Low cost method for rapidly synthesizing ITQ-13 molecular sieve

A molecular sieve, low-cost technology, applied in the field of low-cost and rapid synthesis of ITQ-13 molecular sieve, can solve the problems of long time and achieve the effects of reducing loss, low price, and shortening crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

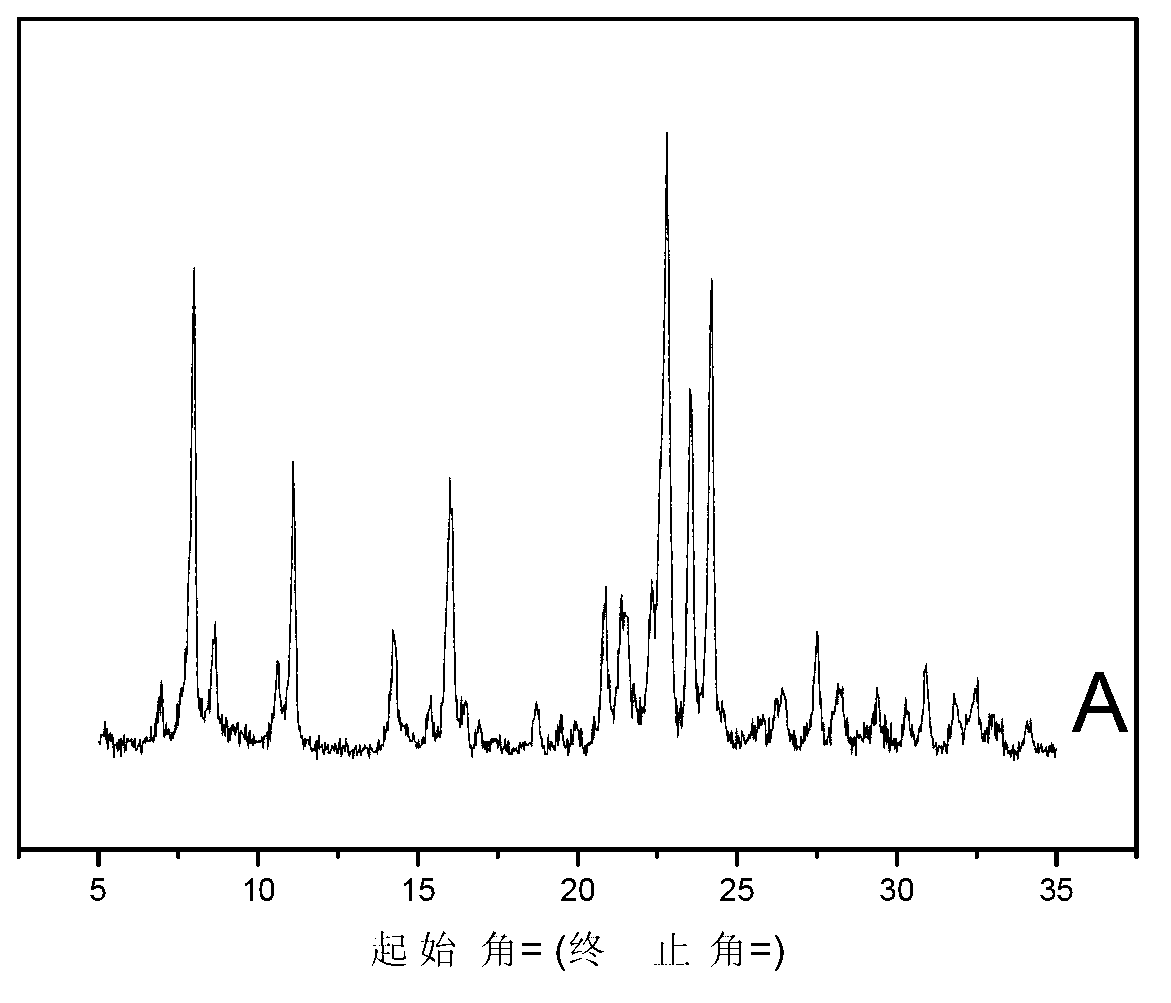

[0037] First, weigh 2g of hexamethonium bromide solid and dissolve it in 2ml of deionized water, add 4ml of accelerator (0.3wt%), 0.4gNaOH, 0.05gGeO 2 , 0.2g NaAlO 2 , 0.1g seed crystal, after mixing evenly, slowly add 2.14g white carbon black, add 0.75gNH under stirring 4 F, continue to stir until a uniform silicon germanium gel is formed, then transfer to a stainless steel reactor, and conduct static crystallization at 180°C for 2 days. The molar ratio of the reaction raw materials is 0.30NaOH: 0.015GeO 2 : 0.024Al 2 o 3 : SiO 2 : 0.17 R (hexamethyldiammonium bromide): 0.59NH 4 F: 10H 2 O. After the reaction kettle was cooled to room temperature, the product was suction-filtered, washed with water until neutral, and dried at 100°C to obtain product A. The XRD of product A is attached figure 1 , It can be seen from the figure that product A has the characteristic peak of ITQ-13, and the crystallinity is very high.

