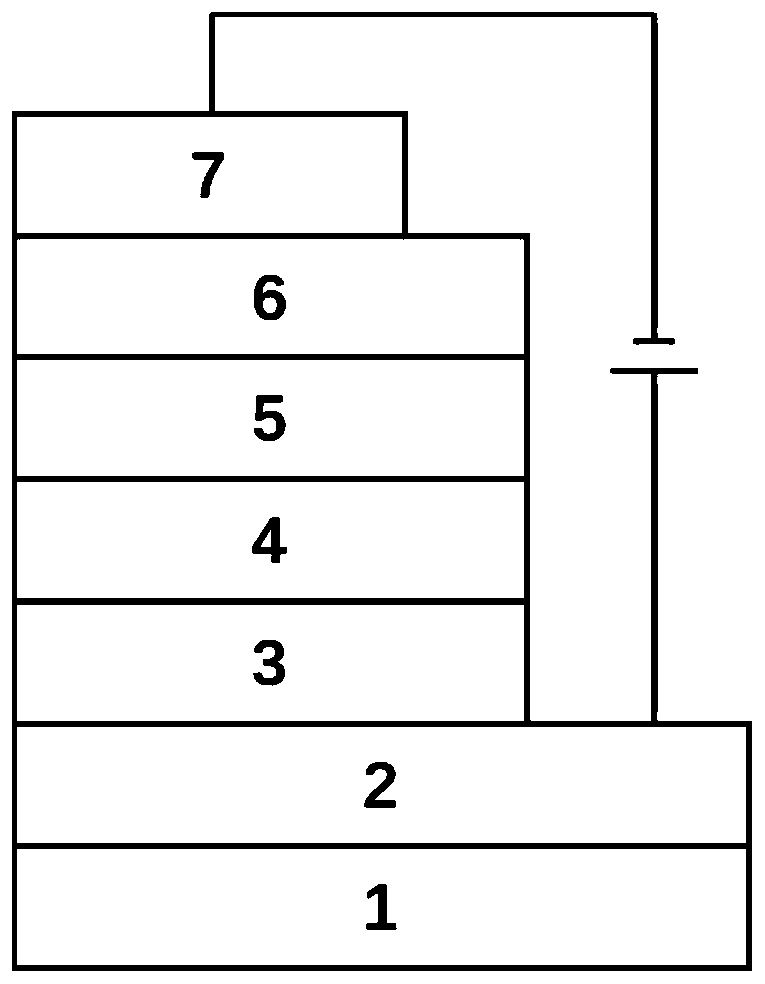

Organic white light emitting device based on stepped multi-reflection intersystem crossing process and preparation method thereof

A light-emitting device, a stepped technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of low efficiency of all-fluorescent white light devices, reduce manufacturing costs, and roll-off efficiency, so as to improve luminous efficiency , reduce the preparation cost and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

