Patents

Literature

55results about How to "Large ratio range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

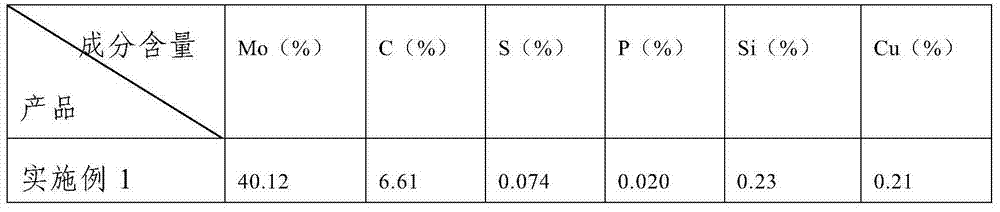

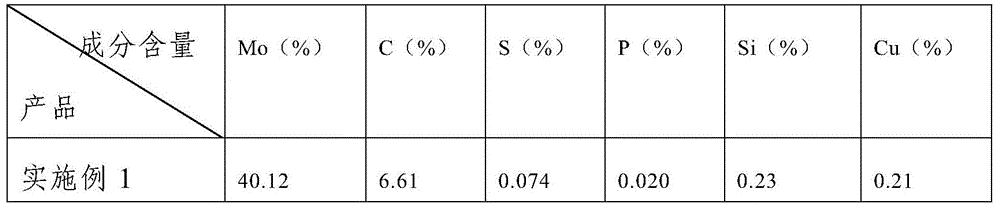

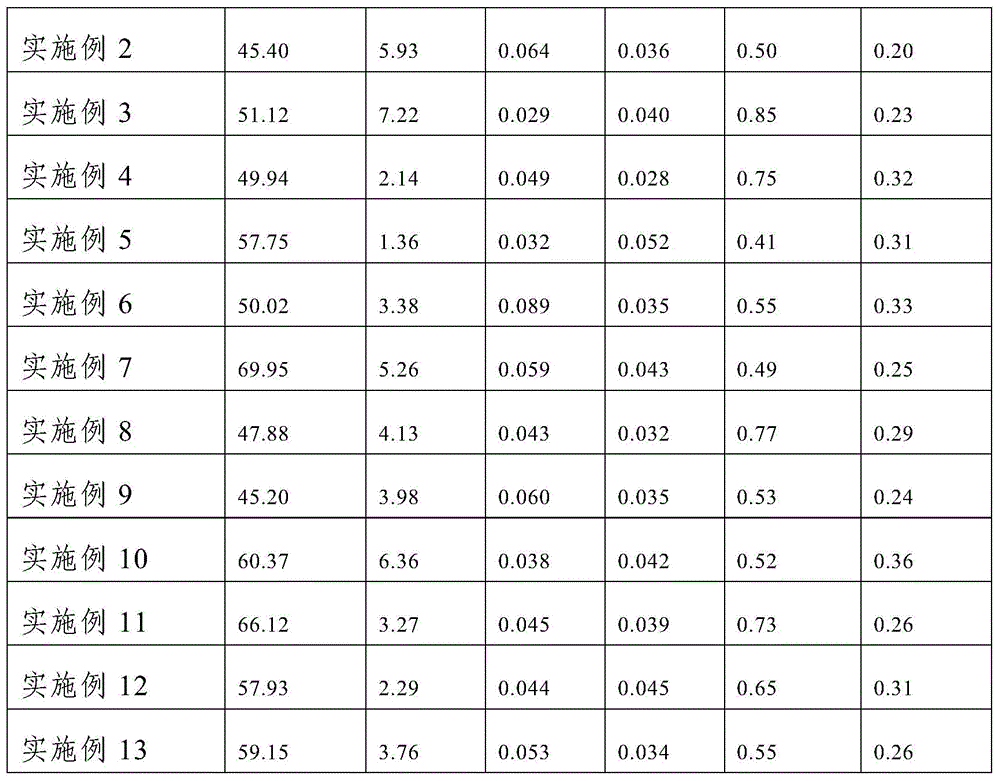

Ferro-molybdenum and preparation method thereof

The invention discloses ferro-molybdenum made of mixture powder and reducing agents. The mixture powder comprises, by weight, 21.0%-42.9% of molybdenum oxide powder, 0%-50.3% of iron oxide powder, 0%-33.2% of iron powder, 3.6%-23.5% of calcium molybdate and 3.2%-22.3% of industrial waste residue. In addition, the invention further discloses a method for preparing the ferro-molybdenum. According to the ferro-molybdenum and the preparation method thereof, carbon powder is adopted to serve as the reducing agents, the mixture powder and the reducing agents are mixed and then roasted at the temperature of not higher than 1600 DEG C to prepare the ferro-molybdenum, and pollutants such as nitrogen oxide and fluoride do not exist in the preparation process; the adaptability of the raw material formula is strong, compared with the traditional aluminothermy adopted to prepare the ferro-molybdenum, the quality adjustment and the quantity adjustment of the raw material formula have a good raw material adaptability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

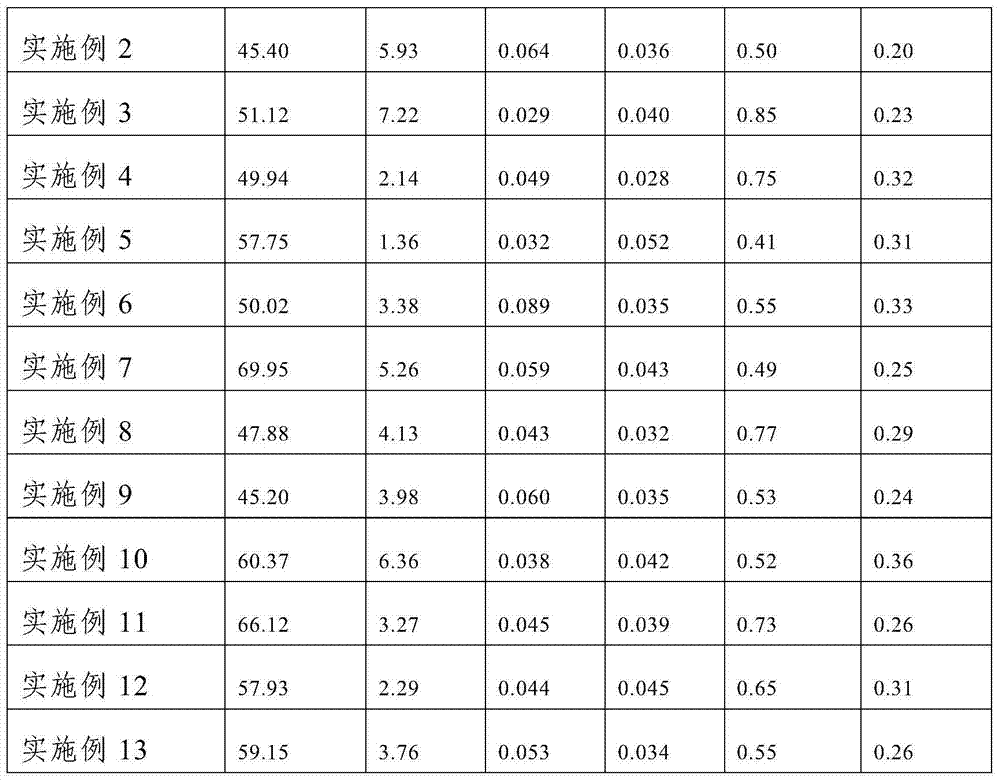

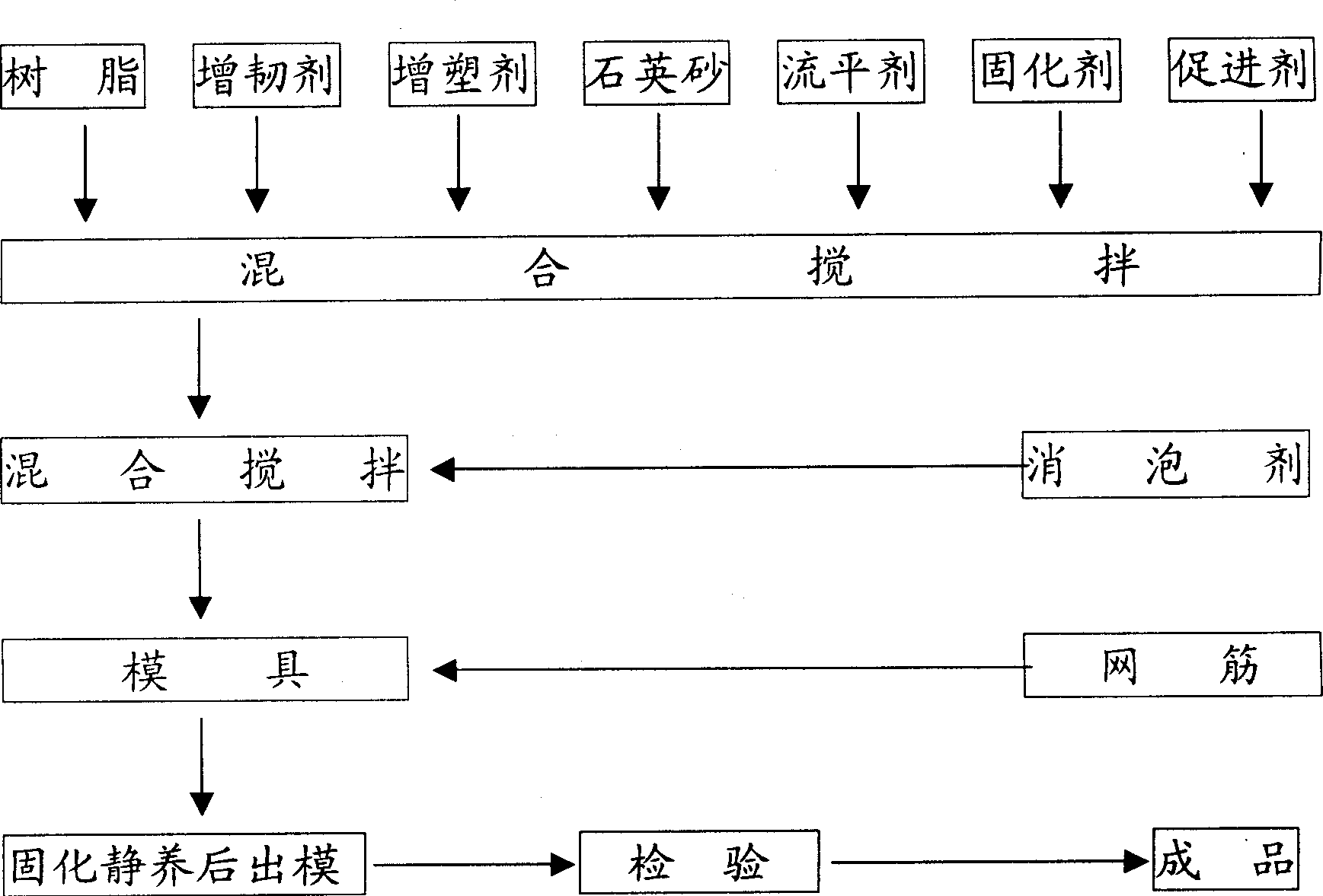

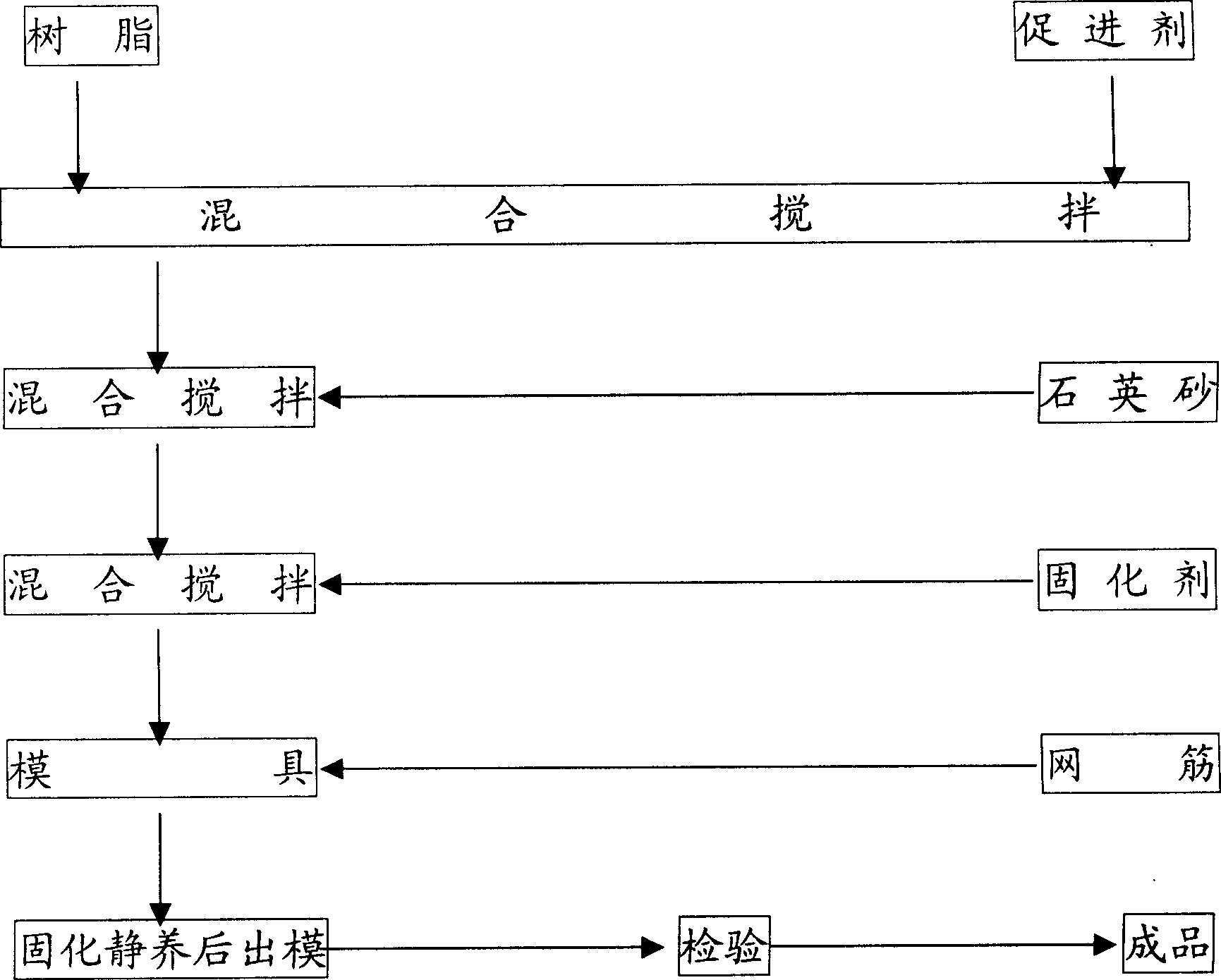

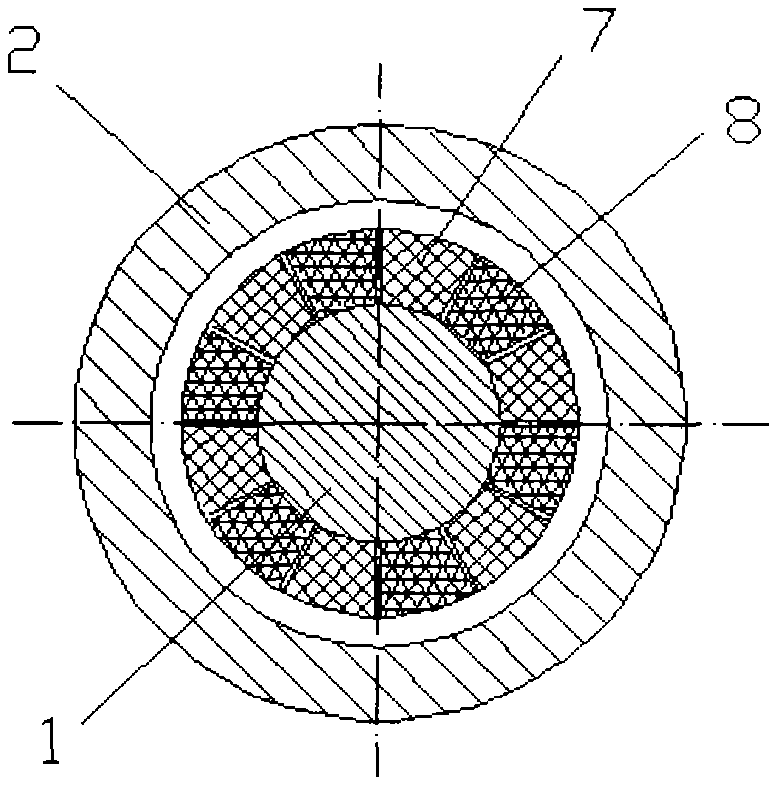

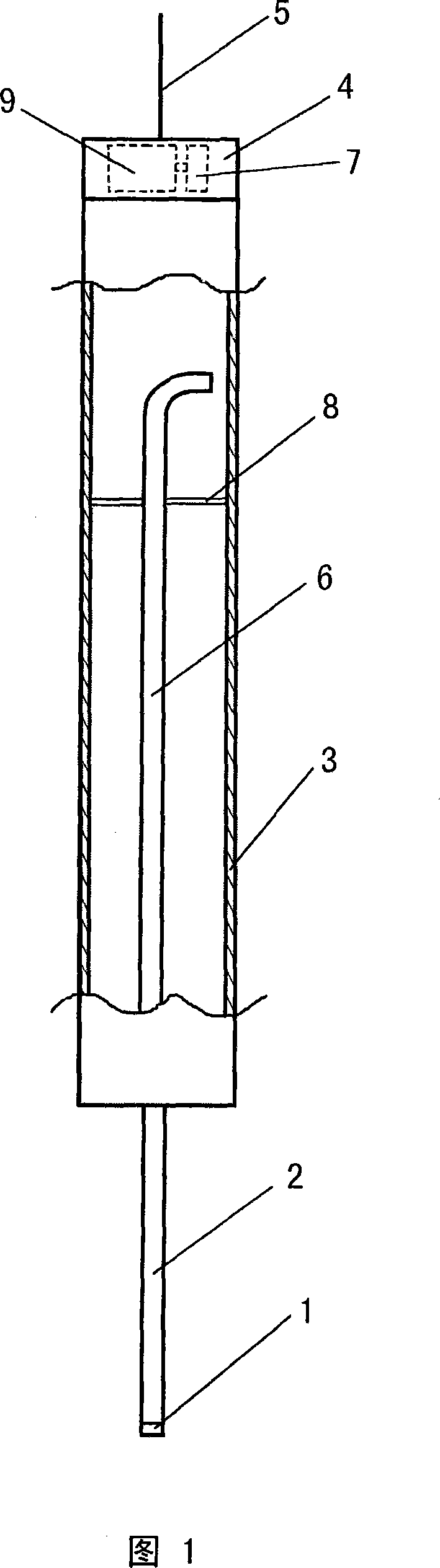

Reinforced concrete resin slurry casting pipe and method for manufacturing the same

InactiveCN1807051ALow priceExtended service lifeMixing operation control apparatusShaping reinforcementsReinforced concreteSlurry

The invention discloses the reinforcement coagulate resin mortar casting tube and preparing method. The method comprises the following steps: 1 10-60% resin, 3.497-15% toughening agent, 1.5-6% plasticizing agent, 5- 80% quartz sand, 0.5-5% levelling agent, 40-3% curing agent, 0.5-5% accelerating agent, 0.003-5% defoaming agent; 2 mixing resin, plasticizing agent, quartz sand, levelling agent, curing agent and accelerating agent; 3 adding defoaming agent; 4 adding them into die with web tendon; 5 curing, stewing and mould unloading; 6 checking; 7 getting the reinforcement coagulate resin mortar casting tube. The tube is used as tube building material. The invention has the advantages of high strength, light weight, good sealing, corrosion prevention, long lifetime and low cost.

