Patents

Literature

45results about How to "Easy for injection molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

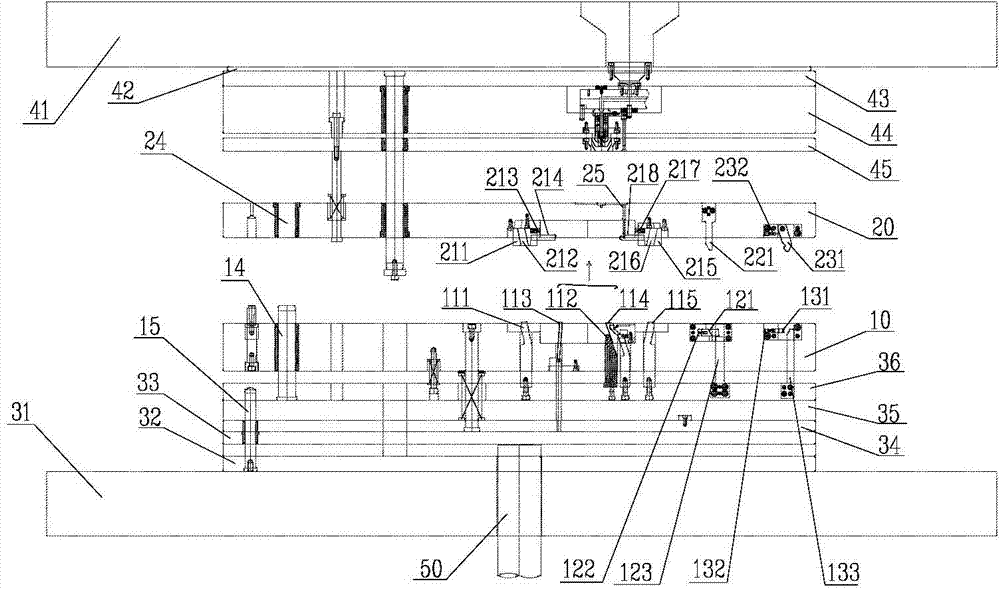

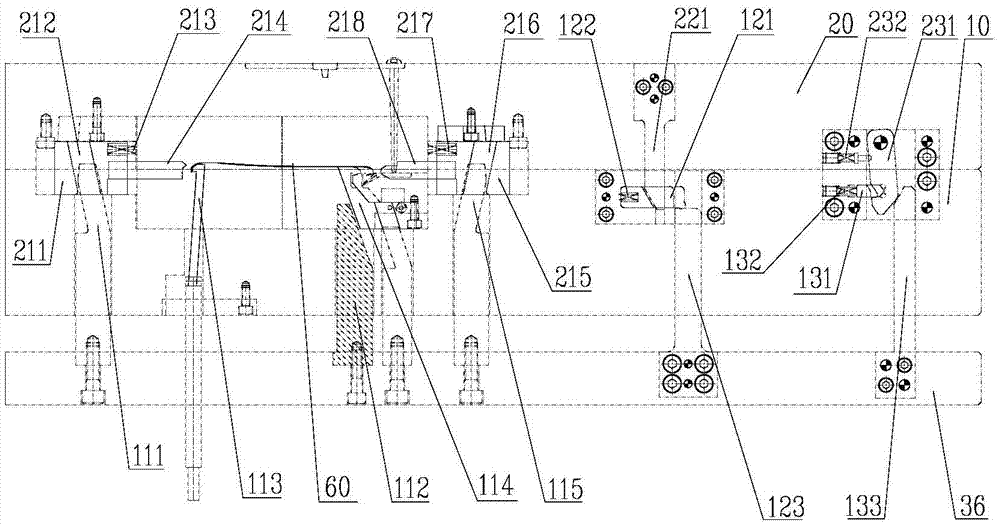

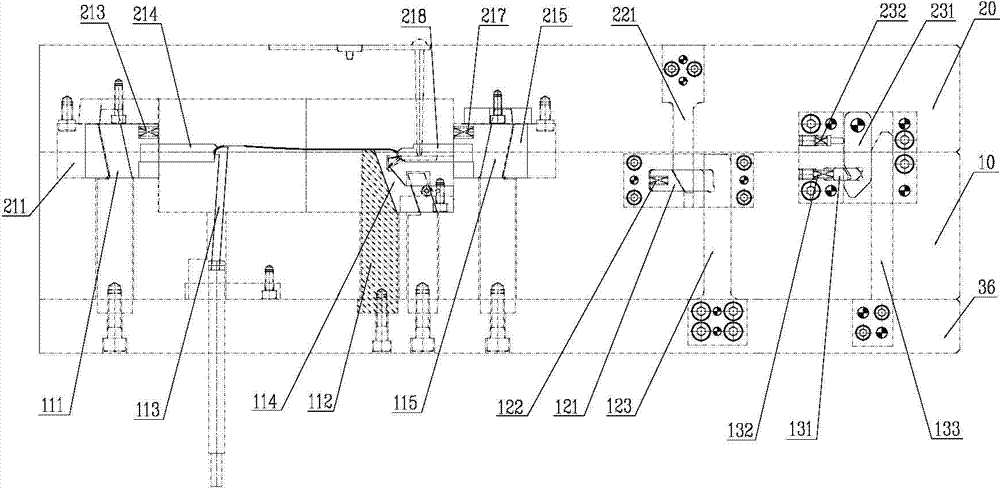

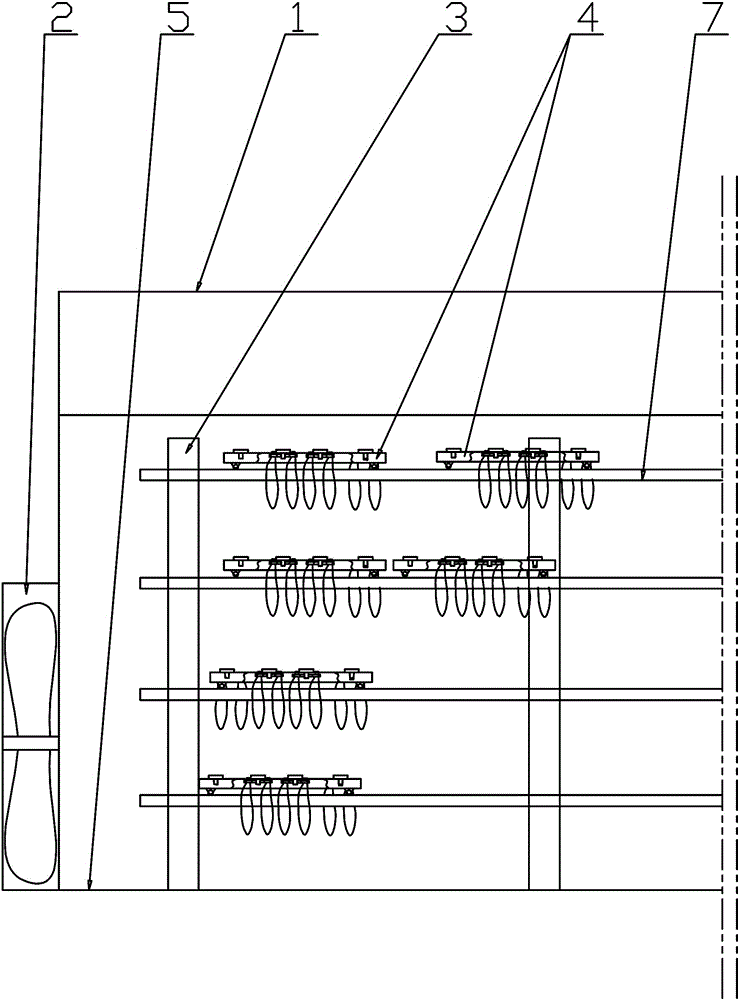

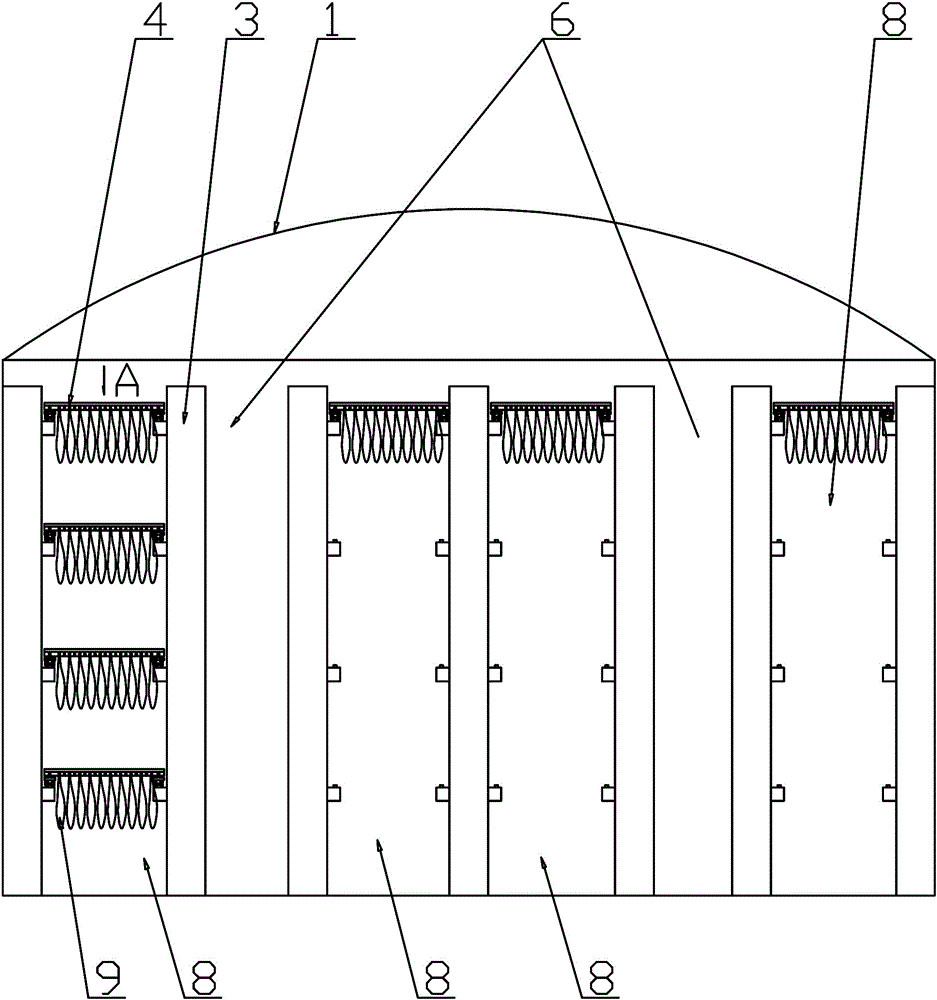

Sun-cure shed for sun-cured tobaccos, sun-cure devices and tobacco clips

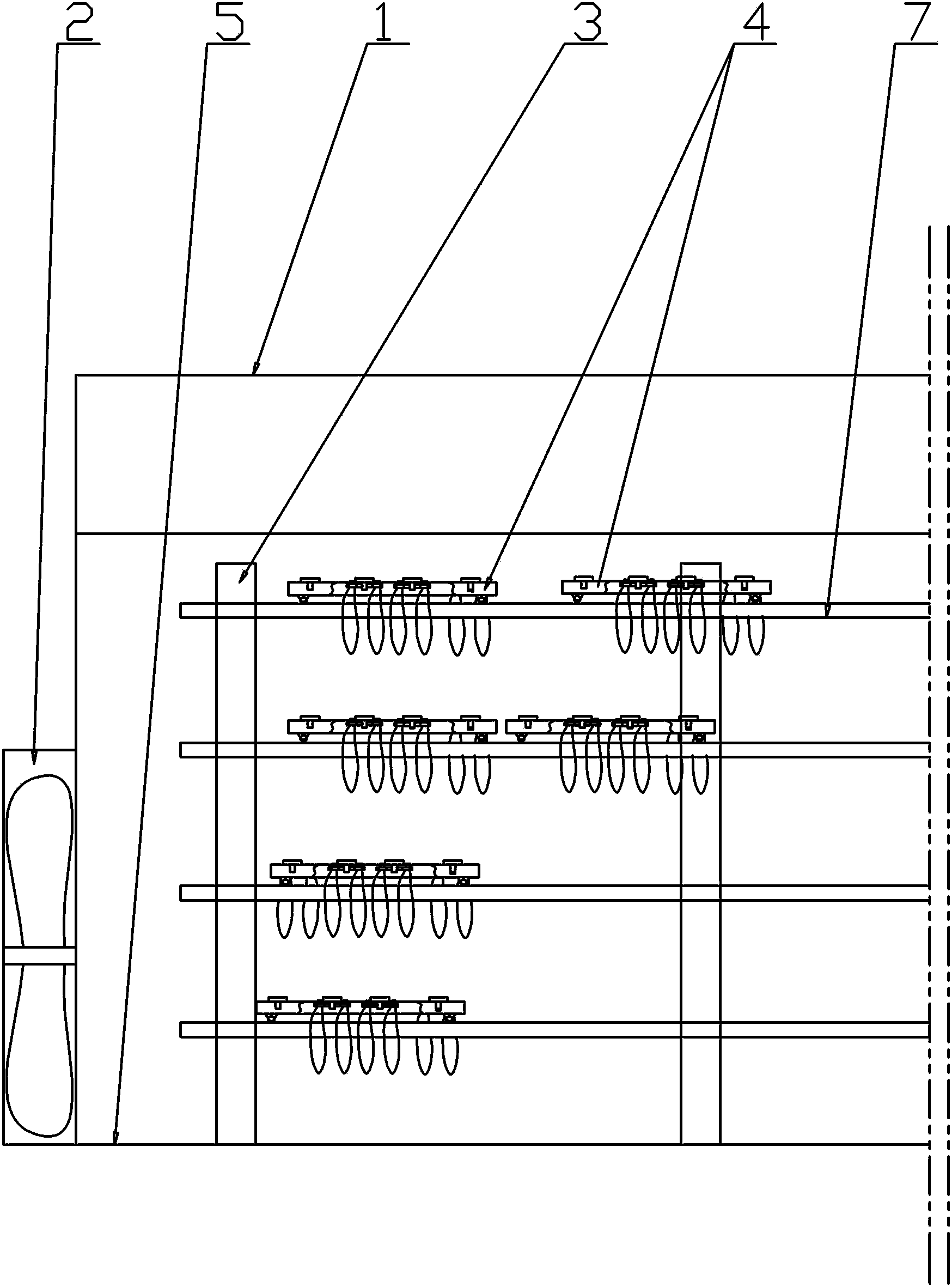

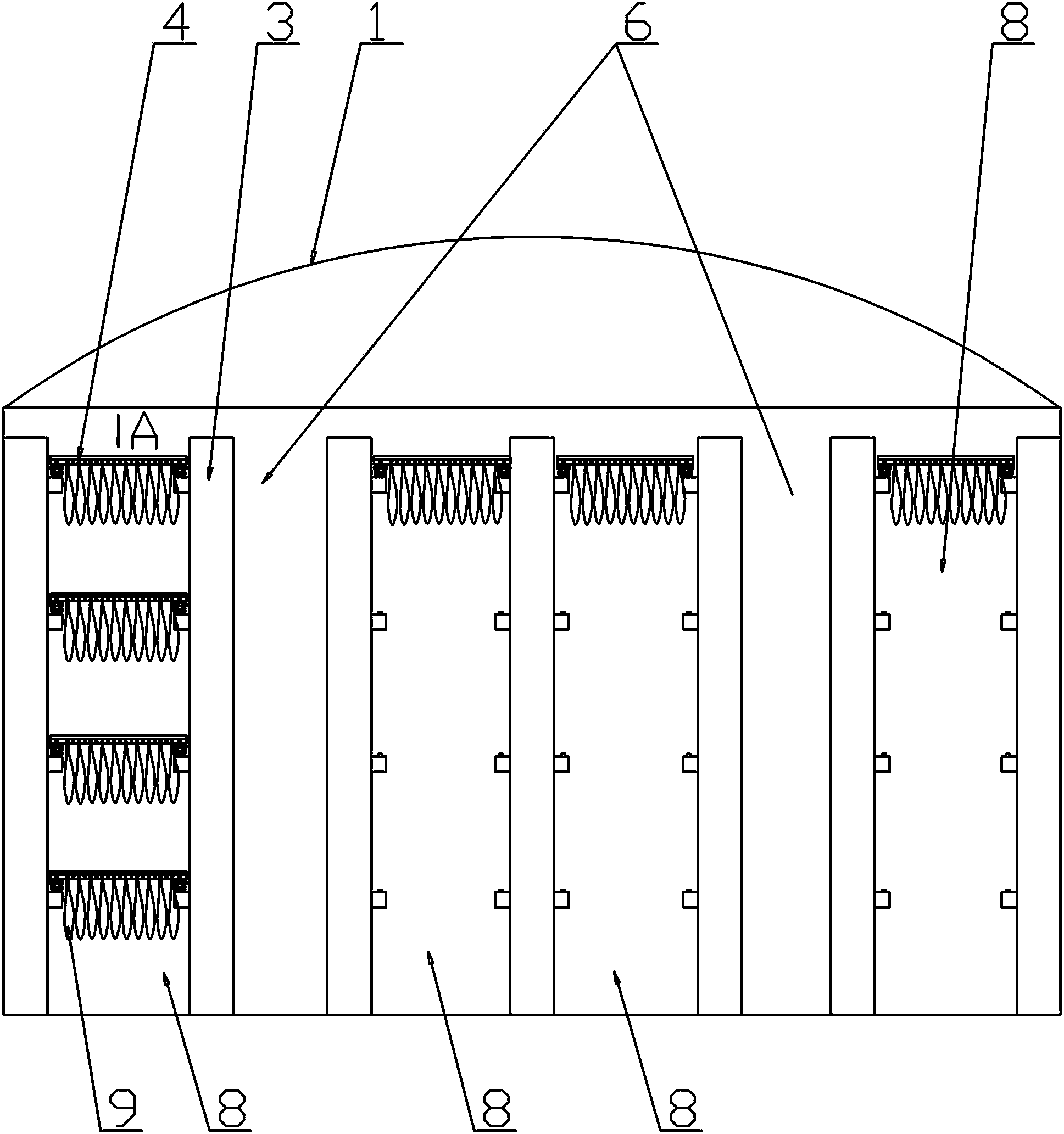

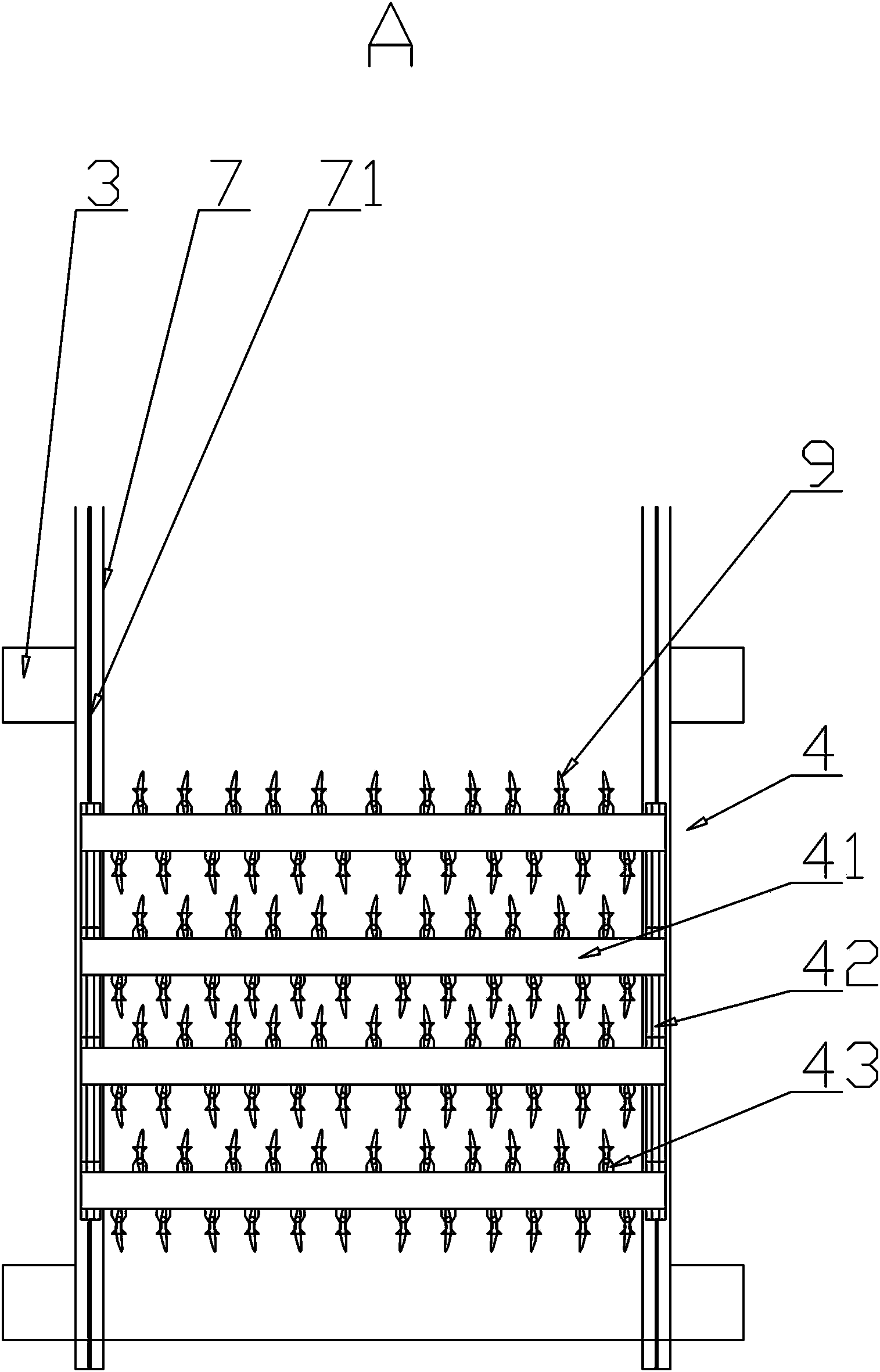

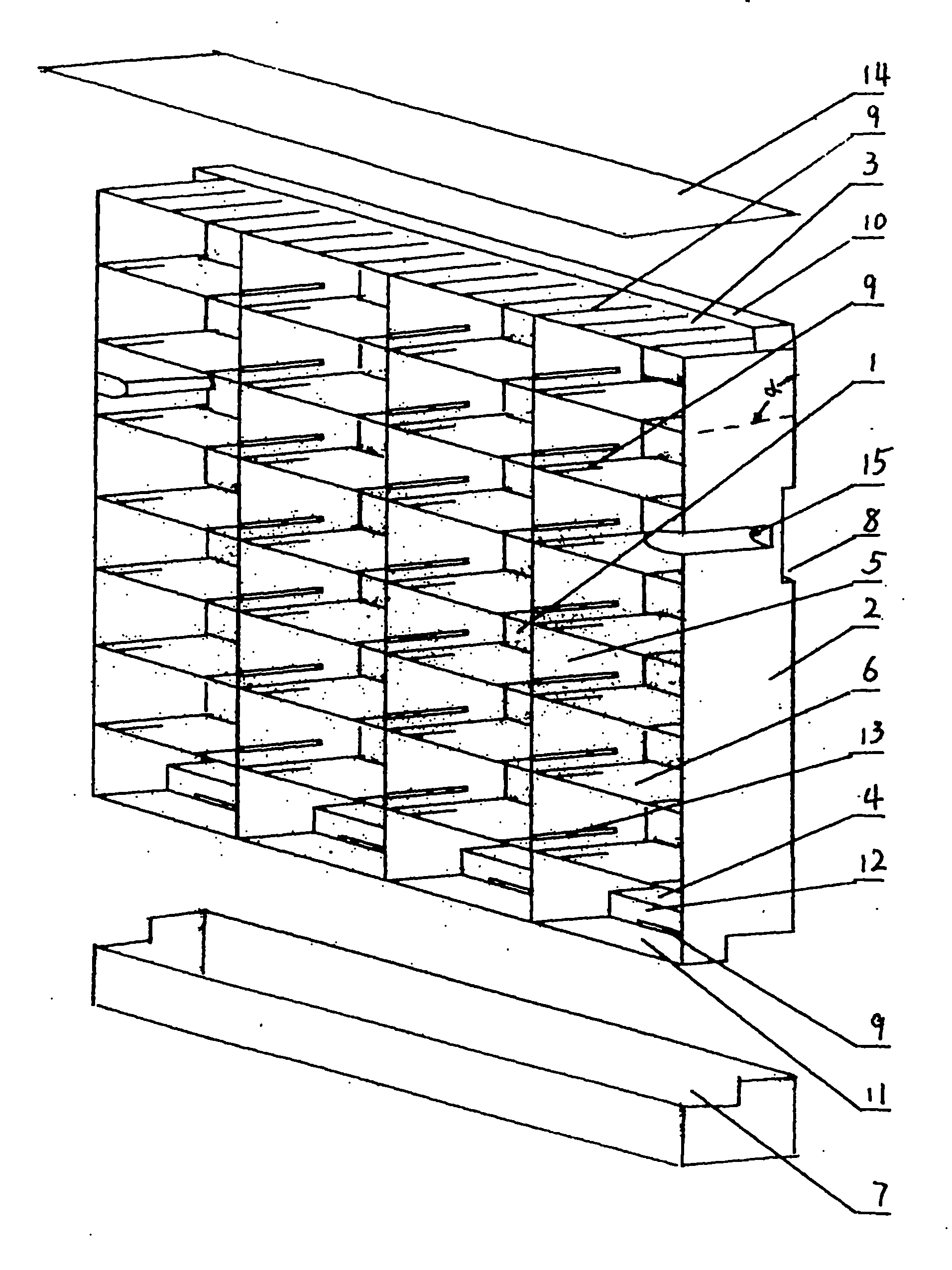

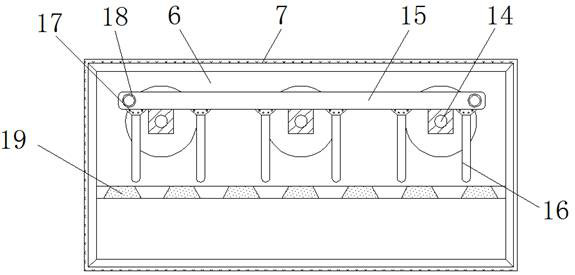

