Germanium-carbon-graphene composite material, and preparation method and application thereof

A composite material, graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of unsuitable industrial application, high cost, insignificant effect, etc., and achieve excellent cycle stability, high output, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the germanium-carbon graphene composite material of the present embodiment may further comprise the steps:

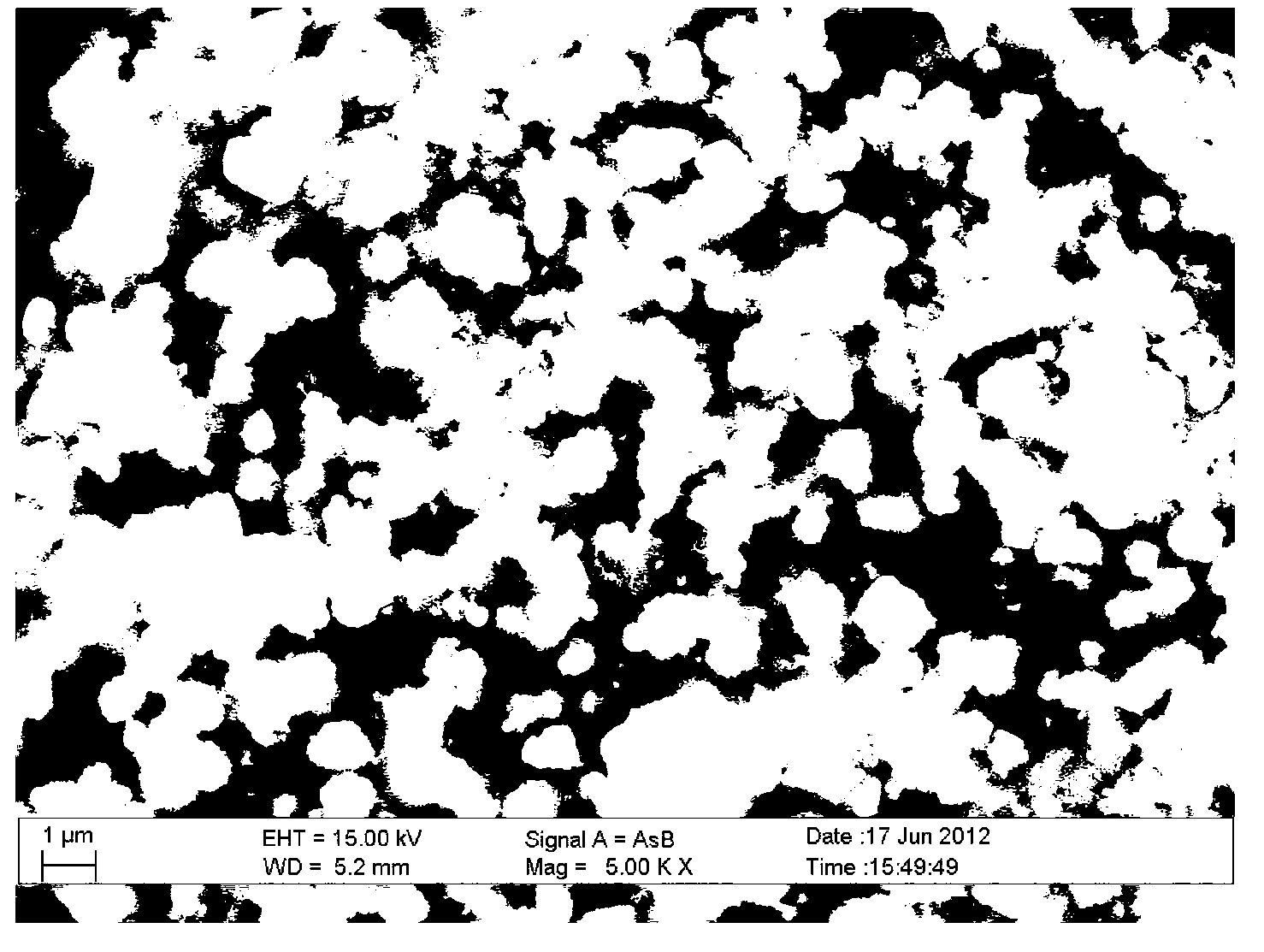

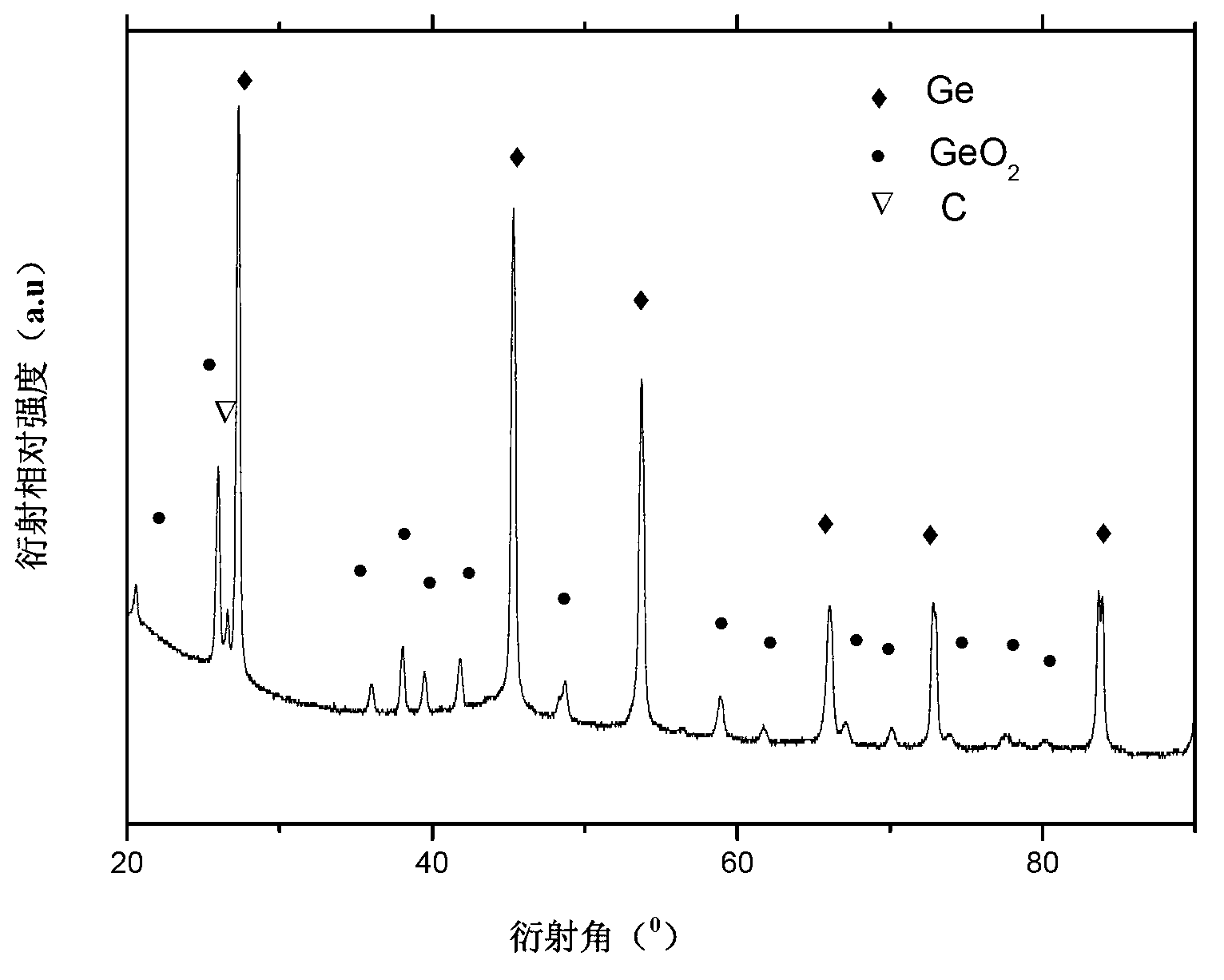

[0030] (1) Use a high-energy pendulum vibration ball mill (QC-3M) to mill pure germanium raw materials and graphite raw materials in an oxidizing atmosphere. During the process of nanonization, a small amount of germanium dioxide shells are formed on the surface of germanium. Among them, pure germanium raw materials and graphite raw materials The mass ratio of raw materials is 1:1; the mass ratio of grinding balls to raw material powder is 20:1, and the ball milling time is 10h. The obtained GeGeO 2 C composite material, its surface morphology is as follows figure 1 shown;

