Reinforced concrete resin slurry casting pipe and method for manufacturing the same

A technology of reinforced concrete resin and production method, which is applied in the direction of mixing operation control, chemical instrument and method, mixing operation control device, etc., and can solve the problems of poor corrosion resistance life of steel pipes and cast iron pipes, low strength of plastic pipes and glass steel pipes, and cement Regardless of the problems of its own weight, etc., it achieves the effect of light weight, tight interface, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

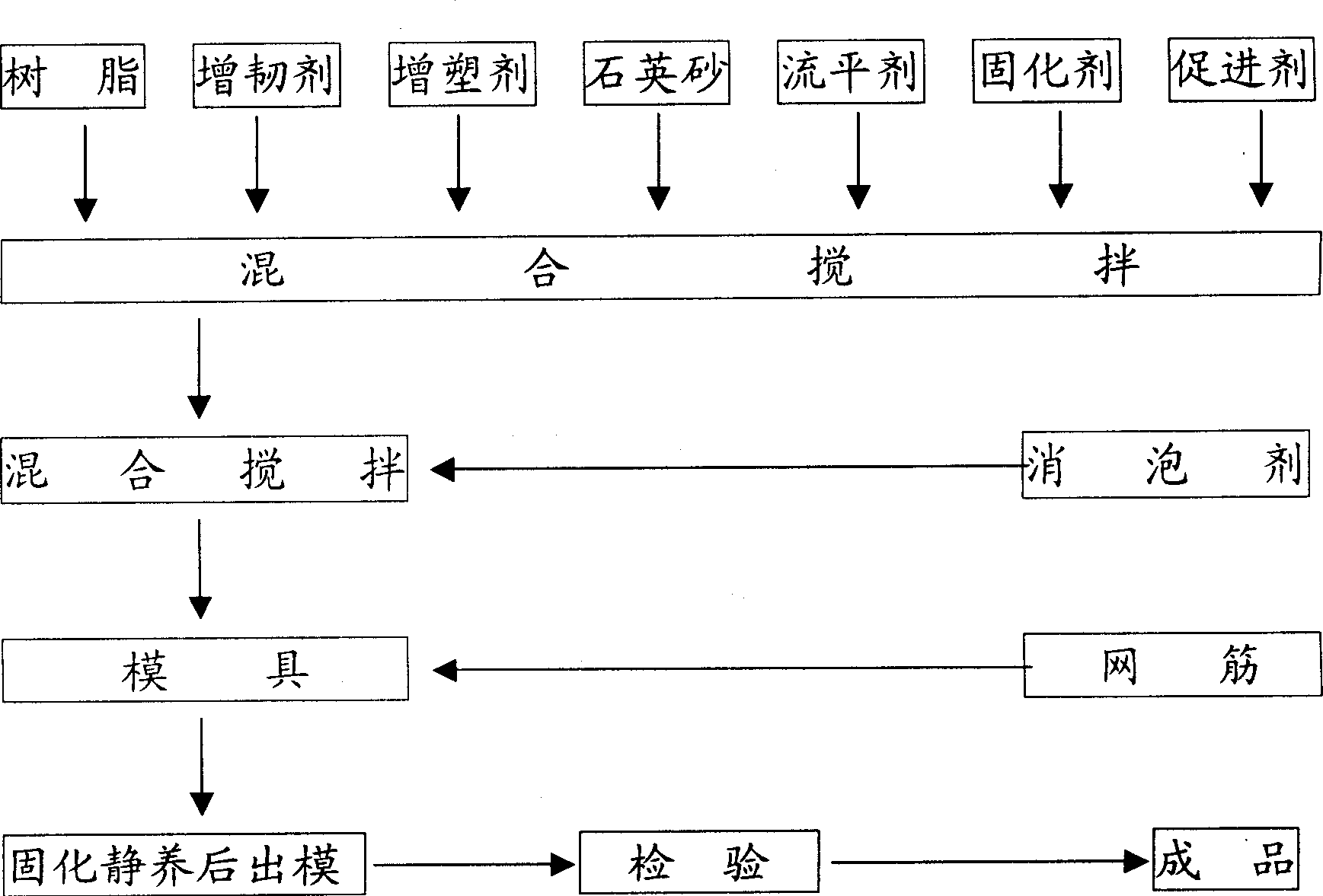

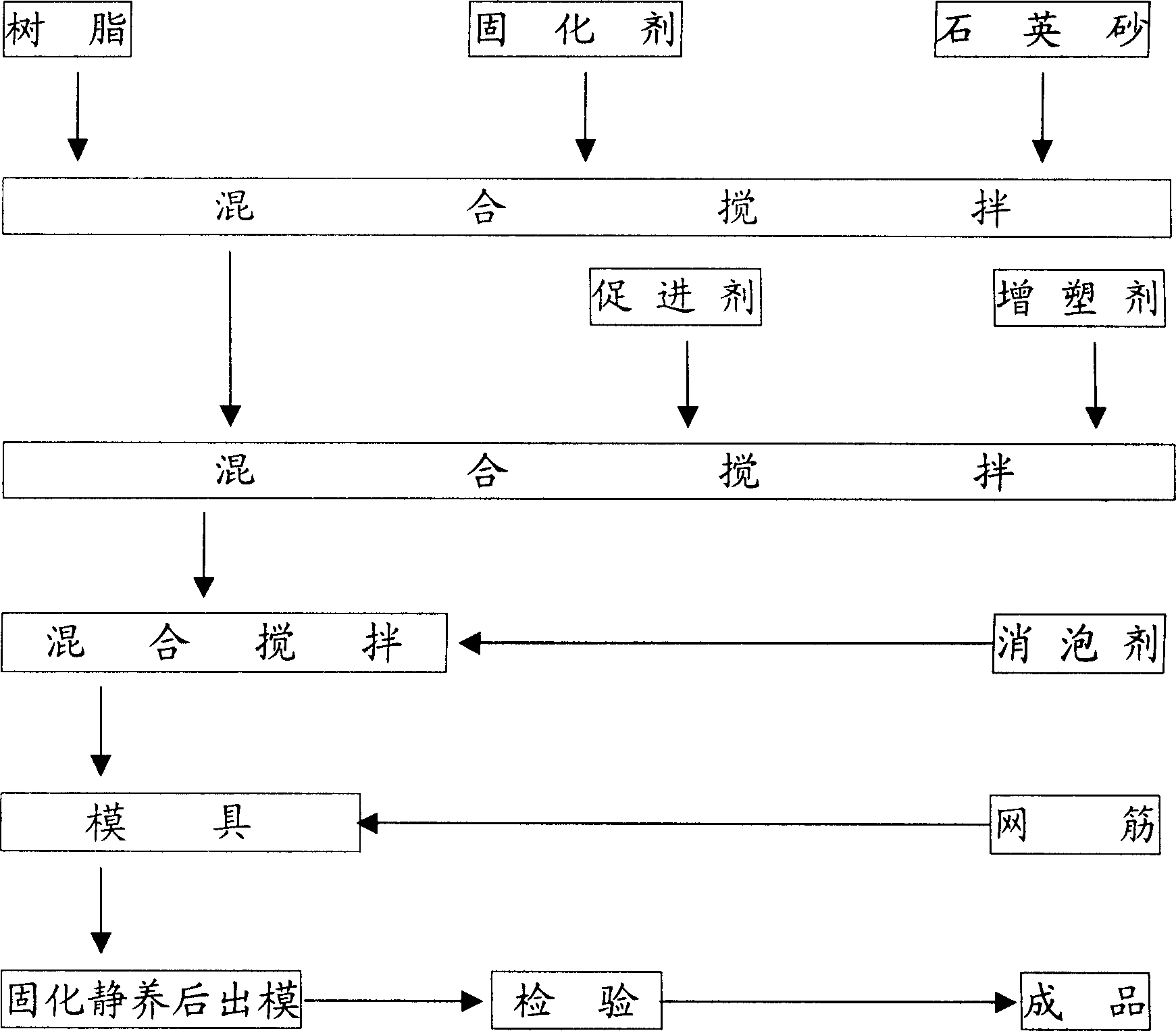

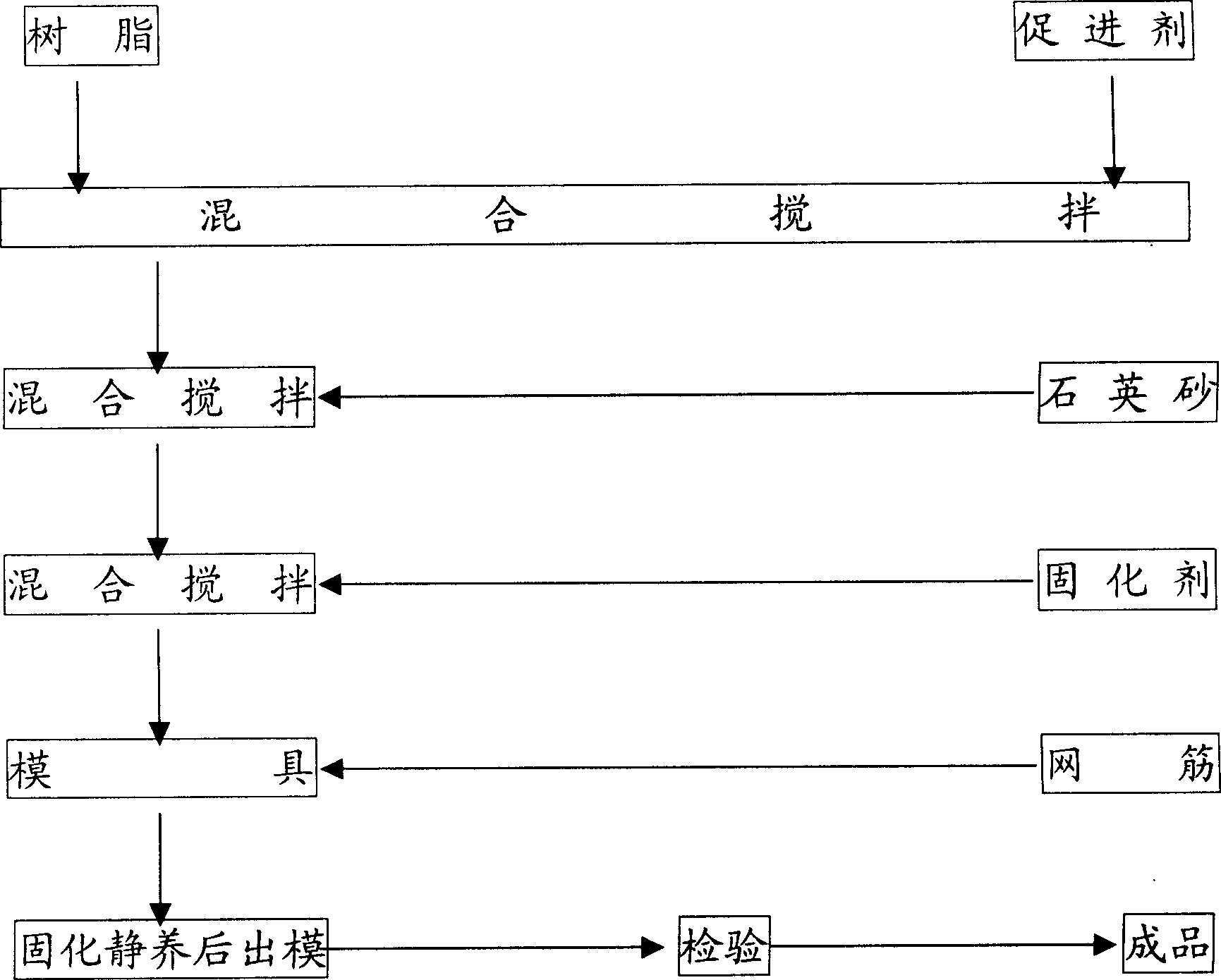

Method used

Image

Examples

specific Embodiment approach 2

[0118] Carry out by specific embodiment one, just operation step 1. is to prepare the following raw materials required by the pipe wall by weight as follows:

