Coal ash roller type fine extractive technique

A fly ash and rolling technology, applied in the direction of lithium carbonate;/acid carbonate, silver compound, silver compound, etc., can solve problems such as interference and complex composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

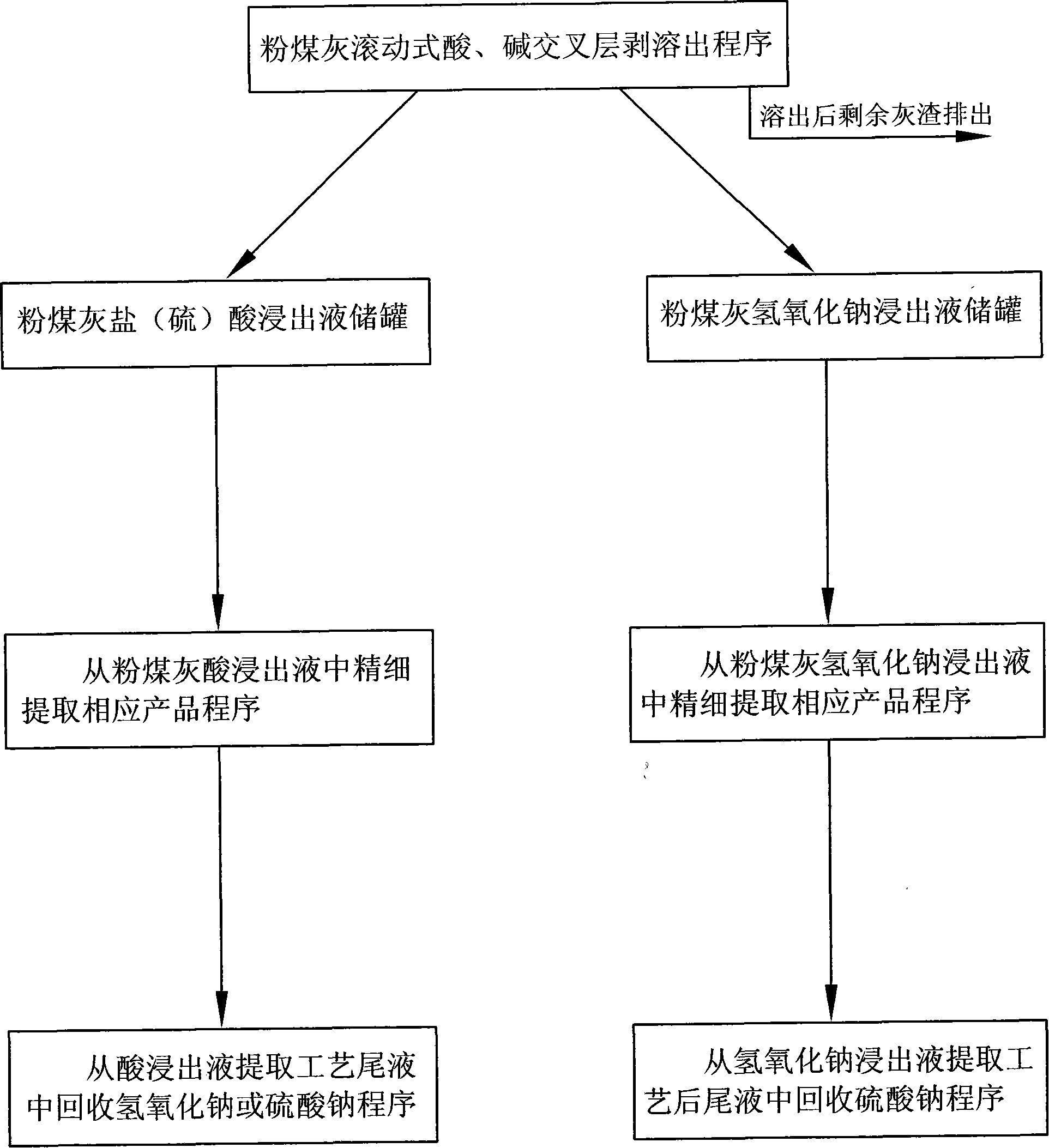

[0015] 1. Rolling layer stripping stripping process

[0016] The purpose of this process is to convert the solid matter extracted from fly ash into soluble matter to the greatest extent, and lay the material foundation for the rolling fine extraction process.

[0017] 1. Use industrial-grade strong acid (or waste acid) to leach and dissolve the basic oxides and secondary oxides in fly ash. If the fly ash is enriched with lanthanide rare earth oxides that can be extracted, it should be soaked with hydrochloric acid HCl solution; if the fly ash is enriched with actinide rare earth oxides that can be extracted, it should be used Sulphate H 2 SO 4 The solution is soaked.

[0018] 2. Following process 1, the remaining fly ash after solid-liquid separation and not less than two times of water washing is soaked with sodium hydroxide solution.

[0019] 3. After process 2, the remaining fly ash after solid-liquid separation and not less than two water washings is soaked with hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com