Magnesium-lithium double-ion battery composite cathode material, preparation method and application thereof, and battery system

A composite positive electrode material and nanocomposite material technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the constraints on the development of magnesium ion batteries, low stable battery cycle capacity, and poor cycle stability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the magnesium-lithium dual-ion battery composite cathode material described in the above technical scheme, which includes the following steps:

[0033] Combine graphene oxide, water, Na 3 VO 4 After mixing with thioacetamide, hydrothermal reaction is performed to obtain VS 4 / rGO nanocomposite materials;

[0034] Will the VS 4 After the / rGO nanocomposite material, aniline and HCl solution are mixed, an ammonium persulfate HCl solution is added to perform a polymerization reaction to obtain the magnesium-lithium dual-ion battery composite cathode material.

[0035] The present invention combines graphene oxide, water, Na 3 VO 4 After mixing with thioacetamide, hydrothermal reaction is performed to obtain VS 4 / rGO nanocomposite materials.

[0036] In the present invention, the Na 3 VO 4 The molar ratio to thioacetamide is preferably 1:5 to 1:6.

[0037] In the present invention, the graphene oxide and Na 3 VO 4 The mass ...

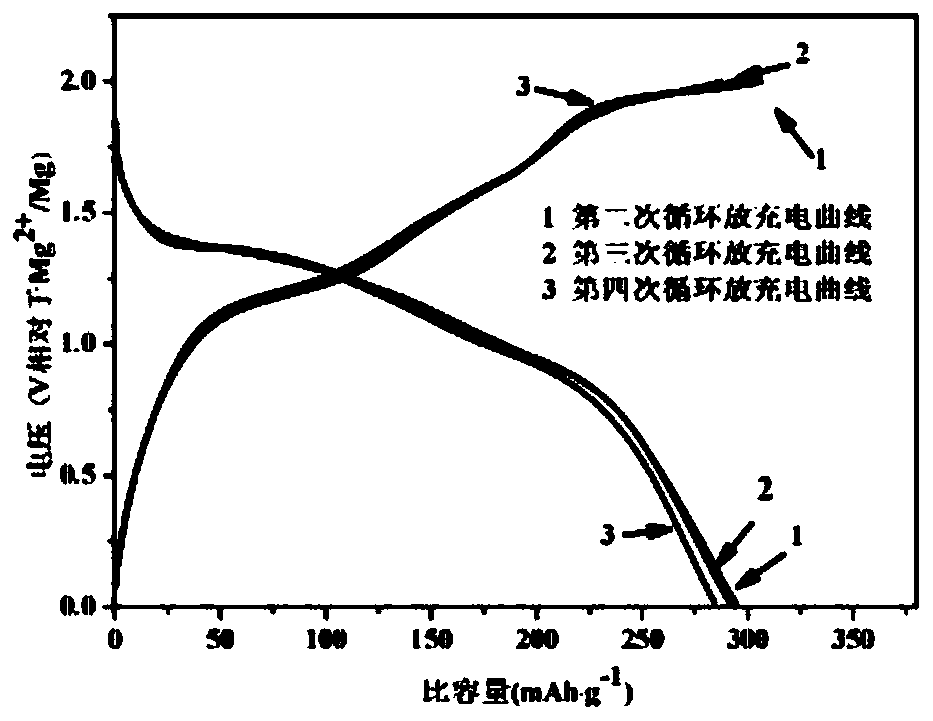

Embodiment 1

[0058] Step 1: Sample preparation

[0059] Hydrothermal synthesis VS 4 / rGO:

[0060] Weigh 75 mg of graphene oxide powder in 150 mL of deionized water, and ultrasonically disperse until the solution is golden yellow. Then sequentially add Na with a metering ratio of 1:5 3 VO 4 (2.0125g) and thioacetamide, stirring for 1h. Transfer the above solution to a hydrothermal reaction kettle and react at 160°C for 24 hours. After the reaction is over, wash with deionized water and ethanol alternately for 4 to 6 times, and vacuum dry at 60°C for 12 hours to obtain VS 4 / rGO black powder, in which rGO carbon content is about 2.5wt.%.

[0061] In situ polymerization of PANI in VS 4 / rGO:

[0062] Weigh a certain amount of VS in turn 4 / rGO powder and aniline (mass ratio 4:1) were ultrasonically dispersed in 0.1M HCl solution at 5°C for 1 hour. The dispersed solution was placed in an ice water bath and stirred, and 0.1M HCl solution of ammonium persulfate was added dropwise to start the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com