Green and high-efficiency mine pavement dust suppressant and preparation method thereof

A dust suppressant and high-efficiency technology, applied in the field of environmental pollution control, can solve the problems of poor wettability, short dust suppression time, soil pollution, etc., and achieve the effects of increasing dust particles, keeping soil moist, and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

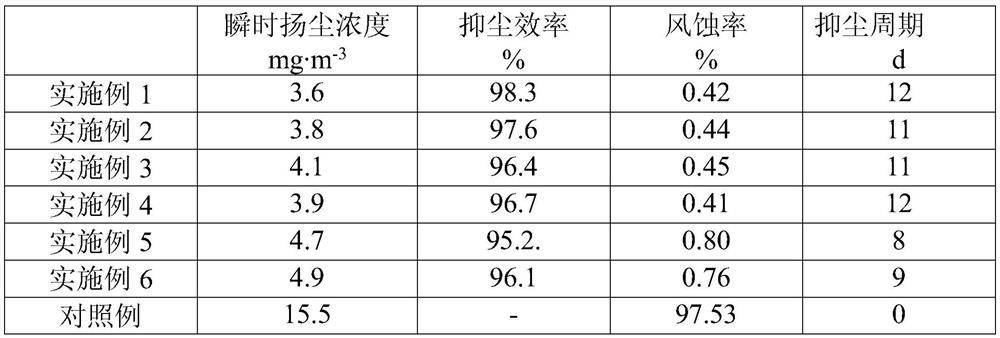

Examples

Embodiment 1

[0021] A green and high-efficiency mine pavement dust suppressant, comprising the following components in mass percentage: 25% of calcium magnesium lactate, 0.25% of calcium lignosulfonate grafted polyacrylic acid / acrylamide compound, 0.06% of cardanol betaine, Glycerin 0.6%, the balance is deionized water.

[0022] Wherein, the calcium-magnesium lactate salt includes 20% of calcium lactate and 80% of magnesium lactate in terms of mass percentage.

[0023] The preparation method of above-mentioned green high-efficiency mine pavement dust suppressant is:

[0024] (1) Add deionized water and calcium lignosulfonate grafted polyacrylic acid / acrylamide compound into a stirring tank, stir until uniformly mixed, and obtain mixture A;

[0025] (2) Add the calcium-magnesium lactate, cardanyl betaine and glycerin to the mixture A respectively, stir until completely dissolved, and let stand for 60-90 minutes to obtain a green and high-efficiency mine pavement dust suppressant.

Embodiment 2

[0027] A green and high-efficiency mine pavement dust suppressant, comprising the following components in mass percent: calcium magnesium lactate 15%, calcium lignosulfonate grafted polyacrylic acid / acrylamide compound 0.1%, cardanol phenolic betaine 0.01%, Glycerin 0.2%, the balance is deionized water.

[0028] Wherein, the calcium magnesium lactate salt includes 80% calcium lactate and 20% magnesium lactate in terms of mass percentage.

Embodiment 3

[0030] A green and high-efficiency mine pavement dust suppressant, comprising the following components in mass percent: 30% of calcium magnesium lactate, 0.3% of calcium lignosulfonate grafted polyacrylic acid / acrylamide compound, 0.15% of cardanyl phenolic betaine, Glycerin 1%, the balance is deionized water.

[0031] Wherein, the calcium magnesium lactate salt includes 50% calcium lactate and 50% magnesium lactate in terms of mass percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com