Owner:泊谊文化传播(北京)有限公司

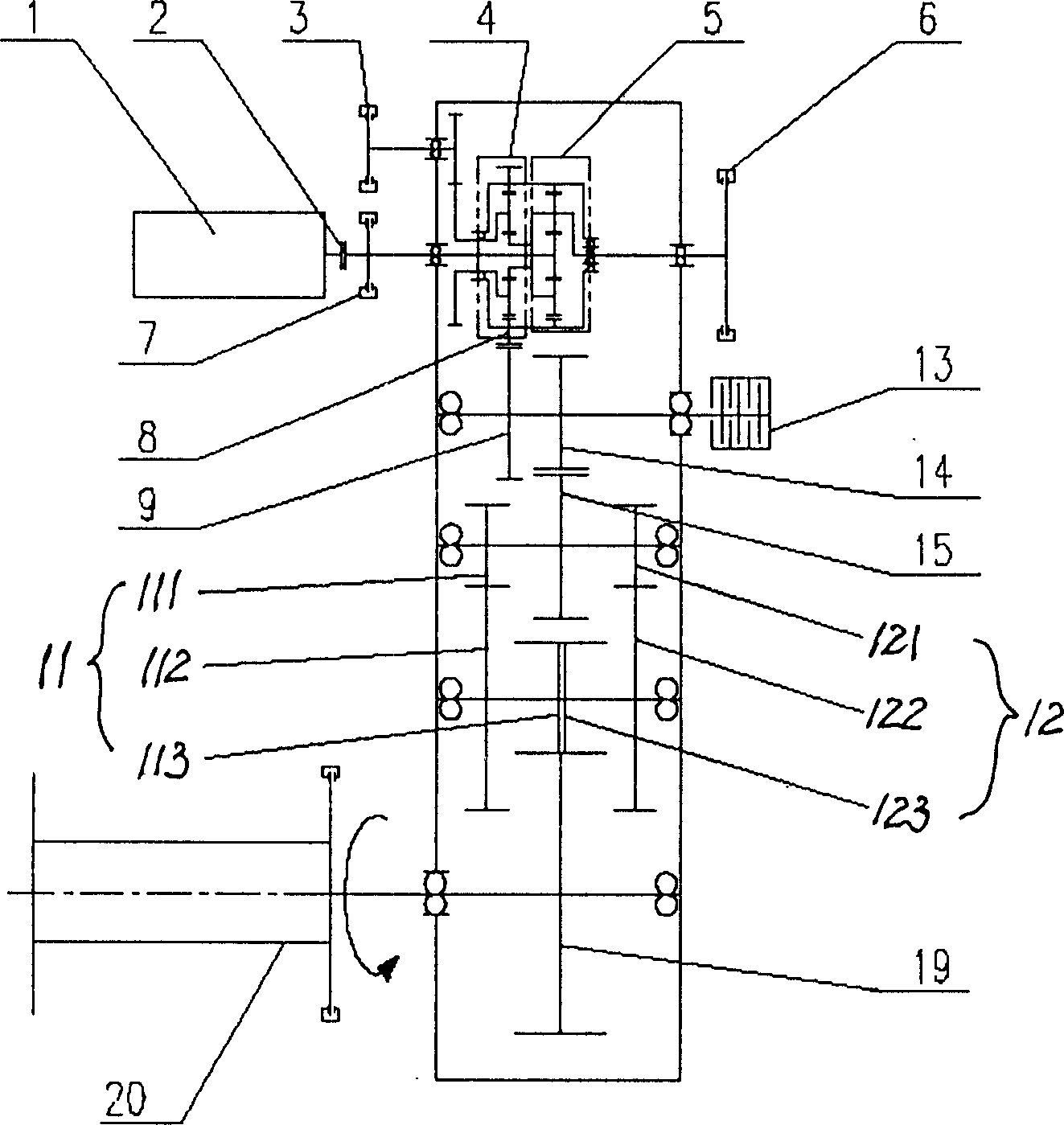

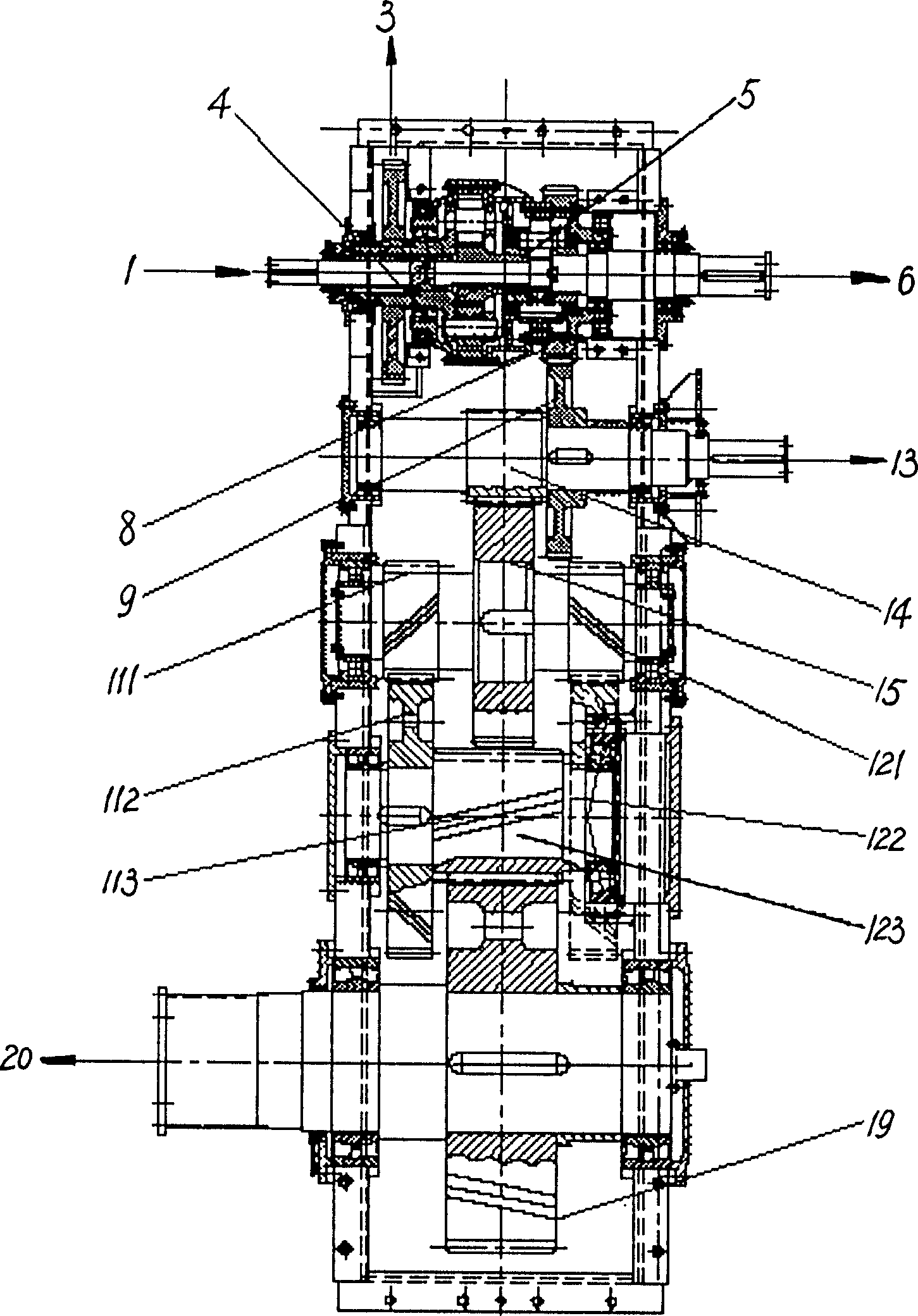

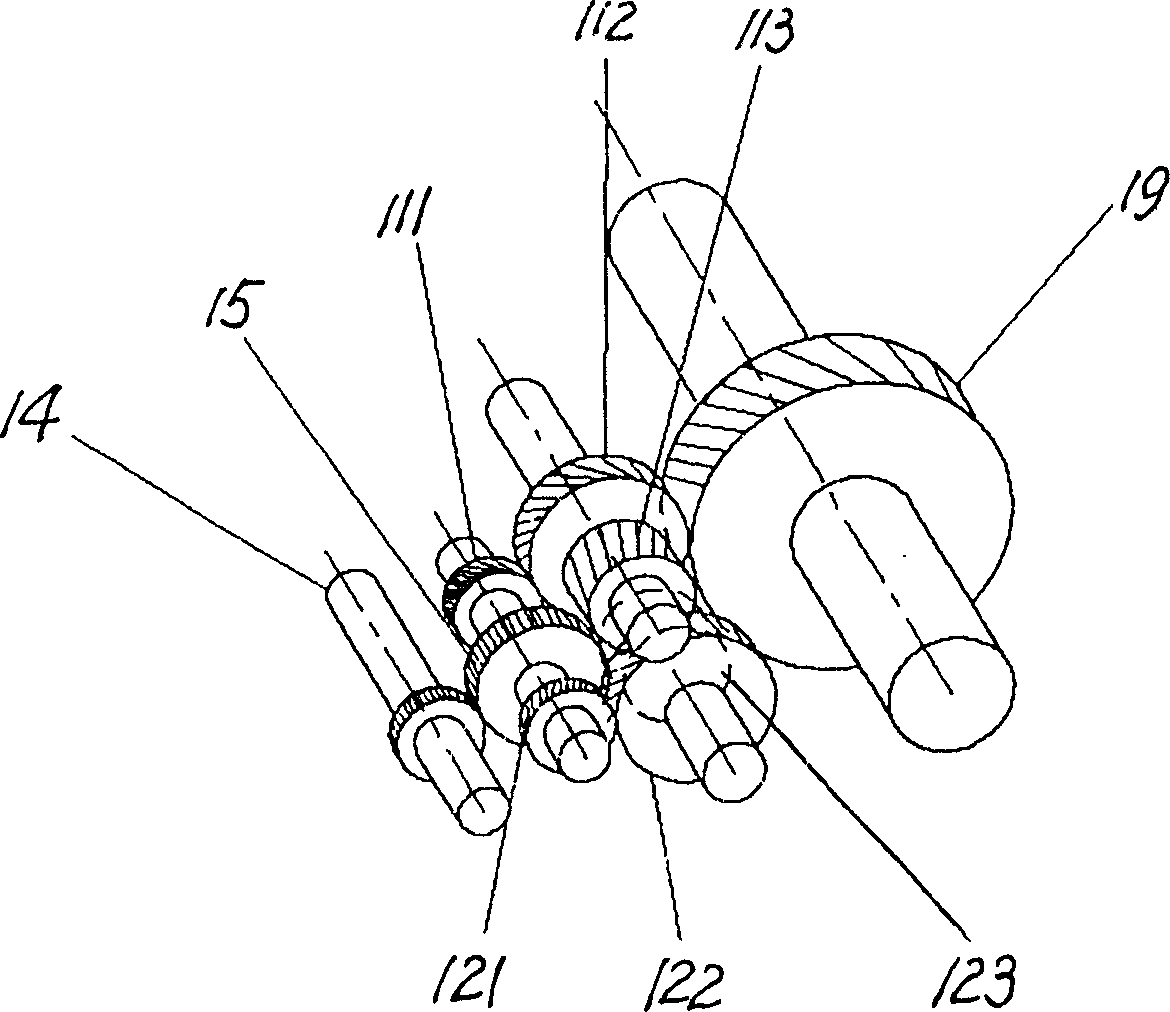

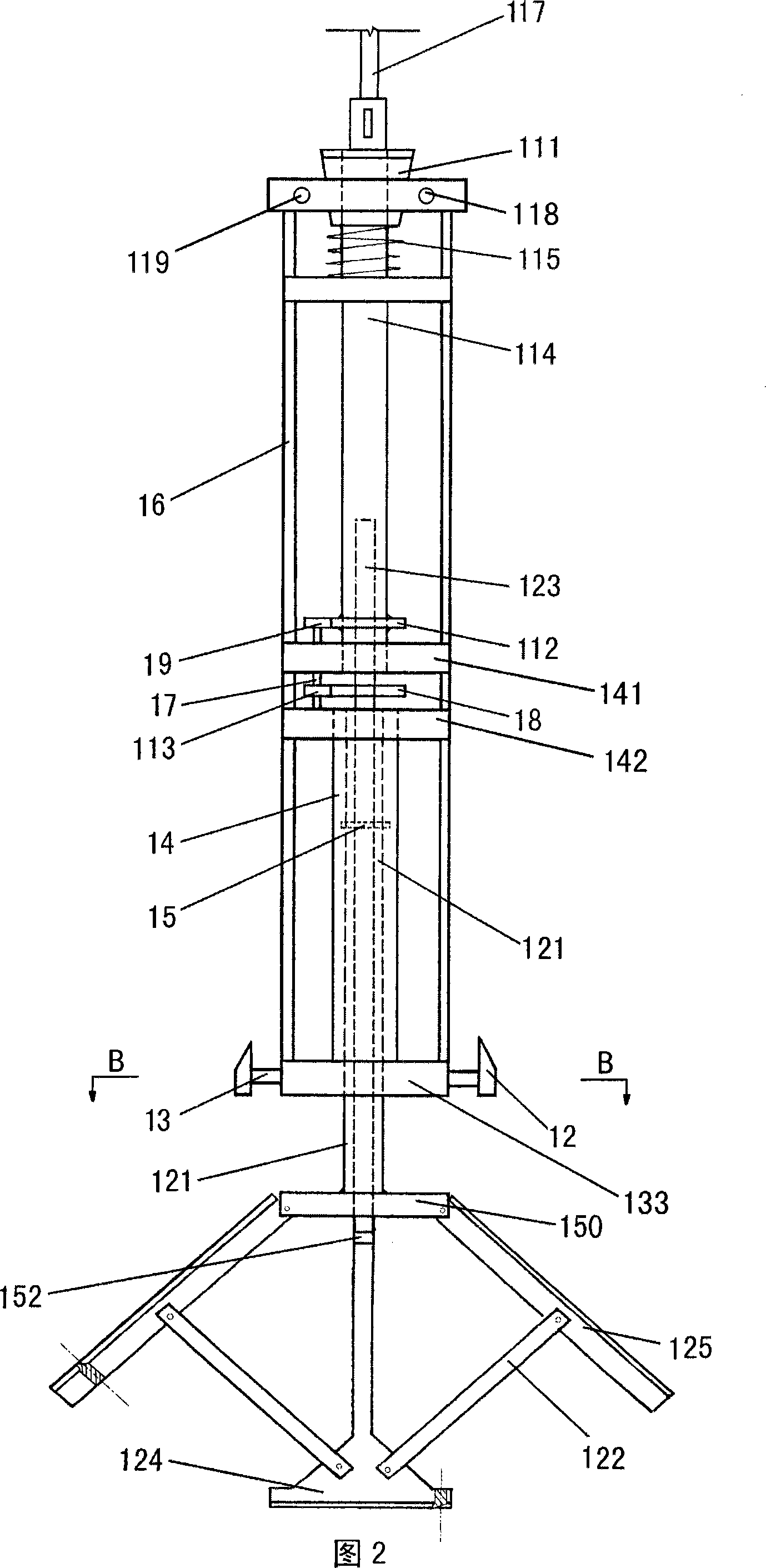

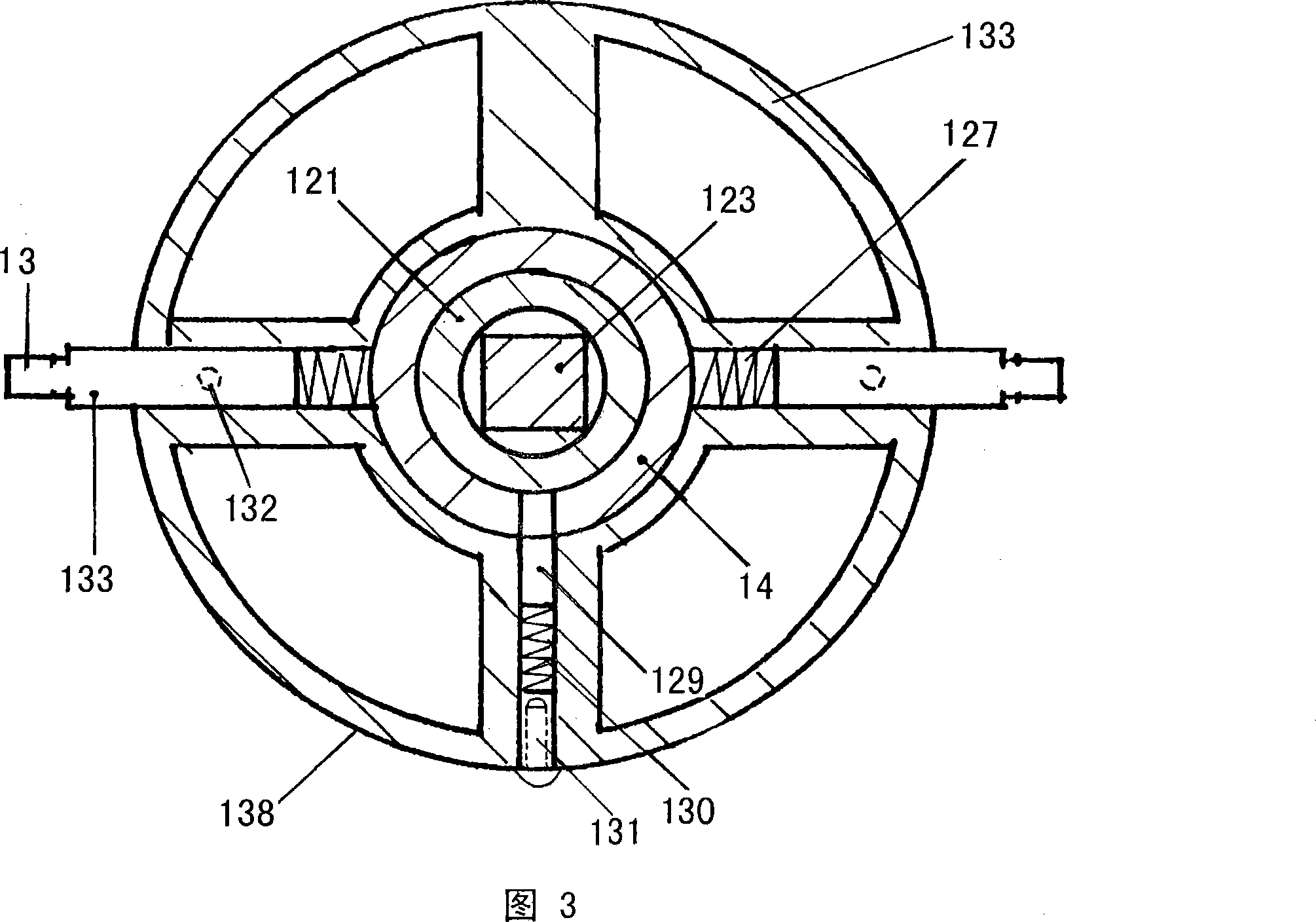

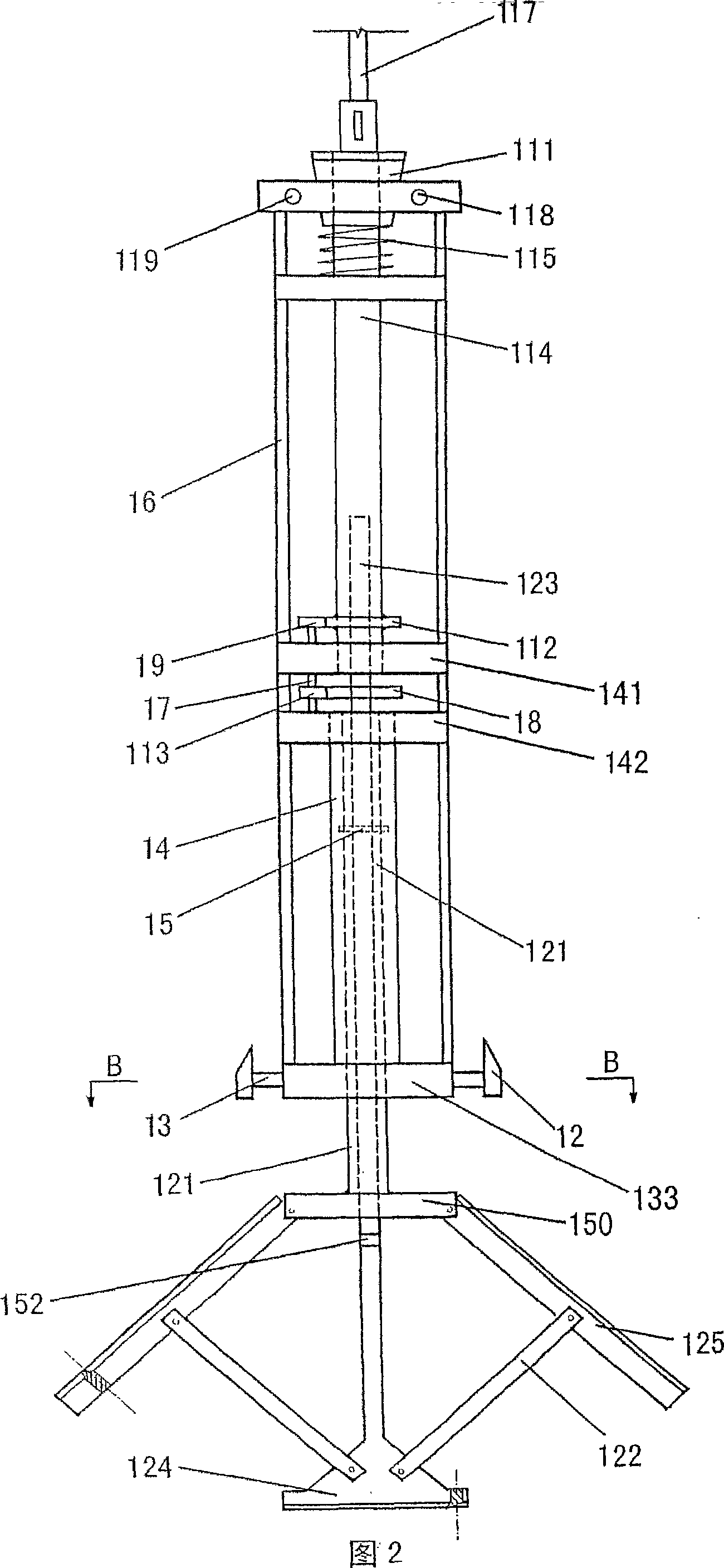

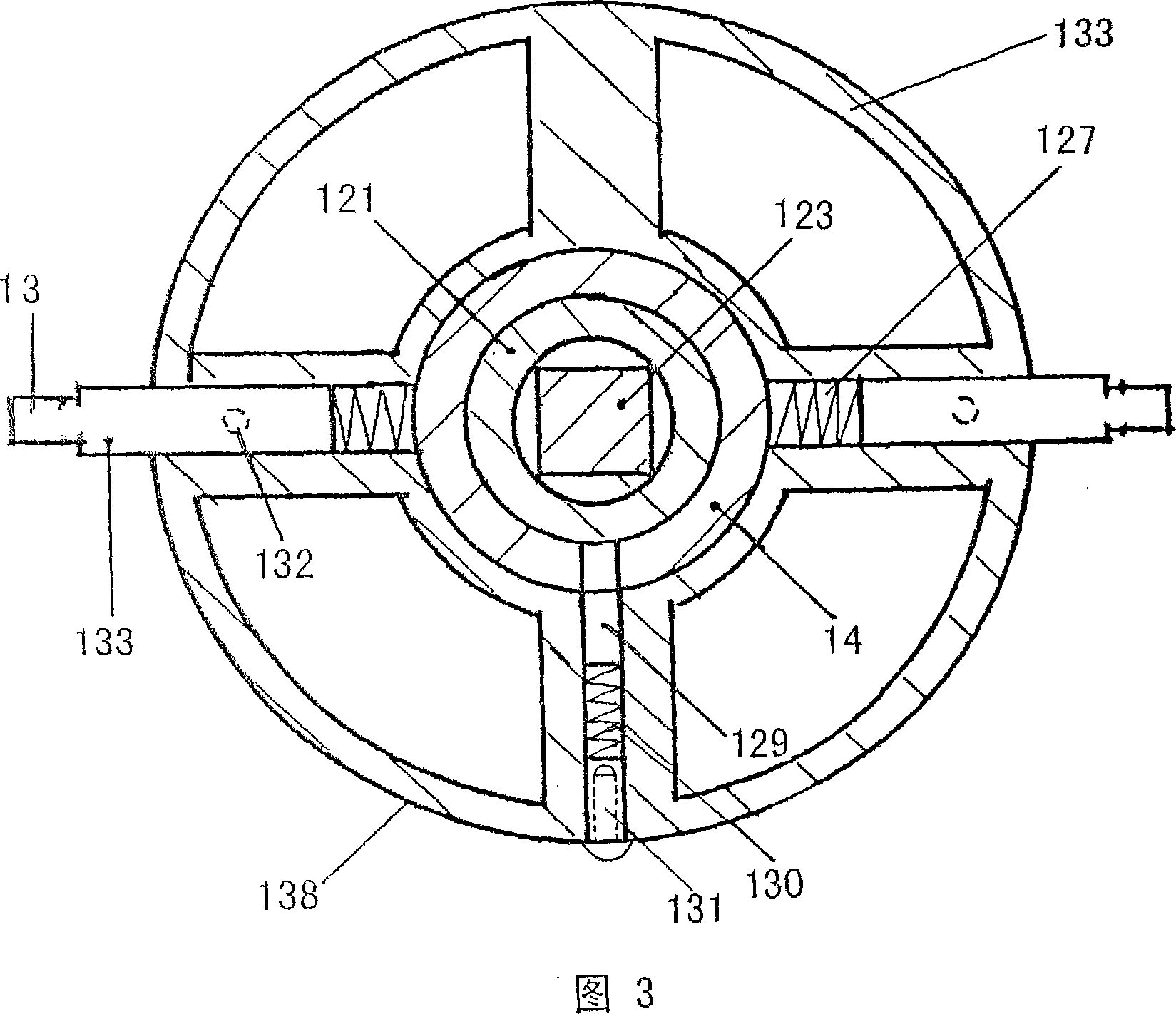

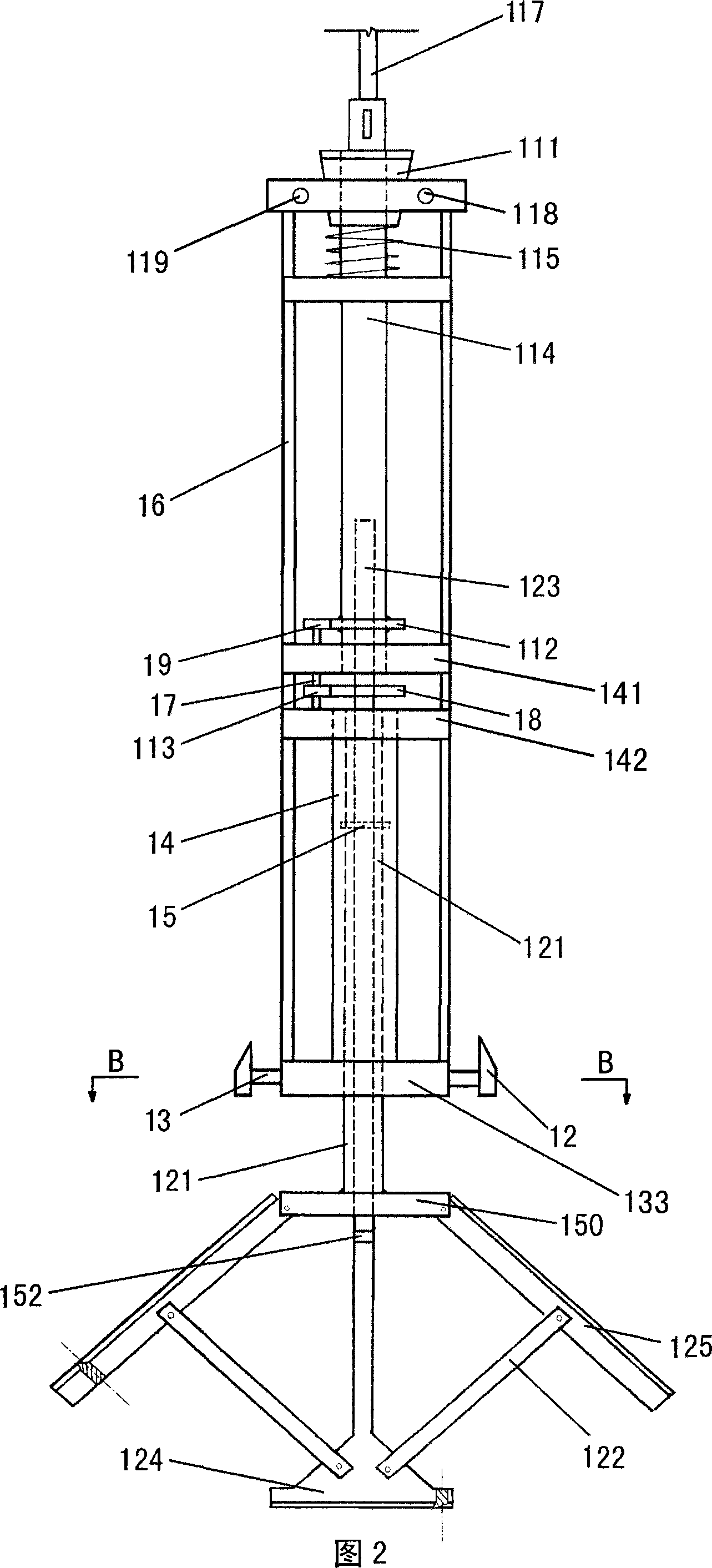

