System and method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash

A technology for sulfoaluminate cement and desulfurized gypsum, applied in chemical instruments and methods, sulfur preparation/purification, sulfur compounds, etc., can solve the problems of rising sulfur prices, insufficient gypsum carbon, and difficult to control atmosphere in the kiln

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

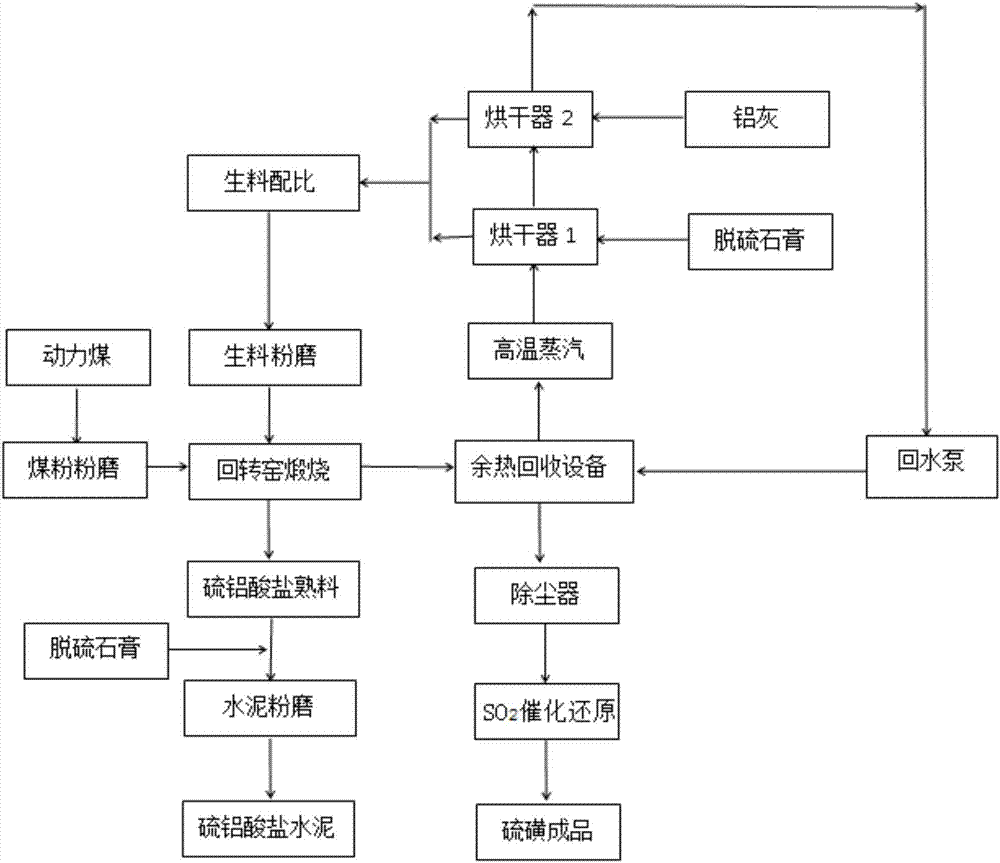

[0068] Such as figure 1 As shown, the aluminum ash and desulfurized gypsum are respectively sent into the dryer. In terms of solid matter after drying, desulfurized gypsum: 61%, aluminum ash: 38%, and activated carbon 1%. It is directly transported into the hollow rotary kiln for calcination, the calcination temperature is 1280°C, and the calcination time is 60 minutes. The high-temperature kiln gas produced passes through the waste heat recovery equipment, and the by-product high-temperature steam and hot water are used for indirect drying of the original aluminum ash and desulfurized gypsum. The kiln gas exiting the waste heat recovery equipment, the gas temperature is reduced to 860°C, and after dust removal, dehumidification purification, supplementary air to adjust the oxygen-sulfur ratio and drying, it enters the fixed bed of activated carbon with a particle size of 10 mesh, and generates elemental sulfur through catalytic reduction. The prepared sulfur The purity reach...

