A kind of ferromolybdenum and preparation method thereof

A technology of ferro-molybdenum and iron powder, applied in the field of ferro-molybdenum and its preparation, can solve the problems of producing nitrogen oxides or fluorides, difficult temperature control, and high reaction temperature, and achieves low price, strong adaptability and low reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

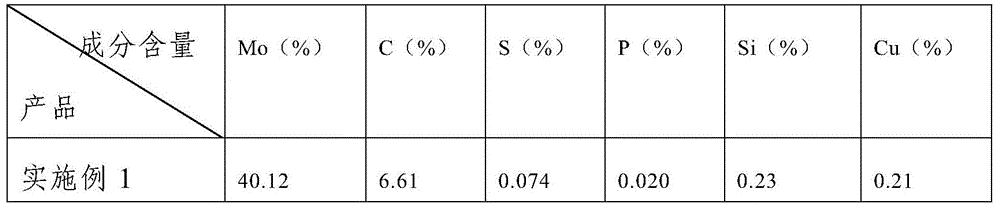

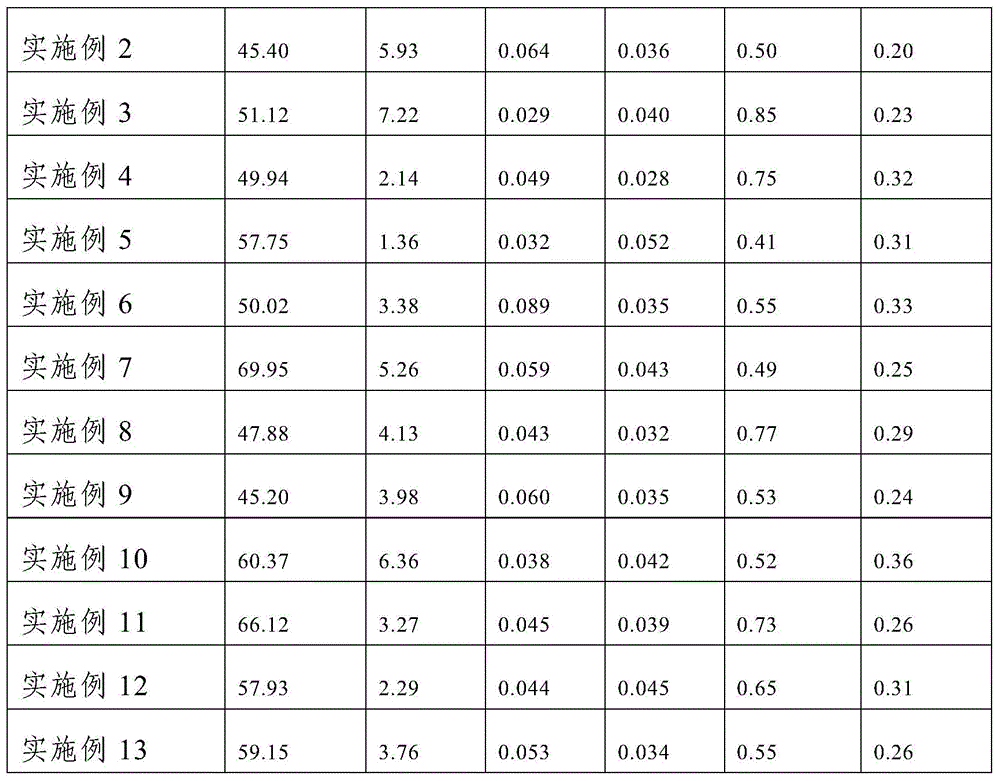

Examples

Embodiment 1

[0018] The ferromolybdenum of the present embodiment is made by mixture powder and reducing agent, and described mixture powder is mixed by the raw material of following percentage by weight: molybdenum oxide powder 21.0%, iron powder 33.2%, calcium molybdate 23.5%, industrial waste residue 22.3%; the reducing agent is carbon powder, the amount of the carbon powder is 3% of the mass of the mixture powder, and the mass content of molybdenum in the industrial waste residue is 15%; the quality purity of the iron powder is not low The mass purity of the iron oxide powder is not less than 98%; the molybdenum oxide powder is molybdenum trioxide powder.

[0019] The method for preparing molybdenum ferromolybdenum in this embodiment is as follows: mix the mixture powder and the reducing agent evenly, place it in a high-temperature furnace, keep it warm for 10 minutes at a temperature of 1400 ° C, and obtain the product after cooling with the furnace, and then carry out the process on t...

Embodiment 2

[0022] The ferromolybdenum of this embodiment is made by mixture powder and reducing agent, and described mixture powder is mixed by the raw material of following percentage by weight: molybdenum oxide powder 42.9%, iron oxide powder 50.3%, calcium molybdate 3.6%, industrial Waste residue 3.2%; Described reducing agent is carbon powder, and the consumption of described carbon powder is 20% of described mixture powder quality, and the mass content of molybdenum is 15% in the described industrial waste residue; The quality purity of described iron powder is not The mass purity of the iron oxide powder is not lower than 98%; the molybdenum oxide powder is molybdenum dioxide powder.

[0023] The method for preparing molybdenum ferromolybdenum in this embodiment is as follows: mix the mixture powder and the reducing agent evenly, place it in a high-temperature furnace, keep it warm for 60 minutes at a temperature of 1600 ° C, and obtain the product after cooling with the furnace, an...

Embodiment 3

[0026] The ferromolybdenum of the present embodiment is made by mixture powder and reducing agent, and described mixture powder is mixed by the raw material of following percentage by weight: molybdenum oxide powder 33.3%, iron oxide powder 16.7%, iron powder 16.9%, molybdic acid Calcium 22.1%, industrial waste slag 11.0%; the reducing agent is carbon powder, the consumption of the carbon powder is 6.0% of the mixture powder mass, and the mass content of molybdenum in the industrial waste slag is 22.0%; the iron The mass purity of the powder is not less than 98%, and the mass purity of the iron oxide powder is not less than 98%; the molybdenum oxide powder is formed by mixing molybdenum trioxide powder and molybdenum dioxide powder with a mass percentage of 9:1.

[0027] The method for preparing molybdenum ferromolybdenum in this embodiment is as follows: mix the mixture powder and reducing agent evenly, place it in a high-temperature furnace, keep it warm for 30 minutes at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com