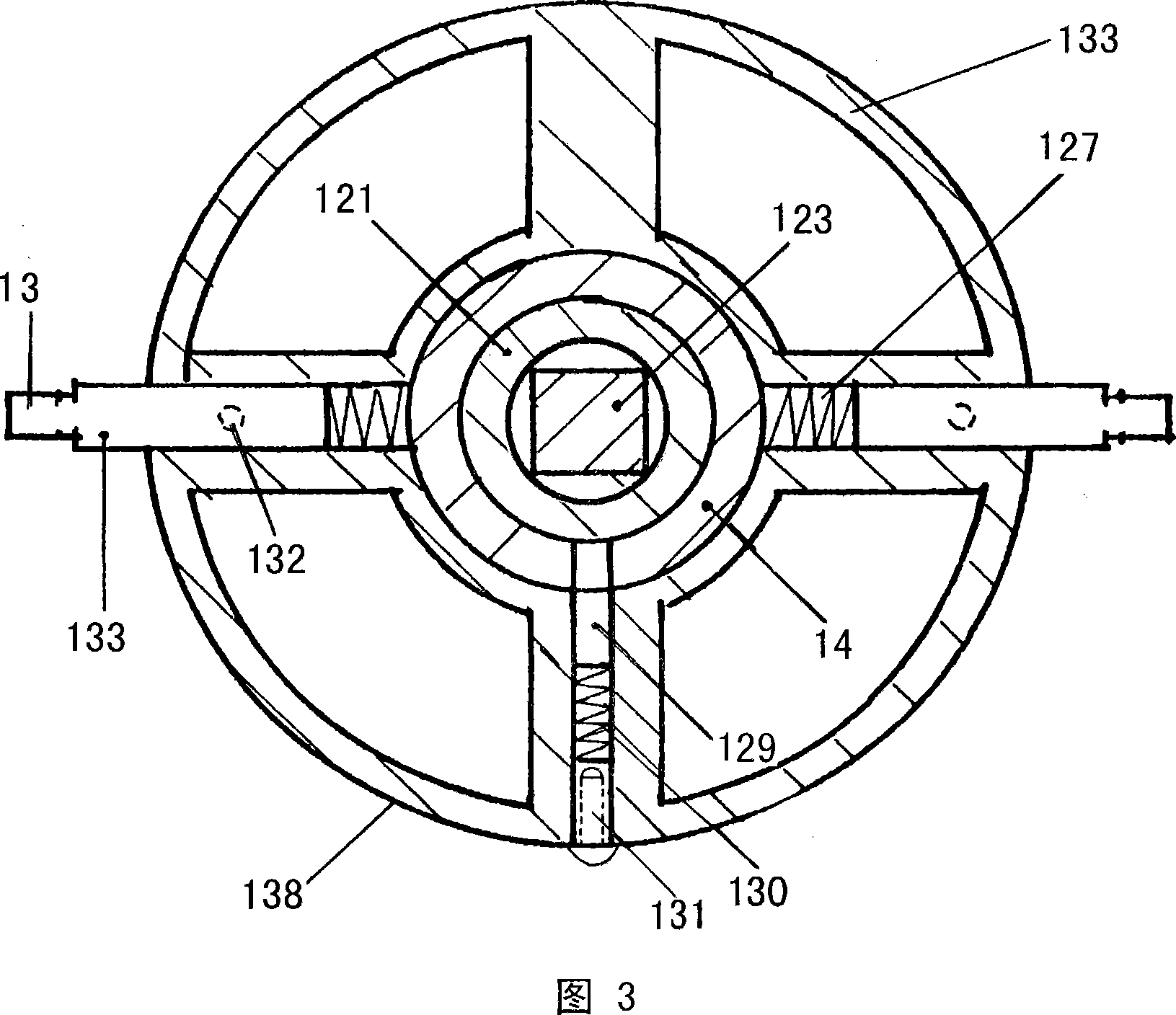

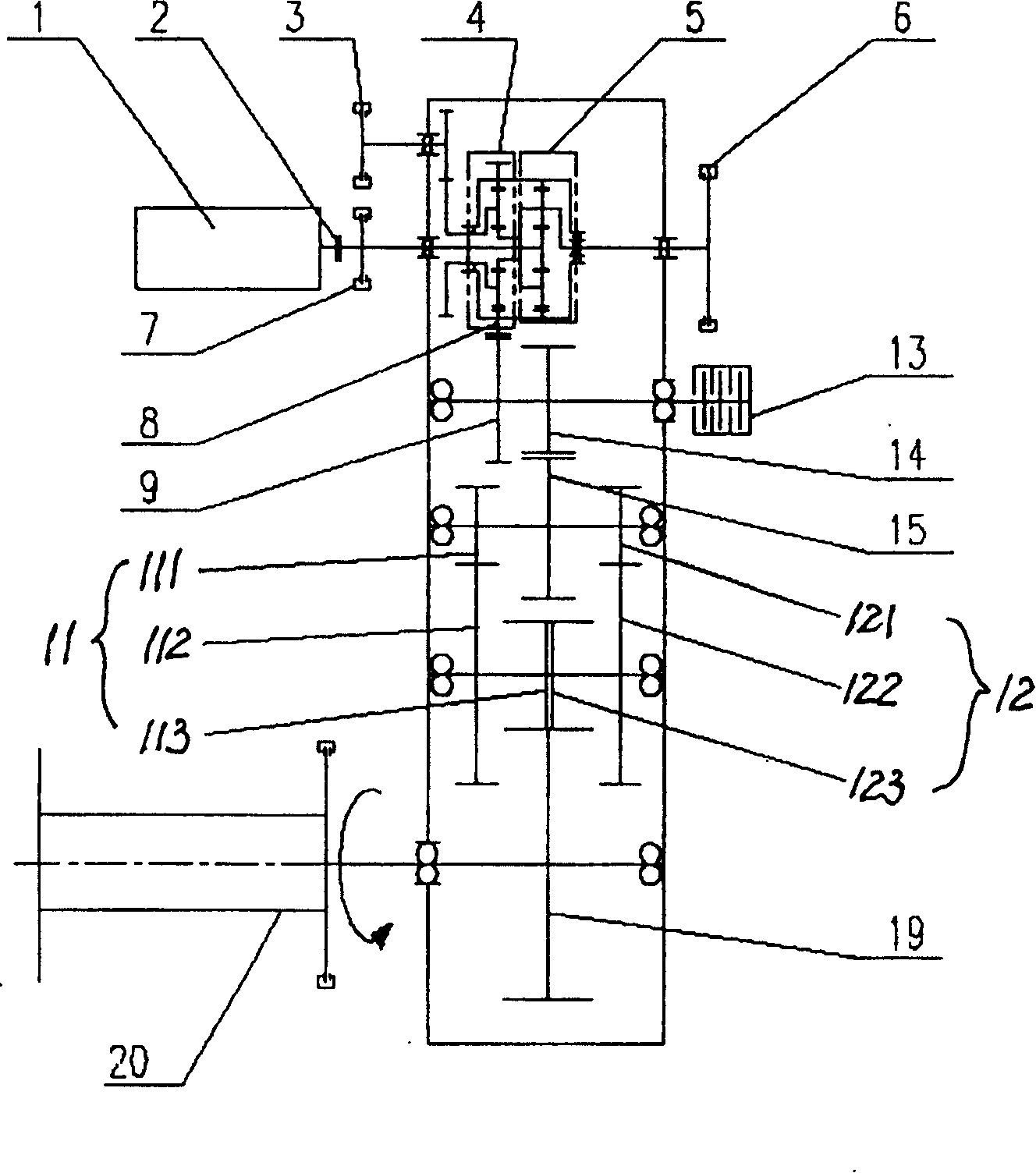

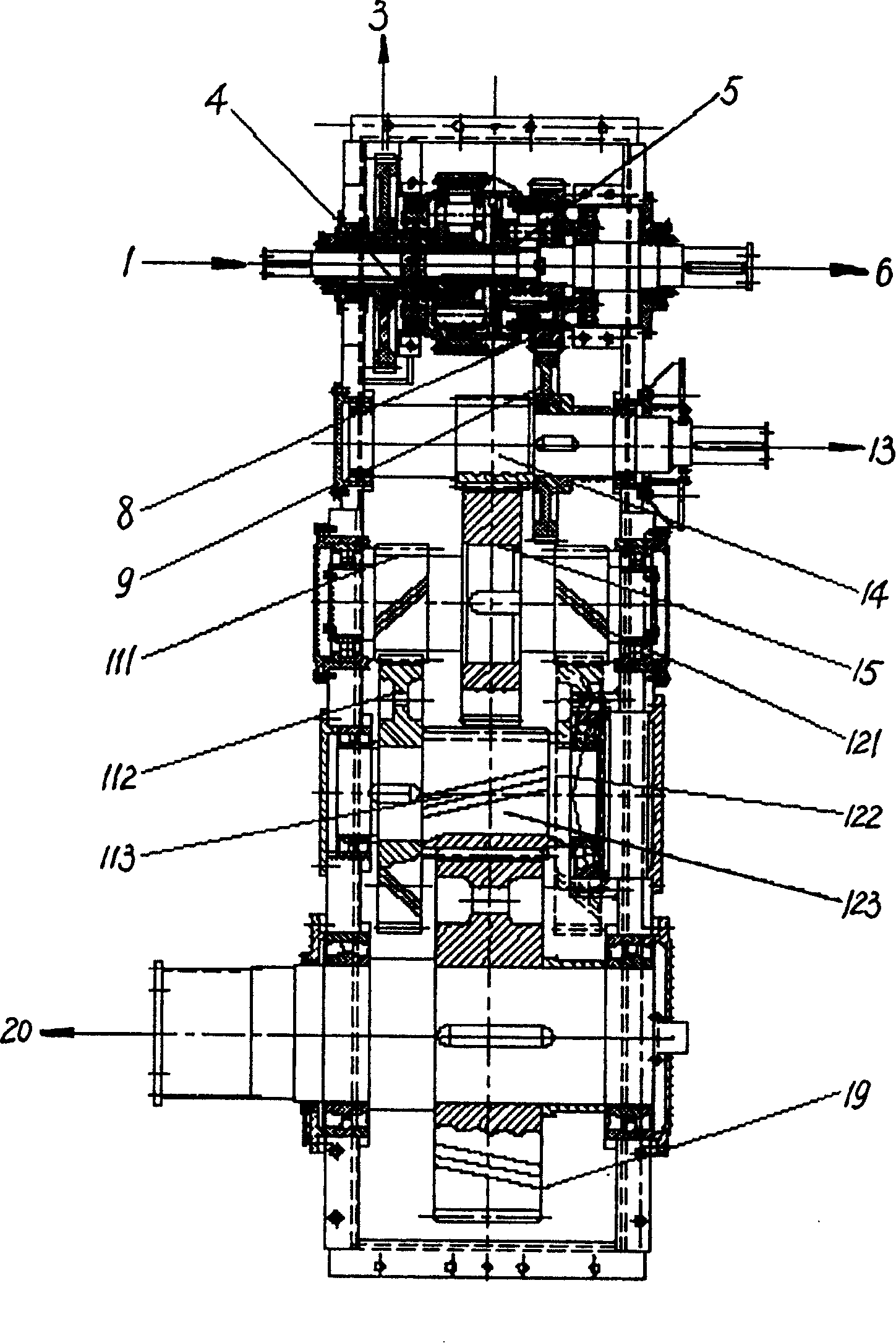

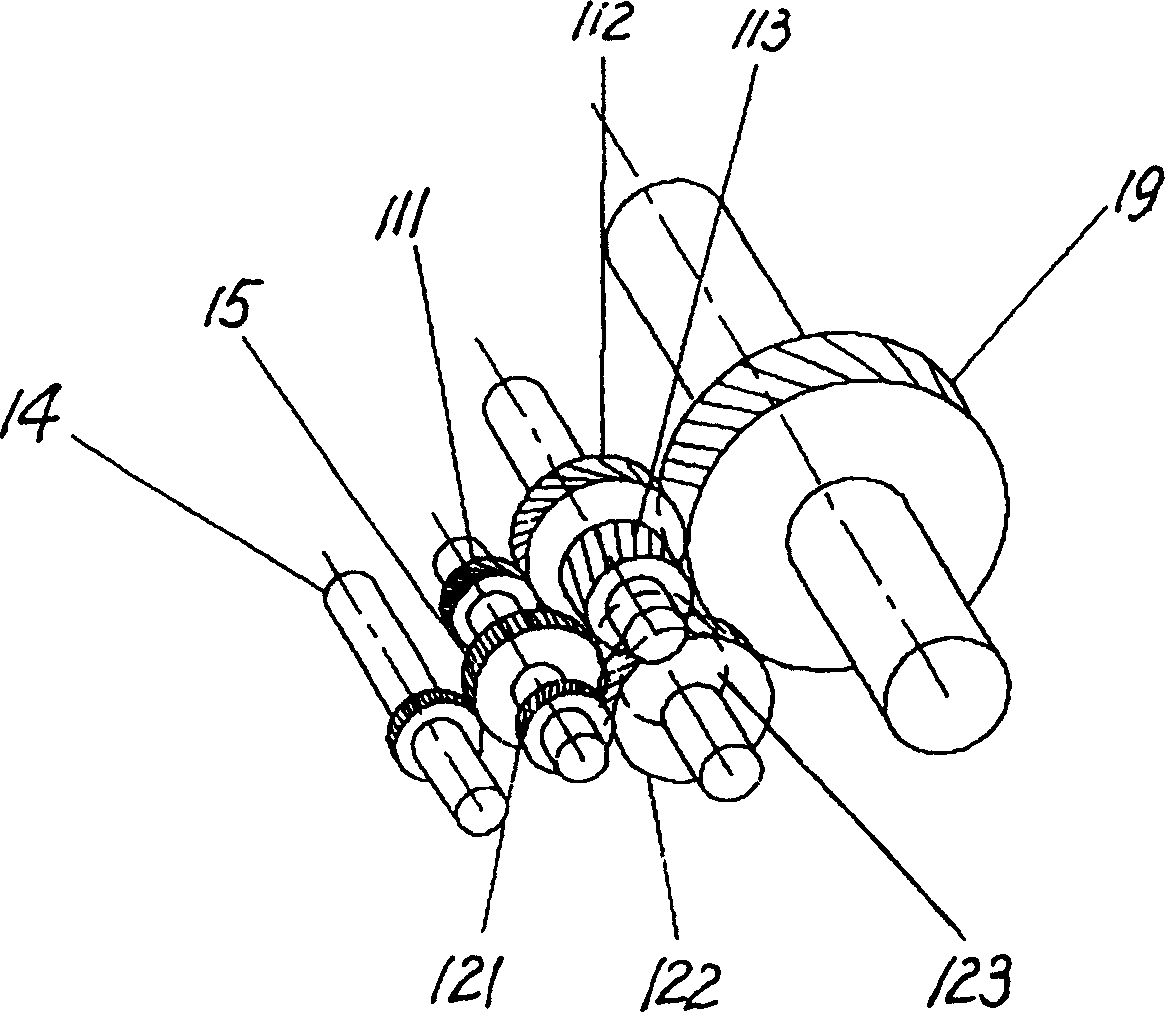

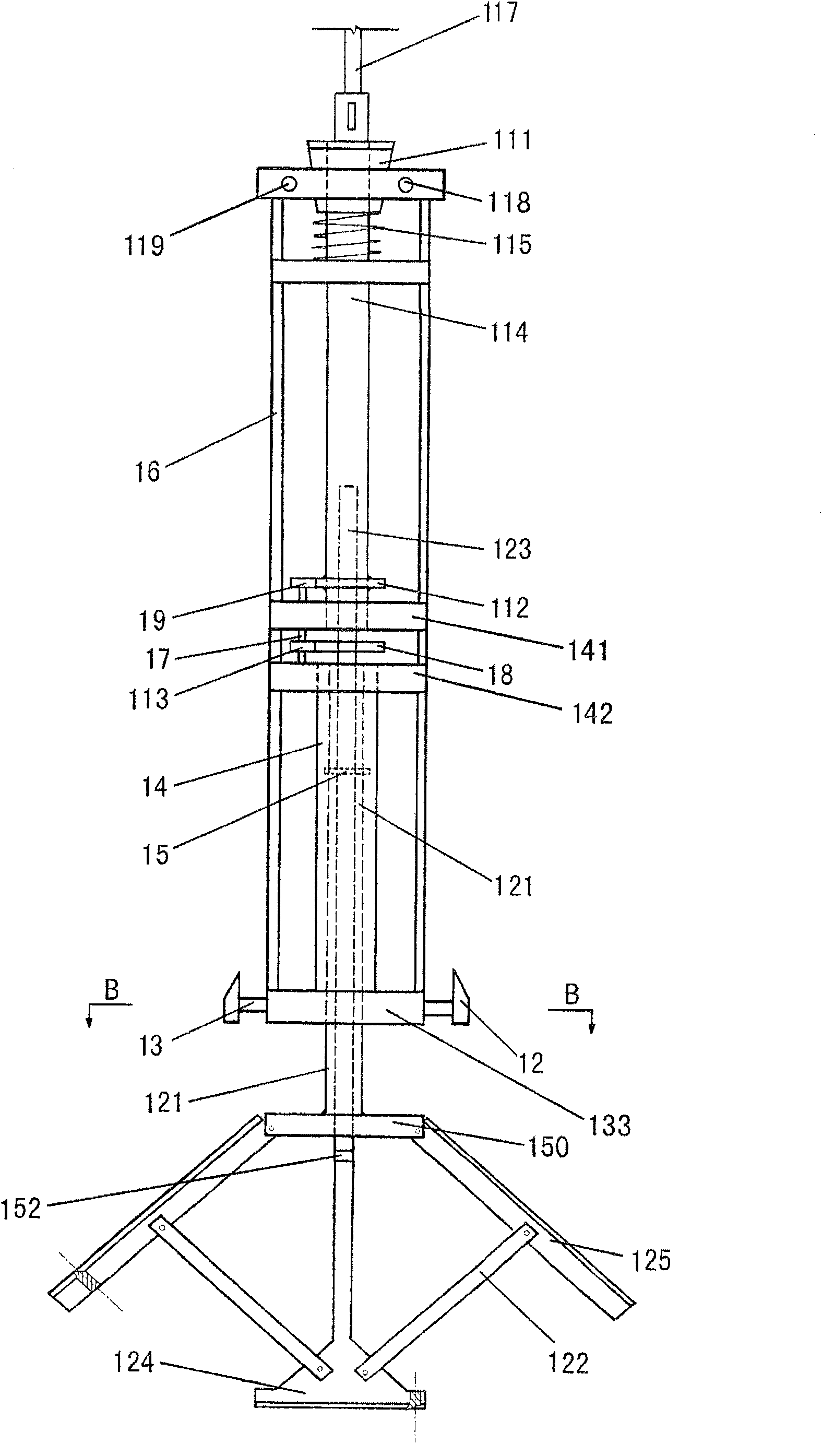

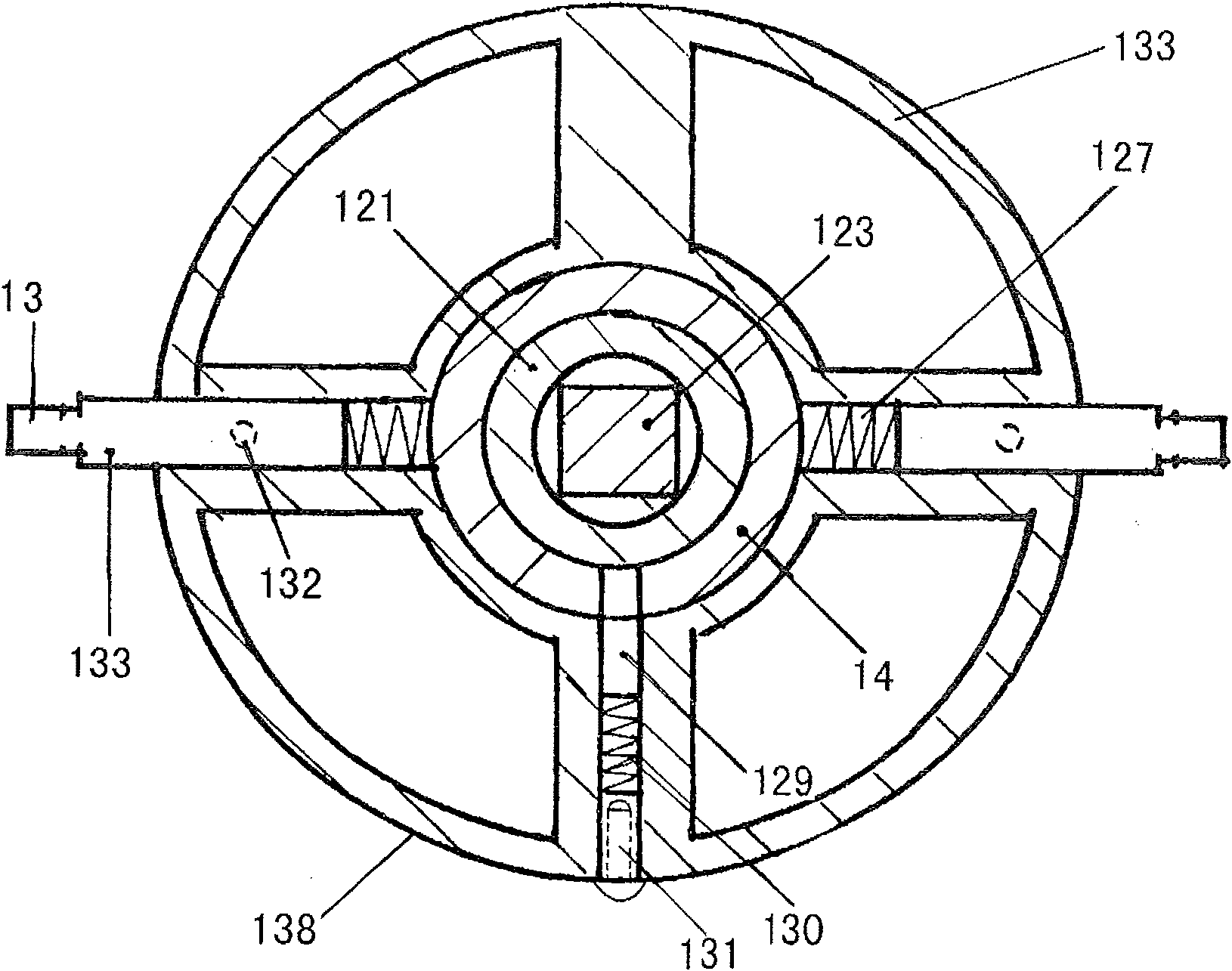

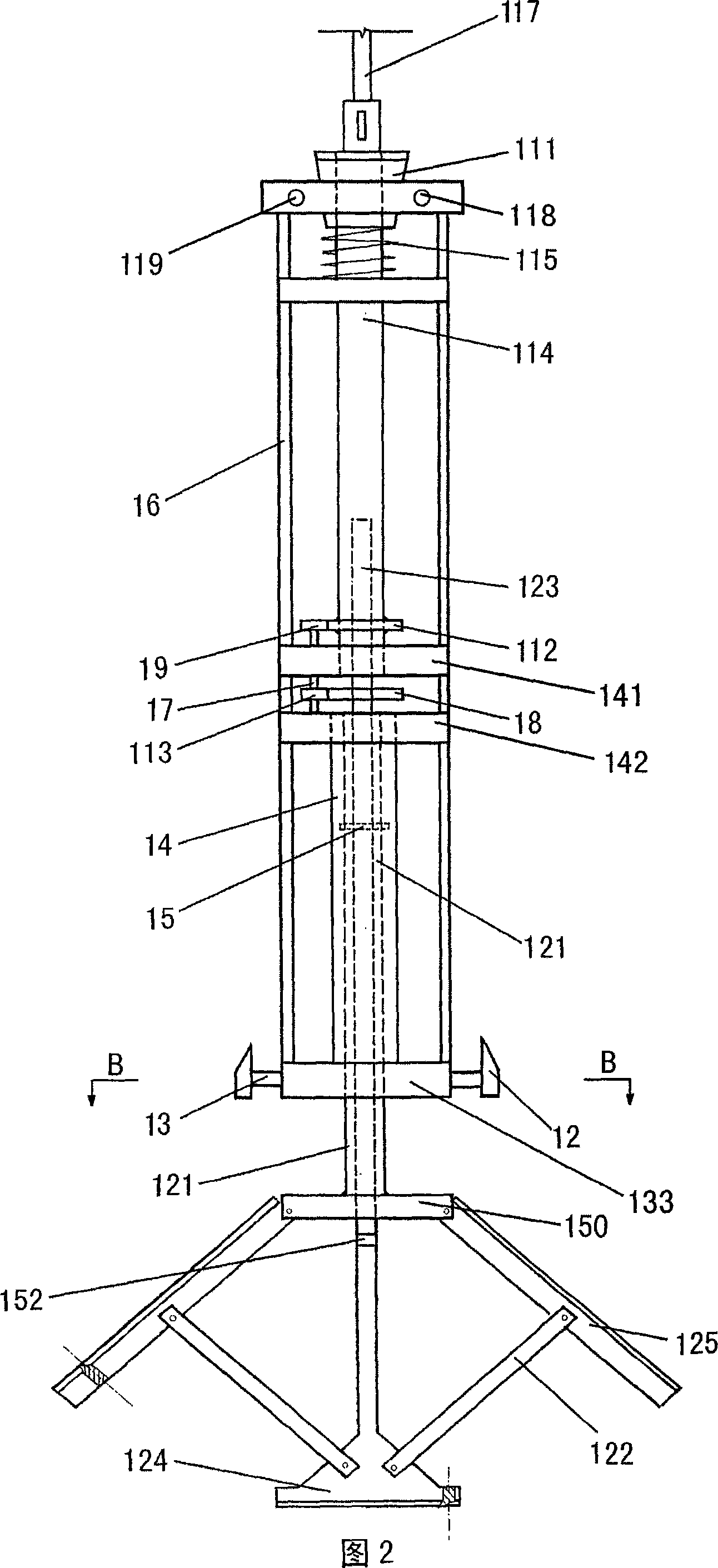

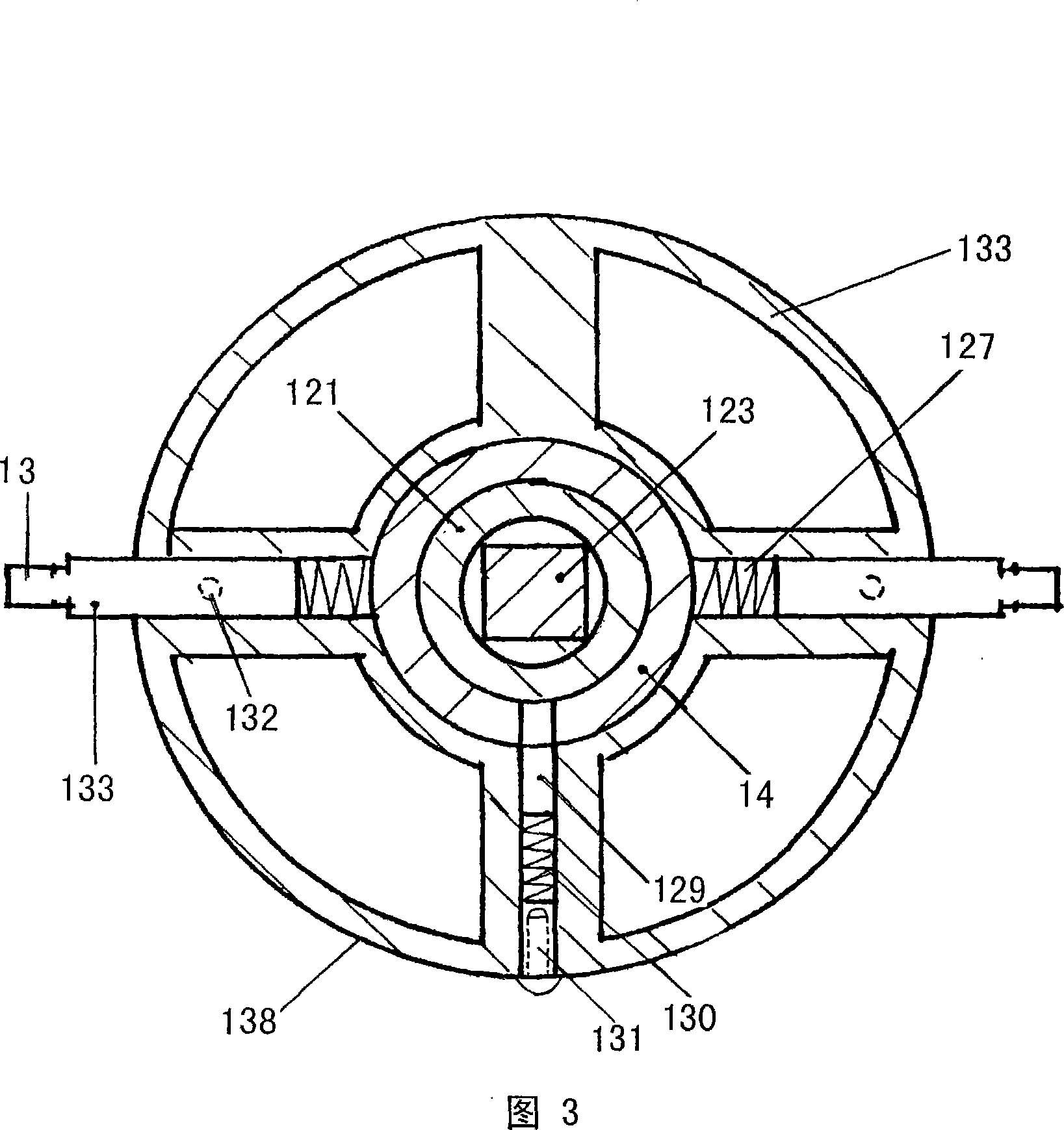

