Lithium ion battery gel polymer electrolyte and preparation method thereof

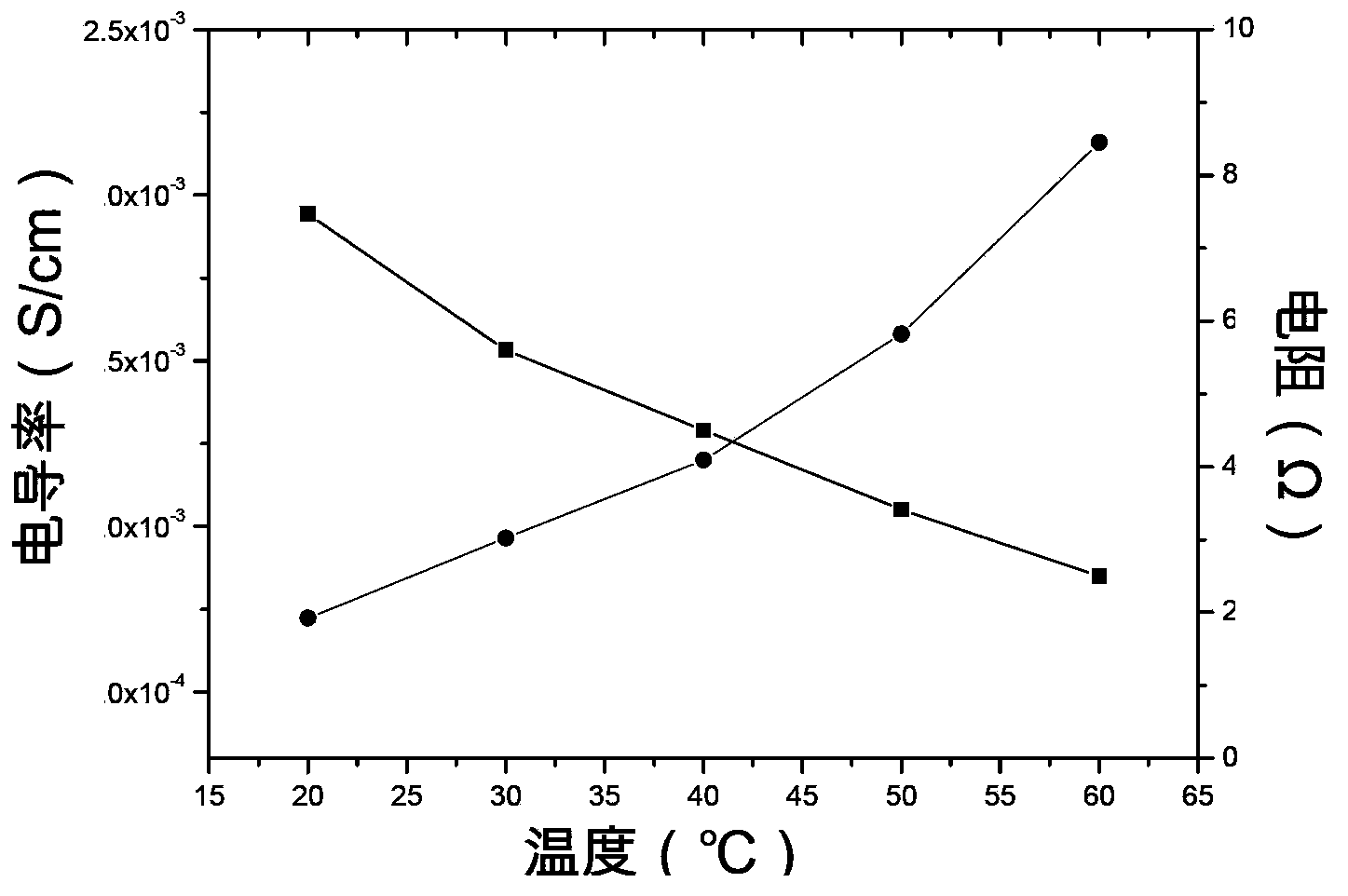

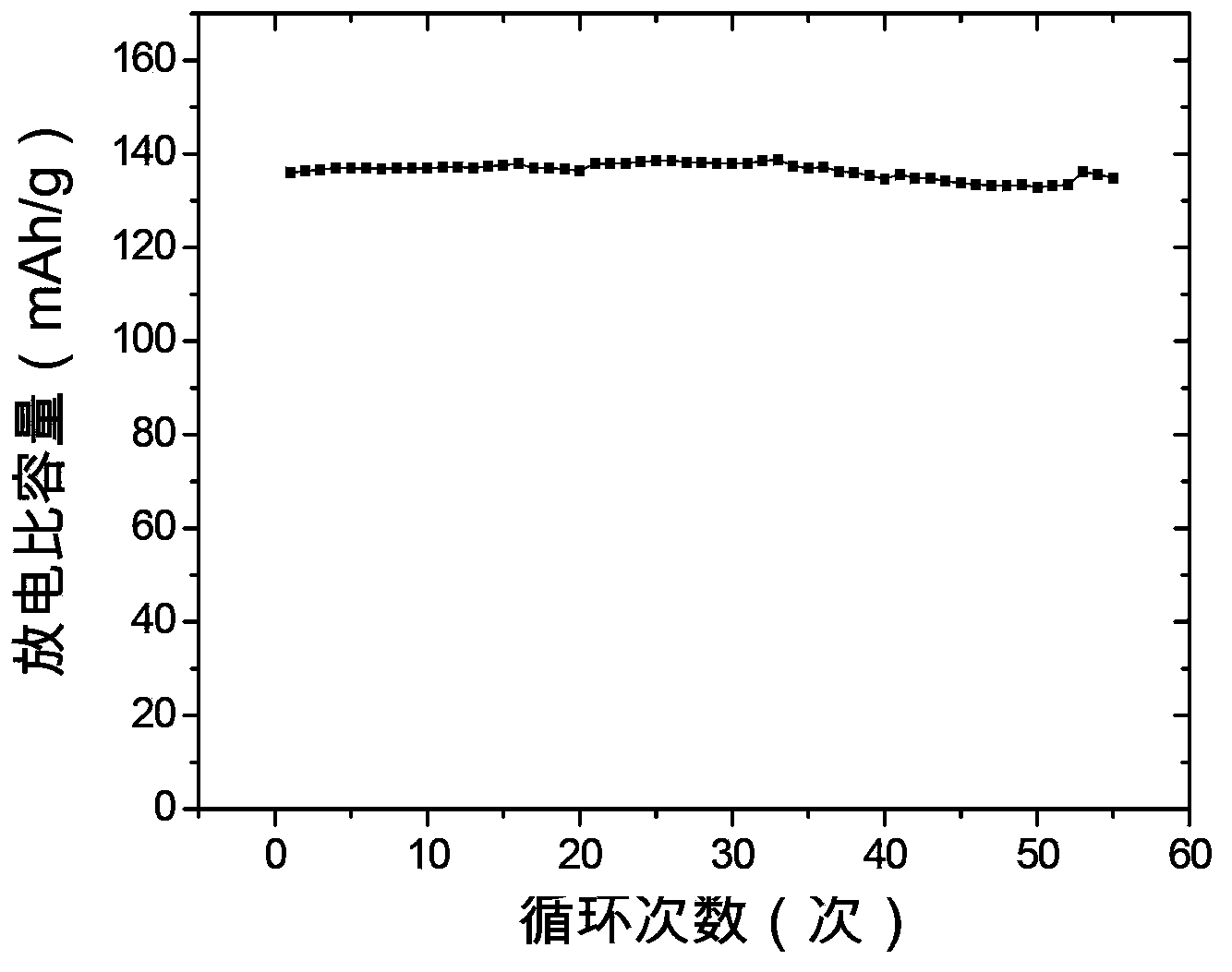

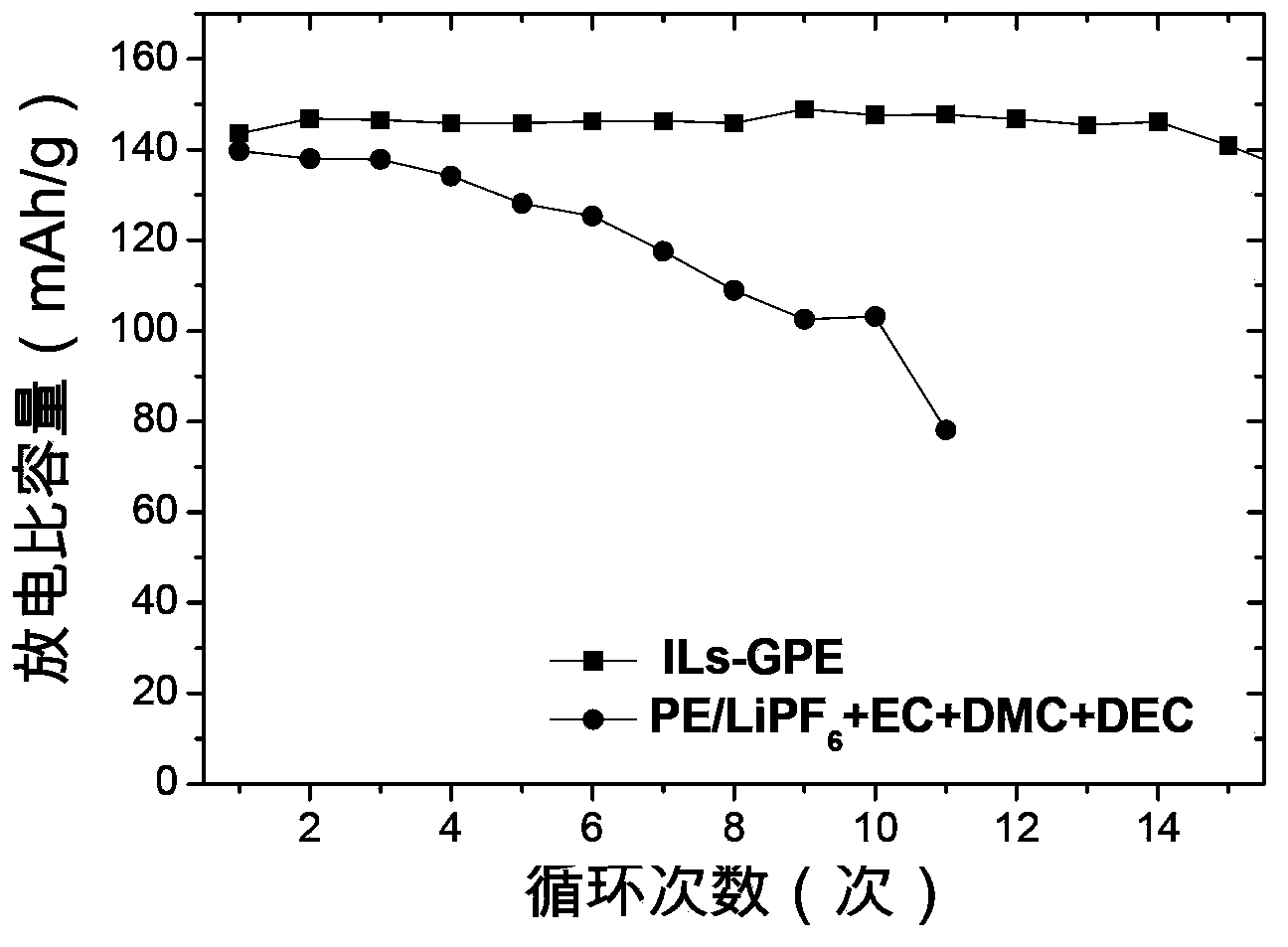

A gel polymer and lithium-ion battery technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of delithiation cycle, lithium ions cannot be effectively intercalated, etc., and achieve good compatibility, electrochemical The effect of wide window and high charge-discharge cycle capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the lithium-ion battery gel polymer electrolyte consists of the following components:

[0040] Polymer: polyvinylidene fluoride PVDF, polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP)

[0041]Ionic liquid: bis(trifluoromethylsulfonyl)imide 1-methyl-3-ethylimidazole (EmimTFSI)

[0042] Organic solvents: ethylene carbonate (EC), propylene carbonate (PC)

[0043] Lithium salt: lithium bis(trifluoromethylsulfonyl)imide (LiTFSI)

[0044] Film-forming additive: ethylene carbonate (VEC)

[0045] Wherein, the mass ratio of the ionic liquid, organic solvent, lithium salt and film-forming additive is 3:2:2:3:0.5; the quality of the high molecular polymer and the ionic liquid, organic solvent, lithium salt and forming additive The mass and ratio of membrane additives is 1:3.

