Spherical molybdenum disulfide composite material and preparation method and application thereof

A technology of molybdenum disulfide and composite materials, which is applied in the direction of secondary batteries, electrochemical generators, electrical components, etc., can solve the problem of limited improvement in the conductivity of molybdenum disulfide materials, and achieve easy operation, high capacity, and high rate The effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example, sodium molybdate and L-cysteine are used as raw materials to prepare molybdenum disulfide by hydrothermal method. The preparation method of the spherical molybdenum disulfide composite material in this example is as follows:

[0031] (1) Mix 20ml 0.04mol / L sodium molybdate aqueous solution and 20ml 0.16mol / L L-cysteine together, transfer to a 50ml polytetrafluoro container, and fix it in a stainless steel reaction kettle Then use an oven to directly heat at 220°C for 12 hours. When the temperature of the reactor naturally drops to 25°C, wash the obtained reactants with water and ethanol three times in sequence, and put the washed samples in an oven at 70°C. Dry for 5 hours to obtain spherical molybdenum disulfide nanospheres;

[0032](2) mixing the spherical molybdenum disulfide nanospheres prepared in step (1) with oleic acid at a weight ratio of 1:20, ultrasonically mixing for 2 hours, centrifuging to remove excess oleic acid, and obtaining molybd...

Embodiment 2

[0038] In this example, 20ml of 0.2mol / L sodium molybdate aqueous solution and 20ml of 0.32mol / L L-cysteine were mixed together to prepare molybdenum disulfide, and all the other steps and conditions were the same as in Example 1.

