Metal oxide cathode materials with improved performance

一种氧化物阴极、阴极材料的技术,应用在活性物质电极、化学/物理过程、化学/物理/物理化学过程等方向,能够解决材料额定容量低、容量损失大、方法太贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

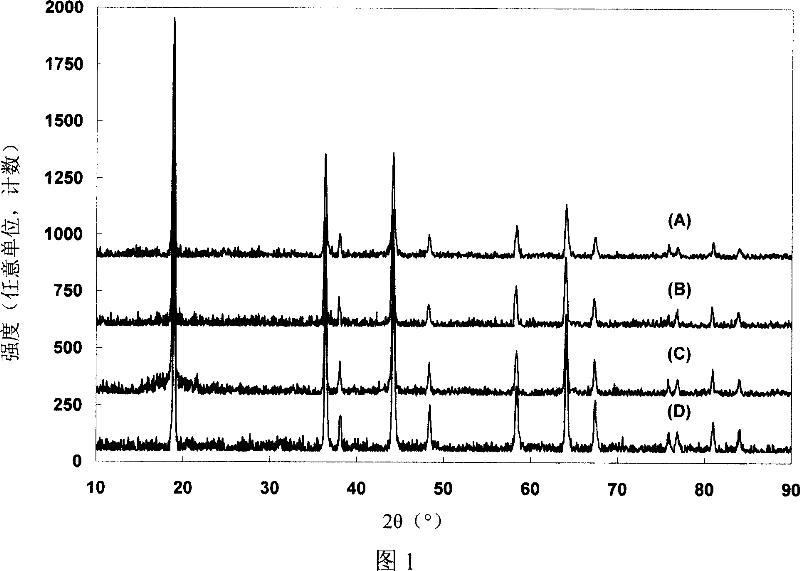

Embodiment 1

[0021] Using commercially available lithium-rich spinel Li 1.05 mn 1.95 o 4 powder as the base lithium manganese oxide spinel material. The base material was treated using a solid-state coating method as follows to produce a 2 final composite material. Weigh 95 grams of base manganese oxide spinel material into a 250 ml rolling mill container. Weigh 3.52 g LiNiO 3 and 14.86 g Co(NO 3 ) 2 Put into this 250 ml mill container with manganese oxide spinel. 50 ceramic mixing balls were placed in the mill container and the container was sealed. The container and its contents were placed on a Roll Mill apparatus and rolled for 12 hours. The rolled mixture was removed and immediately fired in air in a furnace at 700°C for 8 hours. The same material can also be prepared by the same solid-state method using acetate instead of nitrate.

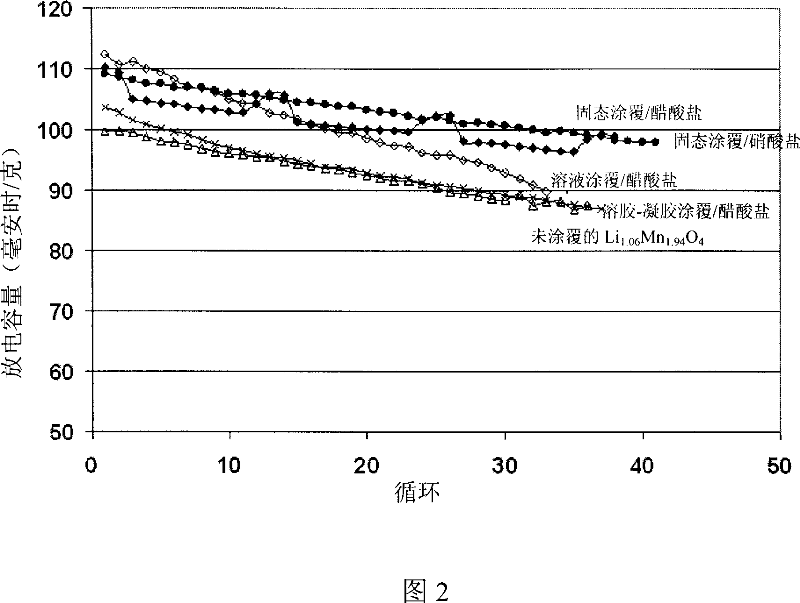

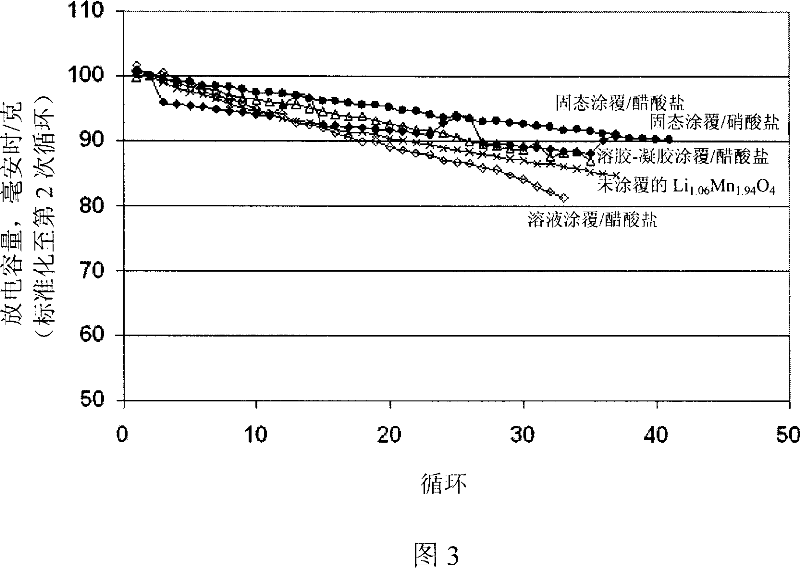

[0022] For comparison, using two different wet-process methods with 5% LiCoO 2 The same base manganese oxide spinel material was modified. S...

Embodiment 2

[0025] Using commercially available LiMn 2 o 4 powder as the base lithium manganese oxide spinel material. The material was solid-state coated using the nitrate salt described in Example 1 to produce 2 final material composition.

Embodiment 3

[0027] Evaluation of LiMn of approximate composition in a coin cell (2032 size, 20 mm in size, 3.2 mm in height) using a lithium counter electrode 2 o 4 , Li 1.05 mn 1.95 o 4 and Li 1.16 mn 1.84 o 4 Standard spinel electrodes and electrodes coated with lithium cobalt oxide material by the method described in Example 1 and Example 2. Cell configuration: Li / 1 mol / L LiPF in 1:1 ethylene carbonate:diethyl carbonate 6 / cathode material. Use modified or unmodified spinel cathode material by preparing cathode material, acetylene black and polyvinylidene fluoride binder (90% / 4% / 6%) in N-methylpyrrolidone slurry materials to make electrodes. The slurry was coated on an aluminum foil current collector and dried under vacuum at 80 °C. Electrodes were punched from the coated side and used to make coin cells. Metal lithium foil was used as the counter electrode. Charge and discharge the button battery with a constant current in the voltage range of 3.2-4.25 volts. The cells w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com