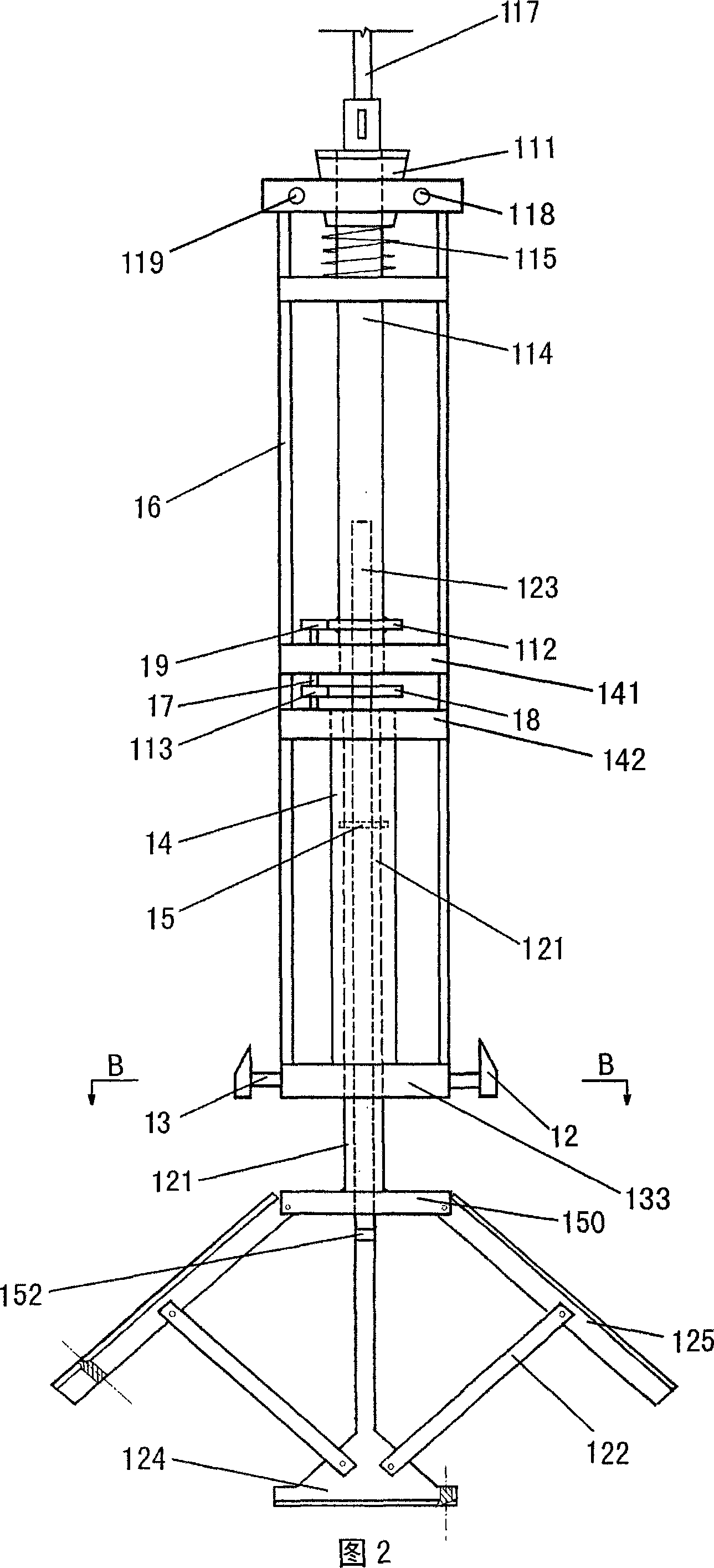

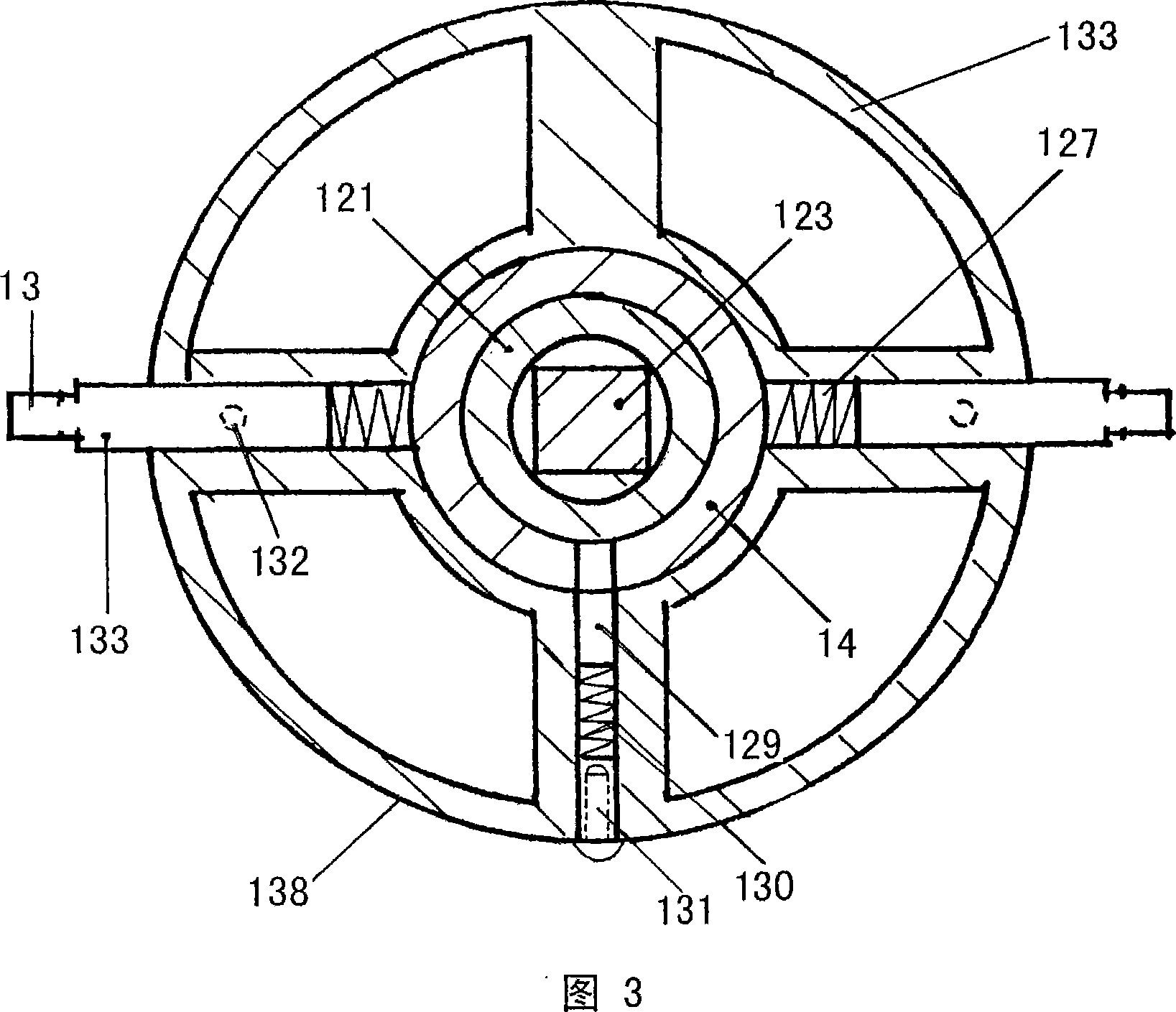

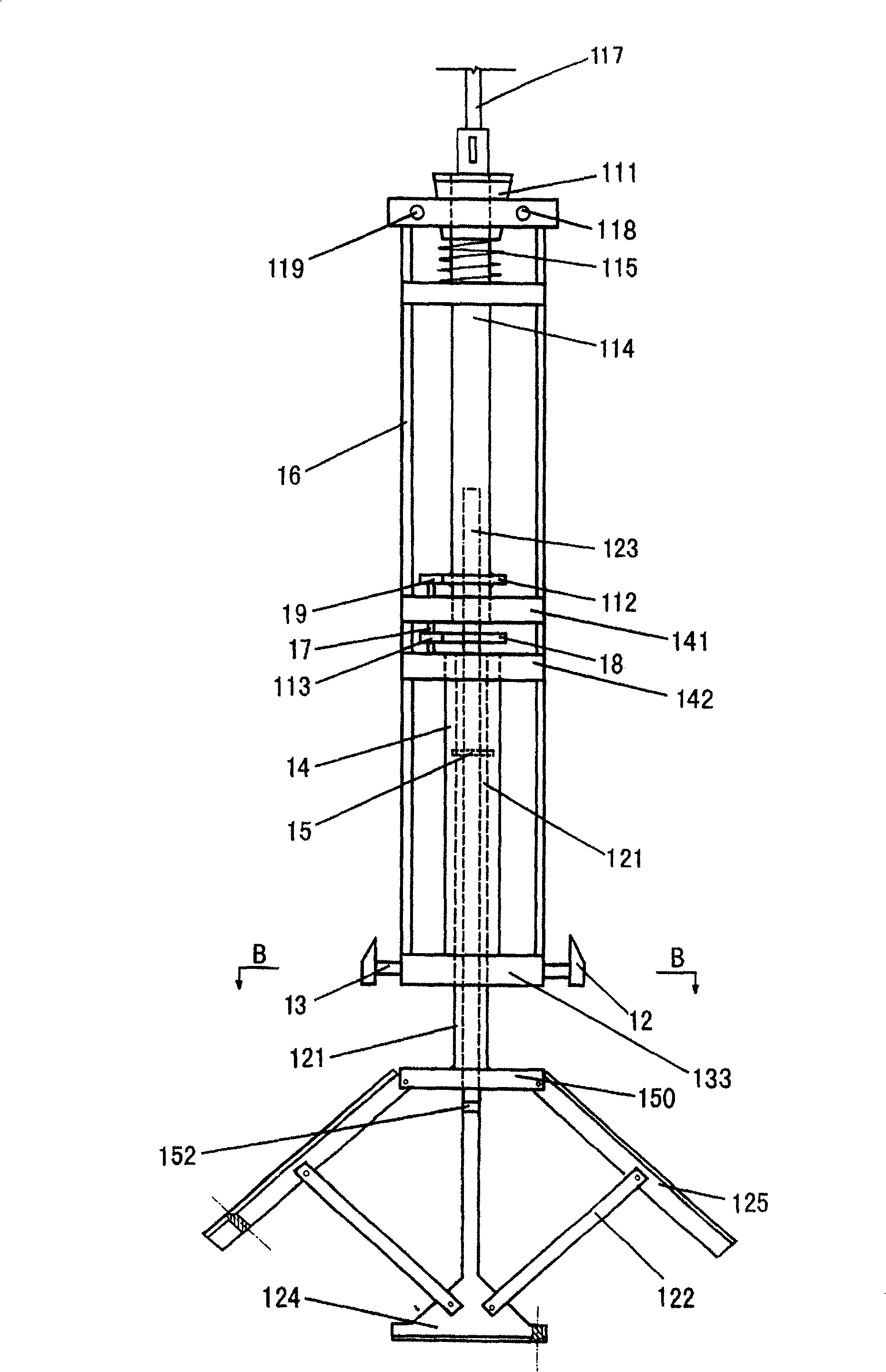

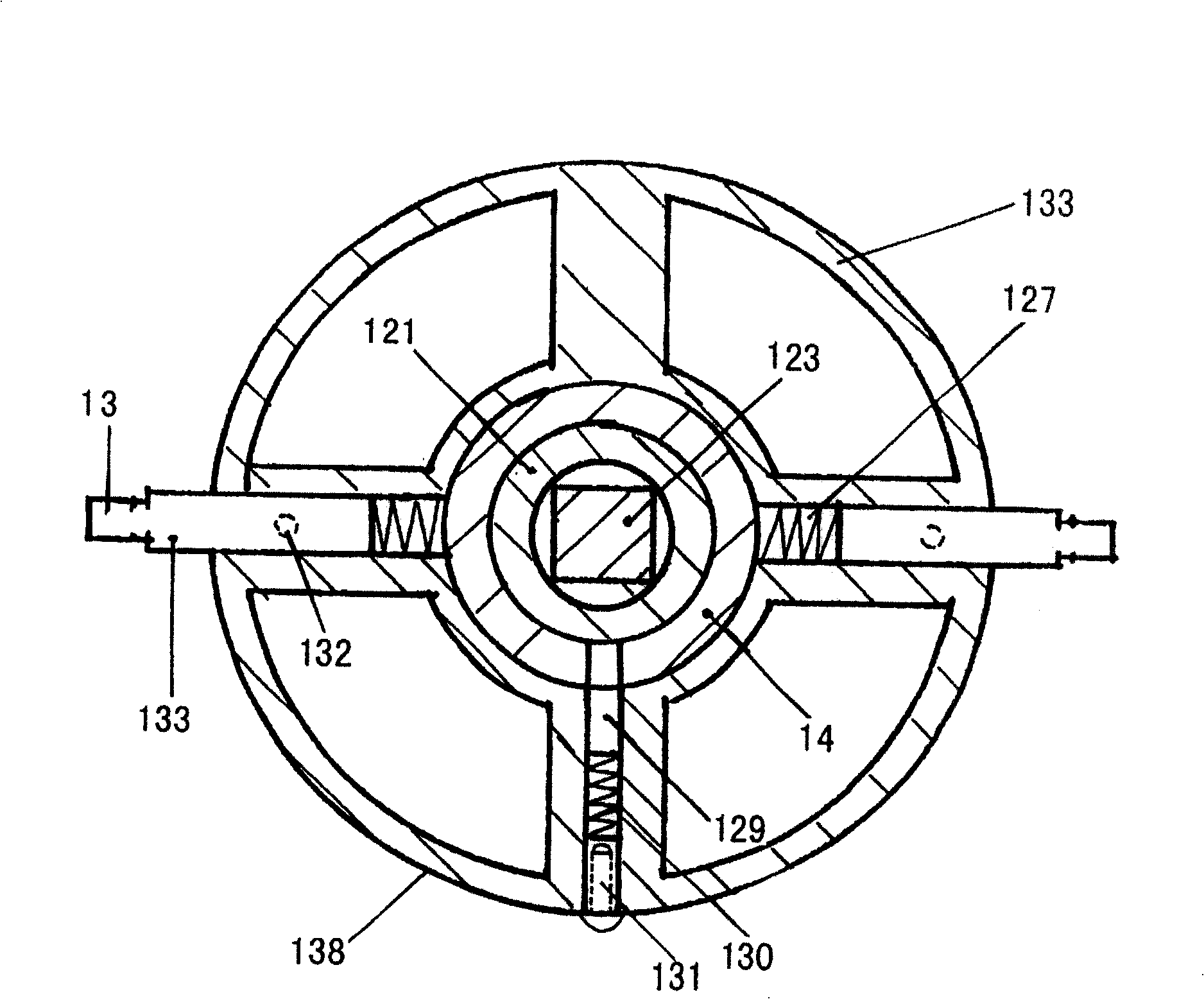

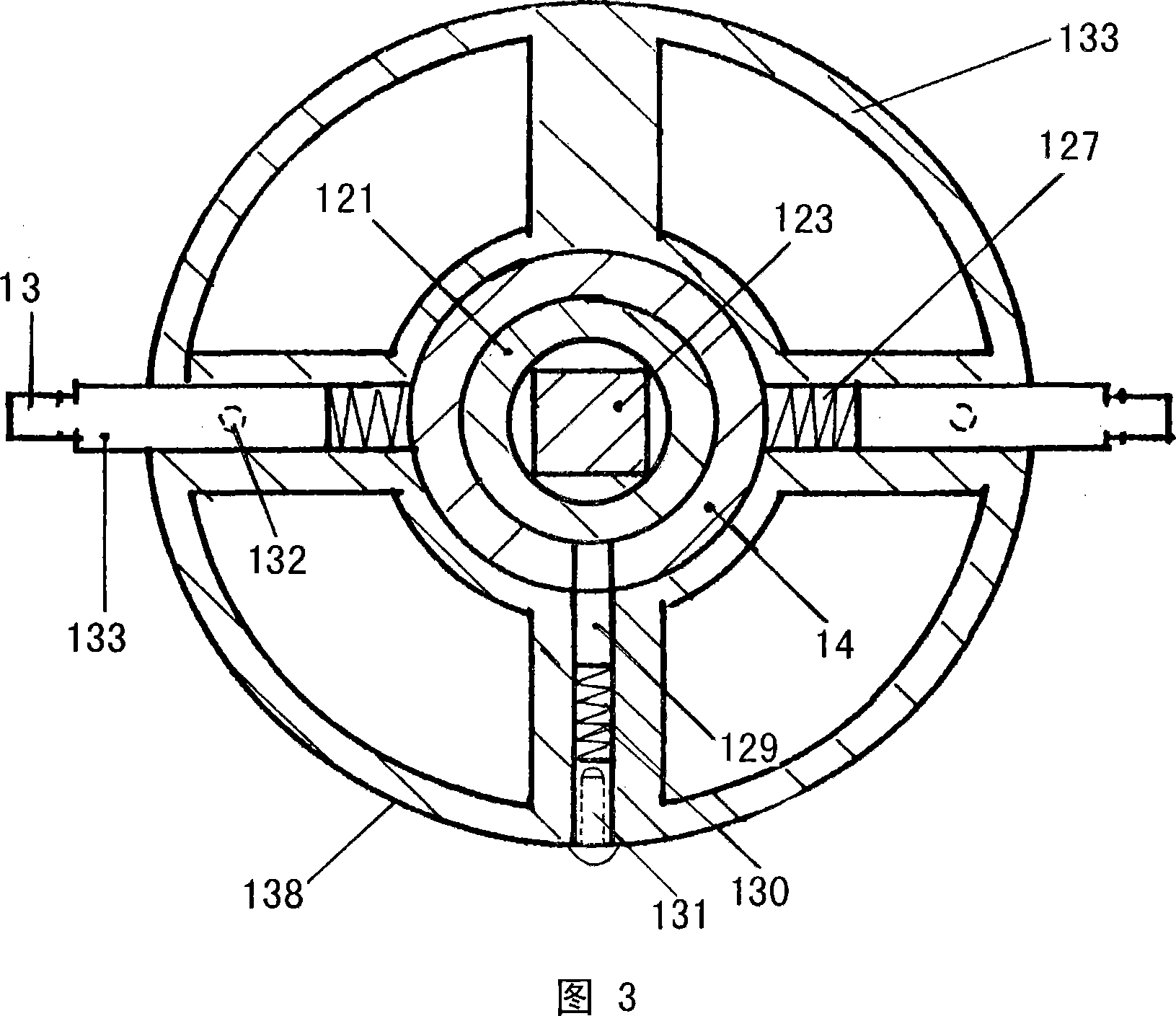

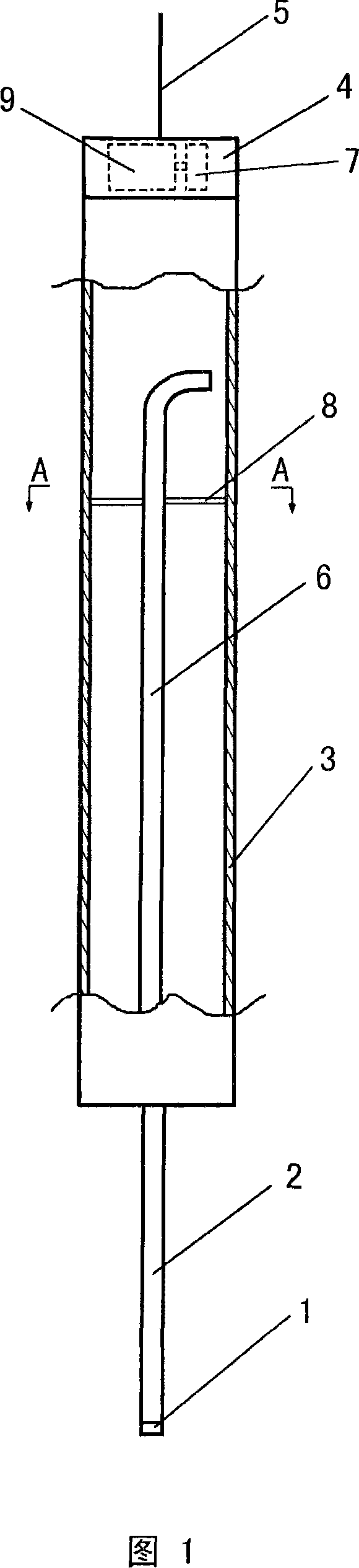

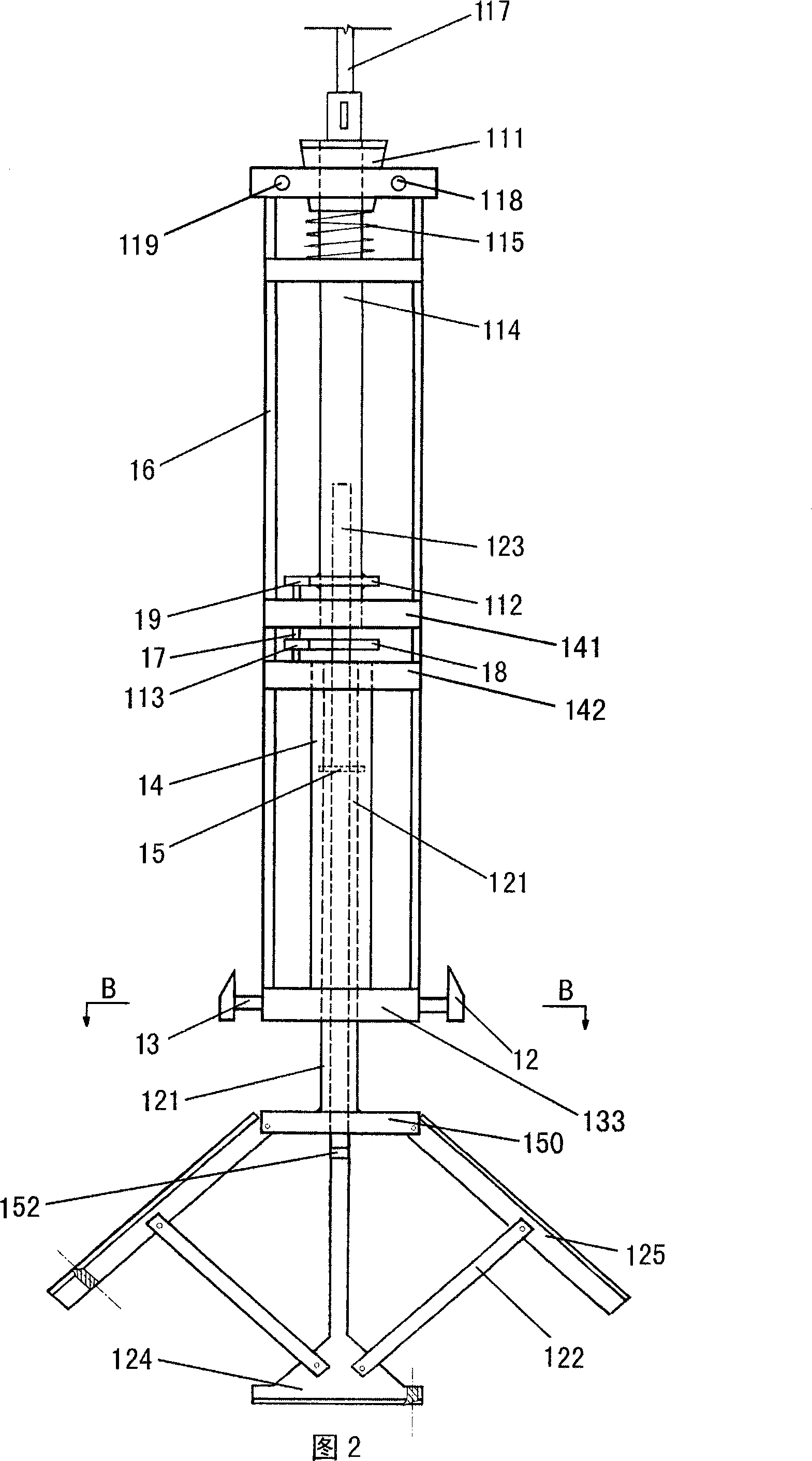

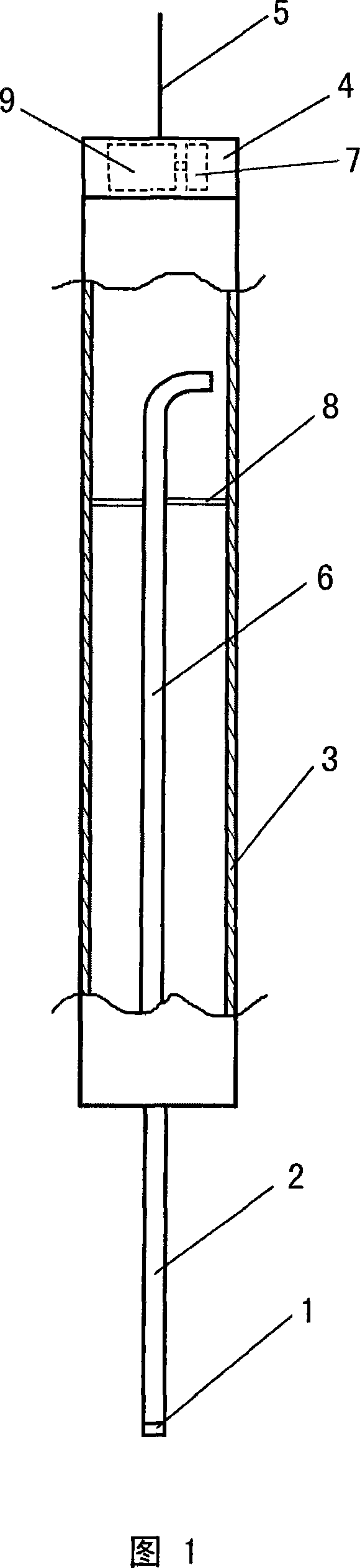