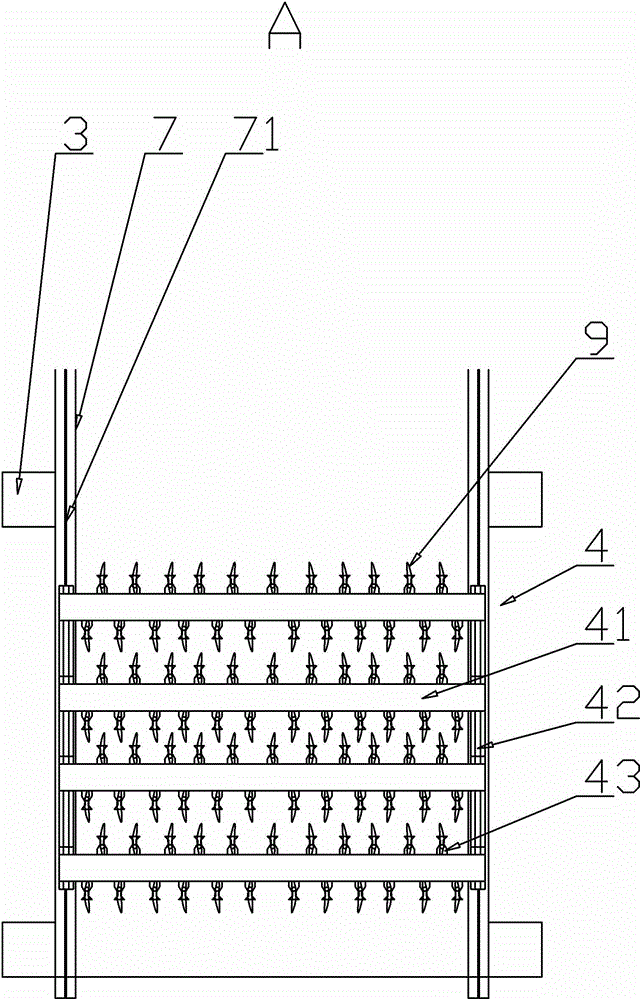

The invention discloses a sun-cure shed for sun-cured tobaccos, sun-cure devices and tobacco clips. The sun-cure shed comprises a shed. The shed is provided with a plurality of rows of sun-cure units, and transverse channels are arrange at the ends of the sun-cure units; a plurality of upright columns are arranged on two sides of each sun-cure unit, a plurality of slide rails are arranged on opposite sides of the upright columns, and the corresponding sun-cure devices are arranged on the slide rails on each same layer and can slide along the slide rails; the multiple tobacco clips used for clamping the tobaccos are arranged on the sun-cure devices. The sun-cure shed, the sun-cure devices and the tobacco clips have the advantages that the sun-cure shed is provided with the sun-cure devices and the tobacco clips used for clamping the multiple tobaccos, and the tobaccos can be subjected to sun-cure in a clustered manner by the aid of the sun-cure devices; the sun-cure devices can slide along the slide rails, so that the tobaccos can be fed mechanically and can be cured in an industrialized manner; the shortcoming of draping of tobacco braiding ropes is overcome, accordingly, the tobacco sun-cure density is increased as compared with a tobacco sun-cure mode implemented by the aid of the tobacco braiding ropes, and tobaccos of 82 tobacco plants can be cured in each square meter of the steel-structured shed while only tobaccos of 33 tobacco plants can be cured in each square meter of an existing standard cure shed; the production efficiency is improved, the integral cost is lowered, and the labor intensity is reduced.

Owner:湖北省烟草公司宜昌市公司

Flexible LED (Light-Emitting Diode) patch lamp strip

ActiveCN103016999AEasy for injection moldingPoint-like light sourceElectric circuit arrangementsEngineeringLight-emitting diode