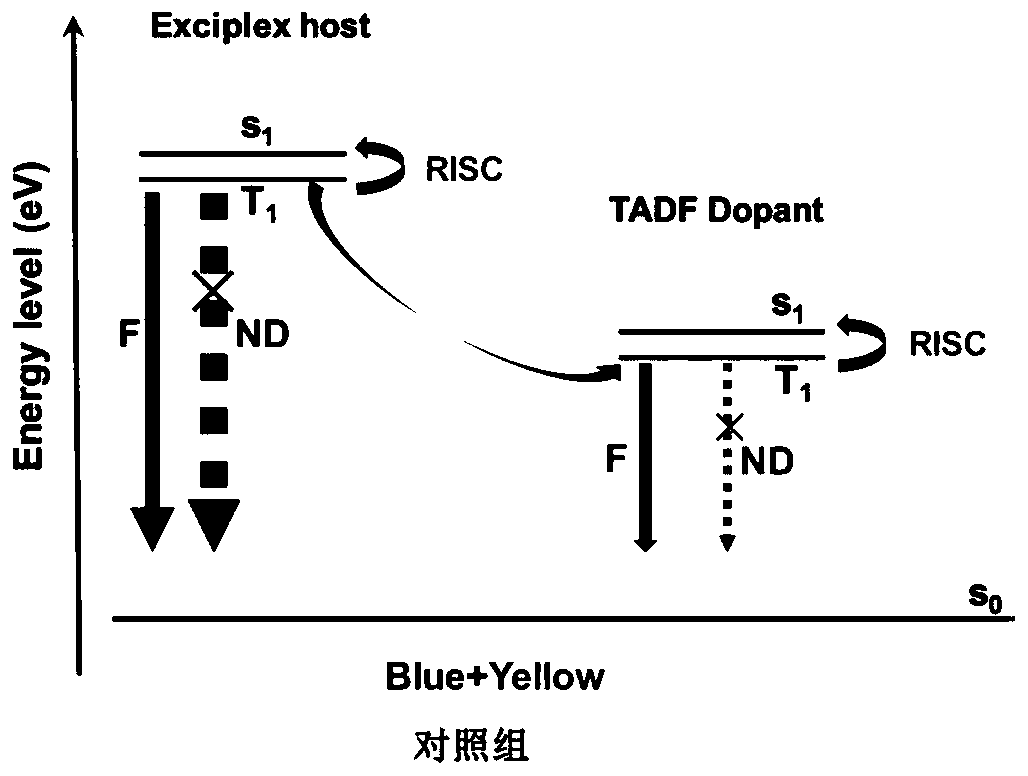

[0043] Embodiment 1: control group

[0044] Clean the substrate composed of the substrate and the transparent conductive anode ITO, put it in a vacuum drying oven to dry after cleaning; put it in the evaporation chamber, and pump the vacuum to 3×10 -4 Pa and below, evaporate a hole transport layer with a thickness of 35nm, and evaporate a light-emitting layer on the hole transport layer (the light-emitting layer adopts ternary co-evaporation, and its ratio is controlled by the calculated rate, and the structure is traditional. The guest structure has an anti-intersystem crossing process, the materials used are MCP, 4CzPNPh, PO-T2T, the ratio of mass content is 1:0.005:1, and the thickness is 30nm), and the electron transport layer (thickness is 40nm), vapor-deposits a metal cathode (thickness is 120nm) on the electron transport layer, wherein, the evaporation rate of the organic layer is The metal cathode evaporation rate is

Embodiment 2

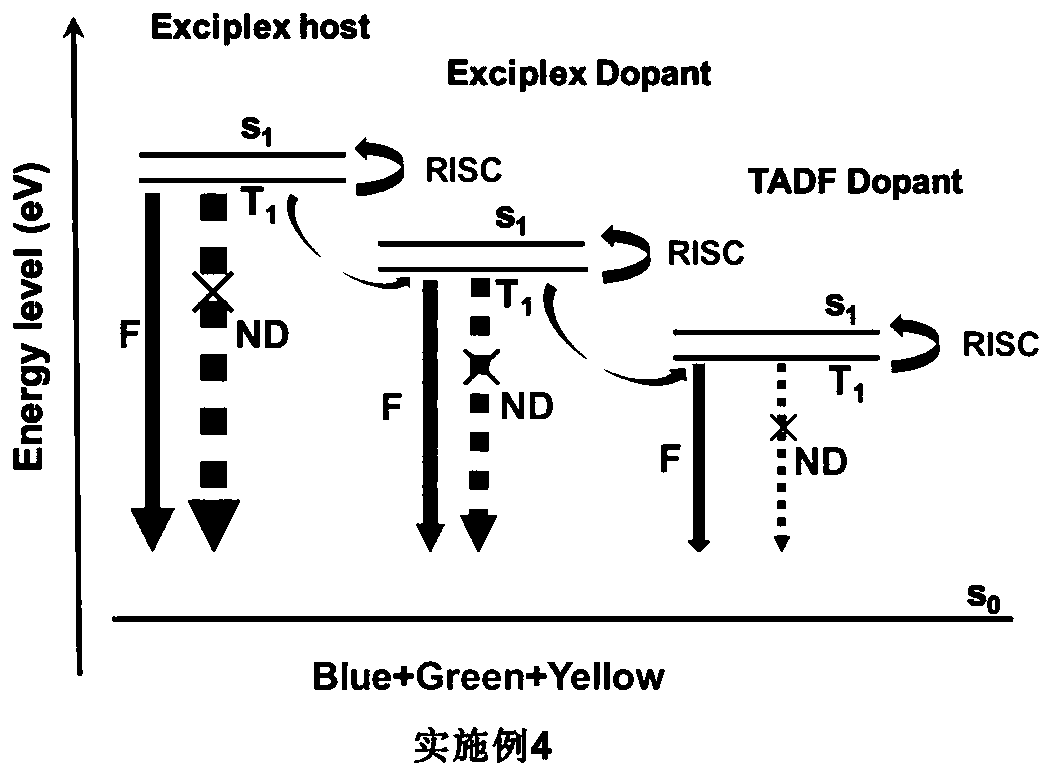

[0046]Clean the substrate composed of the substrate and the transparent conductive anode ITO, put it in a vacuum drying oven to dry after cleaning; put it in the evaporation chamber, and pump the vacuum to 3×10 -4 Pa and below, evaporate a hole transport layer with a thickness of 35nm, and evaporate a light-emitting layer on the hole transport layer (the light-emitting layer adopts ternary co-evaporation, the ratio is controlled by the calculated rate, and the structure is traditional The host-guest structure has two anti-intersystem crossing processes, the materials used are MCP, 4CzPNPh, PO-T2T, the mass content ratio is 1:0.003:1, and the thickness is 30nm), and the electron transport is evaporated on the light-emitting layer layer (thickness is 40nm), evaporate metal cathode (thickness is 120nm) on electron transport layer, wherein, organic layer evaporation rate is The metal cathode evaporation rate is

Embodiment 3

[0048] Clean the substrate composed of the substrate and the transparent conductive anode ITO, put it in a vacuum drying oven to dry after cleaning; put it in the evaporation chamber, and pump the vacuum to 3×10 -4 Pa and below, evaporate a hole transport layer with a thickness of 35nm, and evaporate a light-emitting layer on the hole transport layer (the light-emitting layer adopts ternary co-evaporation, the ratio is controlled by the calculated rate, and the structure is traditional The host-guest structure has two anti-intersystem crossing processes, the materials used are MCP, 4CzPNPh, PO-T2T, the mass content ratio is 1:0.005:1, and the thickness is 30nm), and the electron transport is evaporated on the light-emitting layer layer (thickness is 40nm), evaporate metal cathode (thickness is 120nm) on electron transport layer, wherein, organic layer evaporation rate is The metal cathode evaporation rate is

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com