Doping device for optical fiber preform

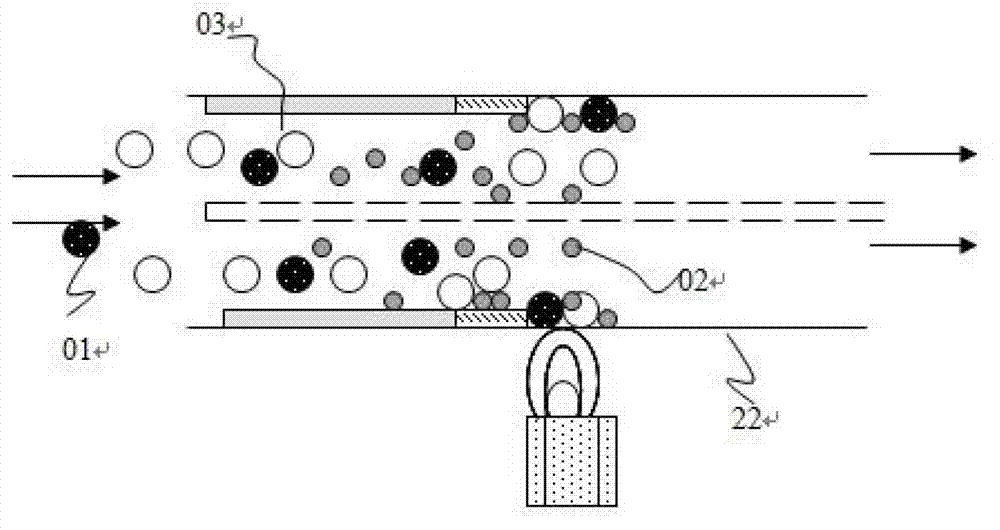

A gas-phase doping and heating device technology, which is applied in the direction of manufacturing tools and glass manufacturing equipment, can solve the problems of uneven distribution of dopant substances, uneven doping, and large dependence on loose and porous layer structures, and achieves guaranteed Effect of doping uniformity and stability, improvement of radial uniformity, and reduction of background loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