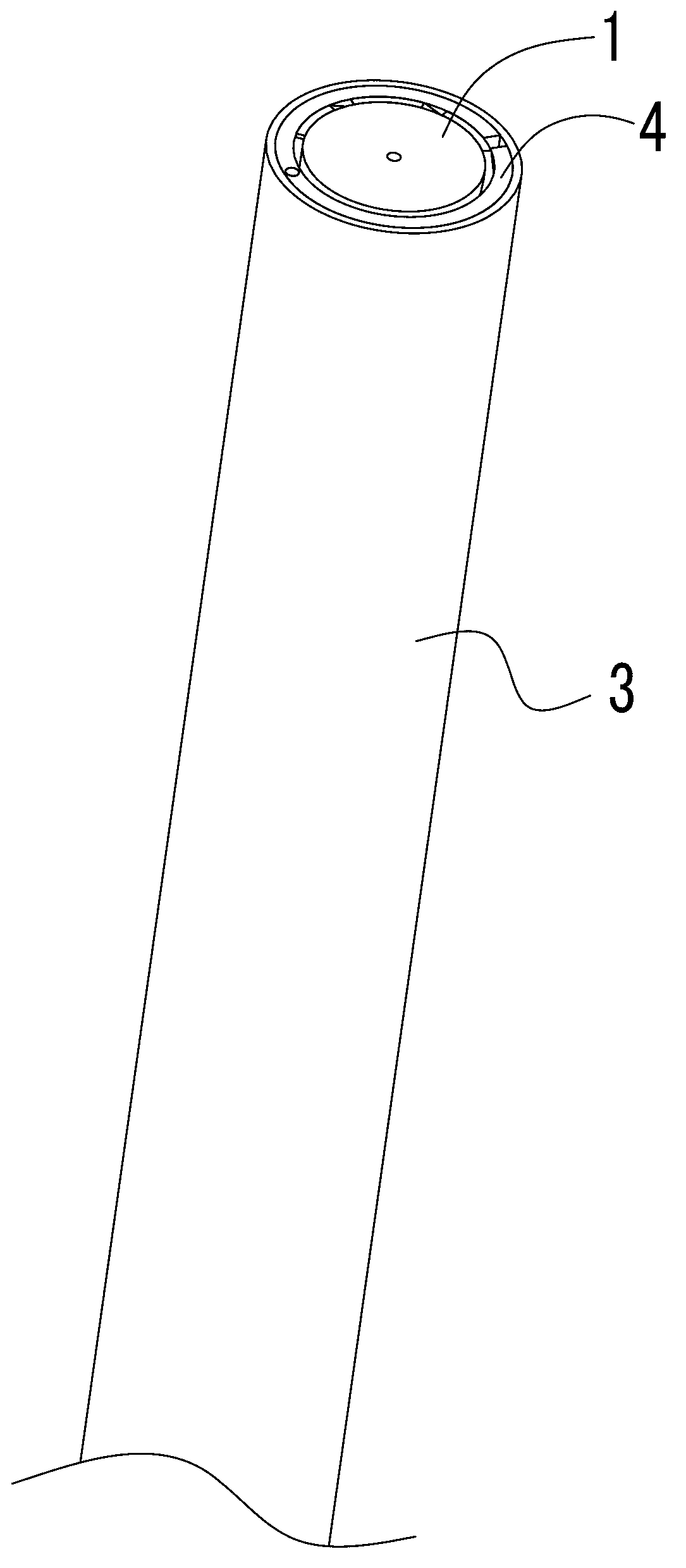

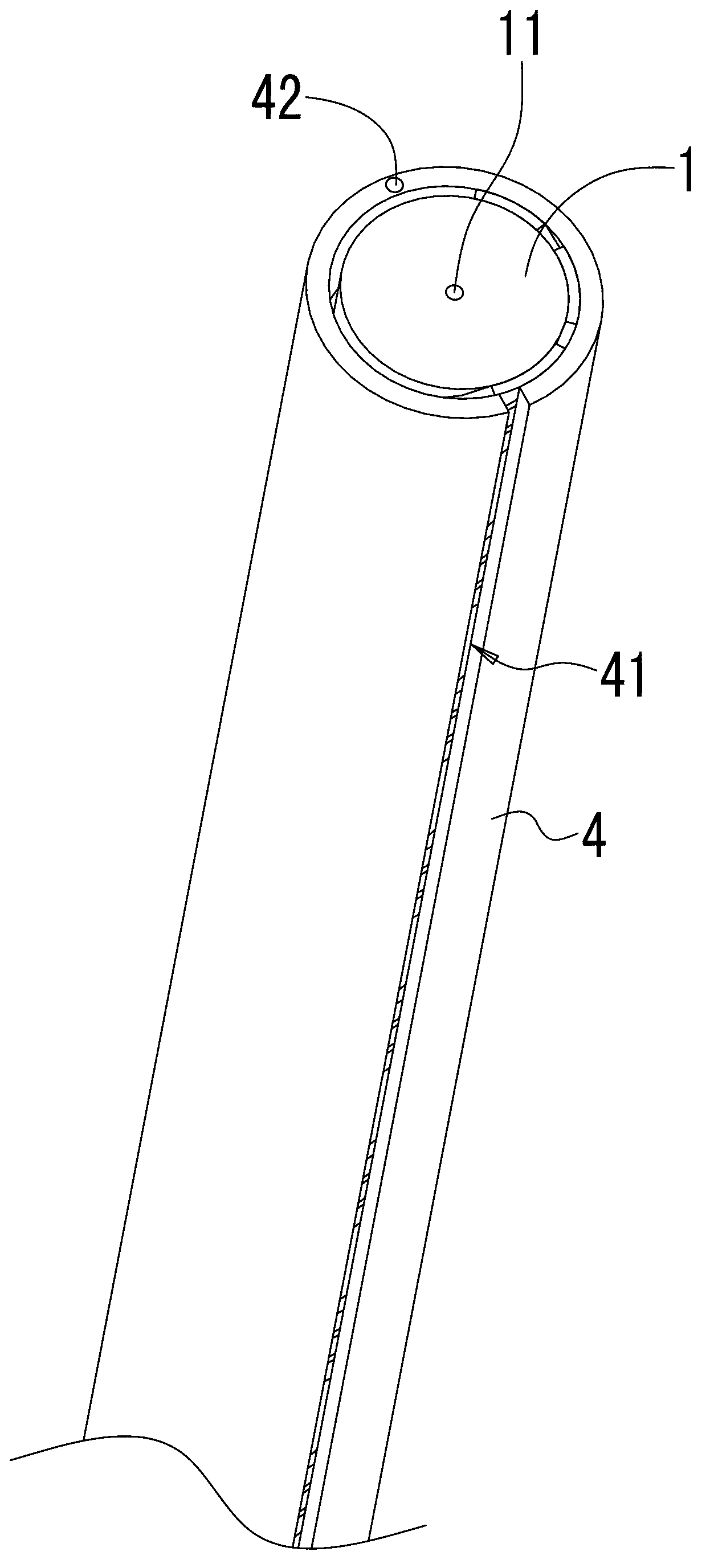

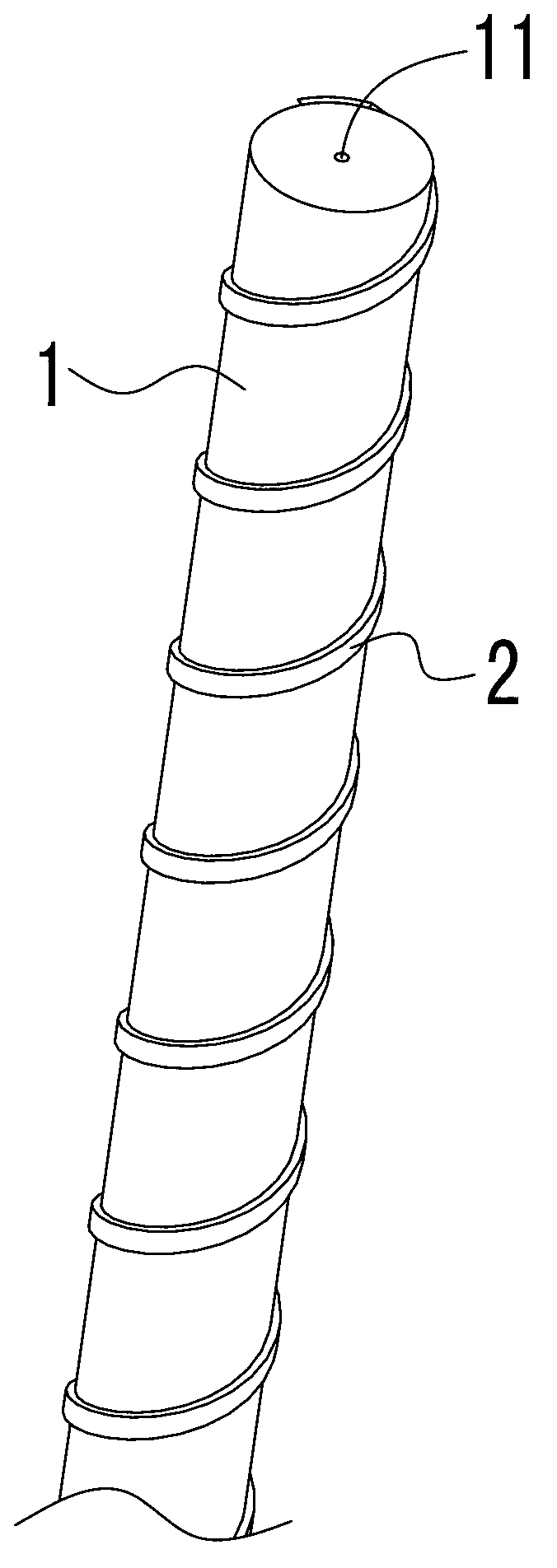

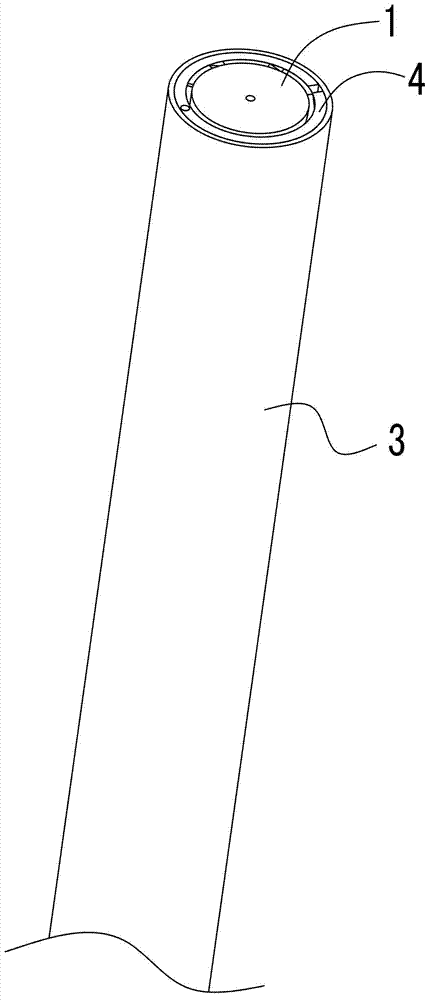

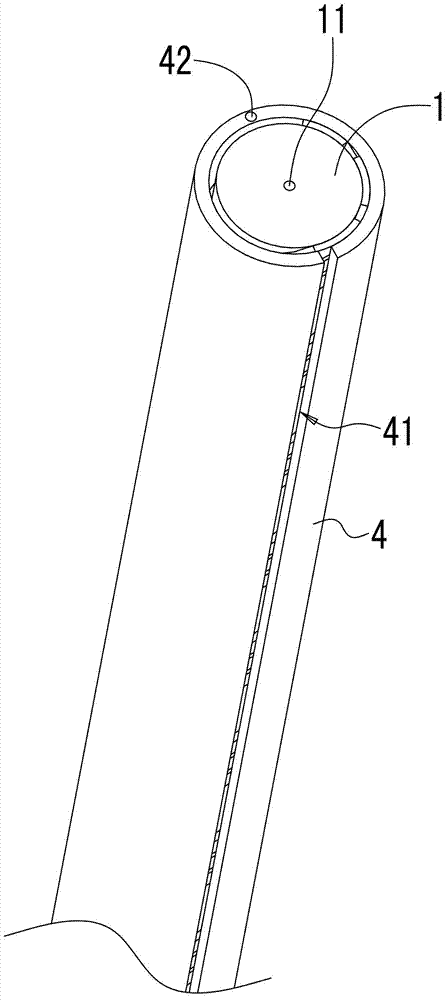

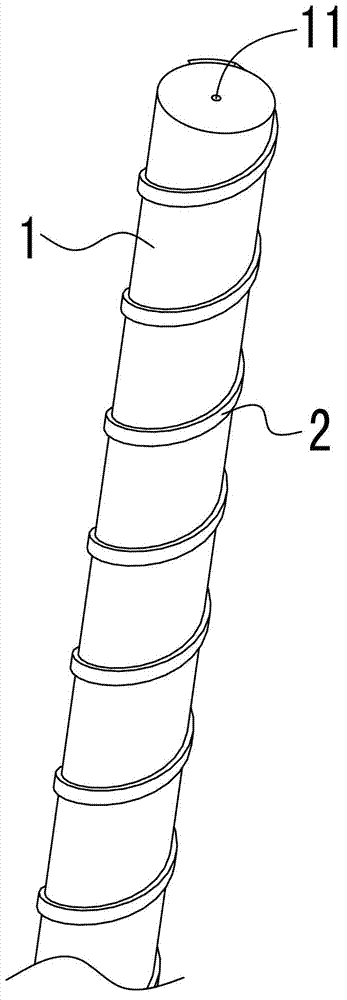

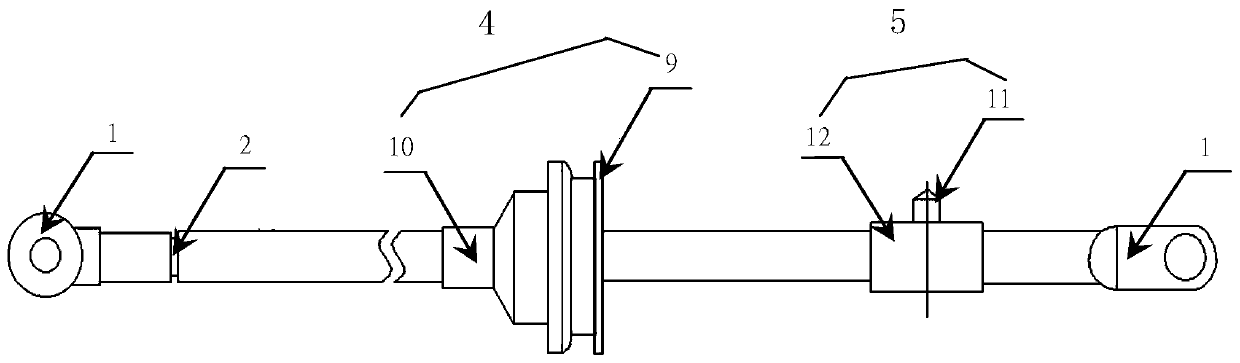

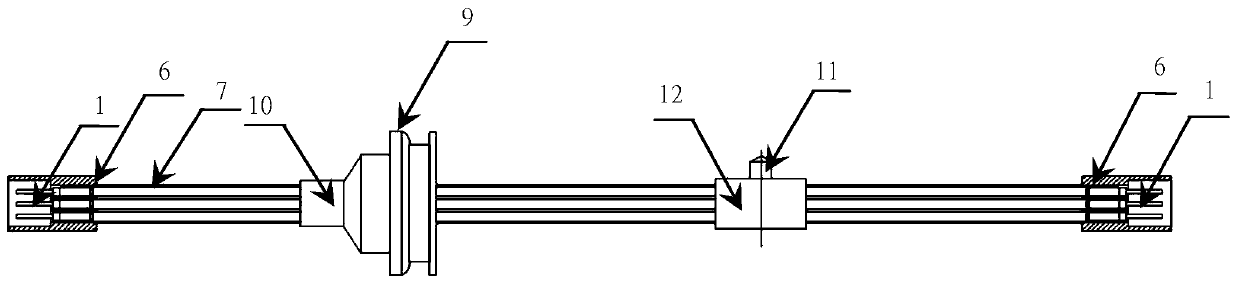

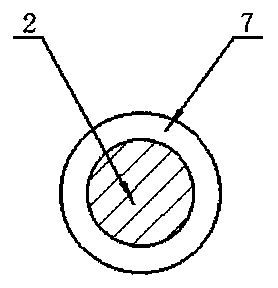

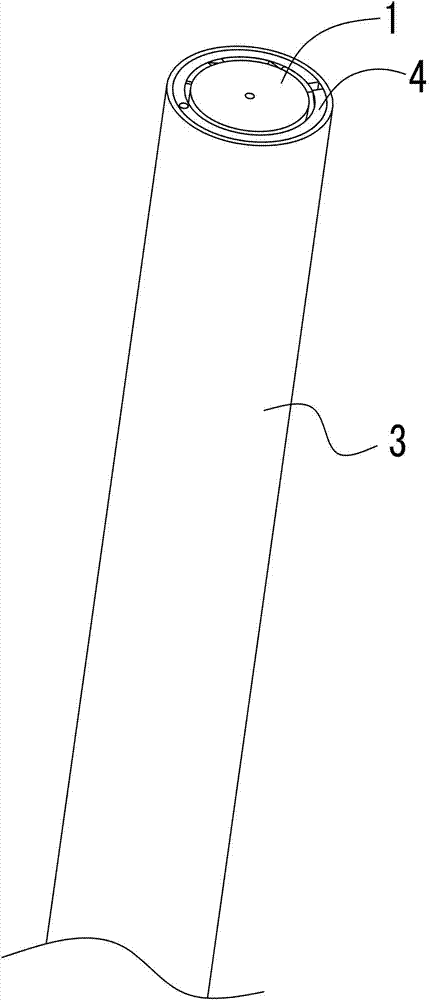

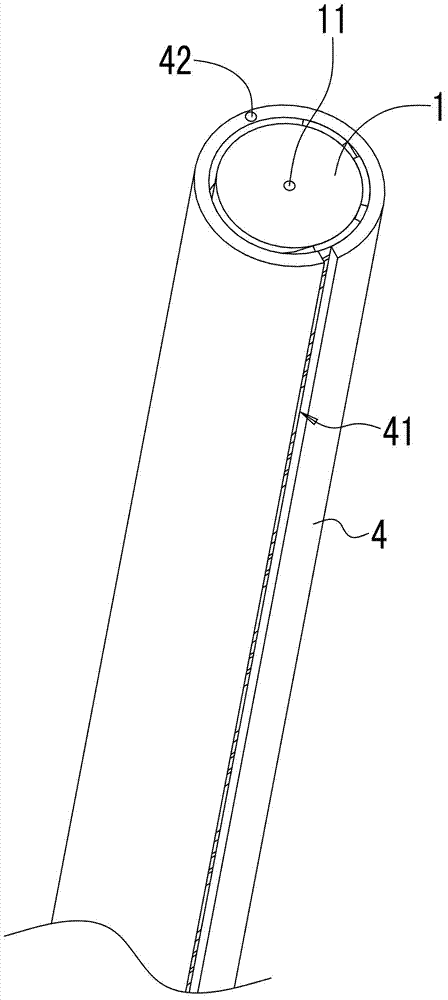

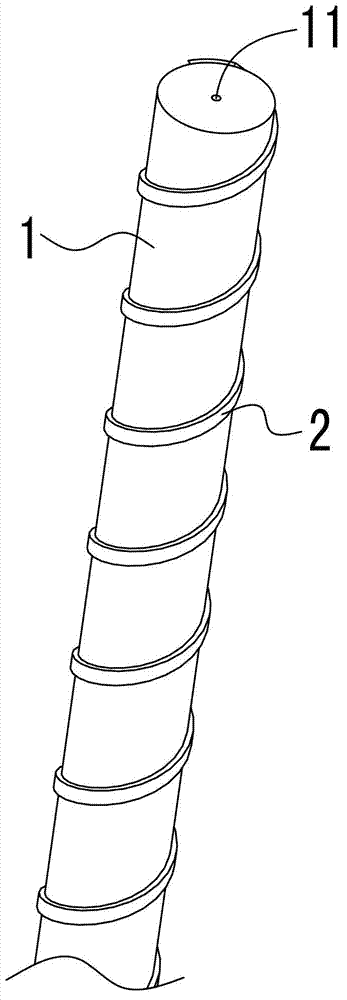

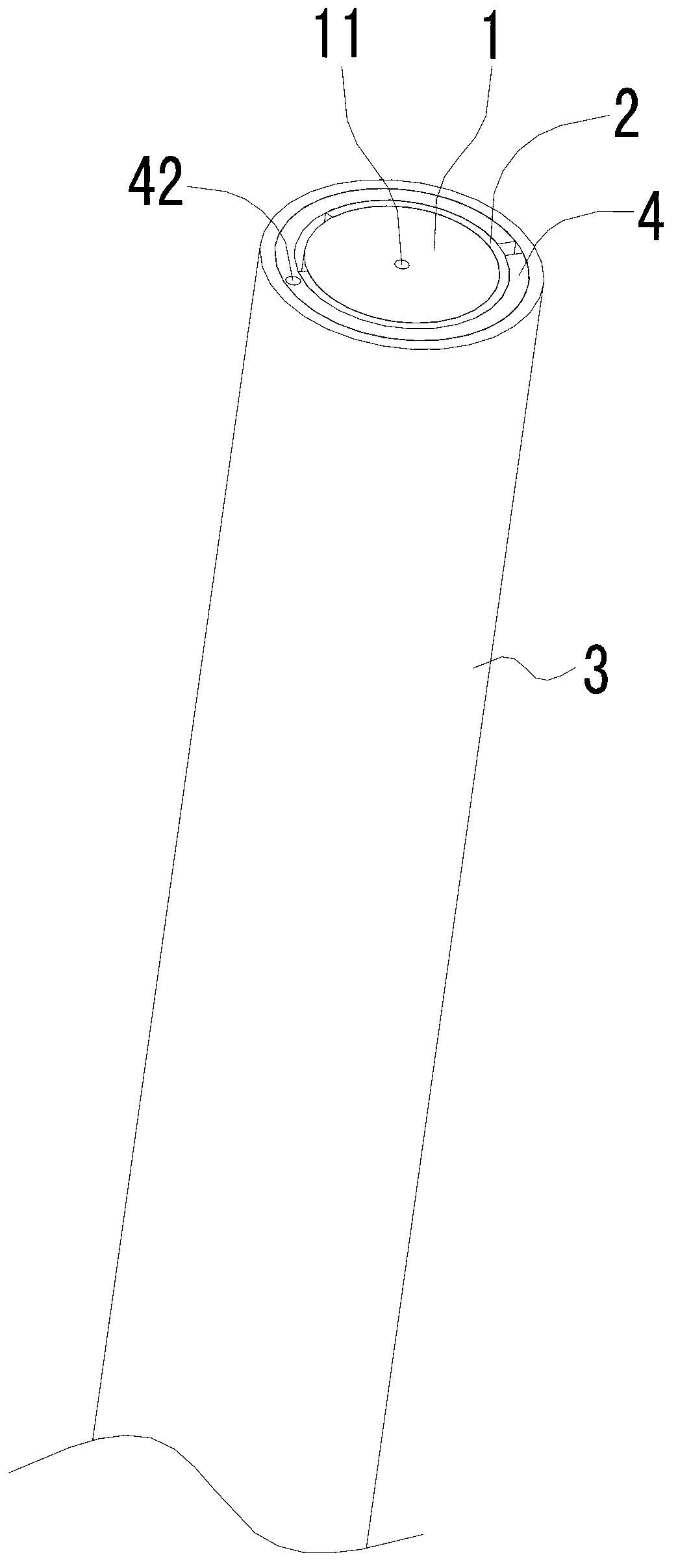

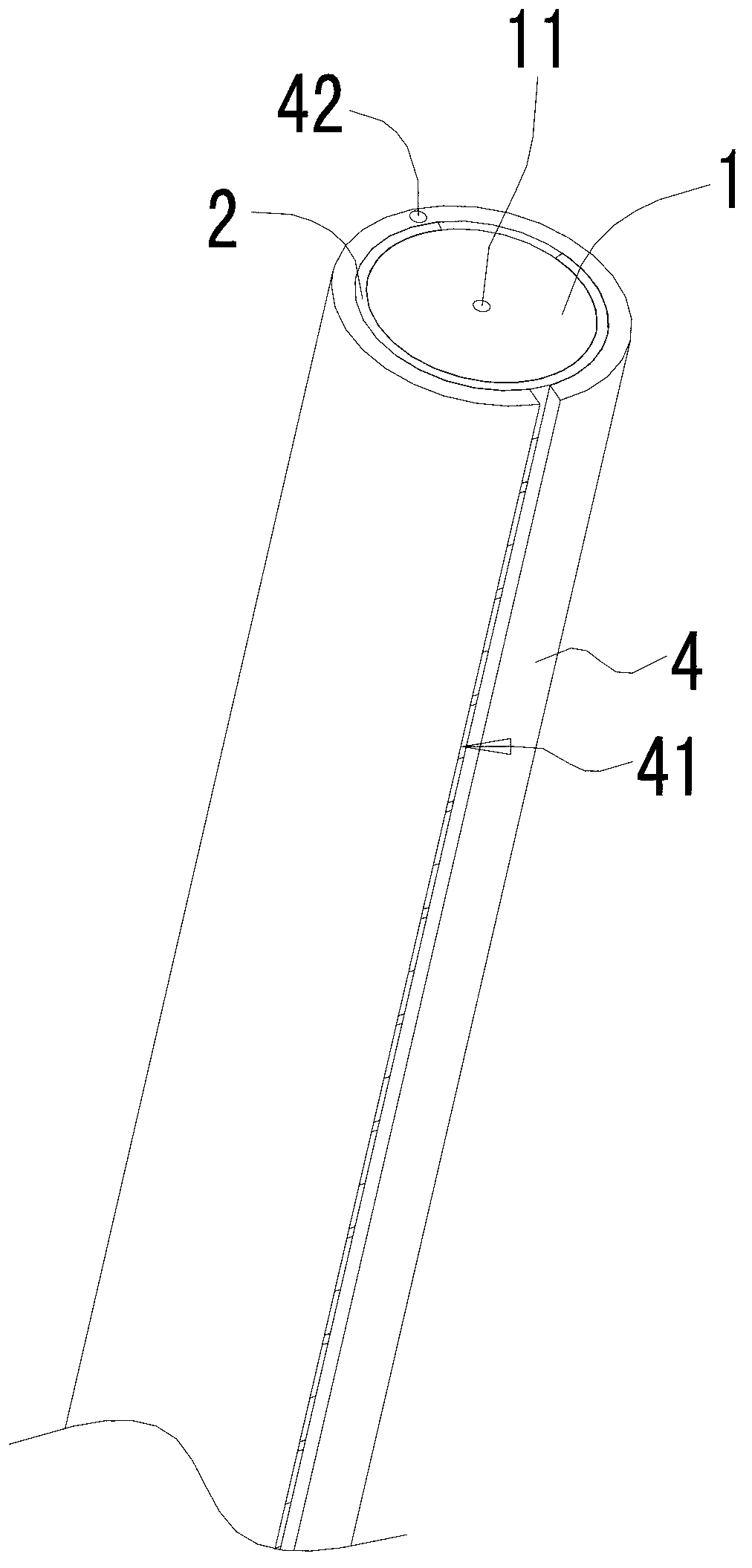

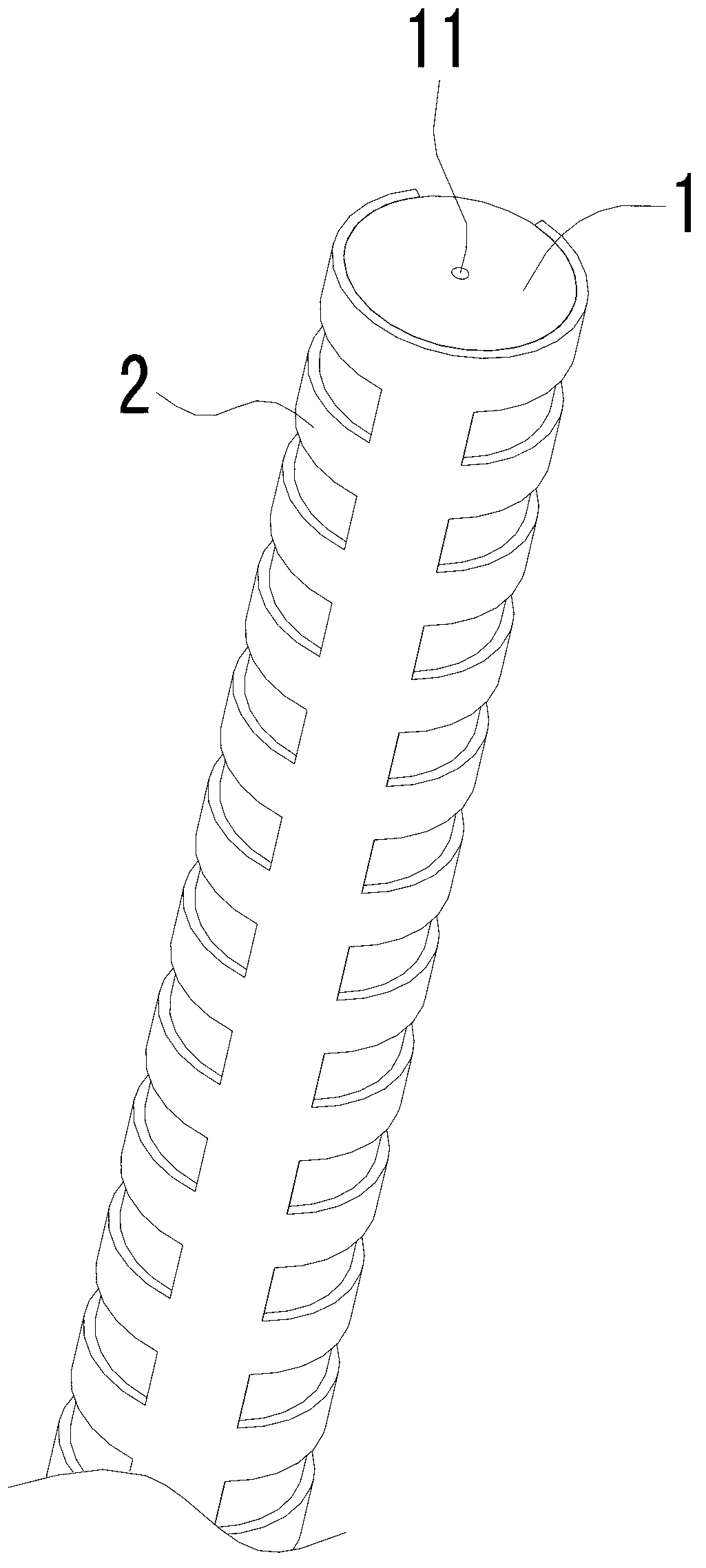

The invention relates to a flexible LED (Light-Emitting Diode) patch lamp strip which comprises a core wire, at least one flexible strip circuit board and a coating layer, wherein the core wire is a strip body