Method for preparing carbon-based transition metal sulfide composite electrode material based on pyrolytic bio-oil

A transition metal and composite electrode technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, hybrid capacitor electrodes, etc., can solve the problems of high cost and complicated preparation process, and achieve low price, simple preparation process and simplified preparation The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

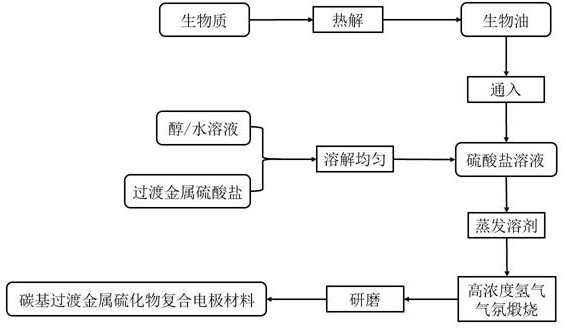

Method used

Image

Examples

Embodiment 1

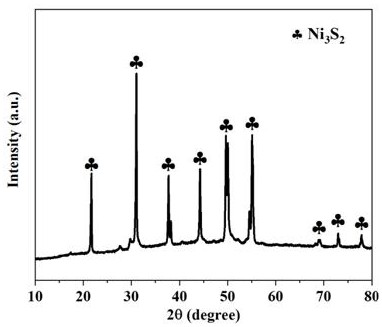

[0030] Preparation of carbon-based Ni from bio-oil 3 S 2 / C-1-550-1 composite electrode material, including the following steps:

[0031] (1) Prepare bio-oil absorption solution, in which the volume ratio of methanol to water is 1:2, add nickel sulfate to the absorption solution to make the mass concentration of nickel sulfate solution 1%, and then stir with a magnetic stirrer for 40 min to make Nickel sulfate is fully dissolved evenly, then take 1 part of the quality of the solution and put it into a bio-oil collection device;

[0032] (2) Add 1 mass of sycamore leaves to the tube furnace, connect the bio-oil collection device, connect the bio-oil collection device, and then raise the temperature of the tube furnace to 600°C under nitrogen atmosphere, and keep it warm for 1 h;

[0033] (3) Dry the collected bio-oil in an explosion-proof blast drying oven at 80°C for 18 h, then transfer the sample to a tube furnace for calcination at a gas flow rate of 60 ml / min, where H 2 ...

Embodiment 2

[0035] Preparation of Ni from bio-oil 3 S 2 / C-3-550-1 composite electrode material, including the following steps:

[0036] (1) Prepare bio-oil absorption solution, in which the volume ratio of methanol to water is 1:2, add nickel sulfate to the absorption solution to make the mass concentration of nickel sulfate solution 3%, and then stir with a magnetic stirrer for 40 min to make Nickel sulfate is fully dissolved evenly, then take 1 part of the quality of the solution and put it into a bio-oil collection device;

[0037] (2) Add 1 mass of sycamore leaves to the tube furnace, connect the bio-oil collection device, connect the bio-oil collection device, and then raise the temperature of the tube furnace to 600°C under nitrogen atmosphere, and keep it warm for 1 h;

[0038] (3) Dry the collected bio-oil in an explosion-proof blast drying oven at 80°C for 18 h, then transfer the sample to a tube furnace for calcination at a gas flow rate of 60 ml / min, where H 2 :N 2 =30 ml:...

Embodiment 3

[0040] Preparation of Ni from bio-oil 3 S 2 / C-5-550-1 composite electrode material, including the following steps:

[0041] (1) Prepare bio-oil absorption solution, in which the volume ratio of methanol to water is 1:2, add nickel sulfate to the absorption solution to make the mass concentration of nickel sulfate solution 5%, and then stir with a magnetic stirrer for 40 min to make Nickel sulfate is fully dissolved evenly, then take 1 part of the quality of the solution and put it into a bio-oil collection device;

[0042] (2) Add 1 mass of sycamore leaves to the tube furnace, connect the bio-oil collection device, connect the bio-oil collection device, and then raise the temperature of the tube furnace to 600°C under nitrogen atmosphere, and keep it warm for 1 h;

[0043] (3) Dry the collected bio-oil in an explosion-proof blast drying oven at 80°C for 18 h, then transfer the sample to a tube furnace for calcination at a gas flow rate of 60 ml / min, where H 2 :N2 =30 ml: 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com