Method for preparing high-purity sulfur from tail gas containing hydrogen sulfide

A hydrogen sulfide and tail gas technology, applied in the direction of sulfur preparation/purification, etc., can solve the problems of difficult control, low sulfur purity, narrow application range, etc., and achieve high purity, high application value, and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

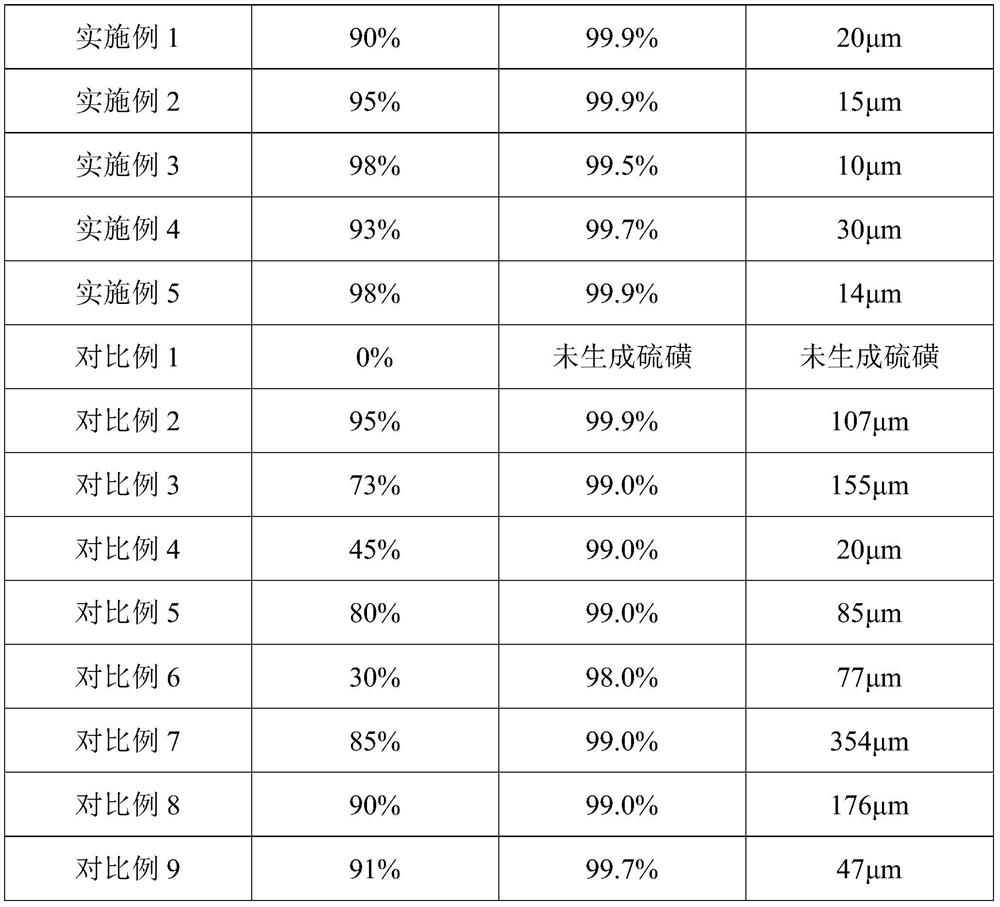

Embodiment 1

[0042] The method adopts sulfuric acid with a mass concentration of 75% as the absorption liquid to absorb hydrogen sulfide-containing tail gas, the hydrogen sulfide content is 5%, the molar ratio of sulfuric acid to hydrogen sulfide is 0.2:1, and the sulfuric acid enters the gas-liquid spray tower from the top and passes through the surface from the bottom. The tail gas of the aeration plate with a pore diameter of 15-20 μm is subjected to countercurrent contact, the reaction time is controlled for 30 minutes, and the reaction temperature is 80°C. The tail gas is subjected to three absorption reactions in series. The final sulfuric acid concentration of each stage of operation is 50%. Separate sulfur and dilute sulfuric acid.

[0043] The index of gained product is shown in table 1.

Embodiment 2

[0045] The method adopts sulfuric acid with a mass concentration of 85% as the absorption liquid to absorb hydrogen sulfide-containing tail gas, the hydrogen sulfide content is 30%, the molar ratio of sulfuric acid to hydrogen sulfide is 0.4:1, and the sulfuric acid enters the bubble tower from the top and passes through the surface pores from the bottom. The tail gas of the aeration plate with a diameter of 15-20 μm is contacted in countercurrent, the reaction time is controlled for 15 minutes, and the reaction temperature is 25°C. The tail gas is subjected to 3 absorption reactions in series. The sulfuric acid concentration at the end of each stage operation is 50%, and the liquid and solid are separated after the reaction Get sulfur and dilute sulfuric acid.

[0046] The index of gained product is shown in table 1.

Embodiment 3

[0048] The method adopts sulfuric acid with a mass concentration of 90% as the absorbing liquid to absorb hydrogen sulfide-containing tail gas, the hydrogen sulfide content is 1%, the molar ratio of sulfuric acid to hydrogen sulfide is 0.6:1, and the sulfuric acid enters the loop reactor from the top and passes through the surface pores from the bottom. The tail gas of the aeration plate with a diameter of 15-20 μm is contacted in countercurrent, the reaction time is controlled for 60 minutes, and the reaction temperature is 30 ° C. The tail gas is subjected to two absorption reactions in series. The final sulfuric acid concentration of each stage operation is 50%, and the liquid and solid are separated after the reaction Get sulfur and dilute sulfuric acid.

[0049] The index of gained product is shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com