with a preset length, and is extruded and formed by flexible plastic; a wire is embedded in the core wire; the wire is arranged along the length direction of the core wire and has the same length with the core wire; the flexible strip circuit board is provided with a plurality of LED patches; the flexible strip circuit board is electrically connected with the wire to supply power for the LED patches on the flexible strip circuit board; the coating layer is extruded and formed by flexible plastic, has the same length with the core wire and is light-transmitting; the coating layer is coated outside the core wire and the flexible strip circuit board; and the flexible strip circuit board is coiled on the core wire and extends along the length direction of the core wire in a spiral manner.

Owner:ZHONGSHAN MLIGHT PHOTOELECTRIC

Flexible LED SMD lamp belt

ActiveCN102788283AEasy for injection moldingPoint-like light sourceElectric circuit arrangementsWhole bodyBand shape

The invention relates to a flexible LED SMD lamp belt, which includes a core line, at least one flexible belt circuit board, and a covering layer, wherein the core line is a strip body made of flexible plastic through extrusion molding and is preset in length, a guide line is embedded in the core line, and the guide line is distributed in the length direction of the core line and is equal in length with the core line; a plurality of LED SMD are arranged on the flexible belt circuit board, the flexible belt circuit board is provided with a leading line, the leading line is electrically connected with the guide line so as to supply power to the LED SMD on the flexible belt circuit board; the