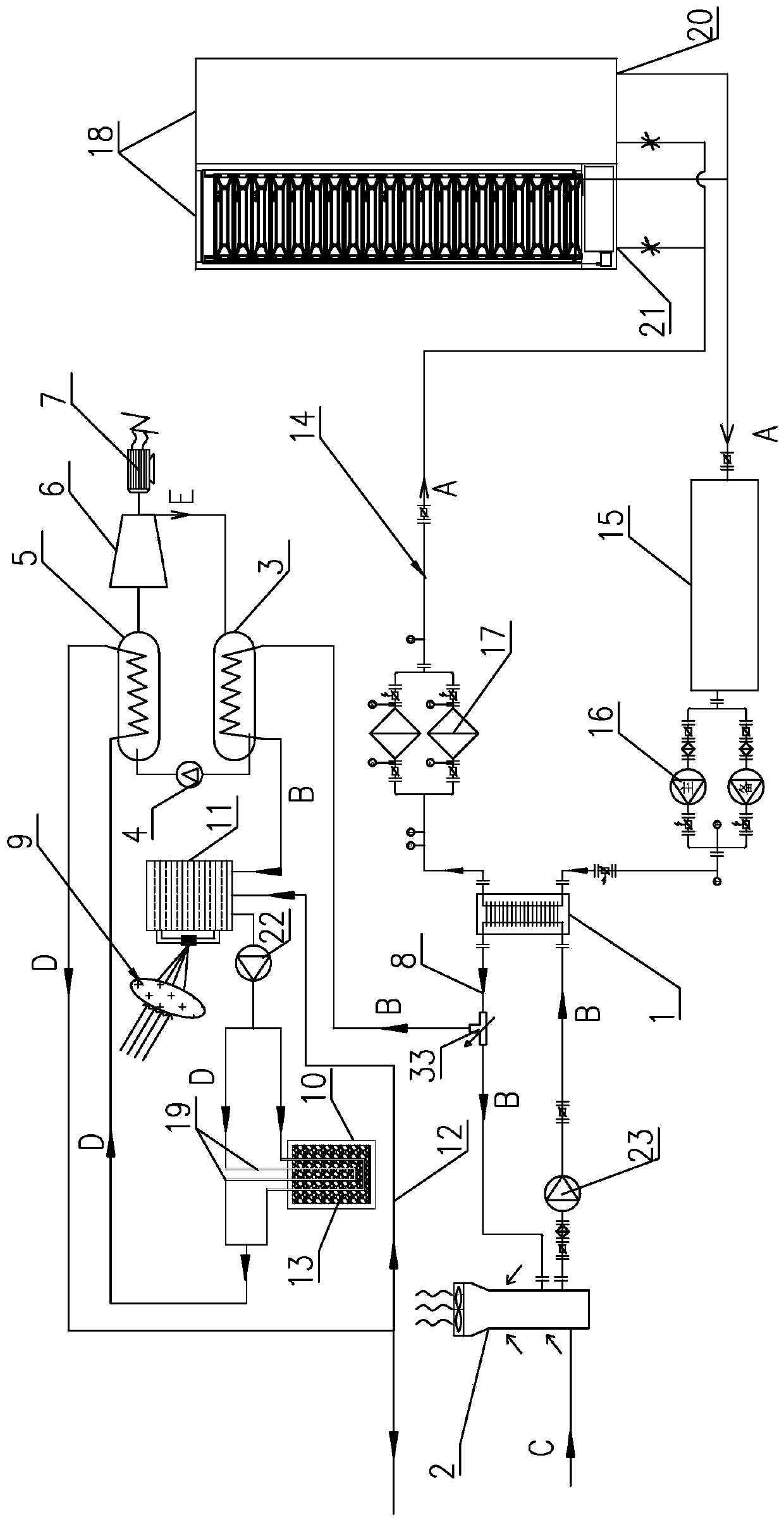

[0029] Such as figure 1 As shown, it is a liquid-cooled data center waste heat recovery system of the present invention, which includes a first heat exchanger 1 for heat exchange with the cooling liquid after absorbing heat in the liquid-cooled data center, a heat dissipation system, and solar heat collection and heat storage system and thermal energy utilization system, in this embodiment, the thermal energy utilization system is a power generation system, and each system is a circulation loop with a working medium flowing inside, wherein the working medium in the heat dissipation system and the solar heat collection and heat storage system is water, The working medium in the power generation system is an organic medium, and the first heat exchanger 1 is an integral part of the heat dissipation system. The heat energy is used for electricity, and the waste heat is used for domestic heating.