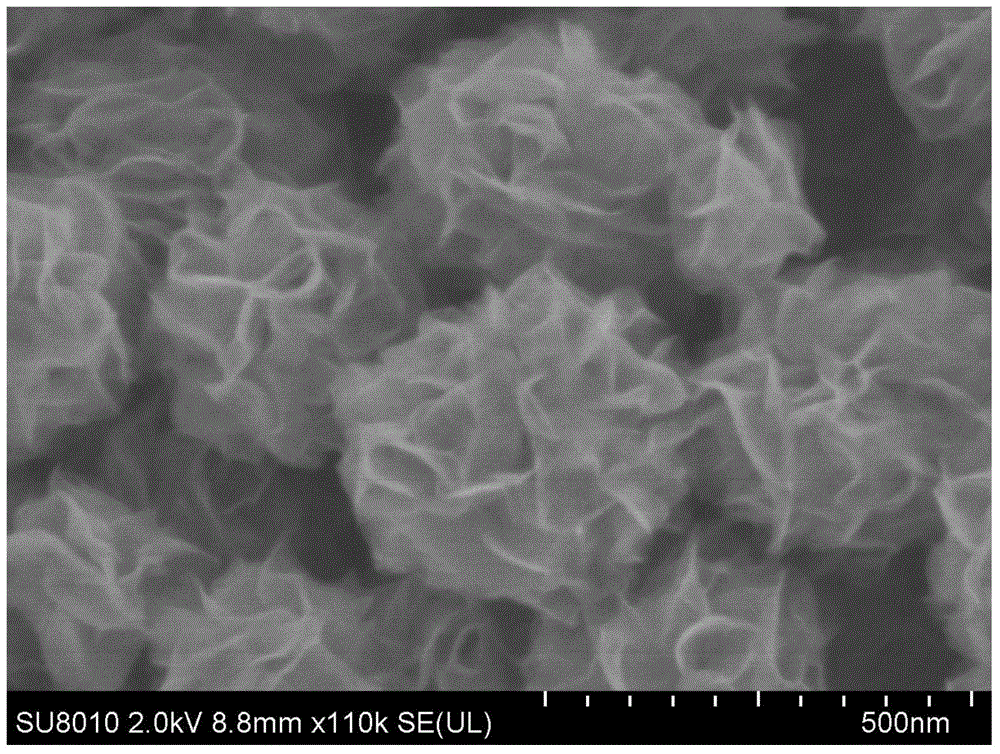

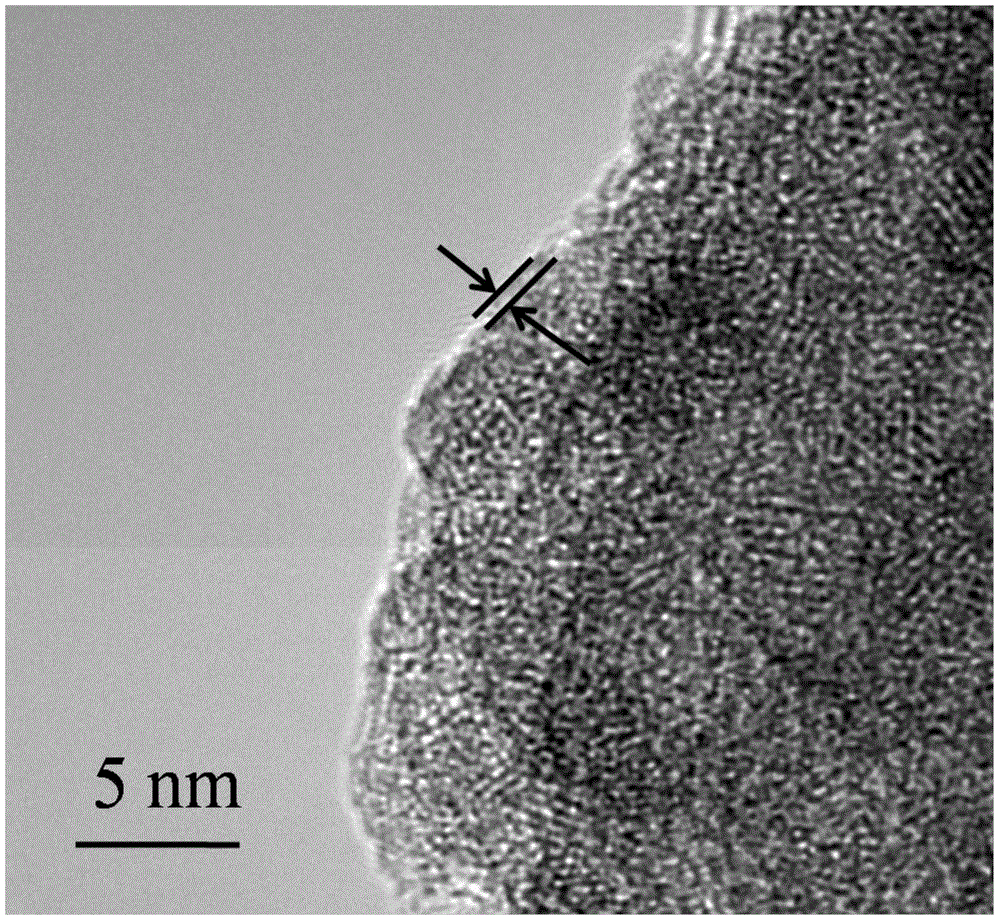

[0039] The composite material prepared in this example was observed with a scanning electron microscope, and the results showed that the diameter of the amorphous carbon-coated molybdenum disulfide nanospheres in this example was about 350 nanometers, the particle size distribution was uniform, and the thickness of the nanosheets was about 5-8 nanometers. It is measured that in the composite material of this example, the amorphous carbon content accounts for 13.6% of the total weight of the amorphous carbon-coated spherical molybdenum disulfide composite material.

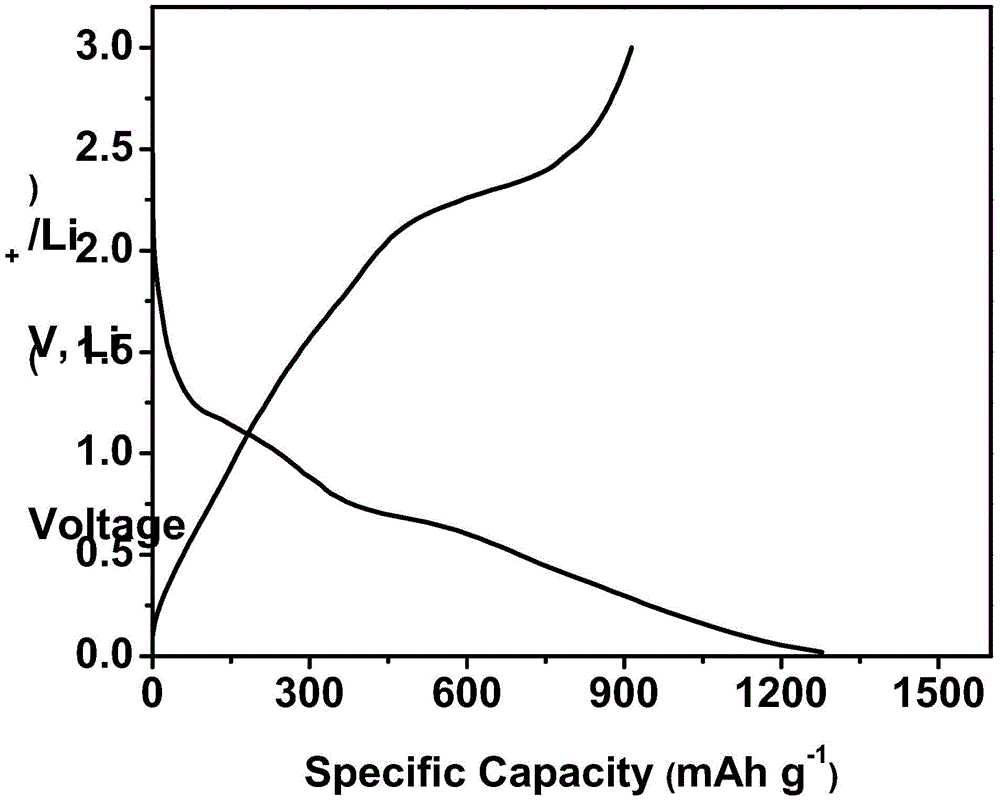

[0040] In this example, the negative electrode material was prepared by the same method as in Example 1, and its electrochemical performance was also tested by using a button cell. The...

Embodiment 3

[0042] In this example, 20ml of 0.1mol / L sodium molybdate aqueous solution and 20ml of 0.16mol / L L-cysteine are mixed together to prepare molybdenum disulfide, and the oven is directly heated at 240°C for 12 hours, that is to say , the hydrothermal reaction temperature was 240°C, and the rest of the steps and conditions were the same as in Example 1.

[0043] A scanning electron microscope was used to observe the composite material prepared in this example. The results showed that the diameter of the amorphous carbon-coated molybdenum disulfide nanospheres in this example was about 400 nanometers, the particle size distribution was uniform, and the thickness of the nanosheets was about 5-8 nanometers. It is measured that in the composite material of this example, the amorphous carbon content accounts for 13.7% of the total weight of the amorphous carbon-coated spherical molybdenum disulfide composite material.

[0044] In this example, the negative electrode material was pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com