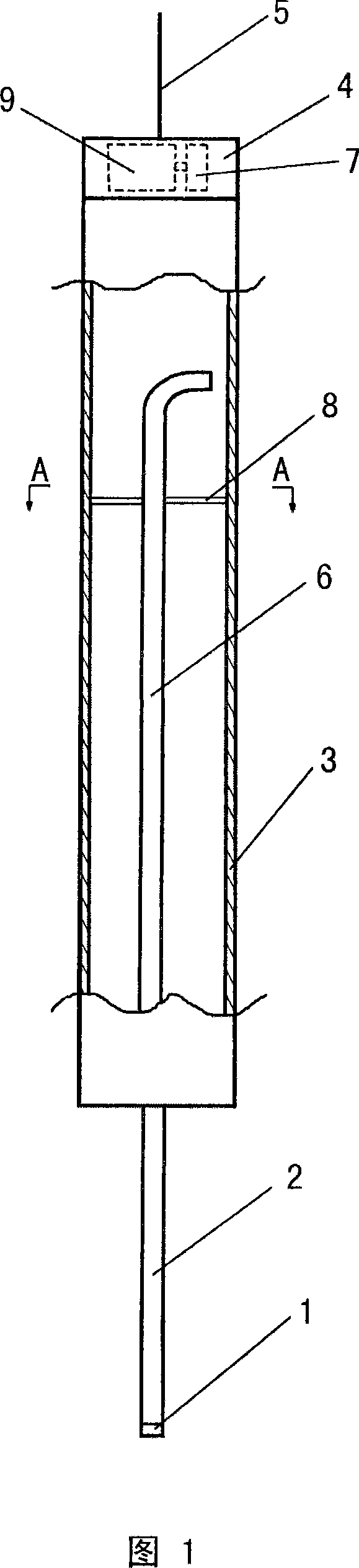

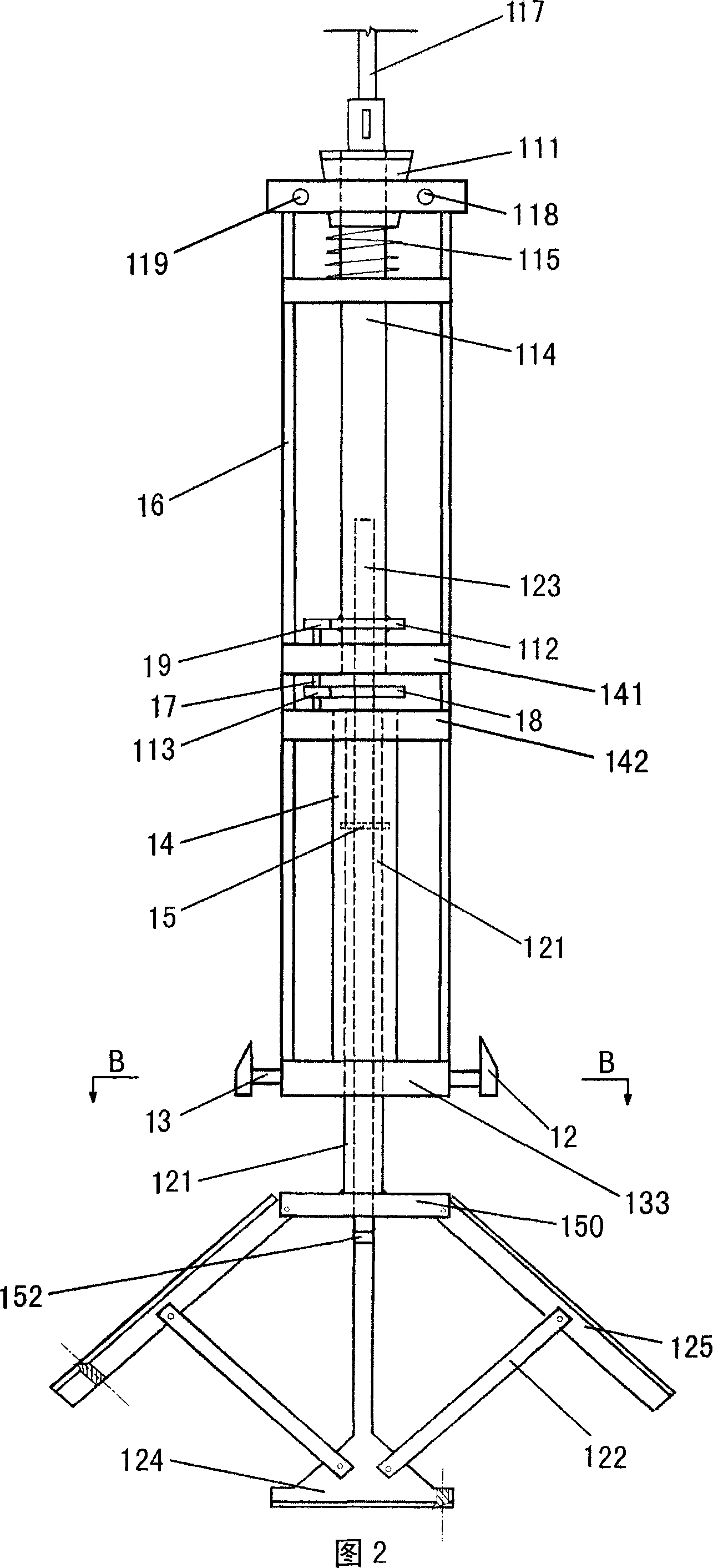

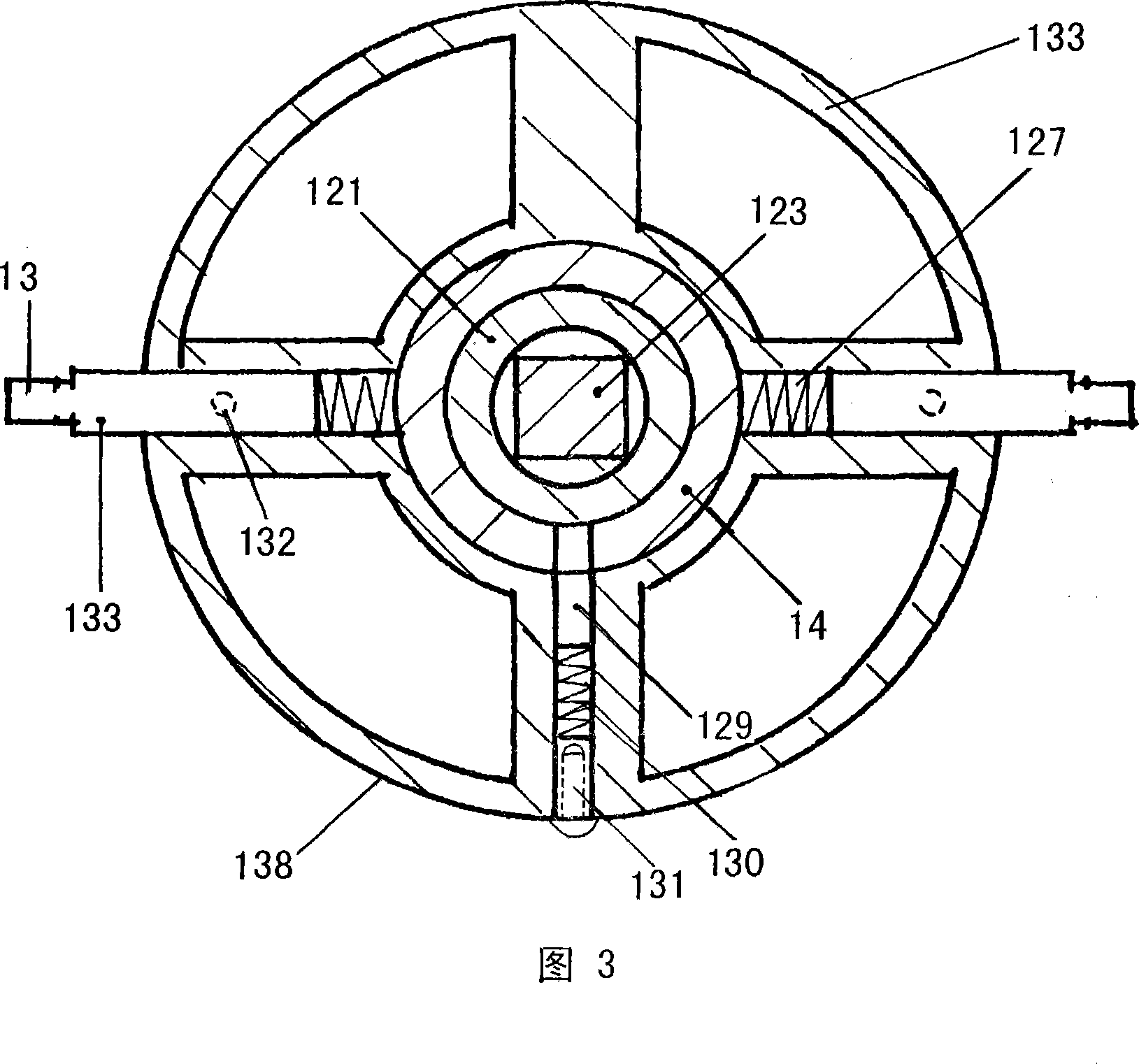

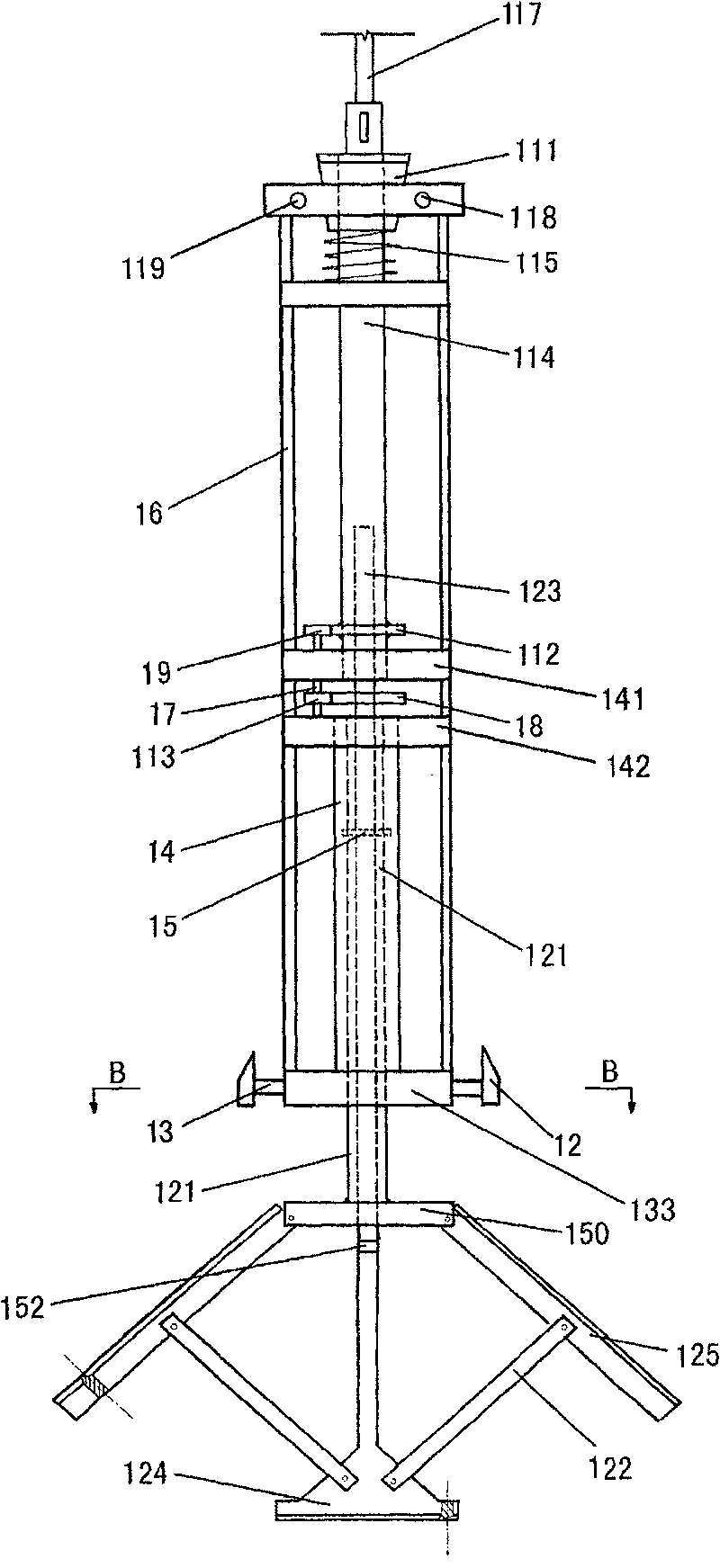

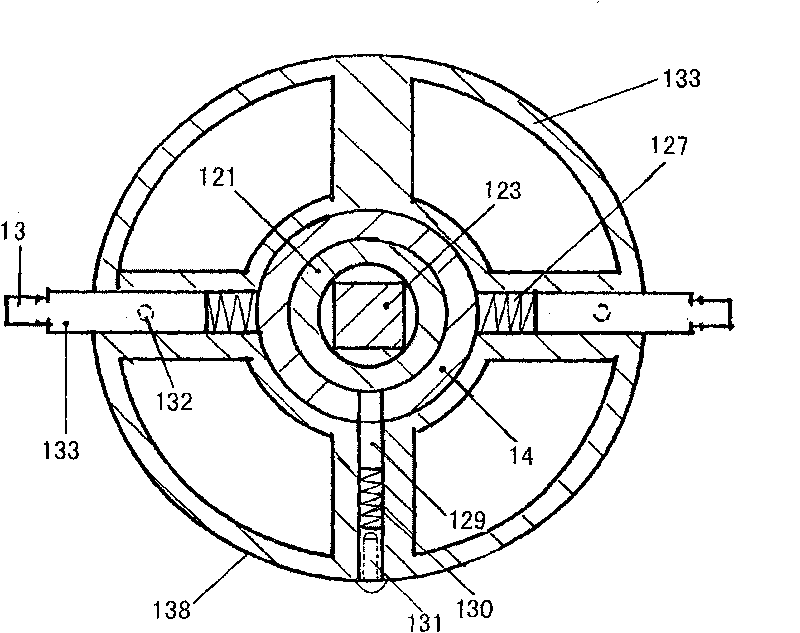

Ship-locating working winch with large pulling force

InactiveCN1843886AImprove work efficiencyShort construction periodWinding mechanismsPull forceCoupling

