Two-dimensional transition metal carbon (nitrogen) compound and two-dimensional transition metal sulfide nano-composite powder, and preparation and application thereof

A technology of nanocomposite powders and transition metals, applied in nanotechnology, nanotechnology, hybrid/electric double-layer capacitor manufacturing, etc., can solve structural instability, poor conductivity and poor cycle performance of two-dimensional transition metal sulfides and other issues, to achieve the effect of low cost, excellent electrochemical performance, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

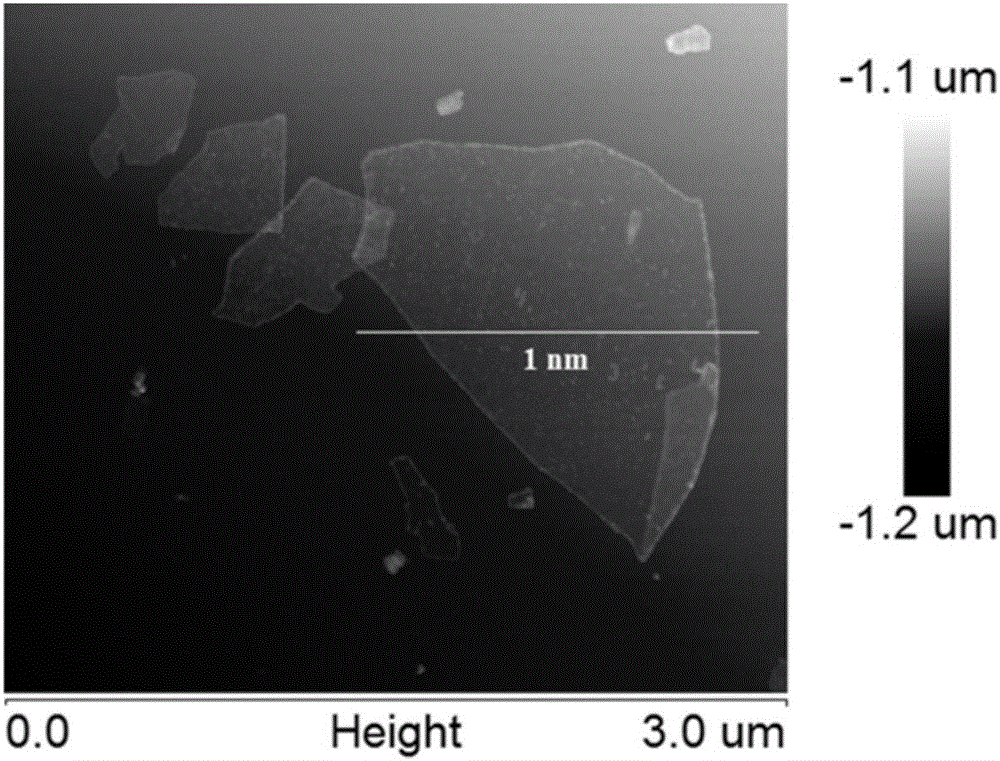

[0027] (1) Two-dimensional transition metal carbide Ti 3 C 2 Preparation of nanosheet suspension: Add 10 mL of dilute HCl with a concentration of 6M and 0.662 g of LiF into a plastic bottle, and slowly add 1 g of ternary layered carbide Ti through a 400-mesh sieve under magnetic stirring. 3 AlC 2 powder, and magnetically stirred at 250r.p.m at 35°C for 22h. After the reaction, the product was washed with alcohol and centrifuged until the pH of the upper layer was 6.2. After the precipitate was dried at room temperature, 0.1g was added to 50mL deionized water. Under the protection of flowing argon, ultrasonic peeling at 40kHz ultrasonic frequency for 1h, followed by centrifugation at 3500r.p.m for 1h to obtain a few-layer or single-layer two-dimensional transition metal carbide Ti 3 C 2 A stable suspension of nanosheets, the concentration of the suspension is 0.6mg / ml. figure 1 Shown is the 2D transition metal carbide Ti 3 C 2 AFM image of nanosheets, from which it can be...

Embodiment 2

[0031] (1) Two-dimensional transition metal carbide Ti 3 C 2 Preparation of nanosheet suspension: Add 10 mL of dilute HCl with a concentration of 6M and 0.662 g of LiF into a plastic bottle, and slowly add 1 g of ternary layered carbide Ti through a 400-mesh sieve under magnetic stirring. 3 AlC 2powder, and magnetically stirred at 33°C and 300r.p.m for 12h. After the reaction, the product was washed with alcohol and centrifuged until the pH of the upper layer was 6.3. After the precipitate was dried at room temperature, 0.1g was added to 50mL deionized water. Under the protection of flowing argon, ultrasonic stripping was performed at an ultrasonic frequency of 50kHz for 1.5h, and then centrifuged at a speed of 3800r.p.m for 1.2h to obtain a few-layer or single-layer two-dimensional transition metal carbide Ti 3 C 2 A stable suspension of nanosheets, the concentration of the suspension is 0.3mg / ml.