[0030] In this embodiment, the heat dissipation system is mainly composed of the fi...

Embodiment 2

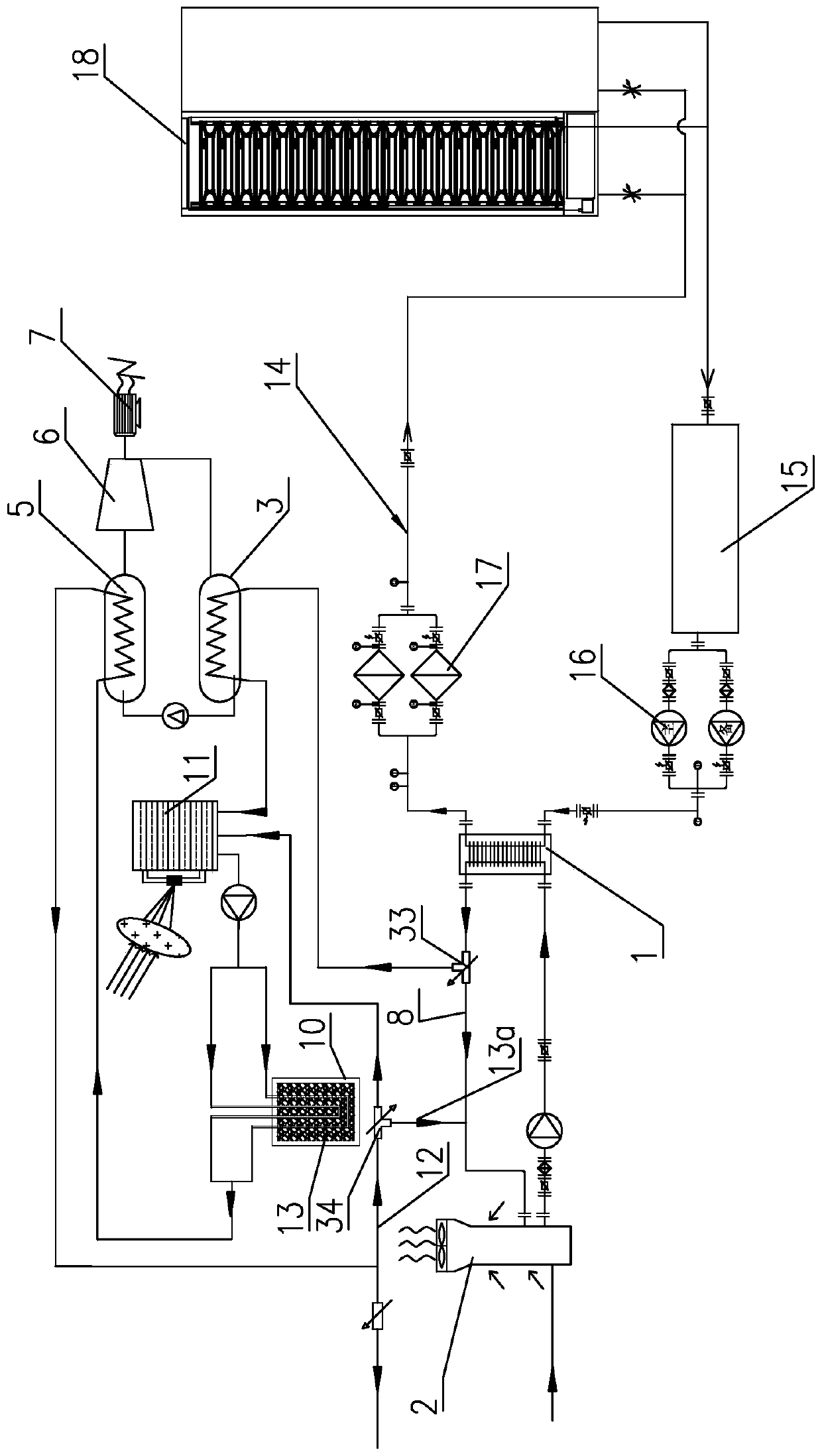

[0039] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a hot water recovery pipe 13a is provided between the first pipeline 12 and the second pipeline 8, and the hot water recovery pipe 13a is connected to the first On the pipeline 12, the hot water recovery pipe 13a can lead the hot water in the solar heat collection and storage system into the heat dissipation system and enter the cooling water tower 2 together with the hot water in it for cooling.

