Multilayer composite film of mulberry bark fibroin protein and preparation method thereof

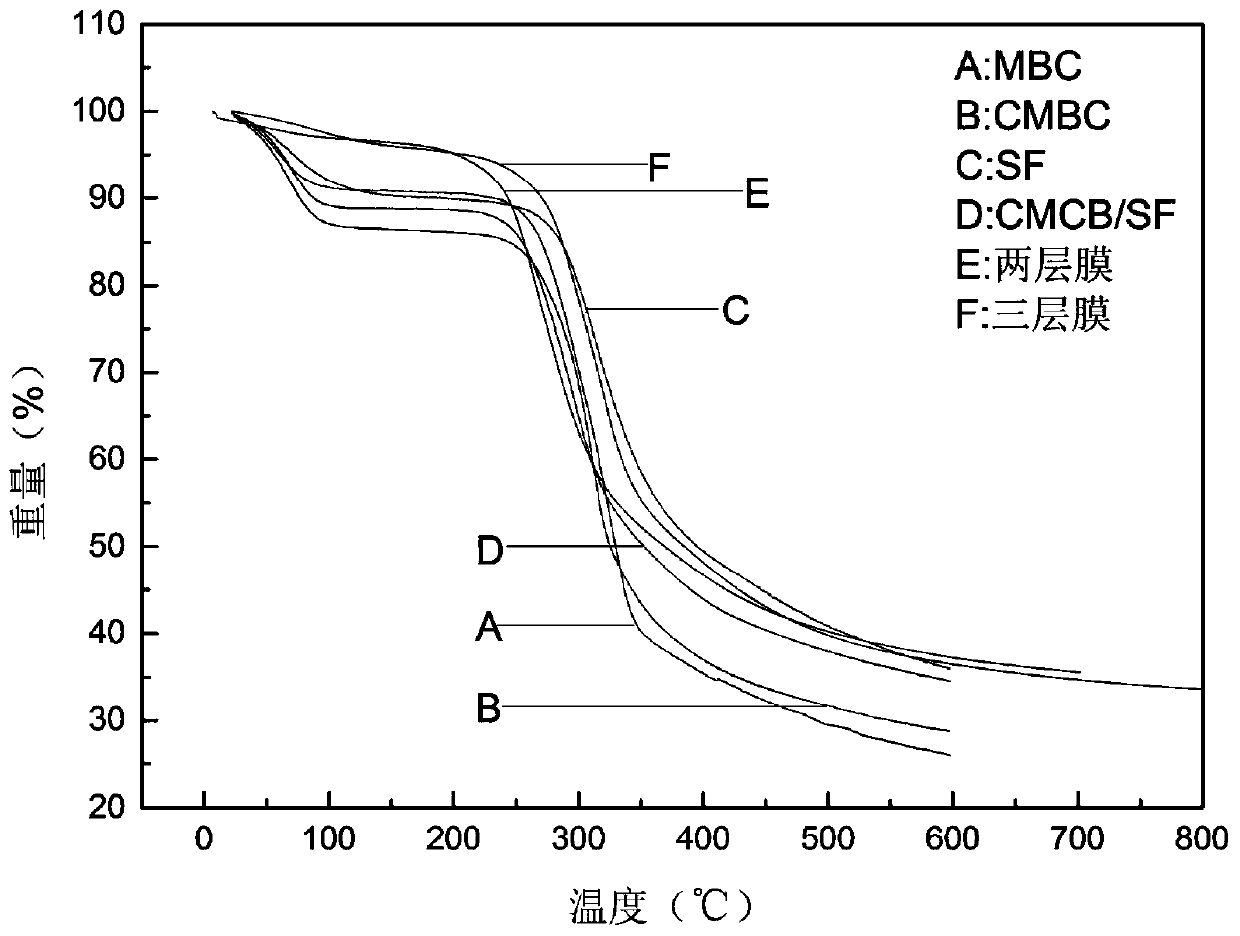

A multi-layer composite film and silk fibroin technology, which is applied in the field of multi-layer composite film of mulberry bark fiber silk fibroin and its preparation, to achieve the effects of rich raw materials, improved mechanical properties, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

