Ship-locating working winch with large pulling force

A ship and work technology, which is applied in the field of marine engineering ship positioning anchor winches, can solve the problems that ships cannot resist sea storms and adapt to harsh working conditions at sea, etc., and achieve the effects of high efficiency ratio, safety protection, and large speed change range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

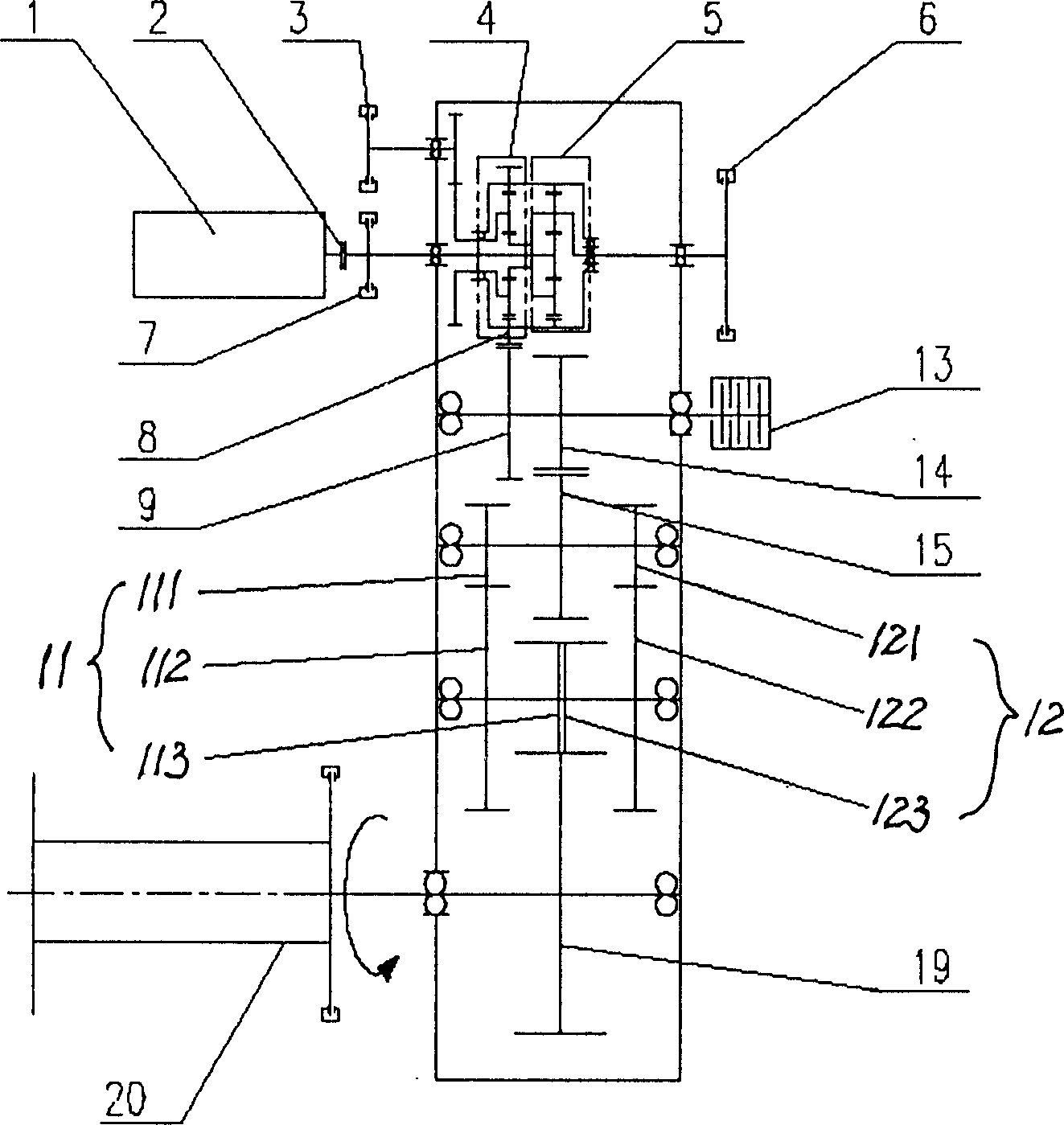

[0016] A positioning work winch for ships with a large pulling force of the present invention includes a power system, a speed change system, a reel set, a rope arrangement system, a ratchet brake system, a fast dragging and dropping system, a constant tension system and a control system.

