Method and device for refining sulfur from desulfurized sulfur paste

A technology of sulfur and sulfur paste, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of high impurities in sulfur products and unqualified products, achieve the effect of saving public works consumption and overcoming low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

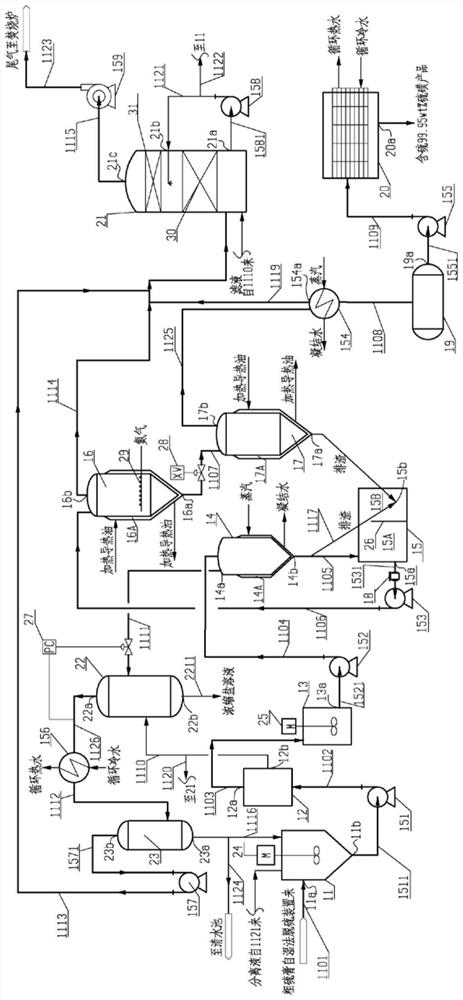

[0034] like figure 1 The device for refining sulfur from desulfurized sulfur paste includes a sulfur paste slurry tank 11 with an agitator assembly 24, a sulfur slurry thickening filter 12, a sulfur slurry buffer tank 13 with an agitator assembly 25, and a sulfur melting kettle 14 , sulfur slurry buffer tank 15, organic matter decomposition kettle 16, liquid sulfur distillation kettle 17, liquid sulfur filter 18, refined liquid sulfur storage tank 19, slicer 20, tail gas scrubber 21 with filler 30, in the vacuum evaporation crystallization unit Vacuum evaporation crystallization tank 22 , flash steam condenser 156 , vacuumized air condensing separator tank 23 and vacuum pump 157 . Wherein, a partition plate 26 is arranged in the liquid sulfur buffer tank 15 to separate the liquid sulfur buffer tank 15 into a liquid sulfur zone 15A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com