Process for comprehensively treating and recycling acid waste gypsum

A technology for comprehensive treatment and waste gypsum, applied in the fields of environmental protection and chemical industry, can solve problems such as difficult control, untreated, environmental hazards, etc., and achieves lower thermal catalytic reduction temperature, good advancement and practicability, and reduced chemical oxygen demand. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

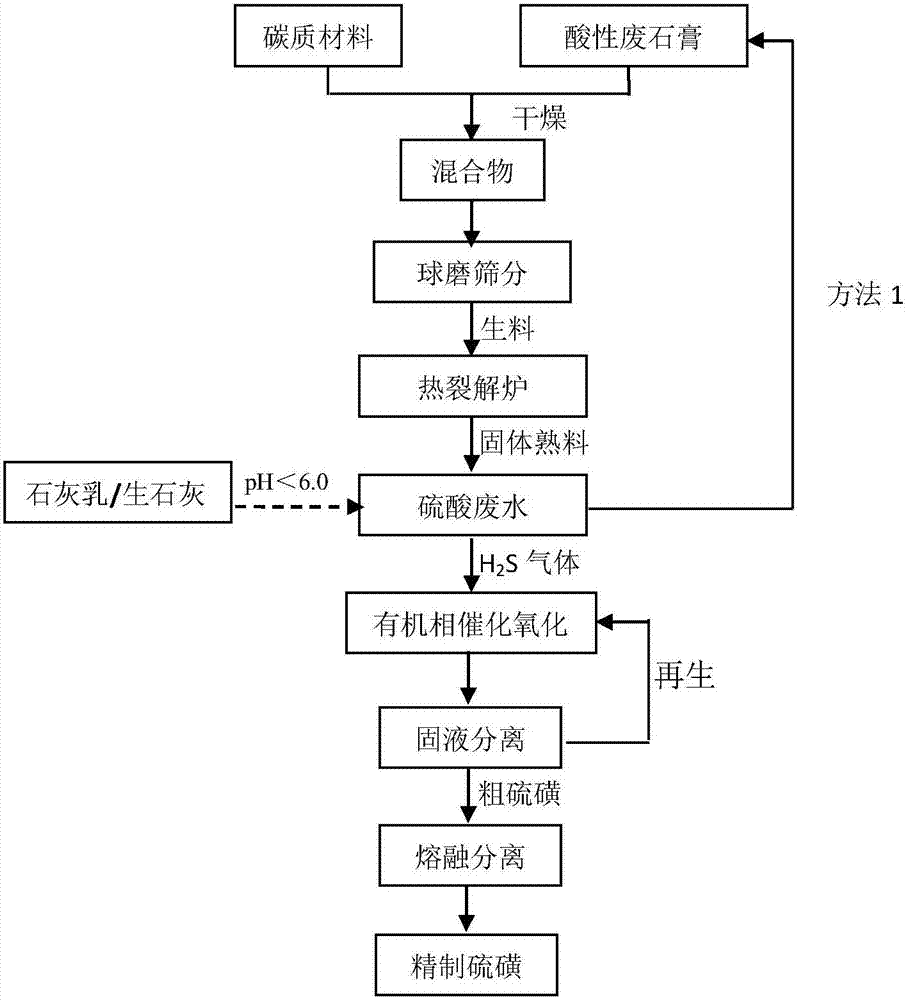

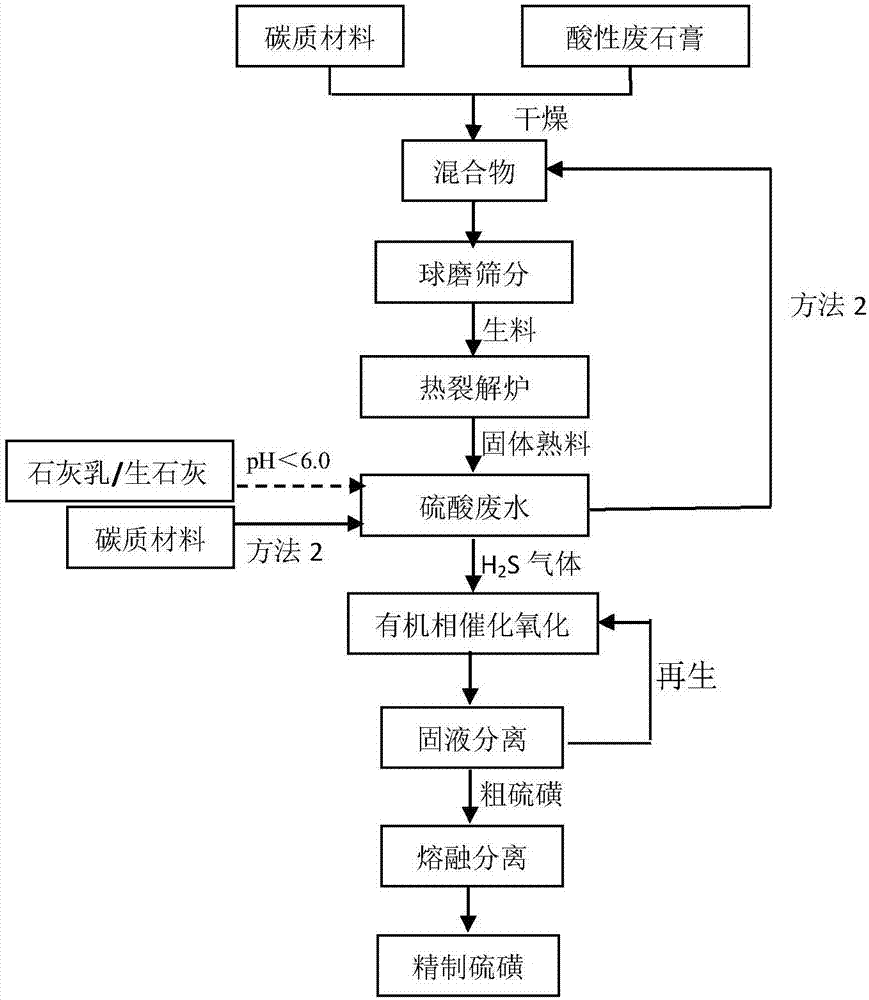

[0044] Refer to the attached figure 1 , a process for comprehensive treatment and recycling of acidic waste gypsum, comprising the following steps:

[0045] (1) Dry acidic waste gypsum and carbonaceous material respectively, the moisture content after drying is 4%, and mix according to the molar mass ratio of carbon of carbonaceous material and calcium of acidic waste gypsum 3.5:1.

[0046] Wherein, the carbonaceous material selects activated carbon, and the mass fraction ω (C) of the elemental carbon content in the activated carbon is 85%; The acid waste gypsum is the mixture of industrial acid waste gypsum and the acid waste gypsum precipitate produced by step (4), The mass fraction of calcium sulfate content in acidic waste gypsum ω(CaSO 4 ) is 85%.

[0047] (2) The mixture of acidic waste gypsum and carbonaceous material is ball milled and sieved to obtain raw meal, and the particle size of the raw meal is 60 mesh.

[0048] (3) Feed the raw material into the thermal cra...

Embodiment 2

[0054] Refer to the attached figure 1 , a process for comprehensive treatment and recycling of acidic waste gypsum, comprising the following steps:

[0055] (1) acid waste gypsum and carbonaceous material are dried respectively, the moisture content of acid waste gypsum after drying is 3%, the moisture content of carbonaceous material is 2%, and according to the carbon of carbonaceous material and the calcium of acid waste gypsum The molar mass ratio is 1.5:1 for mixing.

[0056] Wherein, the carbonaceous material selection coke and petroleum coke are mixed according to any ratio, the mass fraction ω (C) of the elemental carbon content in the coke and petroleum coke mixture is 80%, and the acidic waste gypsum is the acidic waste produced by step (4). Gypsum deposits, the mass fraction ω(CaSO 4 ) is 80%;

[0057] (2) The mixture of acidic waste gypsum and carbonaceous material is ball milled and sieved to obtain raw meal, and the particle size of the raw meal is 20 mesh.

...

Embodiment 3

[0064] Refer to the attached figure 1 , a process for comprehensive treatment and recycling of acidic waste gypsum, comprising the following steps:

[0065] (1) Dry the acidic waste gypsum and carbonaceous materials respectively, and the moisture content after drying is ≤5%, and according to the carbonaceous materials

[0066] The molar mass ratio of carbon and calcium of acid waste gypsum is mixed in 5:1.

[0067] Wherein, the carbonaceous material selects carbon-containing waste residue, and the mass fraction ω (C) of carbon-containing waste residue is 90%; acid waste gypsum is a mixture of industrial acid waste gypsum and acid waste gypsum produced by step (4), and the acid waste The mass fraction of calcium sulfate content in gypsum ω (CaSO 4 ) is 90%.

[0068] (2) The mixture of acidic waste gypsum and carbonaceous material is ball milled and sieved to obtain raw meal, and the particle size of the raw meal is 100 mesh.

[0069] (3) Feed the raw meal into the thermal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com