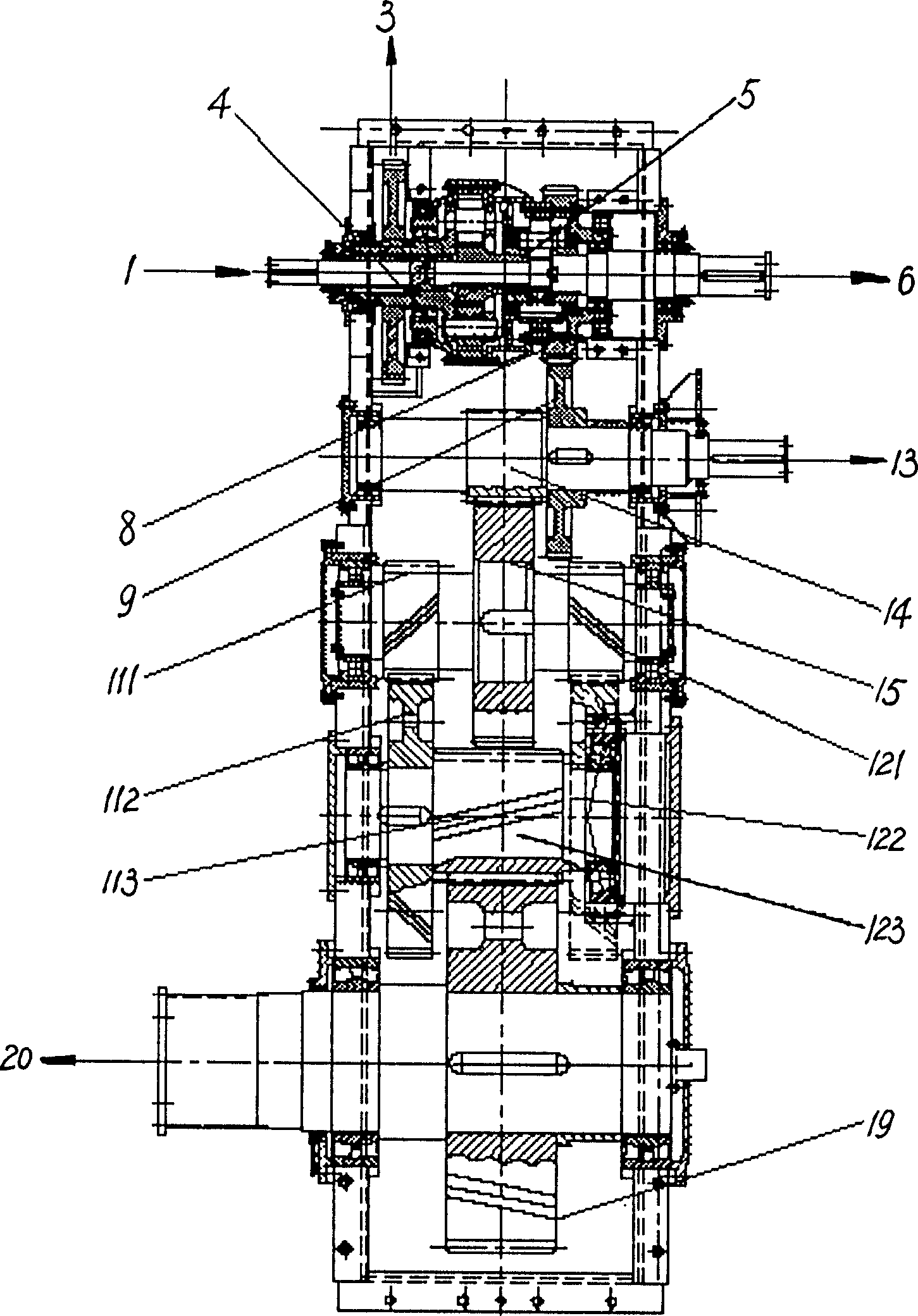

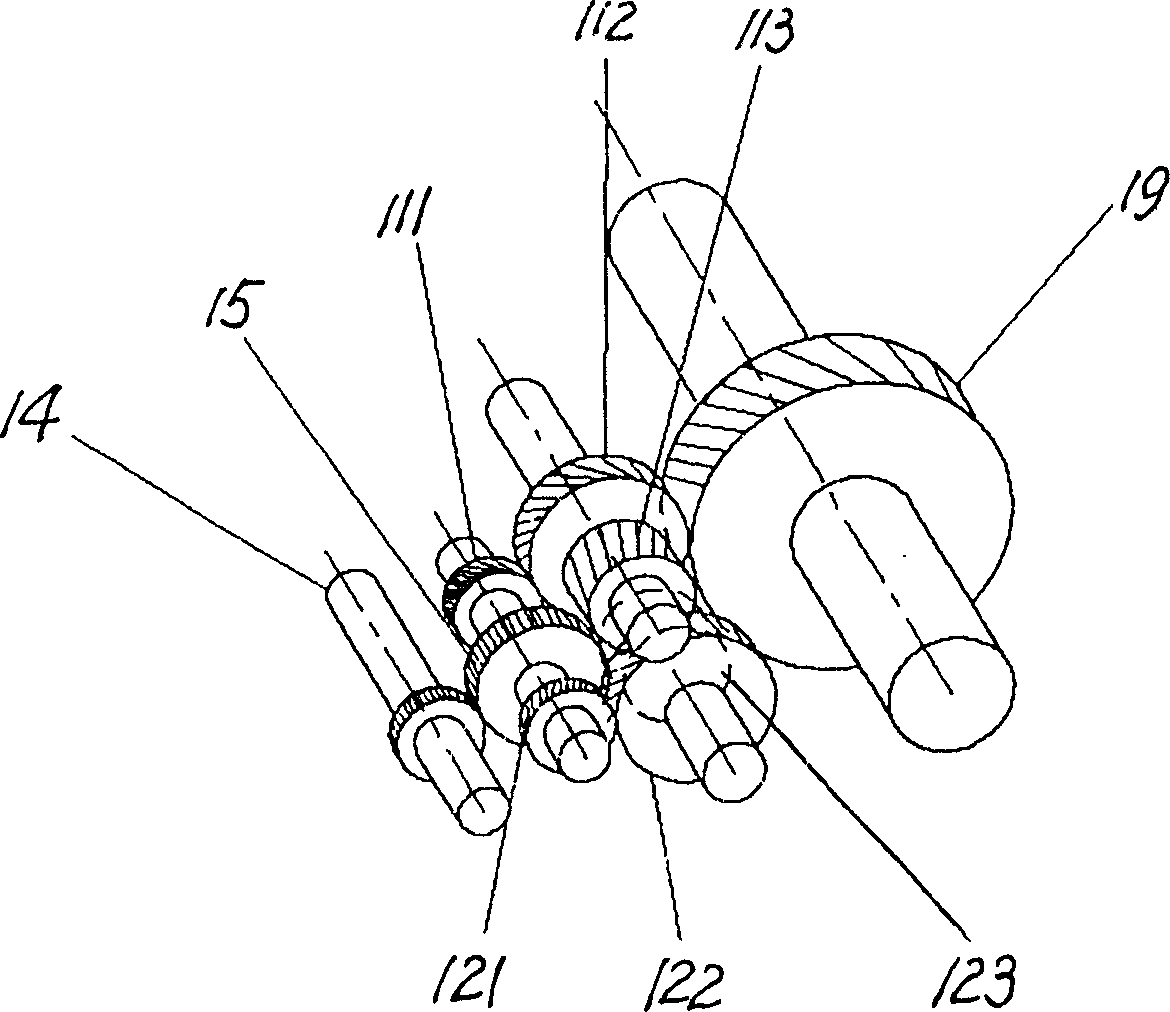

[0017] see Figure 1 to Figure 4 , the transmission system is a non-stop shifting transmission system, which includes a planetary power shifting device and a power double splitting device.

[0018] Such as figure 1 , figure 2 and Figure 4 As shown in , the planetary power shift device is equipped with a motor 1 together with a coupling 2 , a first transmission brake 3 , a second transmission brake 6 , a high-speed brake 7 , a first-stage planetary carrier 5 and a second-stage planetary carrier 4 . The first stage planet carrier 5 is connected with the second stage sun gear 25 . The first stage ring gear 22 is connected with the second stage ring gear 8 . Coupling 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com