Wet circulation desulfurization process for high-sulfur anode slime

A desulfurization process and anode slime technology, applied in the direction of sulfur compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low desulfurization efficiency, affecting filtration performance, difficult recovery of valuable metals, etc., to improve recovery rate and increase The effect of desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

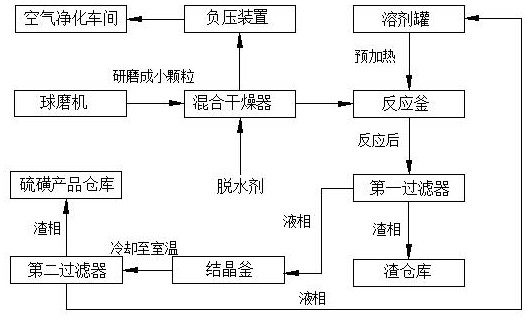

Method used

Image

Examples

Embodiment 1

[0036] Step 1. After grinding 1 ton of high-sulfur anode slime with a water content of 10% into particles in a ball mill, transfer it into a mixing dryer, and add a dehydrating agent (60kg calcium chloride) to the high-sulfur anode slime in the mixing dryer. , A negative pressure device is connected to the mixing dryer, and the negative pressure device is used to remove the moisture to the air purification workshop; when the high-sulfur anode slime is ball-milled in the ball mill, it forms a crystal water compound with calcium chloride.

[0037] Step 2: Transfer the dehydrated and dried high-sulfur anode slime into the reactor, preheat the solvent (carbon disulfide) in the solvent tank to 90°C, and add the solvent (carbon disulfide) into the reactor through the solvent tank.

[0038] Step 3, the product in the step 2 is transferred to the first filter (candle filter), the liquid phase after the first filter (candle filter) filtration is transferred to the crystallization kettle...

Embodiment 2

[0042] Step 1. After grinding 1 ton of high-sulfur anode slime with a water content of 12% into particles in a ball mill, transfer it into a mixing dryer, and add a dehydrating agent (65kg anhydrous magnesium sulfate) to the high-sulfur anode slime in the mixing dryer. ), a negative pressure device is connected to the mixing dryer, and the negative pressure device is used to extract the moisture to the air purification workshop.

[0043] Step 2: Transfer the dehydrated and dried high-sulfur anode slime into the reaction kettle, preheat the solvent (tetrachloroethylene) in the solvent tank to 100°C, and add the solvent (tetrachloroethylene) into the reaction kettle through the solvent tank.

[0044]Step 3, the product in the step 2 is transferred to the first filter (candle filter), the liquid phase after the first filter (candle filter) filtration is transferred to the crystallization kettle for cooling and crystallization, and the crystallization product is cooled to After ro...

Embodiment 3

[0048] Step 1. After grinding 1 ton of high-sulfur anode slime with a water content of 9% into particles in a ball mill, transfer it to a mixing dryer, and add a dehydrating agent (50kg activated alumina) to the high-sulfur anode slime in the mixing dryer. , A negative pressure device is connected to the mixing dryer, and the negative pressure device is used to pump away the moisture to the air purification workshop.

[0049] Step 2: Transfer the dehydrated and dried high-sulfur anode slime into the reactor, preheat the solvent (kerosene) in the solvent tank to 80°C, and add the solvent (kerosene) into the reactor through the solvent tank.

[0050] Step 3, the product in the step 2 is transferred to the first filter (candle filter), the liquid phase after the first filter (candle filter) filtration is transferred to the crystallization kettle for cooling and crystallization, and the crystallization product is cooled to After room temperature, it was transferred to the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com