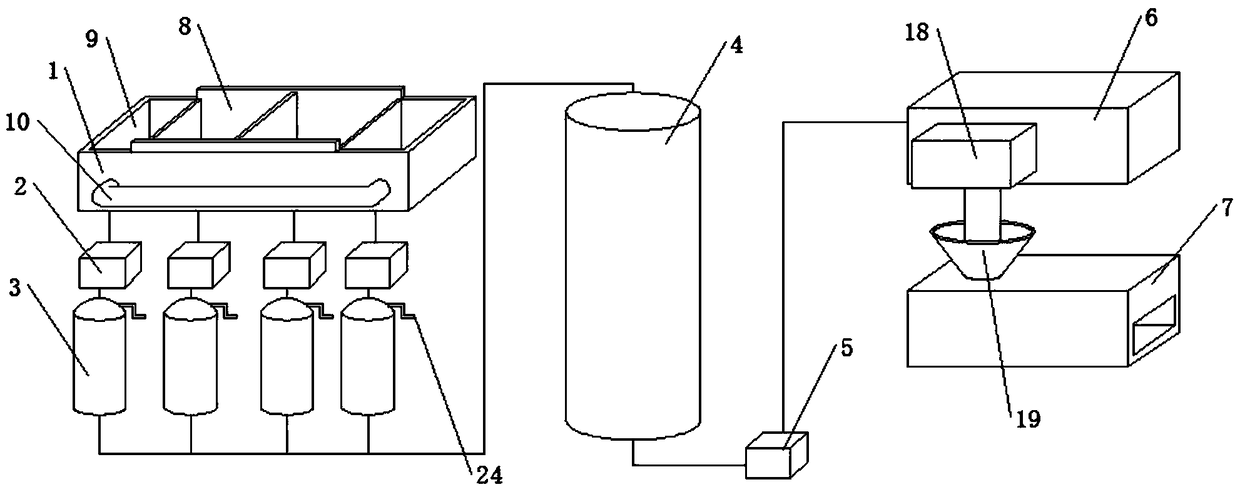

Sulphur refining equipment system

A technology of sulfur and equipment, which is applied in the field of sulfur refining equipment system based on the sulfur recovery unit of the integrated coal gasification combined cycle power generation technology, can solve the problems of poor quality, unstable and efficient sulfur refining work, and large environmental pollution, so as to speed up granulation Speed, improve resource utilization efficiency, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

