Anti-jamming method for sludge scraper of power-plant wastewater concentration treatment pond

A technology for power plant waste water and mud scraper, which is applied in separation methods, chemical instruments and methods, feeding/discharging devices of sedimentation tanks, etc. It can avoid the environmental pollution risks of manual dredging, avoid long-term continuous working mode, and improve the effect of sludge treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

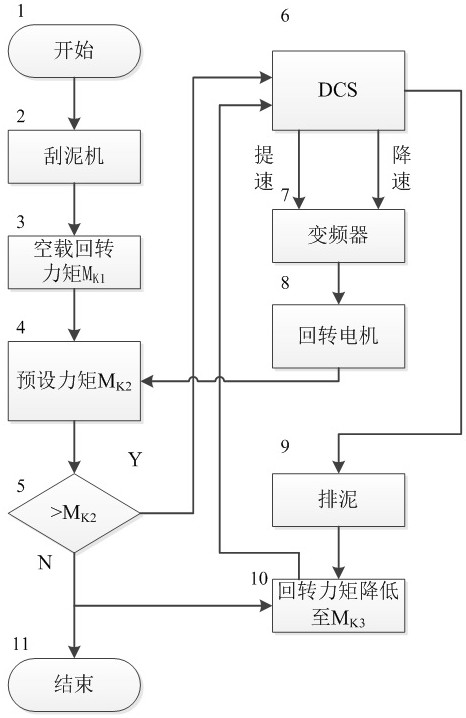

[0023] Such as figure 1 Shown is a block diagram of the operating principle of the present invention. The present invention provides a method for preventing the mud scraper from being stuck in the waste water concentration treatment pool of a power plant. The method is to drive and control the rotary harrow motor of the mud scraper through a The torque of the rotary harrow of the mud machine is continuously measured in the process of scraping mud, and the torque obtained through continuous measurement is used to judge the degree of sludge accumulation in the treatment tank. The torque value obtained by the DCS control system is used to control the variable frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com