A kind of production method of insoluble sulfur

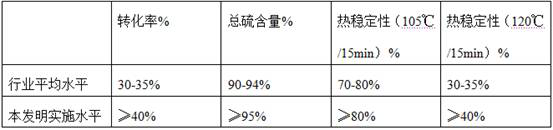

A production method, sulfur technology, applied in the direction of sulfur preparation/purification, etc., can solve the problems of cumbersome transshipment process and low efficiency, and achieve the effect of safe equipment operation and maintenance, high production efficiency, and reduced pollution risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

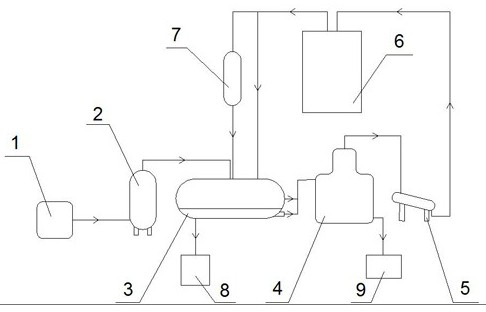

Method used

Image

Examples

Embodiment 1

[0037] The production method of insoluble sulfur, its step is as follows:

[0038](a) Sulfur melting: high-temperature steam is passed into the steam coil in the sulfur melting pool, and the steam coil heats the sulfur powder with a purity of more than 99.95% to a molten state of 110 °C;

[0039] (b) Gasification: The molten liquefied sulfur in the molten sulfur pool is pumped into the sulfur gasification evaporator, and the evaporator heats the sulfur to 450°C to generate high-temperature sulfur vapor, and inert gas is introduced into the evaporator tank to convert the sulfur vapor Press into the sulfur steam pipeline located above the evaporator with a pressure of 0.3MPa; use nitrogen to replace the air in the evaporator tank before using the evaporator;

[0040] (c) Quenching: The high-temperature sulfur steam is passed through the pipeline to the nozzle outlet of the reactor, and the 10°C carbon disulfide liquid nozzle fed into another pipeline is sprayed oppositely in the...

Embodiment 2

[0048] The production method of insoluble sulfur, its step is as follows:

[0049] (a) Sulfur melting: high-temperature steam is introduced into the steam coil in the sulfur melting pool, and the steam coil heats the sulfur powder with a purity of more than 99.95% to a molten state of 130°C;

[0050] (b) Gasification: The molten liquefied sulfur in the molten sulfur pool is pumped into the sulfur gasification evaporator, and the evaporator heats the sulfur to 500°C to generate high-temperature sulfur vapor, and inert gas is introduced into the evaporator tank to convert the sulfur vapor Press into the sulfur steam pipeline located above the evaporator with a pressure of 0.5MPa; use nitrogen to replace the air in the evaporator tank before using the evaporator;

[0051] (c) Quenching: The high-temperature sulfur steam is passed through the pipeline to the nozzle outlet of the reactor, and the 15°C carbon disulfide liquid nozzle fed into another pipeline is sprayed oppositely in...

Embodiment 3

[0059] The production method of insoluble sulfur, its step is as follows:

[0060] (a) Sulfur melting: high-temperature steam is introduced into the steam coil in the sulfur melting pool, and the steam coil heats the sulfur powder with a purity of more than 99.95% to a molten state of 120°C;

[0061] (b) Gasification: The molten liquefied sulfur in the molten sulfur pool is pumped into the sulfur gasification evaporator, and the evaporator heats the sulfur to 480°C to generate high-temperature sulfur vapor, and the inert gas is introduced into the evaporator tank to dissipate the sulfur vapor Press into the sulfur steam pipeline located above the evaporator with a pressure of 0.4MPa; use nitrogen to replace the air in the evaporator tank before using the evaporator;

[0062] (c) Quenching: The high-temperature sulfur steam is passed from the pipeline to the outlet of the reactor nozzle, and the 12°C carbon disulfide liquid nozzle that is fed into another pipeline is sprayed op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com