Preparation method of positive and negative conductive liquid storage layer slurry and thick electrode

A negative electrode conduction and liquid storage layer technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of electrode kinetics deterioration and achieve good kinetic performance, battery DC internal resistance and high rate capacity keep improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The specific embodiment of the present invention also provides a method for preparing a thick electrode, using the above-mentioned positive electrode conductive liquid storage layer slurry, the specific method includes:

[0054] (a) Weigh 0.2-0.5 parts of polyvinylpyrrolidone and 0.8-1.2 parts of polyvinylidene fluoride, add them to 233-400 parts of N-methylpyrrolidone that has been weighed, and stir to make Glue;

[0055] (b) Weigh 50-60 parts of zero-dimensional conductive agent, 20-30 parts of one-dimensional conductive agent, and 10-20 parts of two-dimensional conductive agent, add them to the above glue, and disperse and stir at a high speed to prepare Form positive electrode conductive liquid storage layer slurry.

[0056] (c) Coat the positive electrode slurry on the current collector 3, spray the above-mentioned positive electrode conductive liquid storage layer slurry after drying, apply a layer of positive electrode slurry after drying, and obtain the active ...

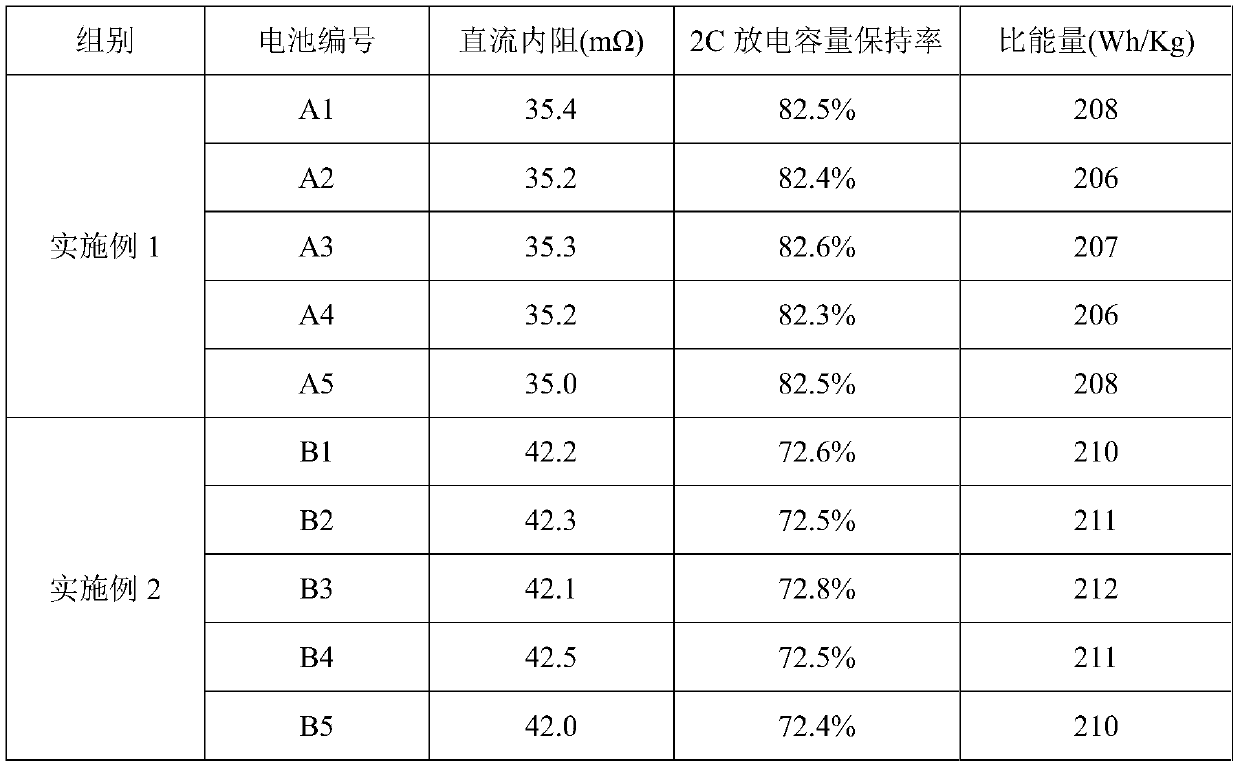

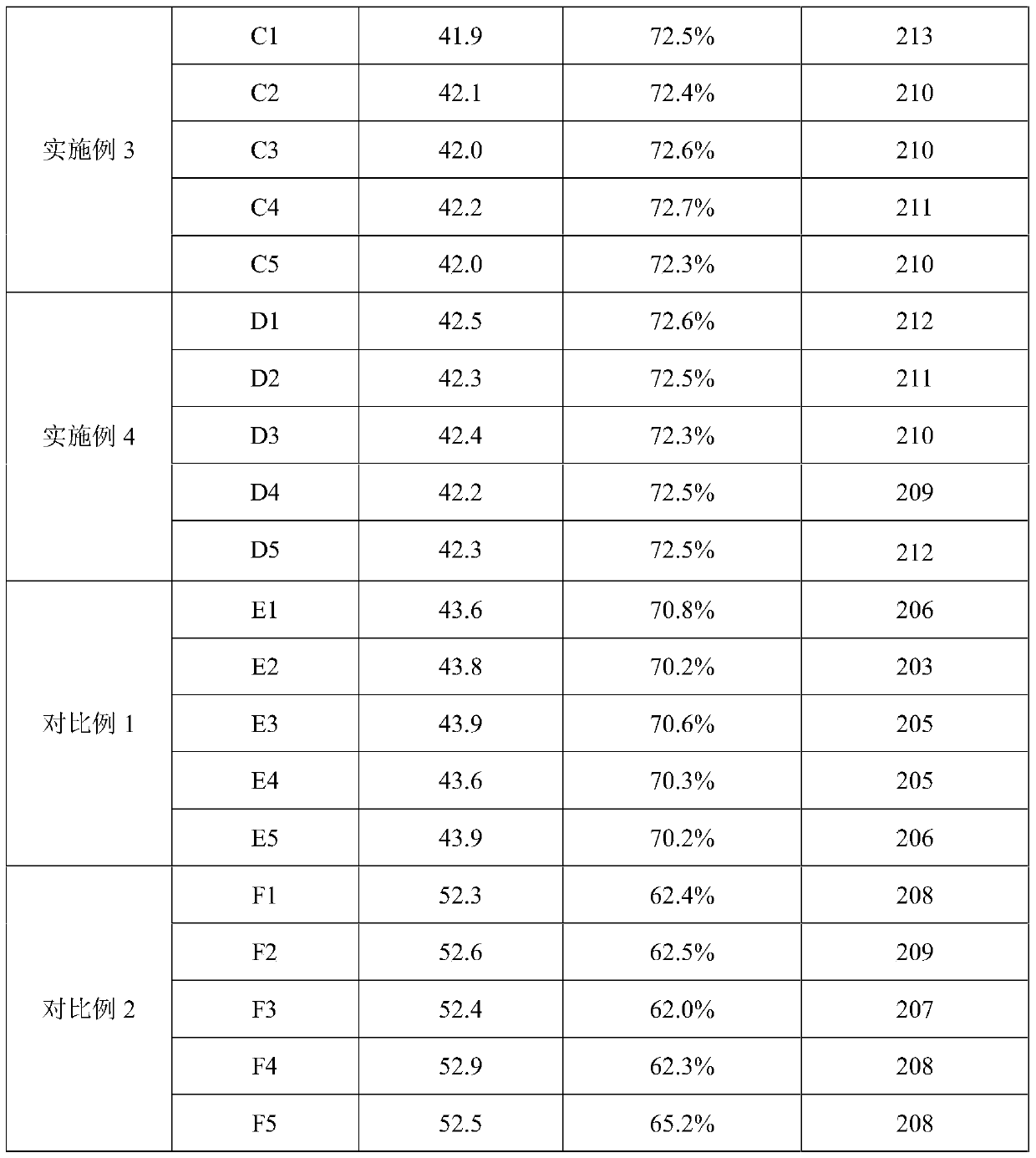

Embodiment 1

[0067] 1. Preparation of conductive liquid reservoir material

[0068] 1.1 Preparation of positive electrode conductive liquid storage layer slurry

[0069] (a) Weigh 0.2 parts of polyvinylpyrrolidone and 1.2 parts of polyvinylidene fluoride, add them to 300 parts of N-methylpyrrolidone that have been weighed, stir for 3 hours, and make a glue;

