Thermoplastic elastomer corner connecting material for bonding ethylene propylene diene monomer and preparation method of thermoplastic elastomer corner connecting material

A technology of EPDM rubber and thermoplastic elastomer, which is applied in the field of thermoplastic elastomer corner material, can solve the problems of easy shrinkage pits due to material shrinkage, poor bonding of thin and narrow edges, and high bonding strength, and achieve shrinkage. Low, convenient injection molding processing, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The above-mentioned preparation method for bonding the thermoplastic elastomer corner material of EPDM rubber may further comprise the steps:

[0049] 1) Mix 5-10 parts by weight of low-molecular-weight SEBS and 15-35 parts by weight of medium-molecular-weight SEBS in a low-mixer to fully mix the aggregated blocks for 5-20 minutes, add 15-35 parts by weight of naphthenic oil for oil extension, Static oil filling time is 1-10h;

[0050] 2) Weigh 5-10 parts by weight of polypropylene and 10-20 parts by weight of maleic anhydride grafted polypropylene and add them into the SEBS filled with oil in step 1), mix them in a low mixer for 5-10 minutes, and mix evenly;

[0051] 3) Weigh 0.1-2 parts by weight of additives, 0.1-0.5 parts by weight of antioxidant and 1-5 parts by weight of black masterbatch, add them to the mixture obtained in step 2), and mix in a low mixer for 1-5 minutes, mix well;

[0052] 4) Weigh 10-25 parts by weight of the filler and add it to the mixture ...

Embodiment 1

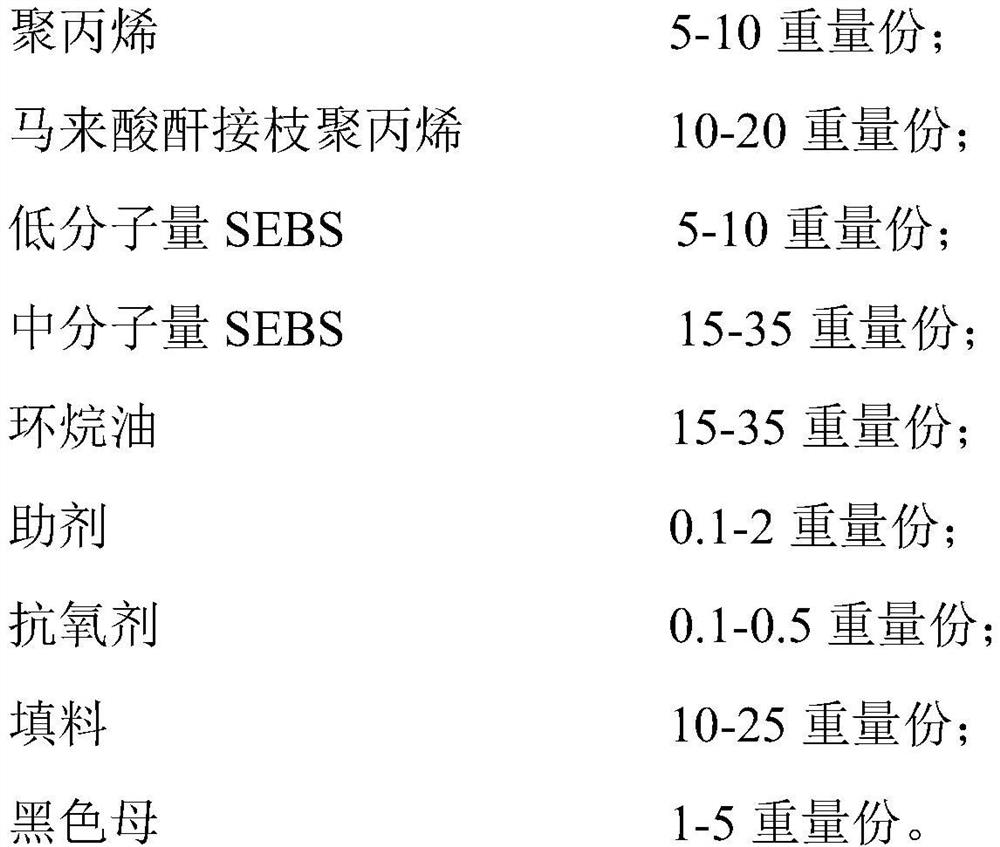

[0056] A thermoplastic elastomer corner material for bonding EPDM rubber, comprising the following components in parts by weight:

[0057]

[0058]

[0059] The above-mentioned preparation method of the thermoplastic elastomer corner material for bonding EPDM rubber may further comprise the steps:

[0060] 1) After fully mixing low molecular weight SEBS and medium molecular weight SEBS in a low mixer for 10 minutes, add naphthenic oil for oil extension, and the static oil extension time is 10 hours;

[0061] 2) Weighing polypropylene and maleic anhydride grafted polypropylene and adding them to the SEBS filled with oil in step 1), mixing in a low mixer for 5 minutes, and mixing evenly;

[0062] 3) Weigh the auxiliary agent, antioxidant and black masterbatch and add it to the mixture in step 2), mix it in a low mixer for 3 minutes, and mix thoroughly;

[0063] 4) Weigh the filler and add it to the mixture in step 3), mix it in a low mixer for 10 minutes, and mix thorough...

Embodiment 2

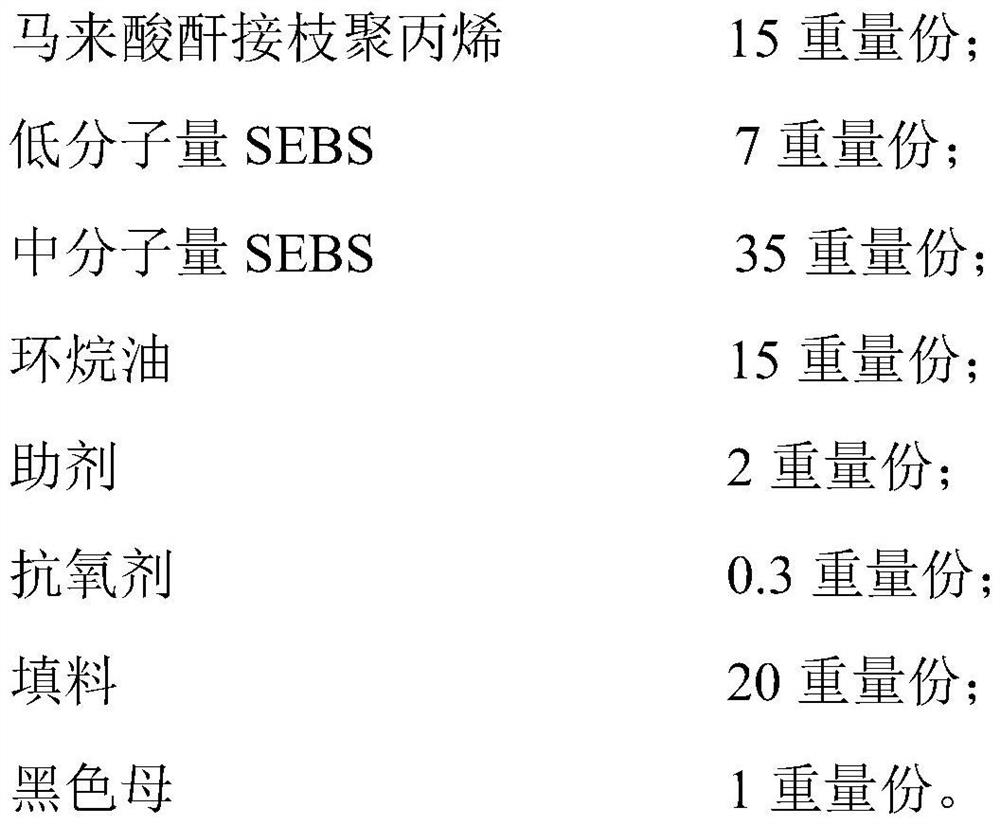

[0066] A thermoplastic elastomer corner material for bonding EPDM rubber, comprising the following components in parts by weight:

[0067]

[0068]

[0069] The preparation method of the scrap material of the present embodiment 2 is the same as that of the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com