Embodiment 2

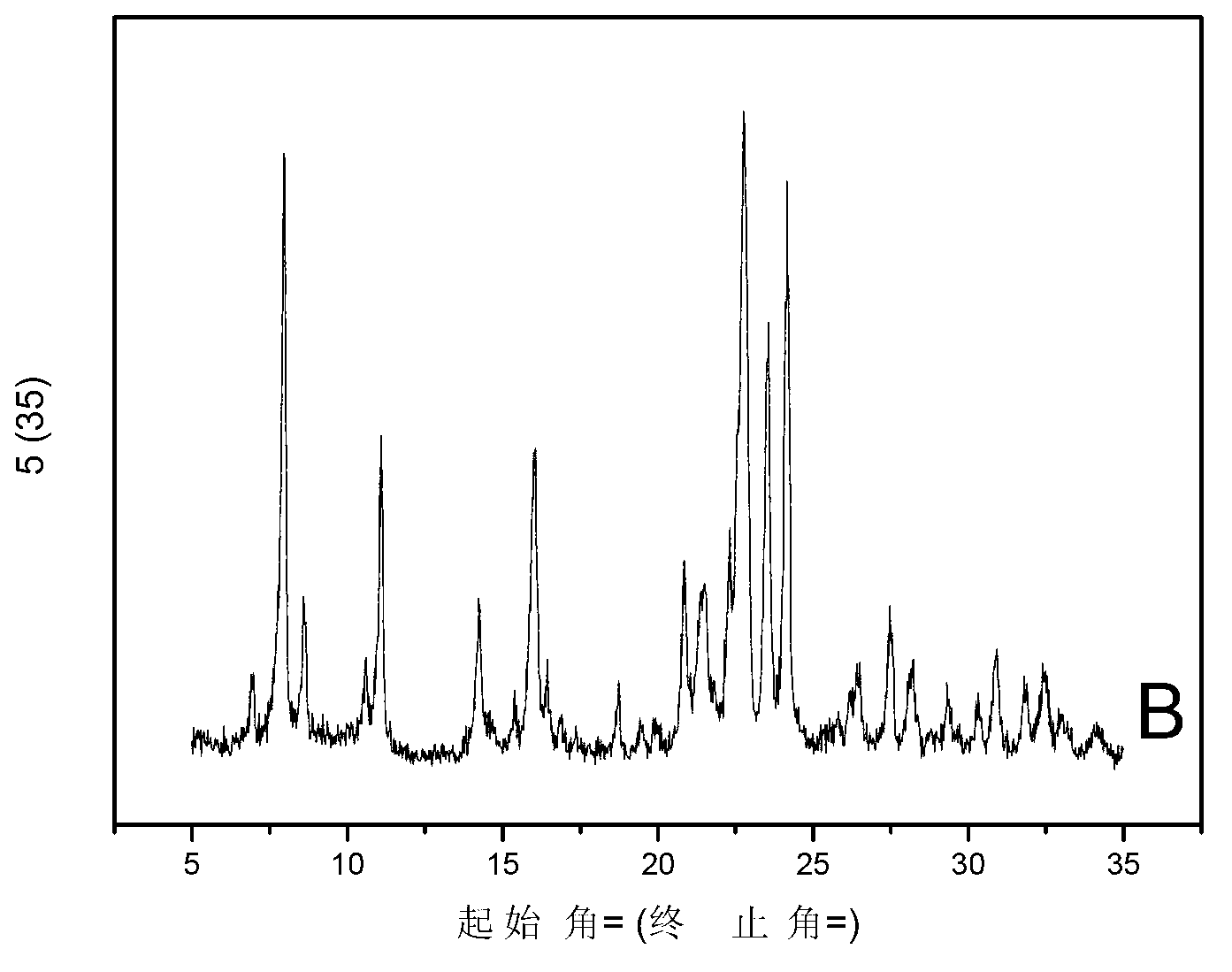

[0039] First, weigh 2g of hexamethonium bromide and dissolve it in 6ml of deionized water, add 0.01g of accelerator, 0.35g of NaOH, 0.15g of GeO 2 , 0.30g NaAlO 2 , after mixing evenly, add 6.86ml of silica sol (30wt%), add 0.7g of ammonium fluoride under stirring, continue to stir until a uniform silicon germanium gel is formed, then transfer to a polytetrafluoroethylene reactor, 175 ° C static Response 3 days. The molar ratio of the reaction raw materials is 0.27NaOH: 0.044GeO 2 : 0.036Al 2 o 3 : SiO 2 : 0.17R (hexamethyldiammonium bromide): 0.55NH 4 F: 18H 2 O. After the reaction kettle was cooled to room temperature, the product was suction-filtered, washed with water until neutral, and dried at 100°C to obtain product B. The XRD of product B is attached figure 2 , It can be seen from the figure that the product B has the characteristic peak of ITQ-13, and has a high degree of crystallinity without miscellaneous crystals.