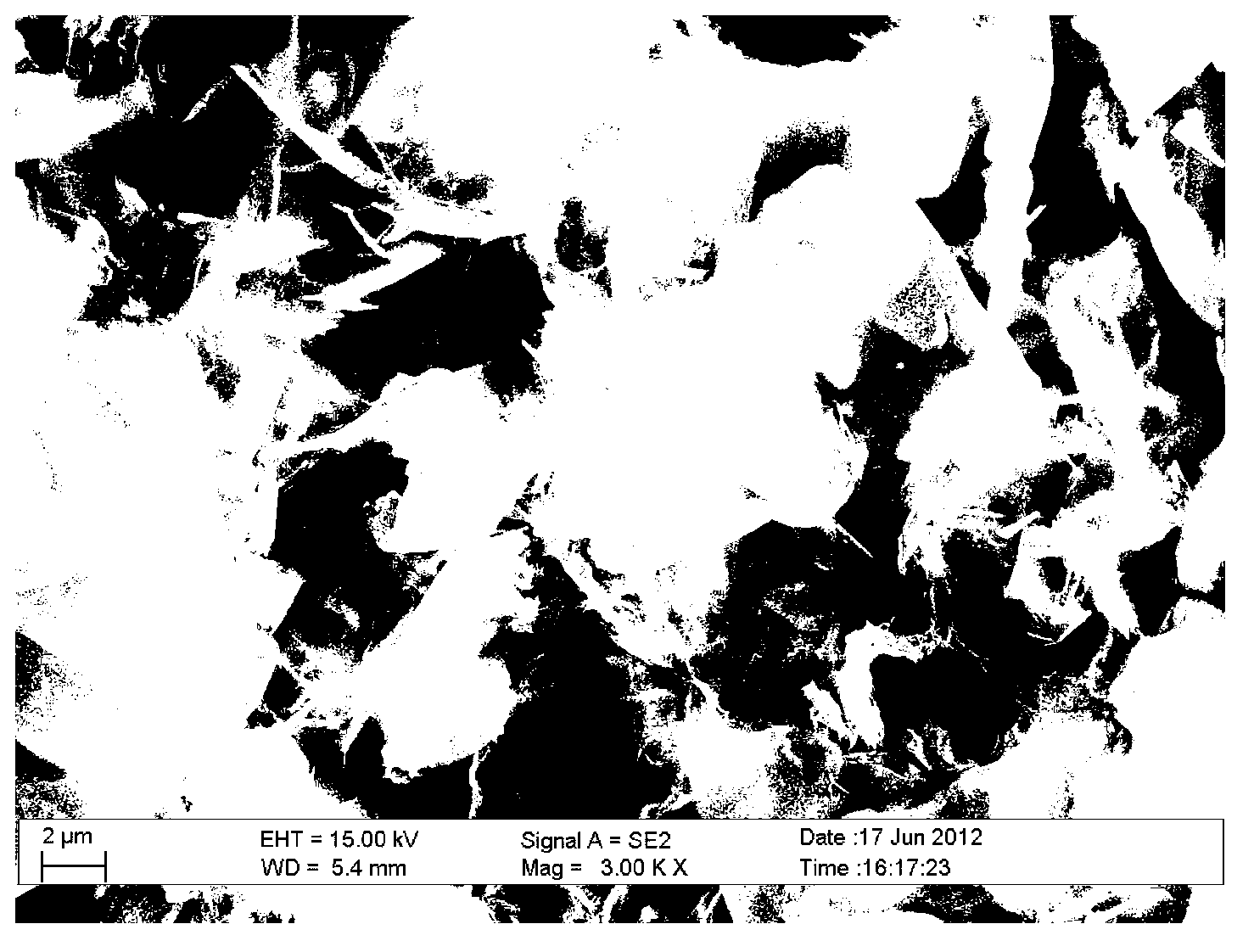

[0031] (2) Graphite oxide was prepared by the improved Hummers method, and reduced graphene oxide was obtained by reduction with hydrazine hydrate. The surface morphology is as follows figure 2 shown;

[0032] (3) The germanium-carbon composite core-shell materia...

Embodiment 2

[0038] The preparation method of the germanium-carbon graphene composite material of the present embodiment, except that the mass ratio of pure germanium raw material and graphite raw material is 1:0.1, GeGeO 2 Except that the mass ratio of C composite material and reduced graphene oxide is 1:0.8, all the other features are the same as in Example 1.

[0039] GeGeO prepared in this embodiment 2 The surface morphology of C / RGO composites is as follows: Image 6 shown.

[0040] The germanium-carbon-graphene composite material prepared in this example was made into a negative electrode sheet of a lithium-ion battery, and after the battery was assembled, a charge-discharge test was performed under 2C charge-discharge rate conditions. Prepared GeGeO 2 The initial discharge capacity of C / RGO composite is 1060mAhg -1 , the capacity remains at 413mAhg after 100 cycles -1 .

Embodiment 3

[0042] The preparation method of the germanium-carbon-graphene composite material of this embodiment is the same as that of Embodiment 1, except that the mass ratio of pure germanium raw material and graphite raw material is 1:0.5, and the ball milling time is 4h.

[0043] The germanium-carbon graphene composite material prepared in this example is made into the negative electrode sheet of lithium-ion battery, and after the battery is assembled, the charge-discharge test is carried out under the condition of 2C charge-discharge rate. The rate cycle performance curve is as follows: Figure 7 As shown, it can be seen that the first discharge capacity is 1841mAhg -1 , the capacity remains at 575mAhg after 100 cycles -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com