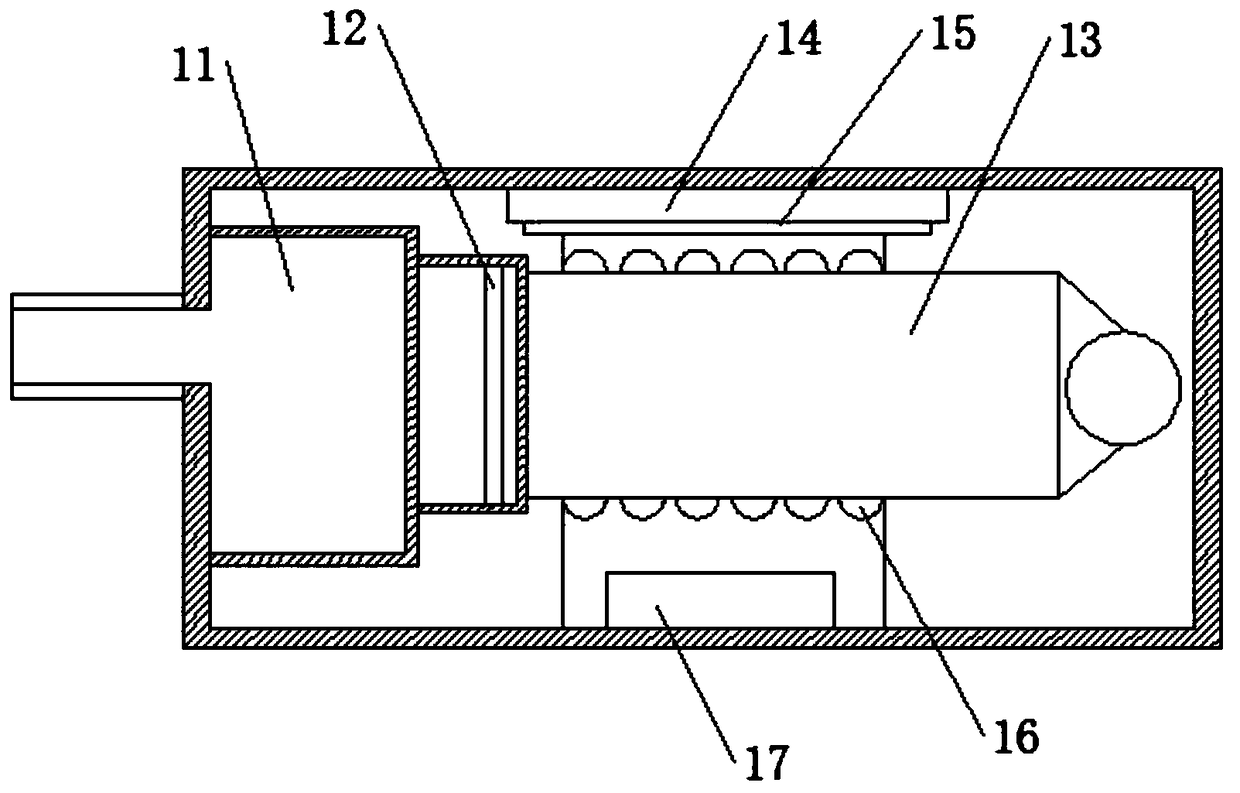

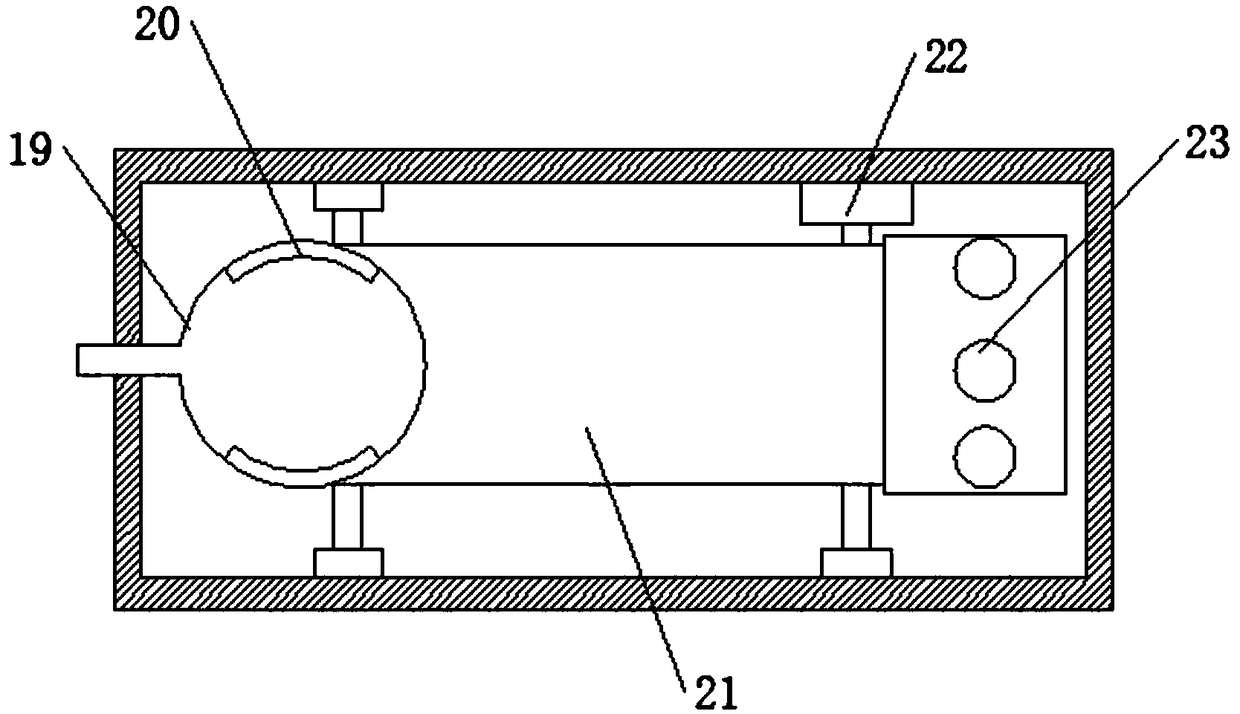

[0030] combined with Figure 4The slurry tank is divided into large and small chambers. The two large chambers are independent, corresponding to the two upstream vacuum belt conveyors. The sulfur slurry in the large chamber overflows to the small chamber. After optimization, the two small chambers are connected to each other. The sulfur slurry in the small chamber passes through The sulfur foam is pumped to the sulfur melting kettle. A total of four sulfur foam pumps, two sulfur foam pumps of A series correspond to two sulfur melting kettles, and two sulfur foam pumps of B series correspond to the other two sulfur melting kettles. After optimization, the rated flow rate of the sulfur foam pump is increased from 2.16m3 / h to 10m3 / h, the head is increased from 50m to 60m, and the pressure of the sulfur melting tank can be maintained at 0.5-0.6MPa. The sulfur melting kettle is heated by low-pressure steam to change the sulfur into liquid and separate with water in the kettle. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com