[0070] (b) Weigh 55 parts of conductive carbon black, 30 parts of carbon nanotubes, and 13.6 parts of graphene, and add them to the above glue, disperse and stir at high speed (>1300 rpm) for 2 hours, and make a solid 25% conductive reservoir slurry.

[0071] 1.2 Preparation of negative electrode conductive liquid storage layer slurry

[0072] (a) Weigh 0.6 parts of sodium hydroxymethyl cellulose, add it to 300 parts of deionized water that has been weighed, stir for 3 hours, and make a glue;

[0073] (b) Weigh 60 parts of conductive carbon black, 25 parts of carbon nanotubes, and 13.3 parts of graphene, and add them to the above g...

Embodiment 2

[0081] The preparation of positive and negative electrode conductive liquid storage layer materials is the same as in Example 1, and the company’s existing ternary positive electrode formula (same as in Example 1) is made into slurry and coated on aluminum foil, with an areal density of 300g / m 2 After drying, spray a positive electrode conductive liquid storage layer with a thickness of 5 μm, and then apply a layer with a density of 300g / m after drying 2 After drying, the positive electrode slurry was cold-pressed and stripped to obtain a positive electrode sheet with a sandwich structure of active layer 1-conductive liquid storage layer 2-active layer 1.

[0082] The company's existing water-based negative electrode formulation (same as Example 1) was made into a slurry and coated on copper foil with an areal density of 142g / m 2 After drying, spray a negative electrode conductive liquid storage layer with a thickness of 5 μm, and then apply a layer with a density of 142g / m af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com