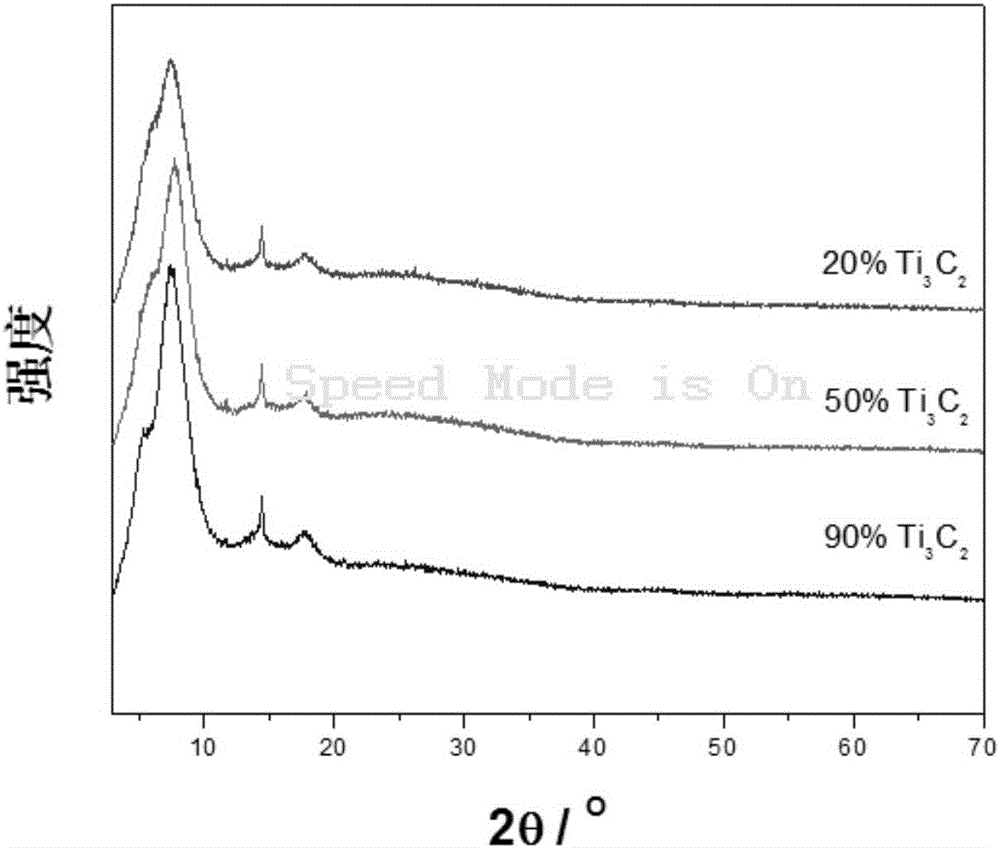

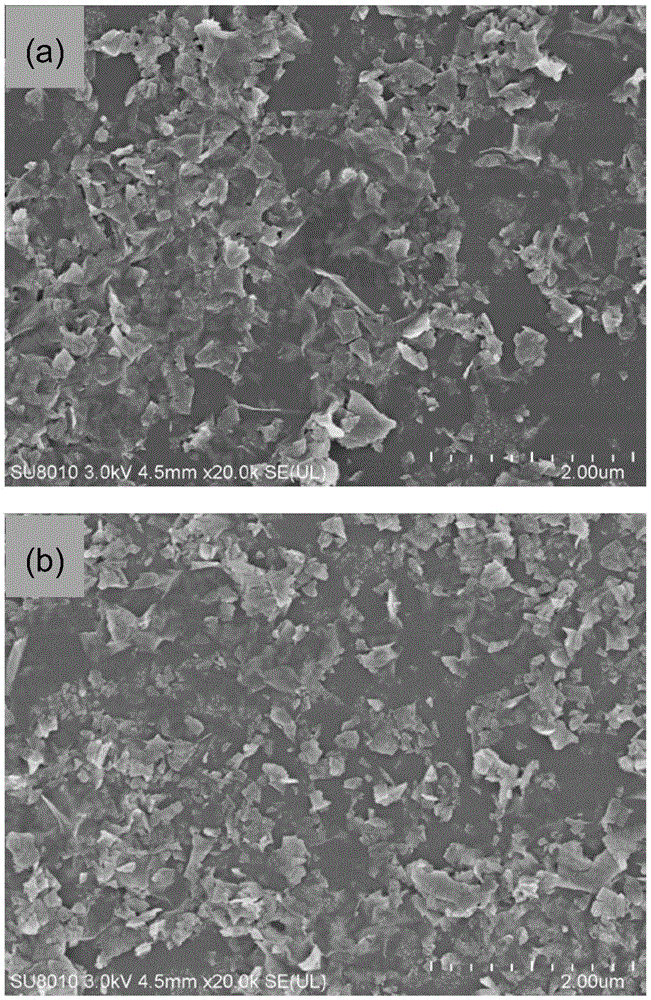

[0032] (2) Two-dimensional Ti 3 C 2 with 2D MoS 2 Preparation of nanoc...

Embodiment 3

[0035] (1) Two-dimensional transition metal carbide Ti 3 C 2 Preparation of nanosheet suspension: Add 10 mL of dilute HCl with a concentration of 6M and 0.662 g of LiF into a plastic bottle, and slowly add 1 g of ternary layered carbide Ti through a 400-mesh sieve under magnetic stirring. 3 AlC 2 powder, and magnetically stirred at 500r.p.m at 36°C for 23h. After the reaction, the product was washed with alcohol and centrifuged until the pH of the upper layer was 6.5. After the precipitate was dried at room temperature, 0.1g was added to 50mL deionized water. Under the protection of flowing argon, ultrasonic stripping was performed at an ultrasonic frequency of 80kHz for 0.8h, and then centrifuged at a speed of 3200r.p.m for 0.8h to obtain a few-layer or single-layer two-dimensional transition metal carbide Ti 3 C 2 A stable suspension of nanosheets, the concentration of the suspension is 0.9mg / ml.

[0036] (2) Two-dimensional Ti 3 C 2 with 2D MoS 2 Preparation of nanoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com