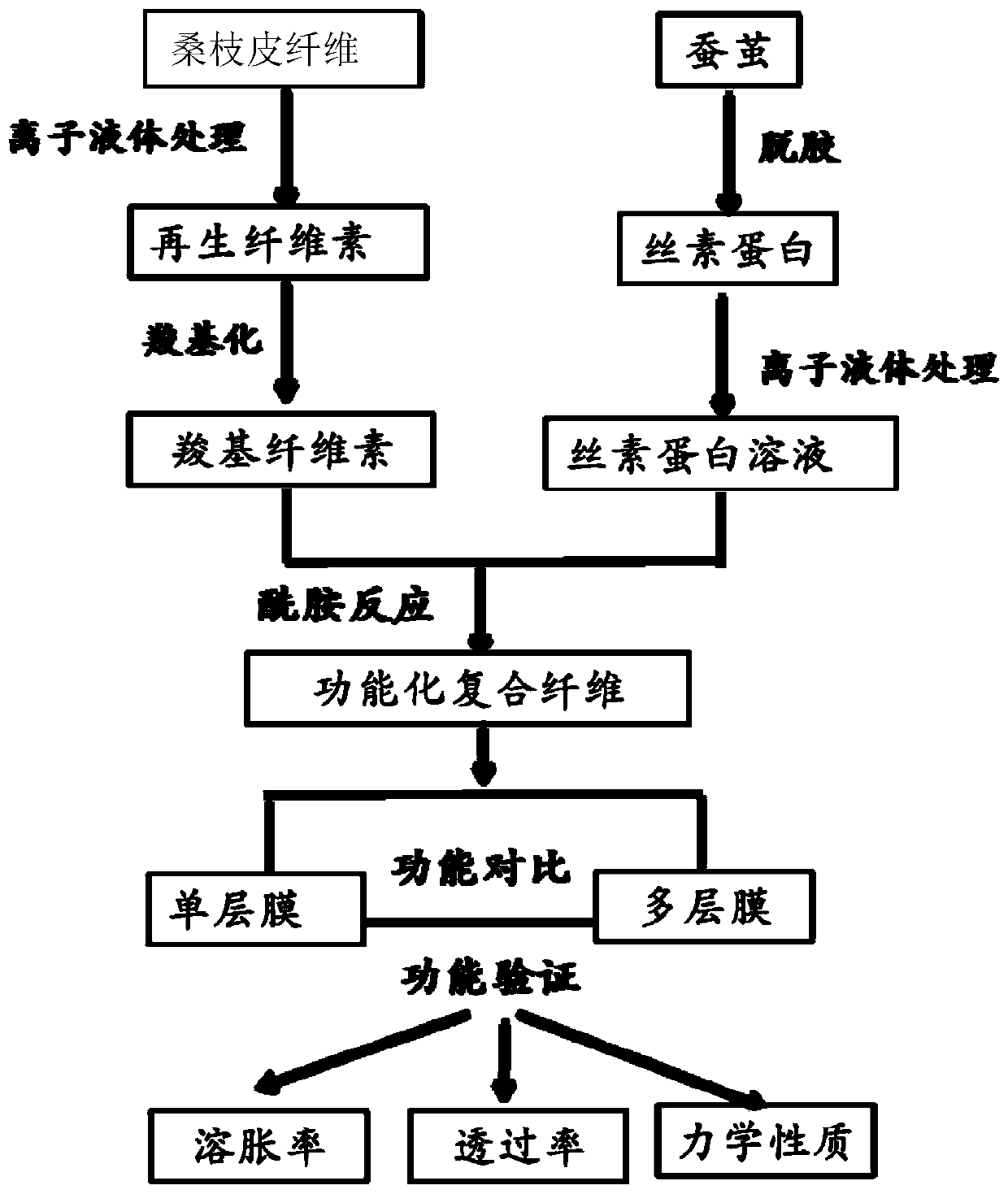

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of mulberry bark fibroin protein multilayer composite film, comprising the steps of:

[0037] (1) Preliminary separation of mulberry bark fiber: treat mulberry bark powder with 4% NaOH solution at room temperature for 2 h with a mass fraction, so that cellulose and hemicellulose are preliminarily separated from lignin;

[0038] (2) Identification of the purity of the mulberry bark fiber content: get 1 g of the mulberry bark fiber obtained in step (1) and carry out reaction treatment with nitric acid ethanol at 1:25 (in V / W), the reaction temperature is 100 ° C, and the reaction time is 70min, calculate the cellulose purity that described step (1) obtains after washing and drying and further separate;

[0039] (3) Modification of mulberry bark fiber: get 3 g of mulberry bark fiber obtained in step (2) and 30 mL of anhydrous pyridine and mix it in a three-necked flask, place it in an ultrasonic cleaning tank for ultrasonic pretreatment, and the ultras...

Embodiment 2

[0044] A preparation method of mulberry bark fibroin protein multilayer composite film, comprising the steps of:

[0045] (1) Preliminary separation of mulberry bark fiber: treat mulberry bark powder with 12% NaOH solution at room temperature for 2 h with a mass fraction, so that cellulose and hemicellulose are preliminarily separated from lignin;

[0046] (2) Identification of the purity of the mulberry bark fiber content: get 1 g of the mulberry bark fiber obtained in step (1) and carry out reaction treatment with nitric acid ethanol at 1:25 (in V / W), the reaction temperature is 100 ° C, and the reaction time is 70min, calculate the cellulose purity that described step (1) obtains after washing and drying and further separate;

[0047] (3) Modification of mulberry bark fiber: get 3 g of mulberry bark fiber obtained in step (2) and 30 mL of anhydrous pyridine and mix it in a three-necked flask, place it in an ultrasonic cleaning tank for ultrasonic pretreatment, and the ultra...

Embodiment 3

[0052] A preparation method of mulberry bark fibroin protein multilayer composite film, comprising the steps of:

[0053] (1) Preliminary separation of mulberry bark fiber: treat mulberry bark powder with a mass fraction of 16% NaOH solution at room temperature for 2 hours, so that cellulose and hemicellulose and lignin are preliminarily separated;

[0054] (2) Identification of the purity of the mulberry bark fiber content: get 1 g of the mulberry bark fiber obtained in step (1) and carry out reaction treatment with nitric acid ethanol at 1:25 (in V / W), the reaction temperature is 100 ° C, and the reaction time is 70min, calculate the cellulose purity that described step (1) obtains after washing and drying and further separate;

[0055] (3) Modification of mulberry bark fiber: get 3 g of mulberry bark fiber obtained in step (2) and 30 mL of anhydrous pyridine and mix it in a three-necked flask, place it in an ultrasonic cleaning tank for ultrasonic pretreatment, and the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com