[0119] Resin is methacrylic resin: 60%

[0120] Toughener as wash oil: 10%

[0121] Plasticizer is polymethyl methacrylate: 3.75%

[0122] Quartz sand: 5%

[0123] Leveling agent is amyl alcohol: 2.75%

[0124] Curing agent is ethylenediamine: 14%

[0125] The accelerator is N,N-dimethylaniline: 2.75%

[0126] Antifoam as vegetable oil: 1.75%

[0127] The proportioning sum of all raw materials constituting the pipe wall is 100%.

specific Embodiment approach 3

[0128] Carry out by specific embodiment one, just operating step 1. is to prepare the following raw materials with the required ratio of pipe wall by weight:

[0129] Resin is unsaturated polyester resin: 10%

[0130] Toughener as benzyl alcohol: 15%

[0131] Plasticizer is dibutyl benzoate: 6%

[0132] Quartz sand: 42.5%

[0133] Leveling agent is n-butanol: 5%

[0134] Curing agent is dicumyl peroxide: 11.5%

[0135] The accelerator is N,N-dimethyl-p-toluene: 5%

[0136] Antifoam as vegetable oil: 5%

[0137] The proportioning sum of all raw materials constituting the pipe wall is 100%.

specific Embodiment approach 4

[0138] Carry out by specific embodiment one, just operating step 1. is to prepare the following raw materials with the required ratio of pipe wall by weight:

[0139] Resin as epoxy: 35%

[0140] Toughener is anthracene oil: 8%

[0141] Plasticizer is polymethyl methacrylate: 2%

[0142] Quartz sand: 12.995%

[0143] Leveling agent is tung oil: 1%

[0144] Curing agent is dibenzoyl peroxide: 40%

[0145] Accelerator is cobalt salt accelerator: 1%

[0146]Antifoaming agent is methyl silicone oil: 0.005%

[0147] The proportioning sum of all raw materials constituting the pipe wall is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com