A kind of preparation method of mulberry fiber composite three-dimensional oil-water separation membrane

A technology of oil-water separation membrane and mulberry fiber, which is applied in the field of preparation of mulberry fiber composite three-dimensional oil-water separation membrane, to achieve the effects of solving resource shortage, rapid regeneration cycle, and increased polymerization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

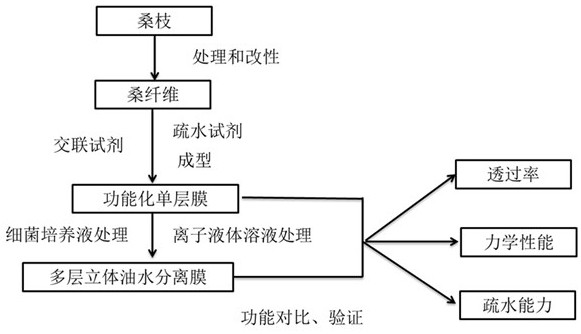

Method used

Image

Examples

Embodiment 1

[0033] Preparation of ionic liquid-sodium hydroxide solution: 90 g of 1-ethyl-3-methylimidazolium diethyl phosphate salt ([EMIM][DEP]) was added to 3 g of sodium hydroxide, stirred and mixed.

[0034] Preparation of mulberry fiber: take 1 g of mulberry branch powder and add it to 20 g of ionic liquid-sodium hydroxide solution, keep stirring at 100 °C for 30 minutes, add water to wash, add 30 U / L of cellulase and laccase, and stir at 50 °C for enzymatic reaction 2h, obtain mulberry fiber;

[0035] Preparation of ionic liquid mixture: 90 g of 1-amido-3-methylimidazolium chloride ([AMIM][Cl]) and 10 g of dimethyl sulfoxide, stir and mix.

[0036] Preparation of monolayer film: Weigh 1 g of mulberry material, add 0.025 g of potassium persulfate, add 10 g of ionic liquid mixture and 0.15 g of deionized water, place in a flask, shake and mix, oil bath for 10 min, temperature is 80 ℃, Then add 0.63 g of butyl methacrylate, 0.5 g of divinyl benzene, oil bath at 70 °C for 3 hours, rem...

Embodiment 2

[0038] The difference from Example 1 is that when preparing the ionic liquid mixture, 85 g of 1-amido-3-methylimidazolium chloride and 15 g of dimethyl sulfoxide are stirred and mixed.

Embodiment 3

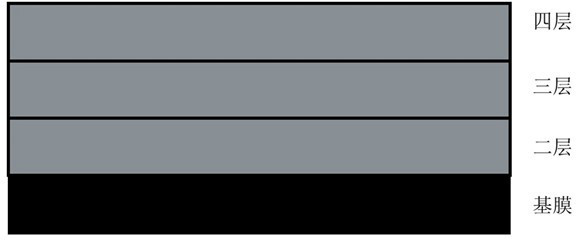

[0040] Preparation of bilayer membrane: Preparation of ionic liquid composite cross-linking reagent: 90 g of ionic liquid and 10 g of 0.15 (wt%) N,N-dimethylaminoethyl methacrylate.

[0041] Preparation of bacterial culture solution: take 1.2 g of glucose, 0.15 g of yeast extract, and 0.15 g of peptone, add 300 mL of distilled water, and adjust the pH of the solution to 6.5. Autoclave at 121°C for 20 minutes. Inoculate 0.5 ml of Acetobacter xylinum seed solution with an inoculation loop, and cultivate at 30° C. for 16 h to obtain a bacterial culture solution.

[0042]Take the single-layer film obtained in Example 1 or 2, and apply 1 g of the ionic liquid composite cross-linking agent on the surface of the film. UV light was used for treatment, and the treatment time was 60 s. 15ml of bacterial culture solution was added, shaken in a shaker, and incubated at 30°C for 2 days. Acetobacter xylinum could produce a bacterial cellulose membrane structure on the membrane surface, whi...

PUM

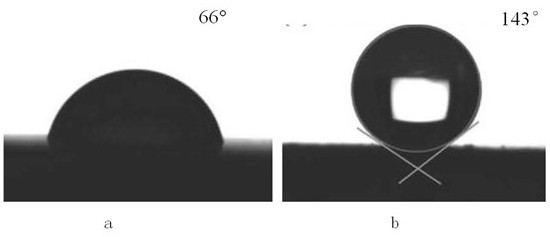

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com