An entrainment-controlled flow-type supercritical extraction pharmaceutical equipment

A pharmaceutical equipment and supercritical technology, applied in solvent extraction, solid solvent extraction, separation methods, etc., can solve the problems of increased extraction cost, reduced extraction efficiency, low single-pass extraction rate, etc., to improve extraction efficiency and effect, and avoid material The effect of leakage, efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

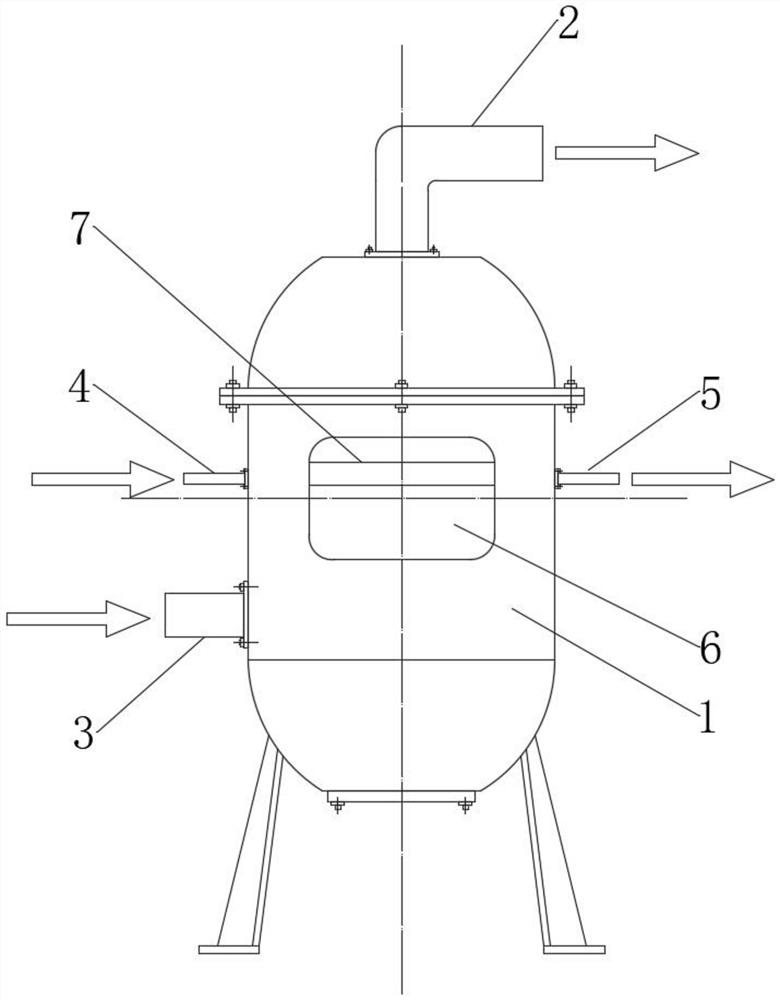

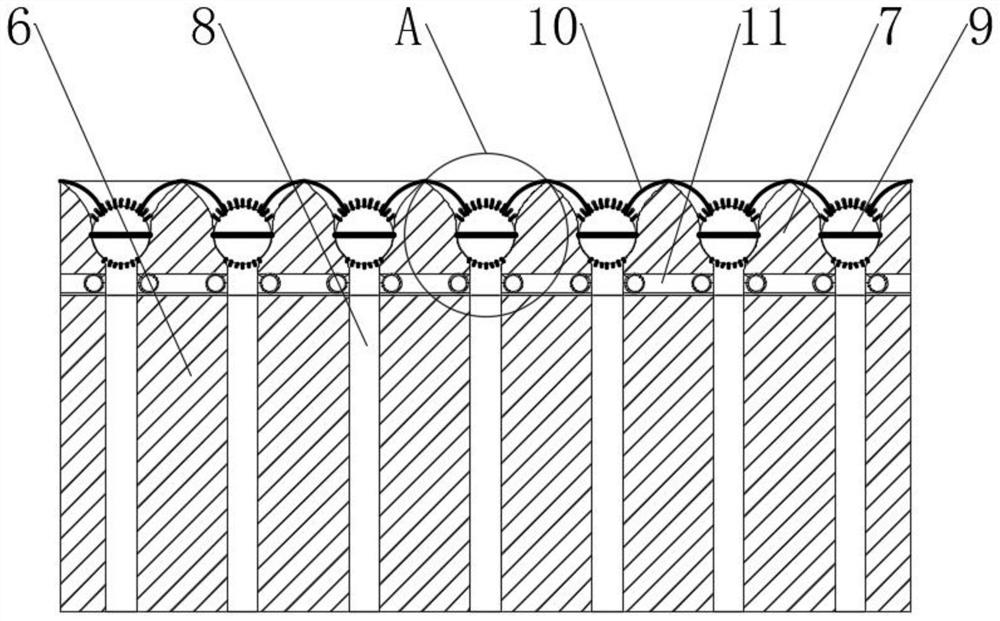

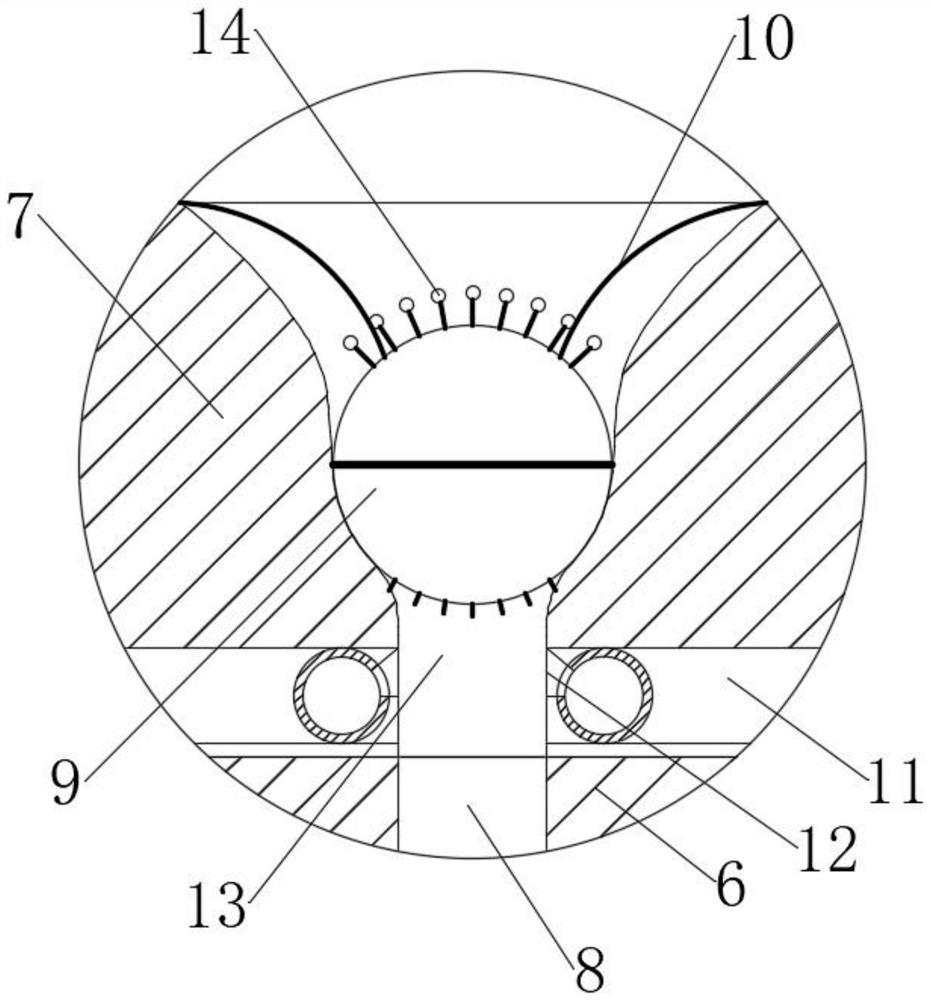

[0043] See Figure 1-2 An entrained flow controlled pharmaceutical supercritical extraction apparatus, comprising an extraction vessel, an extraction vessel upper and lower ends are respectively connected to an output pipe 2 and the input tube 3, tank 1 is attached to the extraction flow separator 6, an upper table 6 mounted split there extraction stage 7, and extracted about 7 units connected to both ends of the feed pipe 4 and outlet pipe 5, 8 split split vertical hole table 6 defines a plurality of uniformly distributed, the extraction stage 7 defines a plurality of uniformly distributed extraction holes 13, and the extraction aperture 13 of the shunt vertical hole 8 correspond to each other, and extracted the station 7 inlaid attached net-shaped tube 11, and the net-shaped tube 11 respectively feed conduit 4 and the outlet tube connected five-port, network type tube 11 comprises a plurality of interconnected annular tube, and an annular tube surrounding the hole 13 to the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com