The invention discloses a large drawing-force positioning winch of ship, which comprises the systems as power, shift, cylinder group, row wire, ratchet wheel brake, quick-drawing, constant tension and control. Wherein, the shift system comprises a planet power shift device and a power dual-dividing device; the planet power shift device is mounted with a motor, a coupler, two shift brakes, a high-speed brake and two planet supports, while the first planet support is connected to the second sun wheel; the first gear ring is connected to the second gear ring; the coupler is connected to the high-speed brake; the first shift brake is connected to the second planet support; the second shift brake via the coupler is connected to the first planet support; the output of first planet support is mounted with the second gear ring and the output big gear wheel; the power dual-dividing device is mounted with a gear wheel axle, a transmission gear wheel, two branch gear transmission devices and water-cooling brake that meshed with output big gear wheel; the water-cooling brake is connected to the gear wheel axle and the transmission gear wheel to realize damping brake. The inventive winch can work on marine with high efficiency, high support ability, anti-impact ability and shortened construction time.

Owner:SHANGHAI ZHENHUA HEAVY IND

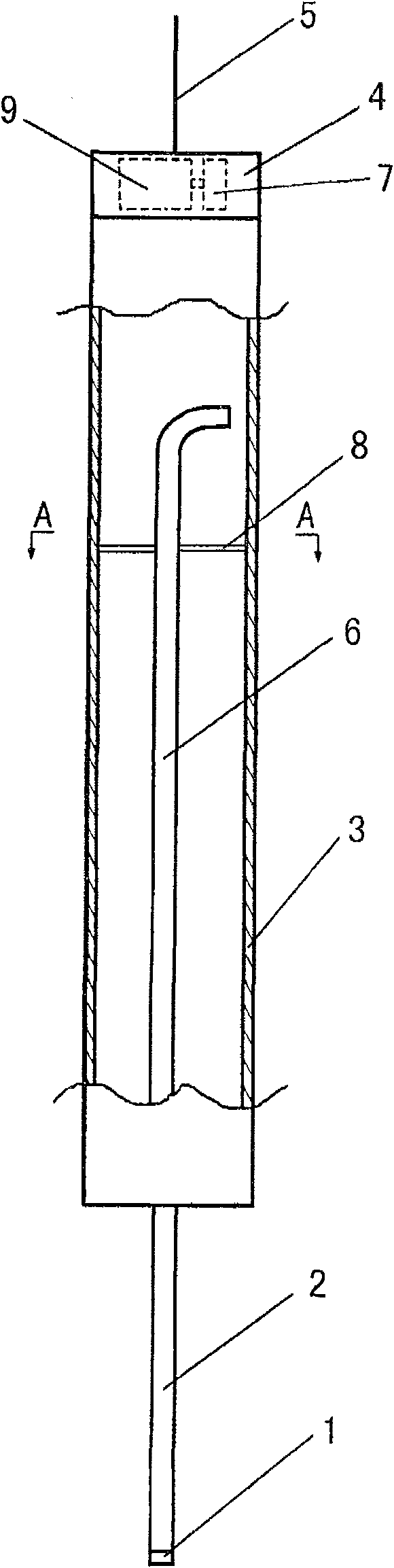

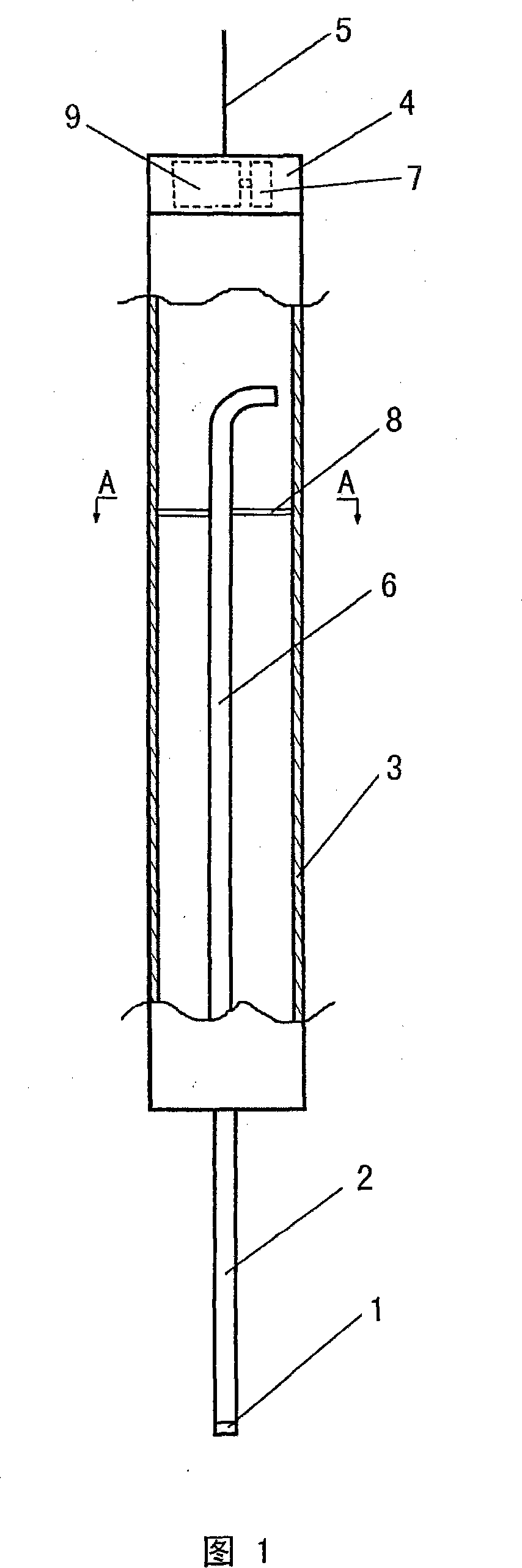

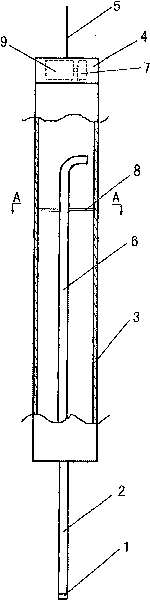

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101161948AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concreteBottom gate

The invention discloses a building pile foundation project and a construction method thereof, in particular a method for enlarging pedestal and forming pile of an immersed tube precast reinforced concrete pedestal pile; the method comprises the following steps that: the immersed tube is passed through a soft earth layer and pressed to a designed level hard earth layer; a metal pile head is taken out, and put into the immersed tube to enlarge the pedestal; the earth is extracted by a device which uses air to absorb earth, when a small amount of earth is left in a base, water is poured from the mouth of the immersed tube, the water is absorbed while the poured until the earth is completed absorbed; radial reinforcing steel bars are arranged in the cavity of the base, and the hard earth is hammered into the cavity of the base, the concrete precast on the ground is filled in a long barrel and the barrel is put to the bottom of the immersed tube from the mouth of the immersed tube, when iron bars arranged on the bottom of the barrel touch the hard earth, the bottom gate of the barrel is forced open, then the concrete falls into the cavity of the base to form a cast-in-situ base, the precast reinforced concrete pile body is sunk and in even joint with the cast-in-situ base through the dowel bars of the reinforced concrete pile body to be jointed and anchored into a whole; the immersed tube is extracted out and the pile is formed. The invention extracts earth completely without granular loose earth, has high efficiency, improves the bearing capacity of single pile effectively and meets the design requirements, thereby ensuring the quality of the pile foundation work project and reducing construction cost.

Owner:王国奋

Bottom expanding and piling method by demolishing of pipe sank prefabricated steel concrete bottom expansion pile

The invention discloses a construction pile foundation project and a method for constructing the same, in particular a method for explosively expanding bottom and forming pile through immersed tube prefabrication steel concrete. The method comprises the following steps that: an immersed tube is pressed into a firm ground layer with a designed height; a metal pile head is taken out, emulsified oils or ammonium-antimony detonators are put into the immersed tube through the immersed tube orifice, and then the immersed tube orifice is sealed after the detonators are detonated; soil is taken out by using an air absorption soil device; whether the quality reaches the designed specification is checked by a camera with the light source in the base cavity; radial reinforcing steel bars are put into the base cavity and are hammered into the firm ground, stiff cement mortars which are prepared well on the ground are poured into the base cavity along the immersed tube orifice, and then carpolites are poured into the base cavity and a concrete base without sands is formed, the prestressing prefabrication hollow pile body which is put into the concrete base and the cast-in-place concrete base are butt jointed and anchor fixed to form a whole through the inserted reinforcing steel bars at the bottom of the concrete base; the immersed tube is pulled out, and then cement mortars are poured into along the gap which is formed after the immersed tube is pulled out, and then a pile is formed. The invention has the advantages that soil is cleanly taken out without granular loose soil and the efficiency is high.

Owner:王国奋

Bottom-expanding pile-forming method for immersed tube club-footed pile

InactiveCN101240539AImprove bearing capacityGuarantee the quality of the projectBulkheads/pilesImmersed tubeCement paste

The invention discloses construction pile engineering and construction method, especially bottom expanding and pile forming method for sinking-pipe bottom expanded piles, comprising following steps: pressing the first segment of sinking tube into soil, connecting the second segment of tube with the thread on the top of the first segment of tube, pressing the sinking tube to hard soil of designed elevation; taking out the metal pile head, putting into emulsible oil or AN-TNT explosive through the sinking tube mouth, and removing the articles blocking the sinking tube mouth after explosion is completed; taking out the broken soil by using an air soil suction device; activating the device to expand the bottom; taking out soil by using the air soil suction device; disposing a radial steel bar into the base cavity and hammering same into hard soil, pouring thick concrete along the sinking tube mouth into the base cavity, sinking the prefab concrete pile body and anchoring same with the cement paste base which is poured on site is anchored integrally by inserted steel bars at the bottom of the pile body; pouring cement paste along the sinking tube mouth inner side, and pulling out the first segment of sinking tube and the second segment of sinking tube. Thereby, the pile is constructed. According to the invention, the expanded bottom has a regular geometric figure, soil is taken out cleanly, no granule soil is left, and efficiency thereof is high.

Owner:王国奋

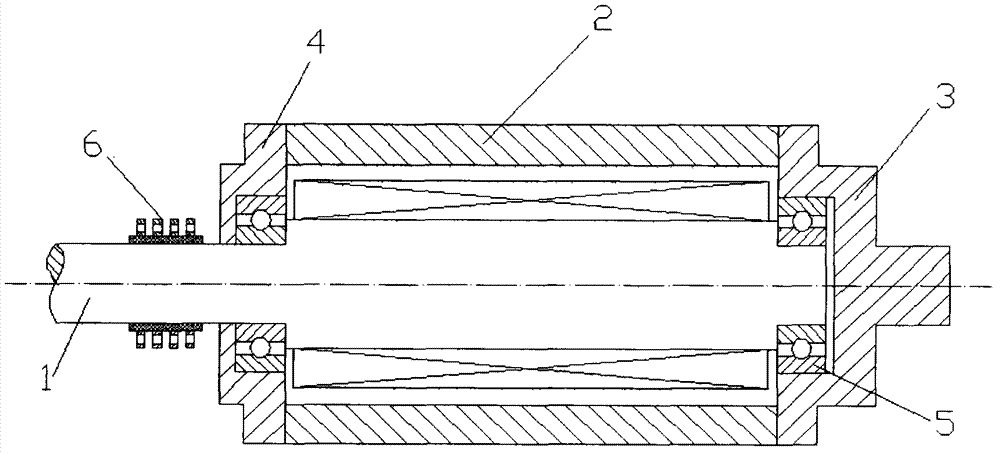

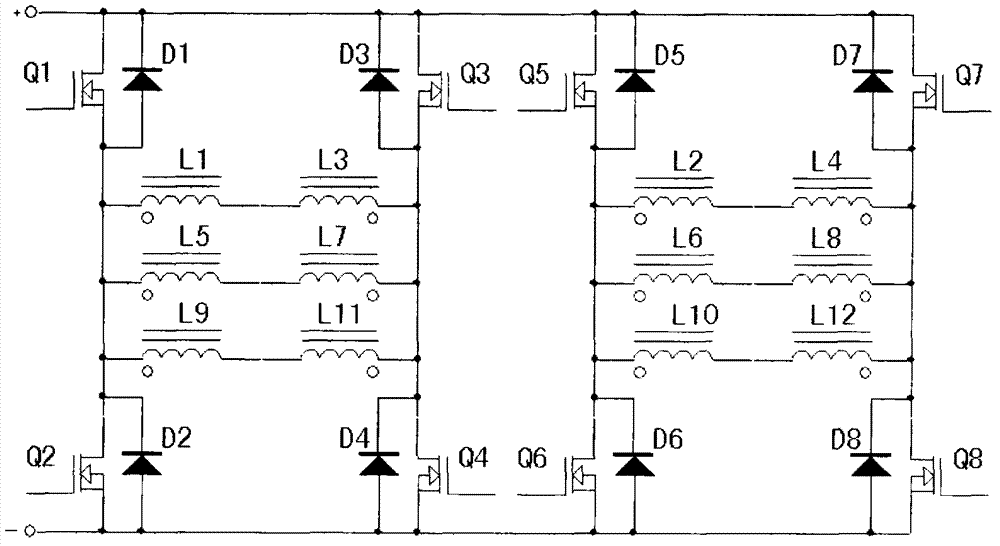

Automatic transmission of automobile

ActiveCN103401397ASimple structureLow costAssociation with control/drive circuitsDynamo-electric brakes/clutchesAutomatic transmissionFull bridge

The invention discloses an automatic transmission of an automobile. The automatic transmission comprises an outer rotor, an inner rotor, a left end cover, a right end cover, bearings and collecting rings, wherein the inner rotor is connected with an output shaft of an engine, and the outer rotor is connected with an input shaft of a main speed reducer. The automatic transmission is characterized in that the outer rotor is made of solid steel and can bear larger torque; the inner rotor is also made of solid steel; two-phase excitation windings are uniformly distributed on the inner rotor, and every two two-phase excitation windings are interphase; the collecting rings are of four-wire type and are respectively connected to two full-bridge outputs of a controller; and direct current can be fed into the collecting rings, thus forming a constant magnetic field on the rotor, and two-phase alternating current with a phase difference of + / - 90 degrees can be also fed into the collecting rings, thus forming a positive rotation magnetic field and a reverse rotation magnetic field. The problems of high manufacturing cost and small speed range of an existing automatic transmission of the automobile are solved; and the automatic transmission is suitable for various automobiles taking gasoline and diesel engines as power.