[0046] The preparation method of above-mentioned lithium ion battery gel polymer electrolyte comprises the steps:

[0047] (1) Mix polyvinylidene fluoride (PVDF) with polyvinyli...

Embodiment 2

[0057] In this embodiment, the lithium-ion battery gel polymer electrolyte consists of the following components:

[0058] Polymer: polyvinylidene fluoride PVDF,

[0059] Ionic liquid: 1-methyl-3-ethylimidazole tetrafluoroborate (EmimBF4)

[0060] Organic solvent: propylene carbonate (PC)

[0061] Lithium salt: lithium tetrafluoroborate (LiBF 4 )

[0062] Film-forming additives: and vinylene carbonate (VC)

[0063] Wherein, the mass ratio of described ionic liquid, organic solvent, lithium salt and film-forming additive is 1:1:1:0.1; The mass sum ratio is 1:3.

[0064] The preparation method of above-mentioned lithium ion battery gel polymer electrolyte comprises the steps:

[0065] (1) Dissolve polyvinylidene fluoride PVDF in N-methylpyrrolidone (NMP) under heating and stirring (60°C), where the mass ratio of PVDF:NMP is 1:8, and stir and dissolve for 2 hours to obtain PVDF-based body fluids, the solution is clear and transparent;

[0066] (2) 1-methyl-3-ethylimidazole...

Embodiment 3

[0072] In this embodiment, the lithium-ion battery gel polymer electrolyte consists of the following components:

[0073] Polymer: polyvinylidene fluoride PVDF,

[0074] Ionic liquid: 1-methyl-3-ethylimidazole tetrafluoroborate (EmimBF4)

[0075] Organic solvent: propylene carbonate (PC)

[0076] Lithium salt: lithium tetrafluoroborate (LiBF 4 )

[0077] Film-forming additives: and vinylene carbonate (VC)

[0078] Wherein, the mass ratio of described ionic liquid, organic solvent, lithium salt and film-forming additive is 1:1:1:0.1; The ratio of the mass and sum is 1:2.5.

[0079] The preparation method of above-mentioned lithium ion battery gel polymer electrolyte comprises the steps:

[0080] (1) Dissolve polyvinylidene fluoride (PVDF) in acetone under heating and stirring (60°C), where the mass ratio of PVDF: acetone is 1:10, stir and dissolve for 2 hours to obtain a PVDF matrix liquid, which is clear and transparent;

[0081] (2) 1-methyl-3-ethylimidazole tetrafluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com