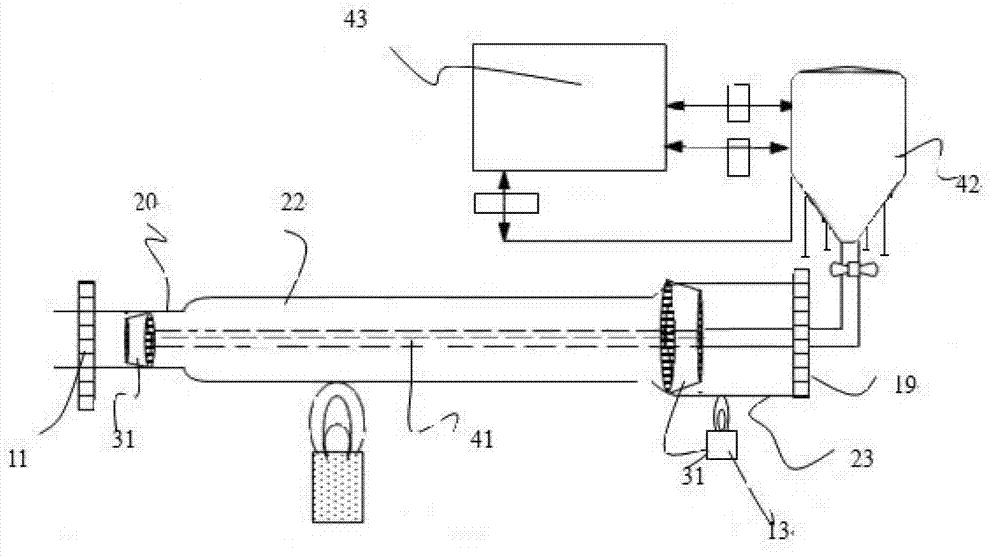

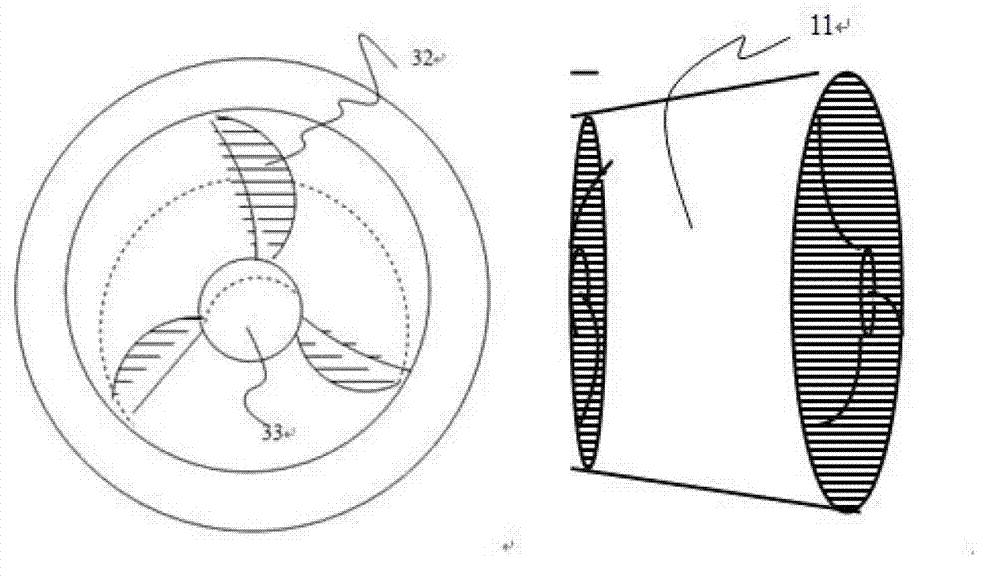

[0035] Example 1: Erbium-doped optical fiber preform

[0036] When the MCVD method is used to prepare the doped optical fiber preform, the first tail pipe 20 with the circular protrusion 21, the reaction tube 22 and the second tail pipe 23 are welded together, and the two joints are respectively inserted into the The liquid-phase injection joint device 31 is to support the reaction tube 21 with both tailpipes connected on the MCVD lathe, put the micro-hole injection tube 41 into it, and complete the connection between the micro-hole injection tube 41 and the solution tank 42 . Firstly, polishing and etching preparatory processes are carried out. After the deposition of the cladding material is completed, the deposition of the core layer is started by using the composite doping method of gas phase and liquid phase. This implementation case is to prepare an erbium-doped optical fiber preform.

[0037] When preparing erbium-doped optical fiber preforms, the raw materials require...

example 2

[0043] Example 2: Preparation of ytterbium-doped optical fiber preform

[0044] Adopt the same steps as the implementation case 1 to set up the reaction tube 21 with both ends connected to the tailpipe on the MCVD lathe, complete the heating and solution preparation of the gas phase and liquid phase composite doping mode, put it into the microporous injection tube 41, and complete The connection of the microporous injection pipe 41 and the solution tank 42. First deposit the outer cladding, the composition of the outer cladding is silicon dioxide and germanium dioxide, then turn on the gas phase heating device, start to deposit the inner cladding, the raw materials required for depositing the inner cladding are: high-purity oxygen, aluminum chloride, Silicon chloride, germanium tetrachloride, when aluminum chloride evaporates at 180 degrees Celsius and white smoke appears, open the pneumatic valves of silicon tetrachloride, germanium tetrachloride and high-purity oxygen, when ...

example 3

[0045] Example 3: Thulium-doped optical fiber preform

[0046] Adopt the same steps as the implementation case 1 to complete the deposition of the cladding layer and start the deposition of the core layer. The raw materials required for the core layer are: high-purity oxygen, aluminum chloride, silicon tetrachloride, germanium tetrachloride, and chloride Holmium chloride and thulium chloride, among which holmium chloride is doped in solid gas phase, and aluminum chloride and thulium chloride are mixed into a mixed solution for liquid phase online jet doping. First turn on the gas phase heating device 12 to heat the holmium chloride powder packaged with gold foil, evaporate it at a temperature of 200 degrees Celsius, and open the pneumatic valves of silicon tetrachloride, germanium tetrachloride and high-purity oxygen when the gaseous state appears, and open the solution tank at the same time Connect the valve with the online injection device, let the mixed solution enter the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com