Owner:胡晋青

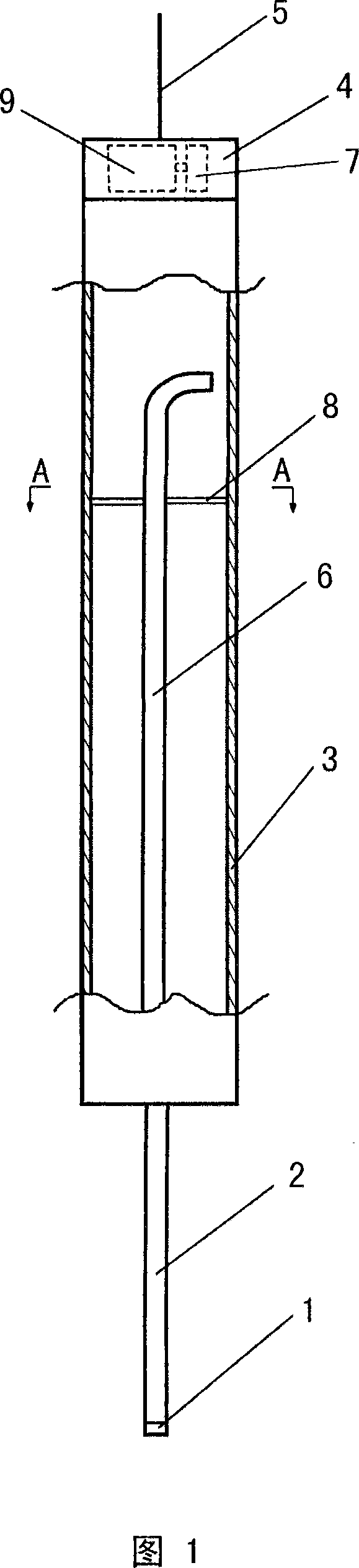

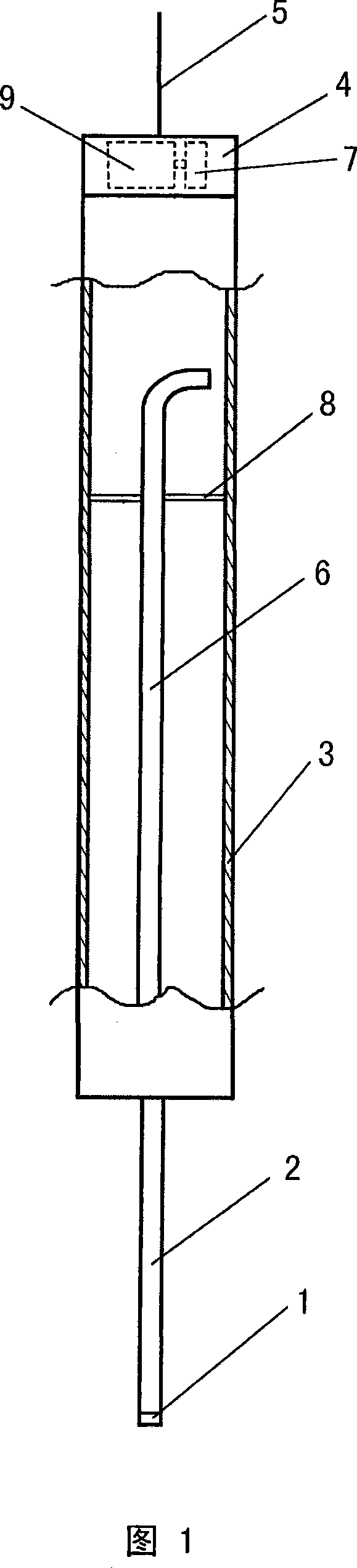

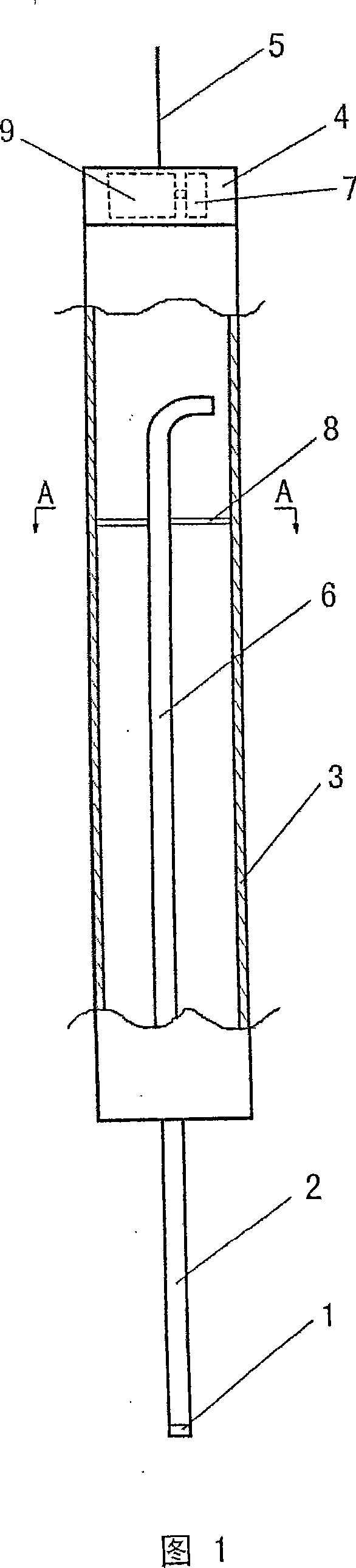

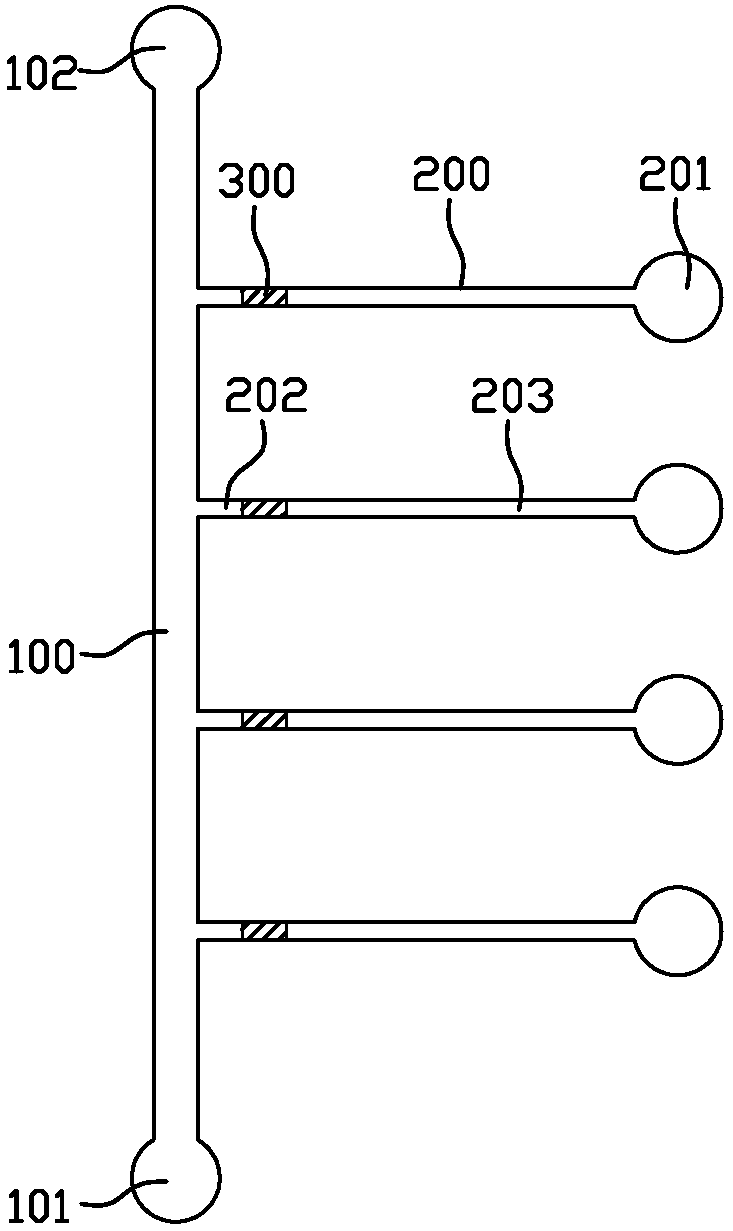

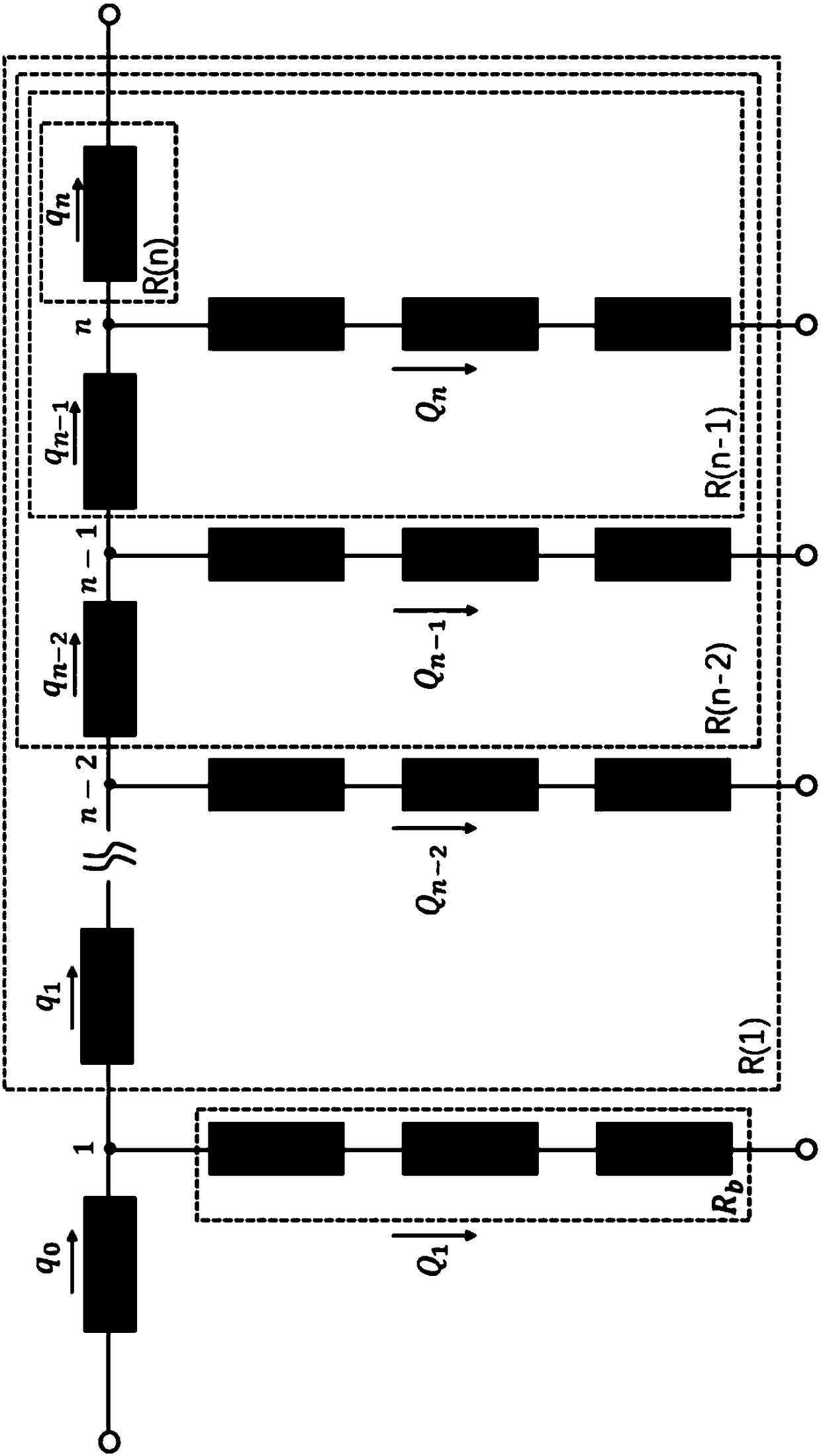

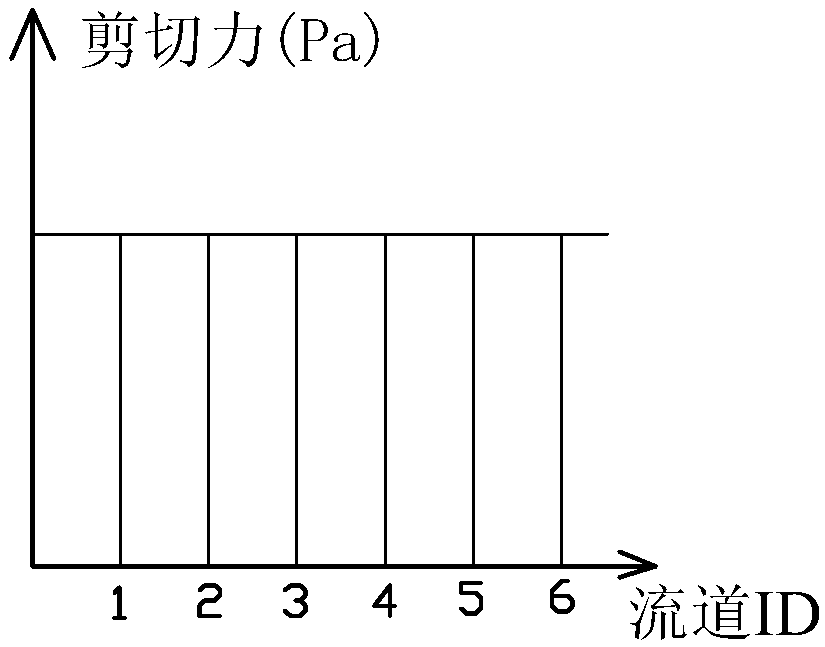

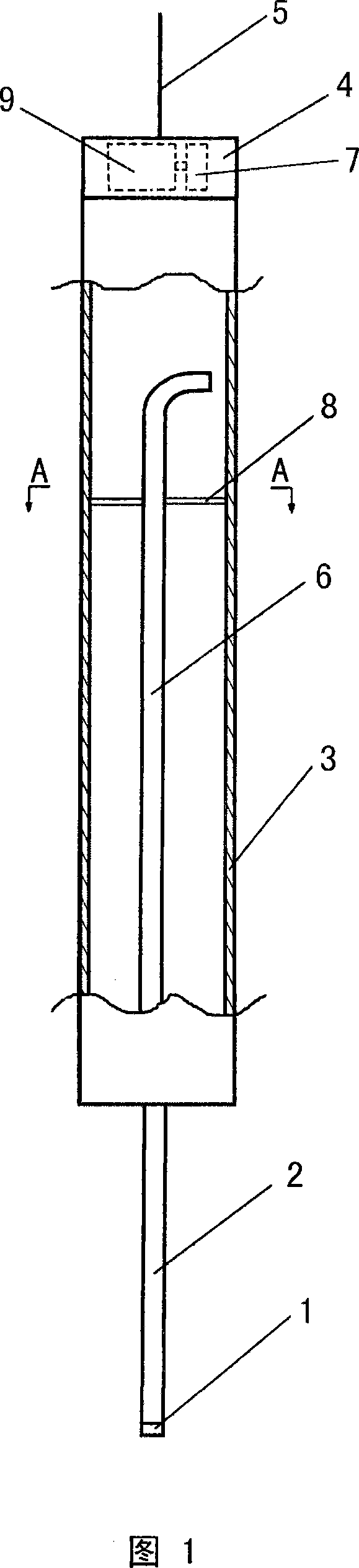

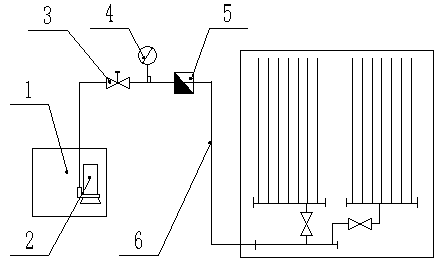

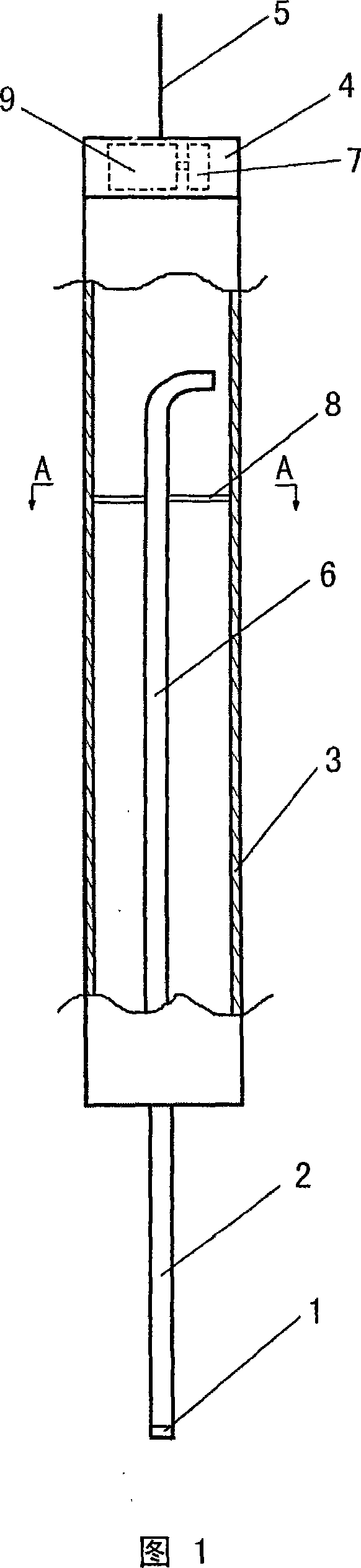

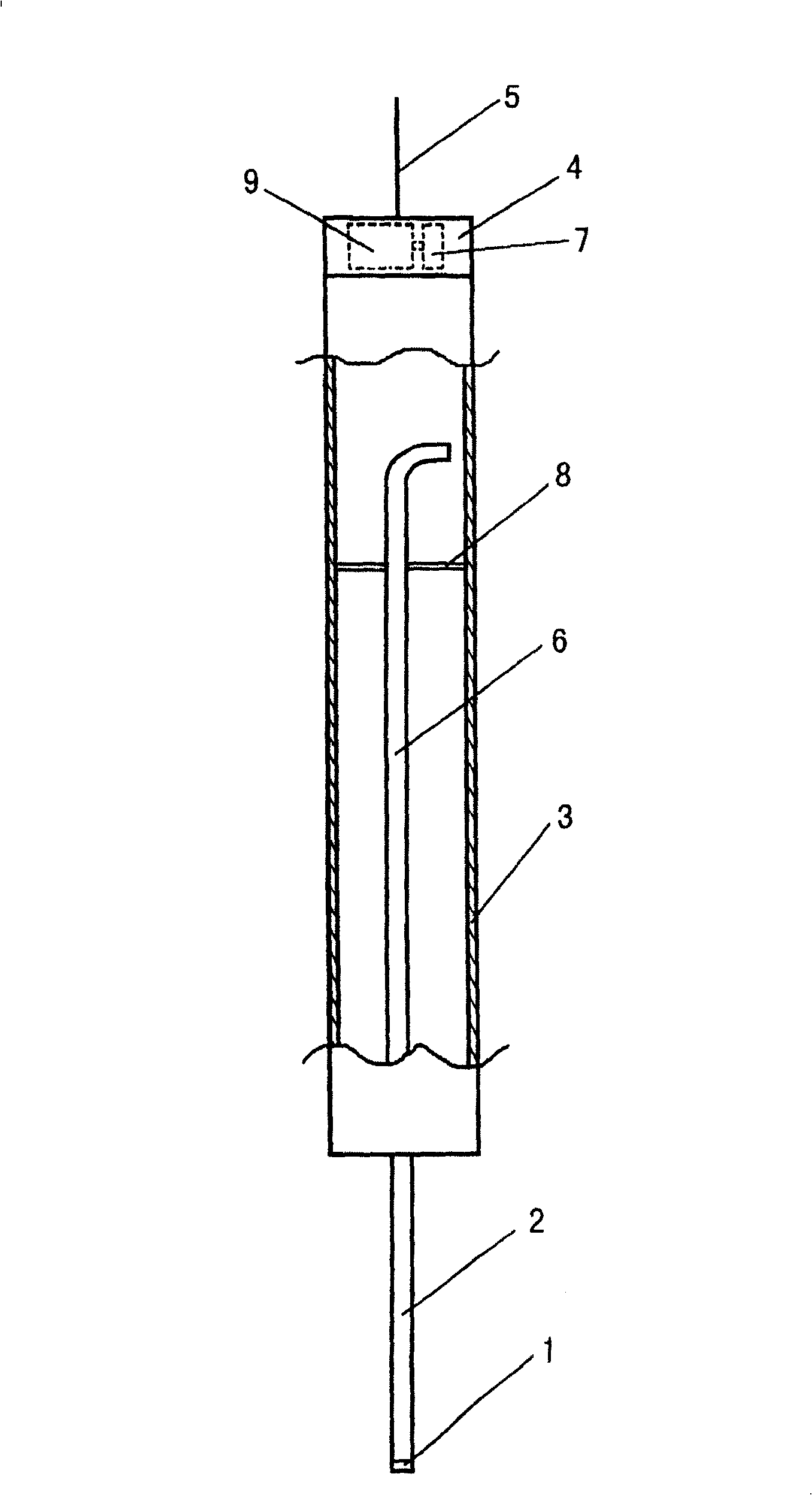

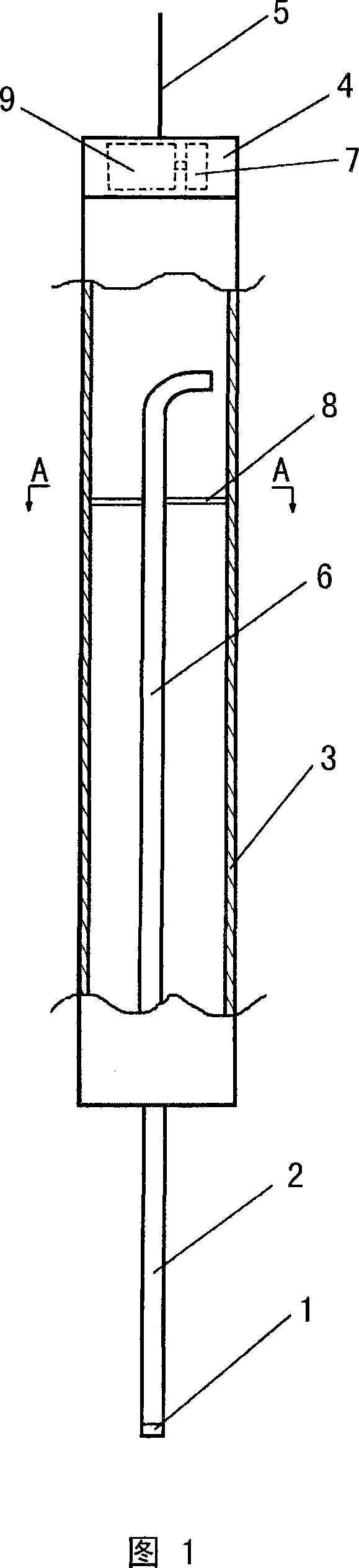

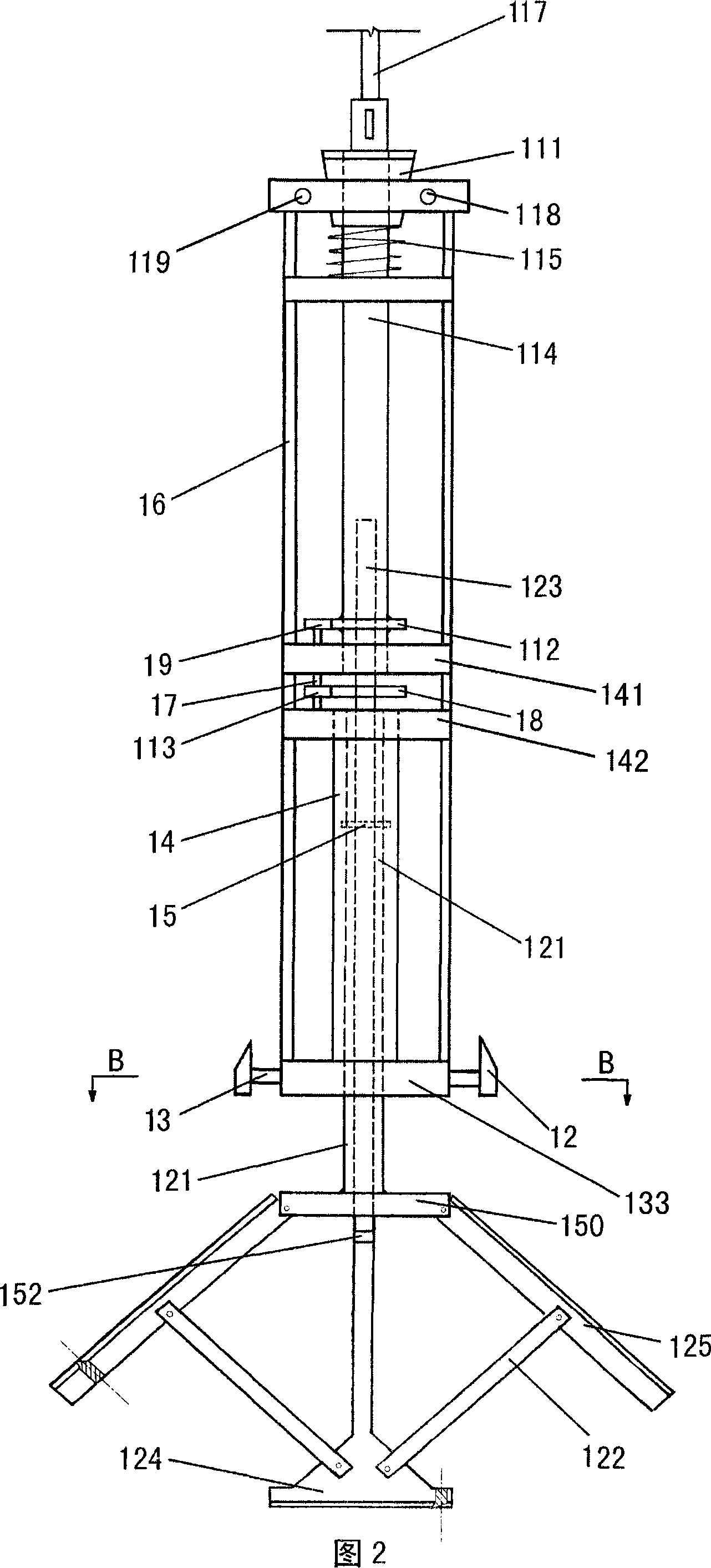

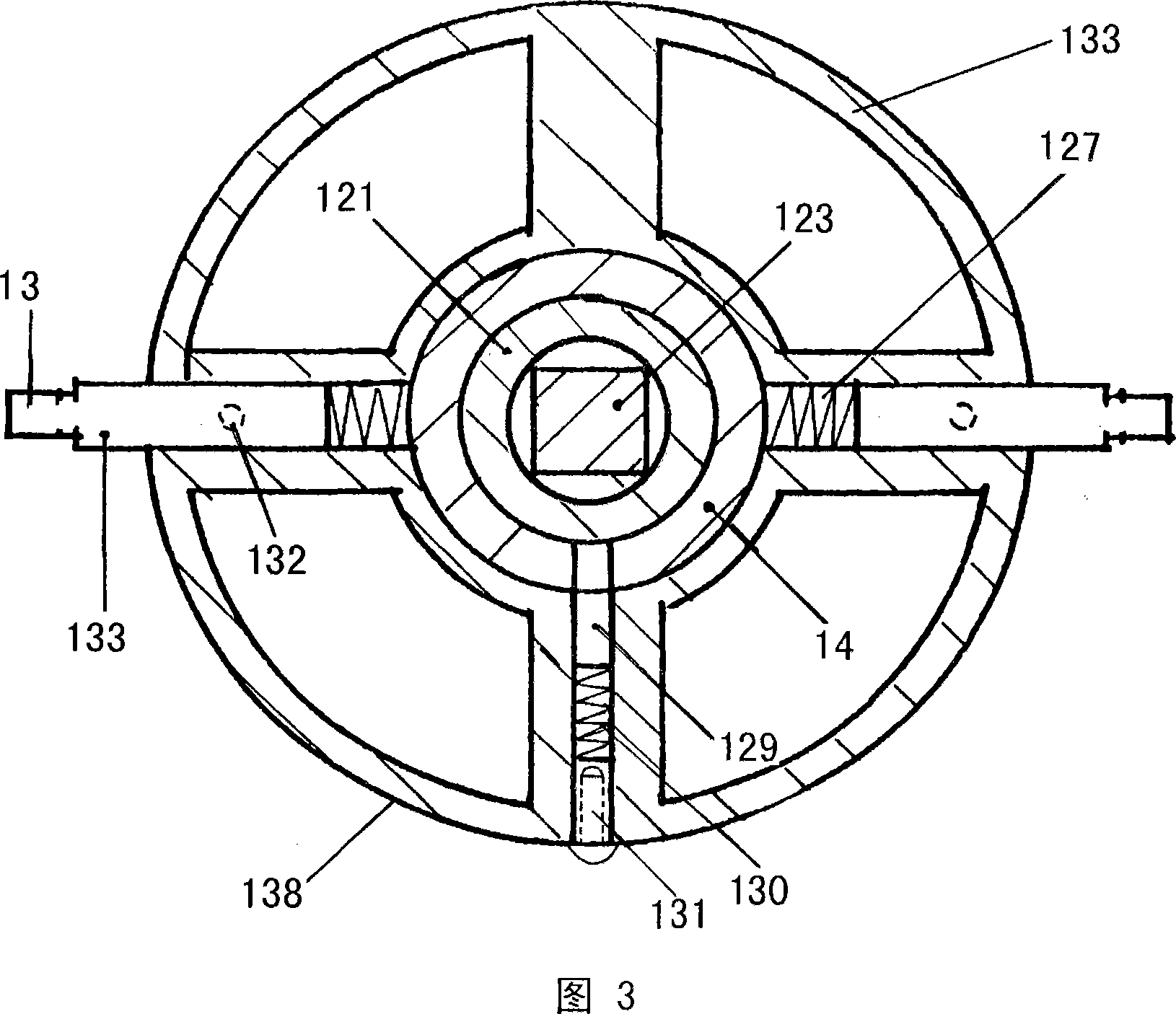

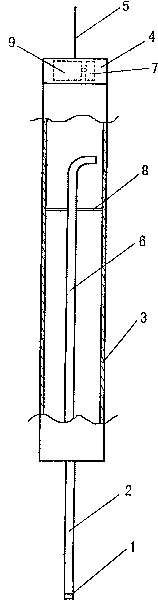

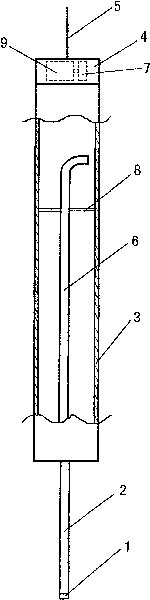

Generation device for fluid shear stress and generation method of fluid shear stress

ActiveCN108339580ALarge ratio rangeSimple structureLaboratory glasswaresMaterial analysisMicrofluidic chipEngineering

The invention relates to the field of microfluidic chips. The invention discloses a generation device for fluid shear stress and a generation method of the fluid shear stress. The device comprises a device main body, wherein the device main body is provided with a main flow passage and at least two branch flow passages; two ends of the main flow passage are provided with a fluid inlet and a main-flow-passage fluid outlet; certain ends of the branch flow passages are communicated with the main flow passage; the other ends of the branch flow passages are provided with branch-flow-passage fluid outlets; valves capable of regulating cross sectional area, which fluid can pass through, in the branch flow passages are arranged in the branch flow passages. The device, by utilizing the cooperationof the main flow passage, the branch flow passages and the valves, can be used for realizing the dynamic changes of the intensity and specific value of the fluid shear stress in the conditions that the flow velocity of the input fluid and the structure of the device are not altered. Meanwhile, the device can be used for greatly expanding the range of the specific value of the fluid shear stress infirst and final branch flow passages; moreover, the specific value of any point in the range can be covered, and the device is simple in structure, and is easy to popularize and realize.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Safety pile foundation construction method

InactiveCN101024960AImprove bearing capacityImprove strength utilizationBulkheads/pilesDetonatorEngineering

The invention discloses a building pile foundation engineering construction process, especially relating to a safe pile foundation construction process, comprising: pressing sinking pipe with metal pile head to the pan at the designed level; taking out the metal pile head and blasting away soil body with detonator; taking out soil; pouring the concrete ready made on ground into foundation cavity to make concrete foundation; placing in prefabricated steel concrete pile body; grouting along the inside of the sinking pipe orifice and then drawing out the sinking pipe to make it. As compared with the existing techniques, it has features of simple and advanced process, high efficiency, effectively improving single pile bearing capacity and reaching design requirements, assuring pile foundation engineering quality, reducing building cost, raising material intensity utilization ratio, making the pile work in the most economic state and assuring engineering quality reaches the design requirements and improving construction safety.