Embodiment 3

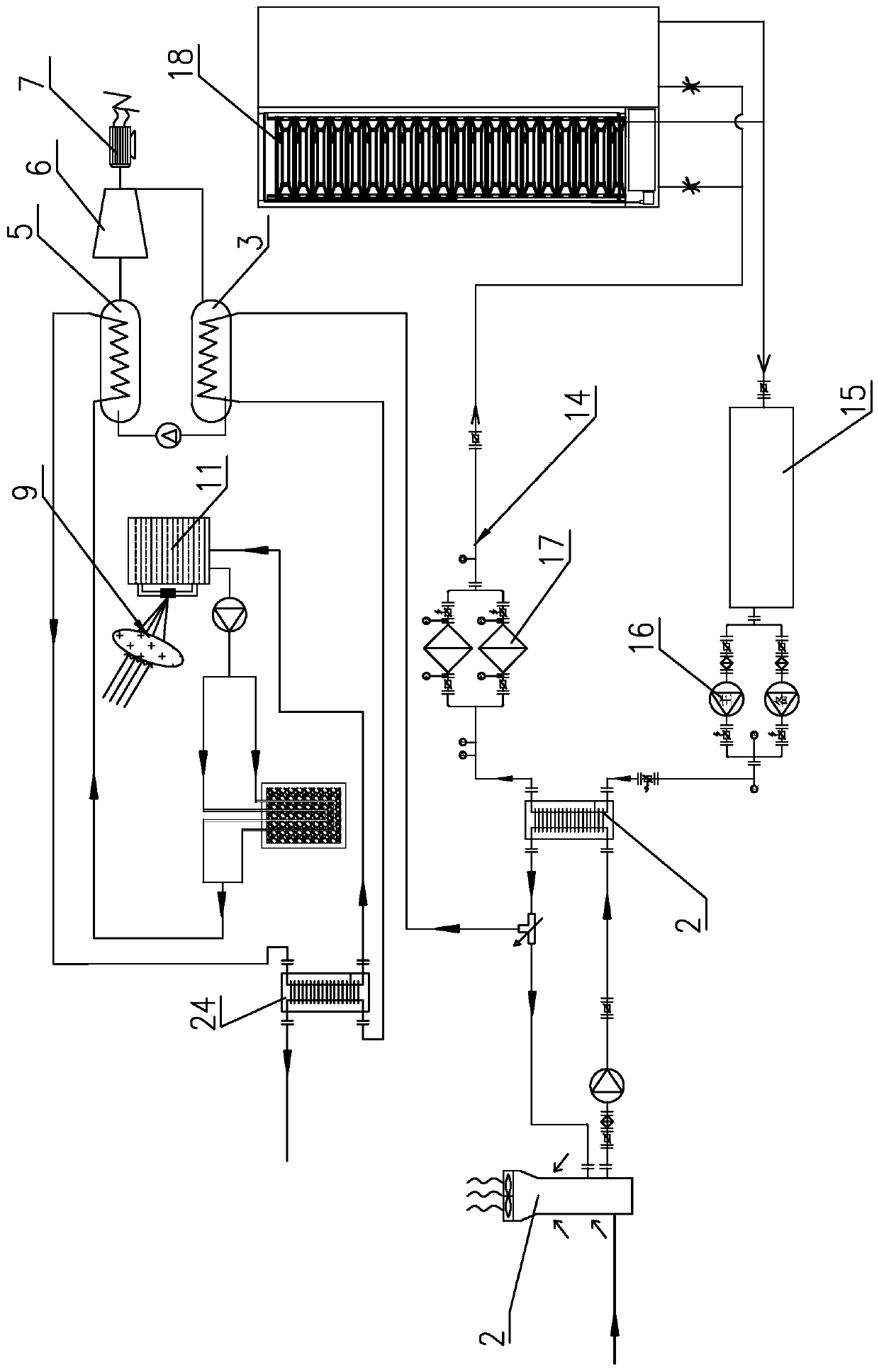

[0041] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the solar heat collection and heat storage system includes a solar heat collector 9, a heat storage device, an evaporator 5 and a second heat exchanger 24 sequentially connected in accordance with the flow direction of the internal working medium , that is, the evaporator 5 is a common component of the solar heat collection and storage system and the power generation system. The working medium in the solar heat collection and storage system uses high-temperature heat transfer oil. The solar heat collector 9 has a coolant tank 11, and the coolant tank 11 The outlet of the evaporator 5 is connected to the heat storage device, the liquid inlet of the evaporator 5 connected to the solar heat collection and storage system is connected to the outlet of the heat storage device, and the liquid outlet of the evaporator 5 connected to the solar heat collection and storage system is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com