A stretchable organic waste residue-based degradable mulch film and its preparation method

A technology for organic waste and degradable mulch, which is applied to floors, buildings, building structures, etc., can solve the problems of unsuitable mechanical film laying, short degradation cycle and high brittleness of mulch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

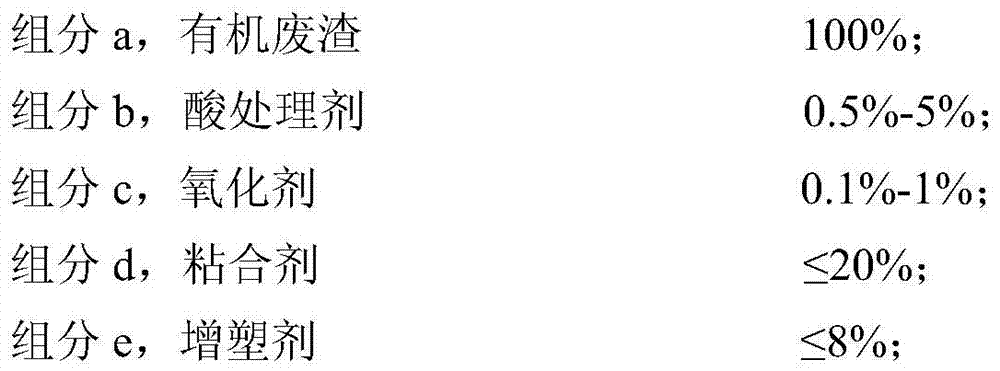

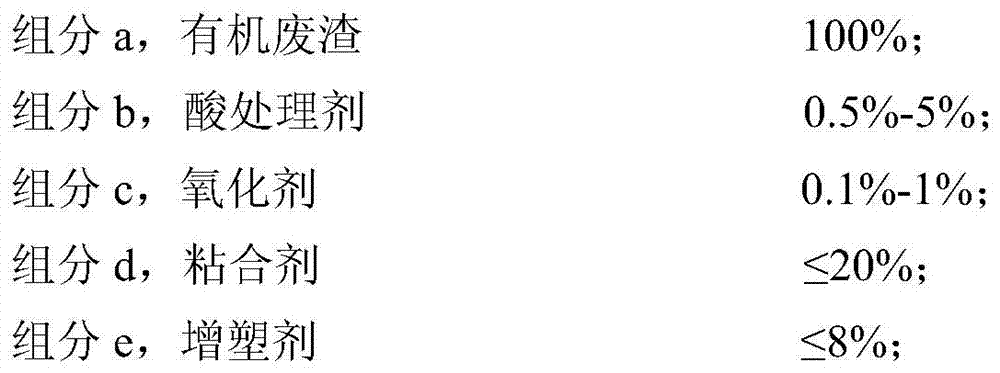

Method used

Image

Examples

preparation example Construction

[0050] The second aspect of the present invention relates to a method for preparing a film as described in the first aspect of the present invention, comprising:

[0051] Step A, preparing the organic waste residue pretreatment liquid: mixing the organic waste residue and tap water according to the solid-to-liquid mass ratio of 1:(2-15) to prepare the organic waste residue pretreatment liquid;

[0052] Step B, preparing a mixed liquid of organic waste residue: adding an acid treatment agent and an oxidant to the pretreatment liquid of organic waste residue, and performing stirring treatment to obtain a mixed liquid of organic waste residue;

[0053] Step C, preparing a film-forming mixed slurry: performing an esterification reaction on the organic waste residue mixed solution under stirring conditions to obtain a film-forming mixed slurry;

[0054] Step D, preparing the film: the film-forming mixed slurry is cast into a film.

[0055] According to the present invention, in st...

Embodiment 1

[0096] Weigh 6 kg of cornstarch residue, and use tap water to prepare a waste residue pretreatment solution with a solid-to-liquid mass ratio of 1:2. 0.9 kg of nitric acid, 0.4 kg of oxalic acid, and 0.36 kg of potassium periodate were added thereto, heated and stirred at 70° C. for 90 min, and the stirring speed was 100 rpm. Weigh 0.5 kg of starch and 0.16 kg of polyvinyl alcohol, prepare a binder solution with a solid-to-liquid mass ratio of 1:17 with tap water, and add 0.83 kg of urea thereto. After blending the pretreatment liquid and the binder solution, add 0.12 kg of ferric chloride and 0.12 kg of zinc acetate, heat and stir at 40° C. for 240 min, and the stirring speed is 150 rpm. After the reaction is over, neutralize the feed solution to neutrality with magnesium oxide. The finished film is made by casting method. The electronic universal testing machine was used to measure the tensile properties of the mulch film, and the prepared mulch film was used in the farmla...

Embodiment 2

[0098] Weigh 300 g of penicillin slag, and use tap water to prepare a waste slag pretreatment solution with a solid-to-liquid mass ratio of 1:5. 35 g of citric acid, 100 g of hydrochloric acid, and 13.5 g of peracetic acid were added thereto, heated and stirred at 90° C. for 15 min, and the stirring speed was 315 rpm. Weigh 5 g of chitosan and 10 g of gelatin, prepare a binder solution with a solid-to-liquid mass ratio of 1:20 with tap water, and add 8.75 g of urea and 7 g of glycerin to it. After blending the pretreatment solution and the binder solution, add 4 g of aluminum potassium sulfate and 5 g of zinc sulfate, heat and stir at 100° C. for 180 min, and the stirring speed is 100 rpm. After the reaction is finished, neutralize the feed solution with ammonia water to neutrality, and make a finished plastic film by casting method. Adopt the method identical with embodiment 1 to evaluate product performance, measurement result is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com