Embodiment 3

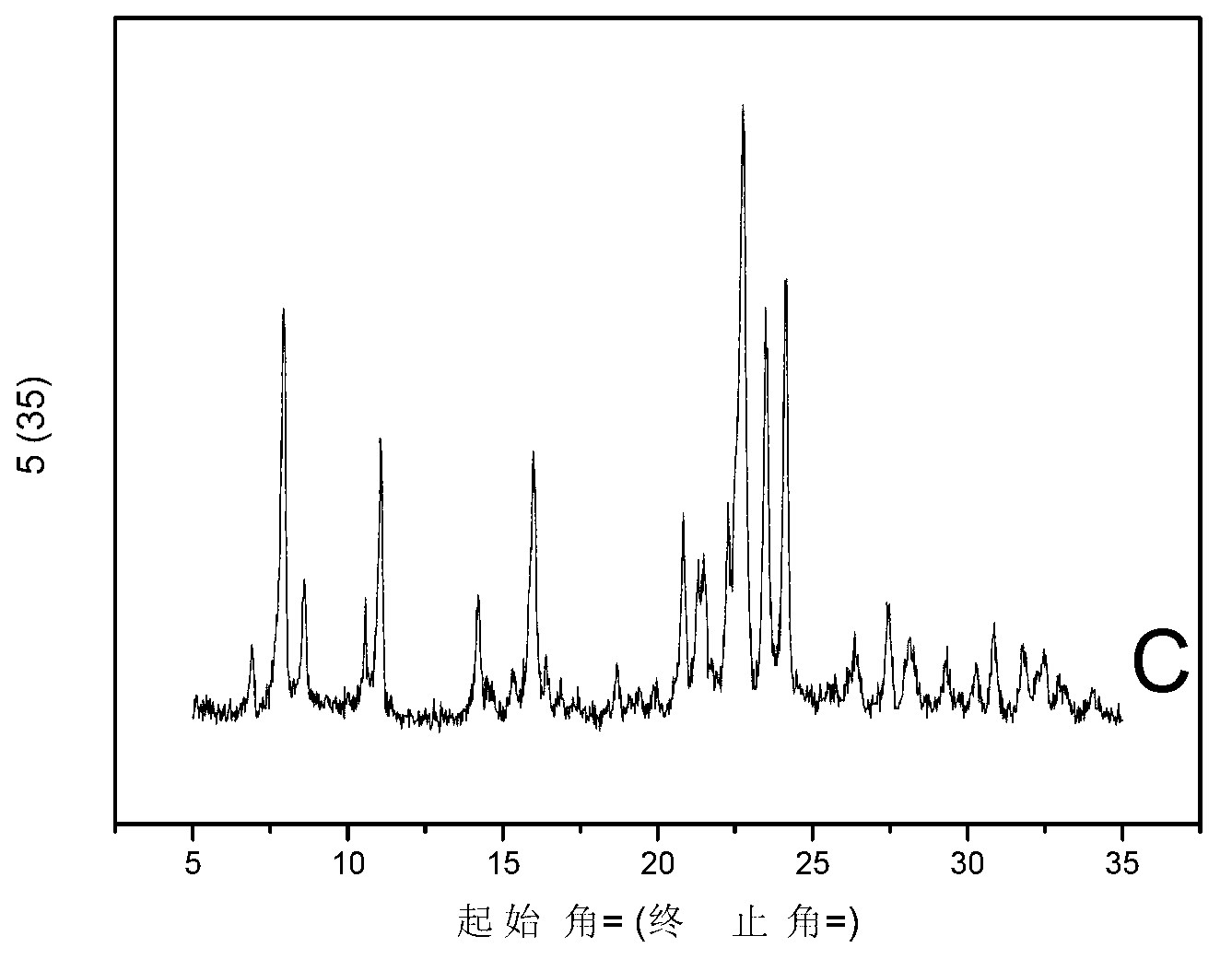

[0041] First, weigh 2g of hexamethonium bromide and dissolve it in 4ml of deionized water, add 0.01g of accelerator, 0.35g of NaOH, 0.15g of GeO 2 , 0.30g of NaAlO 2 , 0.1g seed crystal, after mixing evenly, add 6.86ml of silica sol, add 0.8g of ammonium fluoride under stirring, continue to stir until a uniform silicon germanium gel is formed, then transfer to a polytetrafluoroethylene reactor, 200 ° C Static reaction for 2 days. The molar ratio of the reaction raw materials is 0.27NaOH: 0.044GeO 2 : 0.036Al 2 o 3 : SiO 2 : 0.17R (hexamethyldiammonium bromide): 0.63NH 4 F: 15H 2 O. After the reactor was cooled to room temperature, the product was suction filtered, washed with water until neutral, and dried at 100°C to obtain product C. The XRD of product C is attached image 3 , it can be seen from the figure that the product C has the characteristic peak of ITQ-13, and has a high degree of crystallinity without miscellaneous crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com