Embodiment 2

[0071] Send aluminum ash and desulfurized gypsum into the dryer respectively. In terms of dried solid matter, desulfurized gypsum: 66%, aluminum ash: 33%, and activated carbon 1%. It is directly transported into the hollow rotary kiln for calcination, the calcination temperature is 1250°C, and the calcination time is 50 minutes. The high-temperature kiln gas produced passes through the waste heat recovery equipment, and the by-product high-temperature steam and hot water are used for indirect drying of the original aluminum ash and desulfurized gypsum. The kiln gas exiting the waste heat recovery equipment, the gas temperature is reduced to 855°C, after dust removal, dehumidification purification, supplementary air to adjust the oxygen-sulfur ratio and drying, it enters the fixed bed of activated carbon with a particle size of 10 mesh, and generates elemental sulfur through catalytic reduction. The prepared sulfur The purity reaches 99%. Microwave heating is used to evaporate ...

Embodiment 3

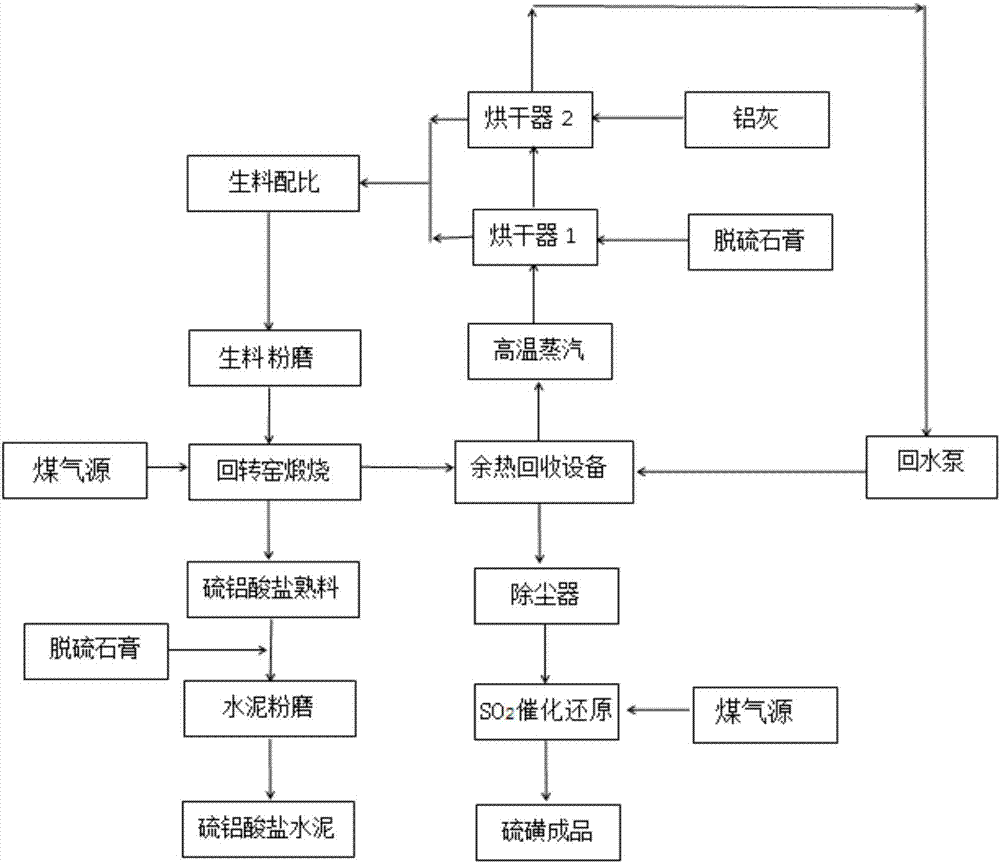

[0074] Such as figure 2 As shown, the aluminum ash and desulfurized gypsum are sent into the dryer respectively. In terms of solid matter after drying, desulfurized gypsum: 65%, aluminum ash: 34%, and activated carbon account for 1%. It is directly conveyed into the hollow rotary kiln, and gas is passed into the rotary kiln for calcination. The calcination temperature is 1300°C and the calcination time is 30 minutes. The high-temperature kiln gas produced passes through the waste heat recovery equipment, and the by-product high-temperature steam and hot water are used for indirect drying of the original aluminum ash and desulfurized gypsum. The kiln gas exiting the waste heat recovery equipment, the gas temperature is reduced to 860°C, and after dust removal, dehumidification purification, supplementary air to adjust the oxygen-sulfur ratio and drying, it enters the two-stage reactor, and each reactor is filled with Cu / Al 2 o 3 Catalyst, and gas is fed into the two-stage re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com