Combined type gas full-cycle gas retort

A gas full-circulation, retorting furnace technology, used in special forms of retorting, direct heating retorting, coke ovens, etc., can solve problems such as difficult, difficult to evenly distribute gas in retorting furnaces, achieve smooth flow, reduce processing capacity, improve The effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

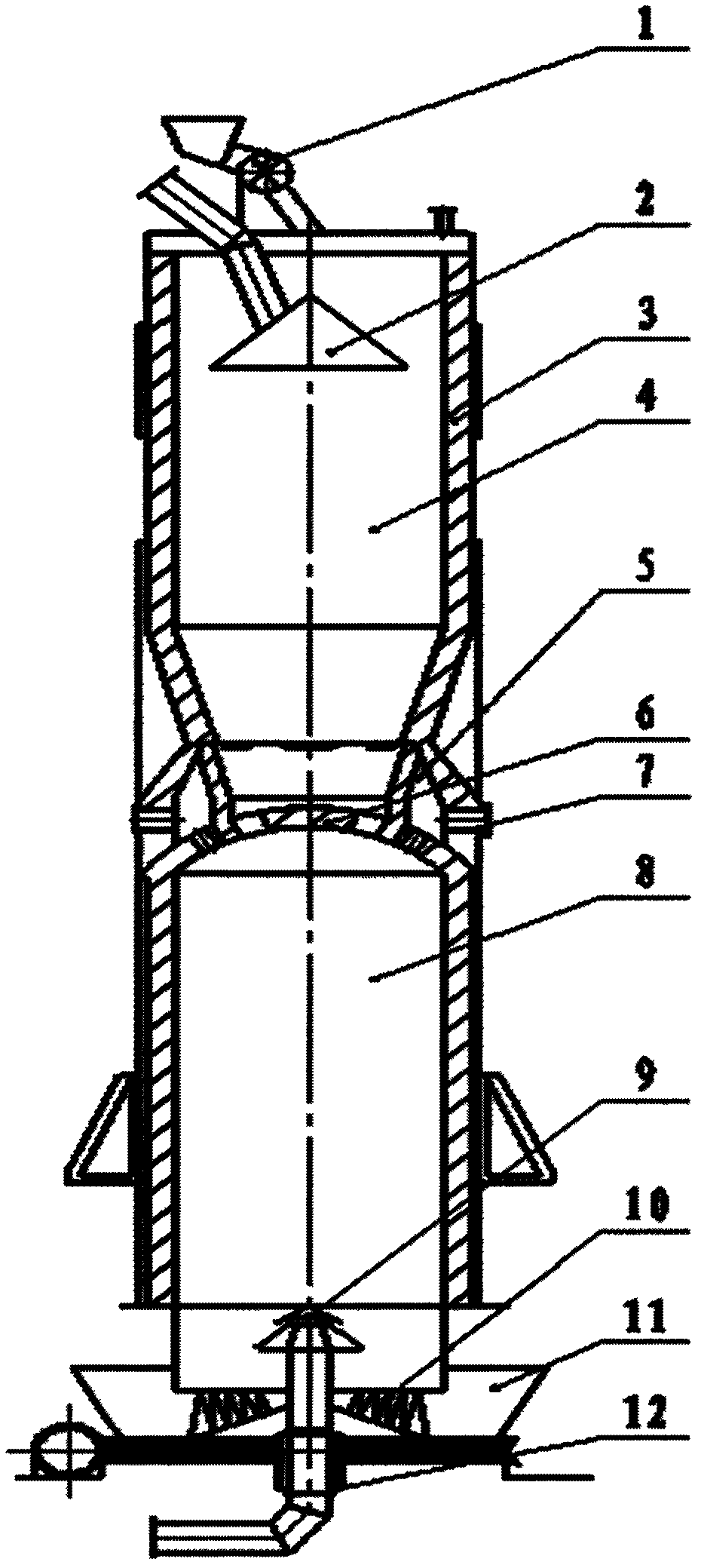

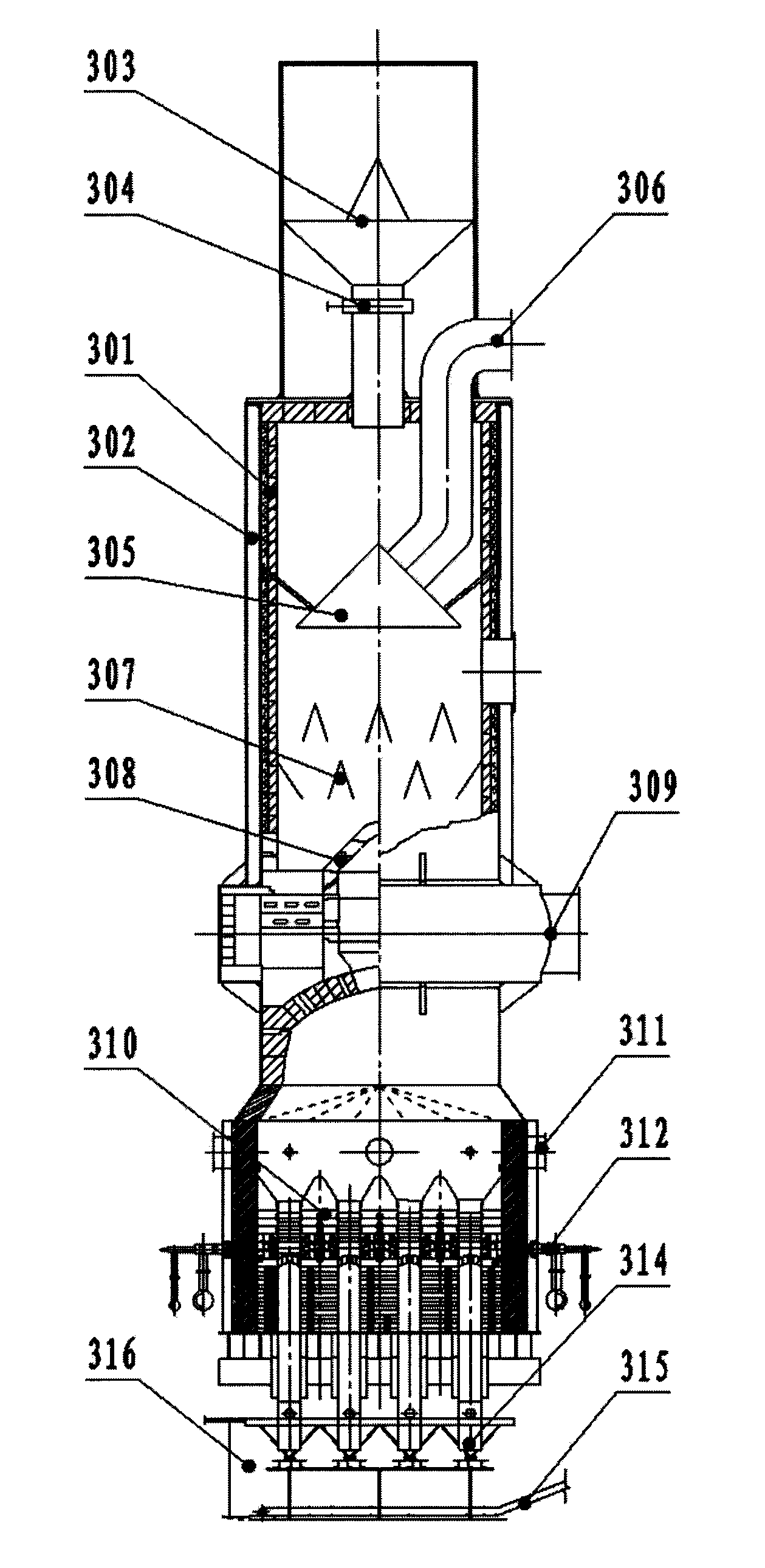

[0043] Figure 4 It is the carbonization subunit structure and working principle diagram of the combined gas full cycle oil shale carbonization furnace. After crushing and screening, the oil shale that meets the technical requirements of the carbonization furnace is added from the upper part of the carbonization furnace through the feeder 403 . After the oil shale is added from the upper part of the retort furnace, it is distributed by the herringbone beam 421 and the herringbone baffle 406 and then falls evenly. During the falling process, the oil shale is in contact with the thermal cycle gas introduced from the lower part, and is heated to 500°C to 540°C for dry distillation. The cold cycle gas at about 40°C enters the cold cycle gas channel 417 in the gas distribution flower wall 409 from the cold cycle gas inlet pipe 410; the cold cycle gas channel 417 is provided with a cold cycle gas nozzle 411, which sprays the cold cycle gas outward, and the cold cycle gas The gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com