Owner:童乐天

Piling method

InactiveCN1974940AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concreteRebar

The present invention discloses a construction method of building pile foundation engineering, in particular, it relates to a pile-forming method of pipe-sinking belled pile. Said pile-forming method includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out the metal pile head, utilizing belling equipment to enlarge base and make said base portion be formed into a base hollow cavity; borrowing; placing the radial steel bars into the base hollow cavity and nailing said radial steel bars into the hard soil layer, pouring the prepared concrete into the base hollow cavity to obtain concrete base; downwards placing the prefabricated reinforced concrete pile body and making said prefabricated reinforced concrete pile body and cast-in-situ concrete base be butt-connected together by means of inserted bars of base portion and anchored into one body; drawing out said sinking pipe so as to obtain the invented pile.

Owner:王茂华

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101158156AImprove bearing capacityImprove strength utilizationBulkheads/pilesEngineeringHardpan

The invention discloses a building pile foundation project and a construction method, in particular to a bottom-expanding and pile forming method for a sinking pipe precast steel concrete pedestal pile, comprising penetrating the sinking pipe through a soft soil layer and pressing the sinking pipe to a design height hardpan; taking out a metal pile head, descending the sinking pipe, starting the device to expand the bottom; taking soil with an air soil absorption device; putting a radiation shaped steel bar into a pedestal cavity and nailing the steel bar into the hardpan, enclosing the concrete produced on the ground into a long barrel from a sinking pipe mouth to a sinking pipe bottom. When an iron bar at the barrel bottom contacts the hardpan, the barrel bottom door is pushed open, and the concrete inside the barrel falls into the pedestal cavity to form an on-the-spot pedestal. The precast steel concrete pile body is descended and is integrated with an on-the-spot poured concrete pedestal docking anchor through the steal bar at the bottom as a whole; the grout is poured along an interior side of the sinking pipe and is pulled out to form a pile. The invention has simple and advanced technique, and the pedestal cavity has a regular geometrical shape, selects clear soil without grain virtual soil, has high efficiency, enhances effectively single pile bearing capacity, and enhances construction security.

Owner:王国奋

Construction foundation working method

InactiveCN1974939AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concreteEngineering

The present invention discloses a construction method of building pile foundation engineering, in particular, it relates to a building foundation construction process of pipe-sinking belled pile. Said construction process includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out said metal pile head, utilizing belling equipment to enlarge base and make the base portion be formed into base hollow cavity; borrowing; placing the radial steel bars into said base hollow cavity and nailing said radial steel bars into the hard soil layer; then pouring the prepared concrete into the base hollow cavity to obtain concrete base, and downwards placing the prefabricated reinforced concrete pile body and making said prefabricated reinforced concrete pile body and cast-in-situ concrete base be butt-connected and anchored into one body by means of inserted steel bars of base portion; drawing out sinking pipe and injecting cement slurry so as to obtain the invented belled pile.

Owner:王茂华

Cultivating method for simple tomato medium

The invention discloses a cultivating method for a simple tomato medium, and belongs to the technical field of plant cultivation. The technical problem to be solved is to provide a cultivating methodfor a tomato medium with good cultivation quality. The technical scheme adopted in the invention is as follows; the cultivating method comprises the following steps: preparing a medium from a spent mushroom substrate and cow dung according to a weight ratio of 1:(1-5), uniformly stirring the medium, and thoroughly decomposing the medium for later use; carrying out deep ploughing and soil preparation, carrying out rotary tillage and leveling on soil in a greenhouse before field planting, and taking out soil blocks in the soil; manufacturing medium grooves, scribing lines on the ground in a north-south direction, taking each line as a center to turn loosened soil to two sides, so that a filling medium groove with an upper base of 45cm in width, a lower base of 20cm in width and a depth of 25cm is formed between every two adjacent north-south lines; filling the medium grooves with the medium, crushing the medium into particles with diameters smaller than or equal to 0.3 cm, filling the medium grooves with the medium particles, and carrying out compaction to enable the upper surface of the medium to be 1.5 cm higher than the upper surfaces of the medium grooves; and carrying out configuration on a drip irrigation system. The cultivating method can be widely applied to the field of cultivation.

Owner:候海燕

Ship-locating working winch with large pulling force

InactiveCN100393605CImprove work efficiencyShort construction periodWinding mechanismsPull forceCoupling

The invention discloses a large drawing-force positioning winch of ship, which comprises the systems as power, shift, cylinder group, row wire, ratchet wheel brake, quick-drawing, constant tension and control. Wherein, the shift system comprises a planet power shift device and a power dual-dividing device; the planet power shift device is mounted with a motor, a coupler, two shift brakes, a high-speed brake and two planet supports, while the first planet support is connected to the second sun wheel; the first gear ring is connected to the second gear ring; the coupler is connected to the high-speed brake; the first shift brake is connected to the second planet support; the second shift brake via the coupler is connected to the first planet support; the output of first planet support is mounted with the second gear ring and the output big gear wheel; the power dual-dividing device is mounted with a gear wheel axle, a transmission gear wheel, two branch gear transmission devices and water-cooling brake that meshed with output big gear wheel; the water-cooling brake is connected to the gear wheel axle and the transmission gear wheel to realize damping brake. The inventive winch can work on marine with high efficiency, high support ability, anti-impact ability and shortened construction time.

Owner:SHANGHAI ZHENHUA HEAVY IND

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN100580189CImprove bearing capacityImprove strength utilizationBulkheads/pilesPre stressPre stressing

The invention discloses a construction foundation-pile project and a construction method, in particular to a bottom-expanding and pile-forming method of a sinking tube precast steel concrete bottom pile, which comprises: compressing the sinking tube to a hardpan of design evaluation through a soft soil layer; taking out a metal pile head for the construction of soil excavating and bottom-expanding; conducting a second soil uploading by using air; putting radiation steel bars into a base cavity and nailing the steel bars into the hard stratum; packing a certain amount of concrete which is made at the ground into a long barrel and putting the concrete on the bottom of the sinking tube through a sinking tube mouth; when an iron bar which is arranged at the bottom of the barrel contacts the hardpan, pressing off a barrel bottom door to cause the inside concrete to fall into the base cavity to form a cast-in-place base; putting a pre-stressed precast hollow pile to connect and fix with the cast-in-place concrete base into a body through the steel bar arranged at the bottom; and pulling out the sinking tube to form the pile. The bottom-expanding cavity of the invention has a regular geometry shape, the clean soil uploading without granular sediment and high efficiency; the invention effectively increases the bearing capacity of a single pile, reduces the construction cost, improves the utilization ratio of material strength, ensures the pile to work under a most economical condition and enhances the working safety.

Owner:王国奋

Bottom-expanding pile-forming method for immersed tube club-footed pile

The invention discloses construction pile engineering and construction method, especially bottom expanding and pile forming method for sinking-pipe bottom expanded piles, comprising following steps: pressing the first segment of sinking tube into soil, connecting the second segment of tube with the thread on the top of the first segment of tube, pressing the sinking tube to hard soil of designed elevation; taking out the metal pile head, putting into emulsible oil or AN-TNT explosive through the sinking tube mouth, and removing the articles blocking the sinking tube mouth after explosion is completed; taking out the broken soil by using an air soil suction device; sinking the sinking tube, activating the machine to expand the bottom; taking out the soil for the second time by using the air soil suction device; sinking the prefab concrete pile body and anchoring same with the cement paste base which is poured on site is anchored integrally by inserted steel bars at the bottom of the pile body; pouring cement paste along the sink tube mouth inner side, pulling out the first segment of the sinking tube and the second segment of the sinking tube at the same time, and then the pile is constructed. According to the invention, the expanded bottom has a regular geometric figure, soil is taken out cleanly, no granule soil is left, efficiency thereof is high, and bearing capacity of a single pile is enhanced effectively.

Owner:王国奋

Bottom-expanding pile-forming method for immersed tube club-footed pile

The invention discloses construction pile engineering and construction method, especially bottom expanding and pile forming method for sinking-pipe bottom expanded piles, comprising following steps: pressing the first segment of sinking tube into soil, connecting the second segment of tube with the thread on the top of the first segment of tube, pressing the sinking tube to hard soil of designed elevation; taking out the metal pile head, putting into emulsible oil or AN-TNT explosive through the sinking tube mouth, and removing the articles blocking the sinking tube mouth after explosion is completed; taking out the broken soil by using an air soil suction device; throwing away dispersed articles from the sinking tube mouth, digging soil to expand the bottom; taking out soil for the third time; disposing the steel bar into the base cavity and hammering same into hard soil, disposing the concrete into a long barrel, disposing the long barrel into the bottom of the sinking tube, sinking the prefab concrete pile body and anchoring same with the cement paste base which is poured on site is anchored integrally by inserted steel bars at the bottom of the pile body; pulling out the first segment of sinking tube and the second segment of sinking tube, pouring cement paste into the gap. Thereby, the pile is constructed. According to the invention, the expanded bottom has a regular geometric figure, soil is taken out cleanly, no granule soil is left, and efficiency thereof is high.

Owner:王国奋

Construction foundation working process

InactiveCN1974943AThe process method is simple and advancedPile fastBulkheads/pilesCement slurryFoundation engineering

The present invention discloses a construction process of building pile foundation engineering, in particular, it relates to a building foundation construction process of pipe-sinking belled pile. Said construction process includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out the metal pile head; making base portion be formed into base hollow cavity; borrowing; pouring the prepared concrete into the base hollow cavity so as to form a concrete base; downwards placing the prefabricated reinforced concrete pile body and making said prefabricated reinforced concrete pile body and the cast-in-situ concrete base be butt-connected together by means of inserted steel bars of base portion and anchored into one body; drawing out sinking pipe and injecting cement slurry so as to obtain the invented building pile.

Owner:王茂华

Exploding bottom-expanding pile-forming method for immersed tube prefabrication steel concrete bottom-expanding pile

InactiveCN101235643AImprove bearing capacityImprove project qualityBulkheads/pilesEngineeringImmersed tube

The invention discloses a construction pile project and a construction process, in particular to an explosive-enlargement and pile forming process of steel concrete belled pile of a immersed tube which is pre-formed , which comprises pressing an immersed tube to a hard stratum with designed height mark through passing through a soft stratum, taking out a metal pile head, sealing the mouth of the immersed tube after detonating blasting agent, opening objects which are used to seal the mouth of the immersed tube after detonating blasting agent, taking soil with an air soil-absorbing device, detecting whether the quality reaches the designed requirement with a camera with light source in a cavity of a chassis, putting steel rids which take on irradiating form into a cavity of a chassis and nailing with firm soil, pouring quantitative cast-in-situ concrete to form a cast-in-situ chassis from the mouth of the immersed tube, putting pre-formed hollow pile body with initial stress which is integrated and anchored with the cast-in-situ chassis through dowel bars on the bottom portion, and drawing out the immersed tube pile after injecting cement plaster along the inner side of the mouth of the immersed tube.. The process can take soil without particle porous soil, has high efficiency, effectively increases the loading of single pile, guarantees the engineering quality of pile, reduces construction cost, and increases the material strength usage.

Owner:王国奋

A kind of ferromolybdenum and preparation method thereof

The invention discloses ferro-molybdenum made of mixture powder and reducing agents. The mixture powder comprises, by weight, 21.0%-42.9% of molybdenum oxide powder, 0%-50.3% of iron oxide powder, 0%-33.2% of iron powder, 3.6%-23.5% of calcium molybdate and 3.2%-22.3% of industrial waste residue. In addition, the invention further discloses a method for preparing the ferro-molybdenum. According to the ferro-molybdenum and the preparation method thereof, carbon powder is adopted to serve as the reducing agents, the mixture powder and the reducing agents are mixed and then roasted at the temperature of not higher than 1600 DEG C to prepare the ferro-molybdenum, and pollutants such as nitrogen oxide and fluoride do not exist in the preparation process; the adaptability of the raw material formula is strong, compared with the traditional aluminothermy adopted to prepare the ferro-molybdenum, the quality adjustment and the quantity adjustment of the raw material formula have a good raw material adaptability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Pile foundation construction method

InactiveCN1974947AImprove bearing capacityImprove strength utilizationBulkheads/pilesCement slurryFoundation engineering

The present invention discloses a construction method of building pile foundation engineering, in particular, it relates to a pile foundation construction method of pipe-sinking belled pile. Said construction method includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out metal pile head, using belling equipment to enlarge base and make the base portion be formed into a base hollow cavity; borrowing; pouring prepared concrete into the base hollow cavity to form a cast-in-situ concrete base; injecting cement slurry along the internal wall of said sinking pipe, then drawing out said sinking pipe so as to obtain the invented building pile.

Owner:王茂华

Method for enlarging bottom and pile making of immersed tube and prefabricated steel concrete under-reamed pile

InactiveCN100453742CImprove bearing capacityImprove strength utilizationBulkheads/pilesSteel barImmersed tube

The invention relates to a method for constructing tile foundation, especially providing a club-footed pile and a pile-forming method of sink tube preset steel concrete club-footed pile, wherein it comprises: designing the sink tube with metallic pile head to standard rigid layer; taking out metallic pile head, using club-footed device to expand the bottom; forming base chamber at the bottom, using air adsorb device to take soil; arranging radial steel bar into chamber and nailing it into rigid soil; pouring the concrete into chamber to prepare the concrete base; inserting the preformed steel concrete post and using its bottom bar to connect the poured base; drawing out sink tube to form post. The invention has standard geometrical shape, without particle soil and with high efficiency.

Owner:王国奋

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101161952AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concretePre stress

The invention discloses a building pile foundation project and a construction method, in particular relates to a method for enlarging pedestal and forming pile of an immersed tube precast reinforced concrete enlarged pedestal pile, and comprises the following steps that: the immersed tube is passed through soft earth layer and pressed to a designed level hard earth layer; a metal pile head is taken out, the construction of earth digging and pedestal enlarging is processed; the air is utilized to perform second earth extraction; radial reinforcing steel bars are arranged in the cavity of the base, and the hard earth is hammered into the cavity of the base, the concrete premade on the ground is arranged in a long barrel and the barrel is put to the bottom of the immersed tube from the mouth of the immersed tube, when iron bars arranged on the bottom of the barrel touch the hard earth, the bottom gate of the barrel is forced open, then the concrete falls into the cavity of the base to form a cast-in-situ base, the prestress precast hollow pile body is put and in even joint with the cast-in-situ base through the dowel bars of the reinforced concrete pile body to be fixed and anchored into a whole; after grout is poured along the inner side of the immersed tube mouth, the immersed tube is extracted and the pile is formed. The invention has regular geometry of the enlarging pedestal cavity and high efficiency; the earth extracted is complete without granular loose earth.

Owner:王国奋

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101158157AImprove bearing capacityImprove strength utilizationBulkheads/pilesPre stressPre stressing

The invention discloses a construction foundation-pile project and a construction method, in particular to a bottom-expanding and pile-forming method of a sinking tube precast steel concrete bottom pile, which comprises: compressing the sinking tube to a hardpan of design evaluation through a soft soil layer; taking out a metal pile head for the construction of soil excavating and bottom-expanding; conducting a second soil uploading by using air; putting radiation steel bars into a base cavity and nailing the steel bars into the hard stratum; packing a certain amount of concrete which is made at the ground into a long barrel and putting the concrete on the bottom of the sinking tube through a sinking tube mouth; when an iron bar which is arranged at the bottom of the barrel contacts the hardpan, pressing off a barrel bottom door to cause the inside concrete to fall into the base cavity to form a cast-in-place base; putting a pre-stressed precast hollow pile to connect and fix with the cast-in-place concrete base into a body through the steel bar arranged at the bottom; and pulling out the sinking tube to form the pile. The bottom-expanding cavity of the invention has a regular geometry shape, the clean soil uploading without granular sediment and high efficiency; the invention effectively increases the bearing capacity of a single pile, reduces the construction cost, improves the utilization ratio of material strength, ensures the pile to work under a most economical condition and enhances the working safety.

Owner:王国奋

Blast bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101161953AImprove bearing capacityImprove project qualityBulkheads/pilesBottom gateEngineering

The invention discloses a building pile foundation project and a construction method, in particular a method for blasting enlarging pedestal and forming pile of an immersed tube precast reinforced concrete enlarged pedestal pile, and comprises the following steps that: the immersed tube is passed through a soft earth layer and pressed to a designed level hard earth layer; a metal pile head is taken out, after explosive is ignited, the mouth of the immersed tube is sealed, after the explosion is finished, objects sealing the mouth of the immersed tube are opened; second earth extracting is processed by a device which uses air to absorb earth; radial reinforcing steel bars are arranged in the cavity of the base, and the hard earth is hammered into the cavity of the base, the concrete premade on the ground is filled in a long barrel and the barrel is put to the bottom of the immersed tube from the mouth of the immersed tube, when iron bars arranged on the bottom of the barrel touch the hard earth, the bottom gate of the barrel is forced open, then the concrete falls into the cavity of the base to form a cast-in-situ base, the prestress precast hollow pile body is put and in even joint with the cast-in-situ base through the dowel bars of the reinforced concrete pile body to be fixed and anchored into a whole; after grout is poured along the inner side of the immersed tube mouth, the immersed tube is extracted and the pile is formed. The earth extracted by the invention is complete without granular loose earth, the efficiency is high, the bearing capacity of single pile is improved greatly, the construction cost is reduced and the construction safety is improved.

Owner:王国奋

Construction piling method

InactiveCN1974949AImprove bearing capacityImprove strength utilizationFoundation testingBulkheads/pilesReinforced concreteImage formation

The present invention discloses a building pile foundation engineering and construction method, in particular, it relates to a building pile-forming method of pipe-sinking belled pile. Said method includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out the metal pile head; utilizing belling equipment to enlarge base; borrowing; using camera to record image formation; placing radial steel bars into the base hollow cavity and railing said radial steel bars into hard soil, pouring the prepared concrete into the base hollow cavity to form a concrete base; downwards placing prefabricated reinforced concrete pile body and making said prefabricated reinforced concrete pile body and cast-in-situ concrete base be butt-connected and anchored into one body; drawing out said sinking pipe so as to form the invented building pile.

Owner:周亚萍

Pile foundation construction process

InactiveCN1974938AImprove bearing capacityImprove strength utilizationFoundation testingBulkheads/pilesImage formationCement slurry

The present invention discloses a construction method of building pile foundation engineering, in particular, it relates to a pile foundation construction process of pipe-sinking belled pile. Said construction process includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out metal pile head, and making the base portion be formed into hollow cavity; borrowing, using camera to record image formation; placing the radial steel bars into the base hollow cavity and nailing said radial steel bars into the hard soil layer, pouring concrete from sinking pipe opening so as to form cast-in-situ concrete base; drawing out said sinking pipe and injecting cement slurry so as to obtain the invented pile.

Owner:王茂华

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101158155BImprove bearing capacityImprove strength utilizationBulkheads/pilesPre stressArchitectural engineering

Owner:王国奋

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

The invention discloses a building pile foundation project and a construction method, in particular to a bottom-expanding and pile-forming method for a sinking pipe precast steel concrete pedestal pile, comprising penetrating the sinking pipe through a soft soil layer and pressing the sinking pipe to a design height hardpan; taking out a metal pile head, descending the sinking pipe to expand the bottom, finishing the bottom expanding and soil digging, hauling the bottom expanding device out of the ground, taking soil with an air soil absorption device until the clearance of the soil; putting aradiation shaped steel bar into a pedestal cavity and nailing the steel bar into the hardpan, pouring a qualitative concrete produced on the ground through the sinking pipe to the pedestal cavity toform a concrete pedestal, descending the precast steel concrete pile body and integrating with an on-the-spot poured concrete pedestal docking anchor through a steal bar at the bottom as a whole; pulling out the sinking pipe to form a pile after pouring grout along an interior side of the sinking pipe. The invention selects clear soil without grain virtual soil, has high efficiency, enhances effectively single pile bearing capacity, reaches design requirements, guarantees pile pedestal project quality, reduces construction cost, increases material strength utilization ratio, and leads the pileto work under a most economic condition, and enhances construction security.

Owner:王国奋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com