covering layer is made of flexible plastic through extrusion molding, is equal in length with the core line, allows light to transmit, and covers the core line and the flexible belt circuit board; the flexible belt circuit board is coiled on the core line, and extends spirally in the length direction of the core line. The flexible LED SMD lamp belt has benefits as follows: the flexible LED SMD lamp belt is coiled on the core line spirally, LED are distributed on the whole peripheral surface of the core line, the 360-degree illumination on the peripheral surface can be realized, and the whole body emits light for illumination.

Owner:ZHONGSHAN MLIGHT PHOTOELECTRIC

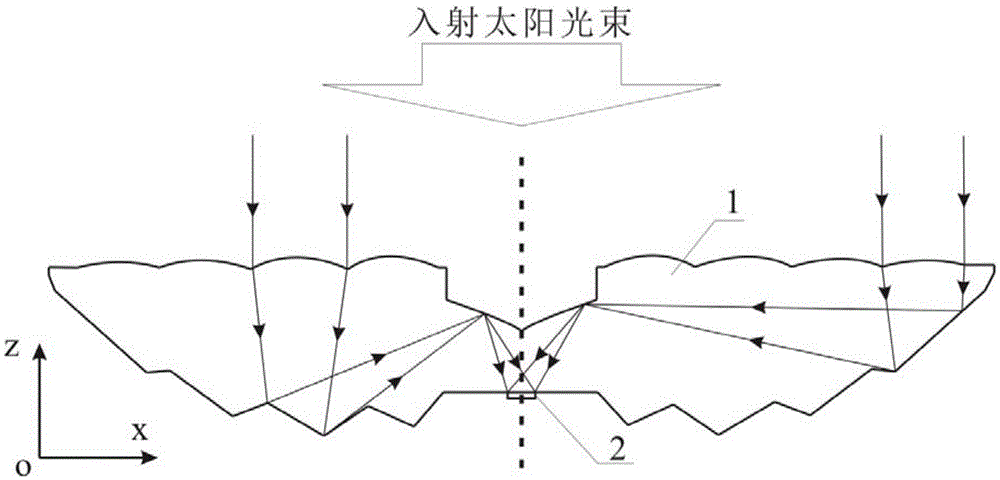

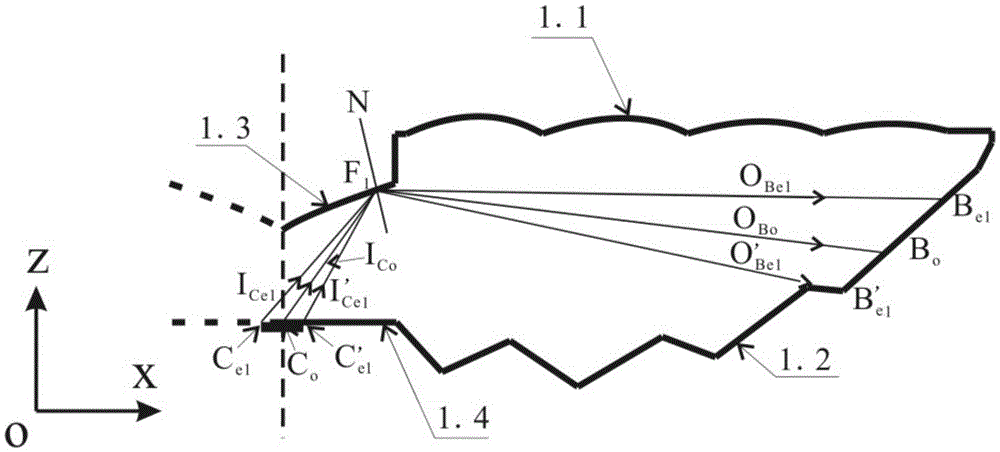

Compact double reflection-type photovoltaic condenser based on compound eyes

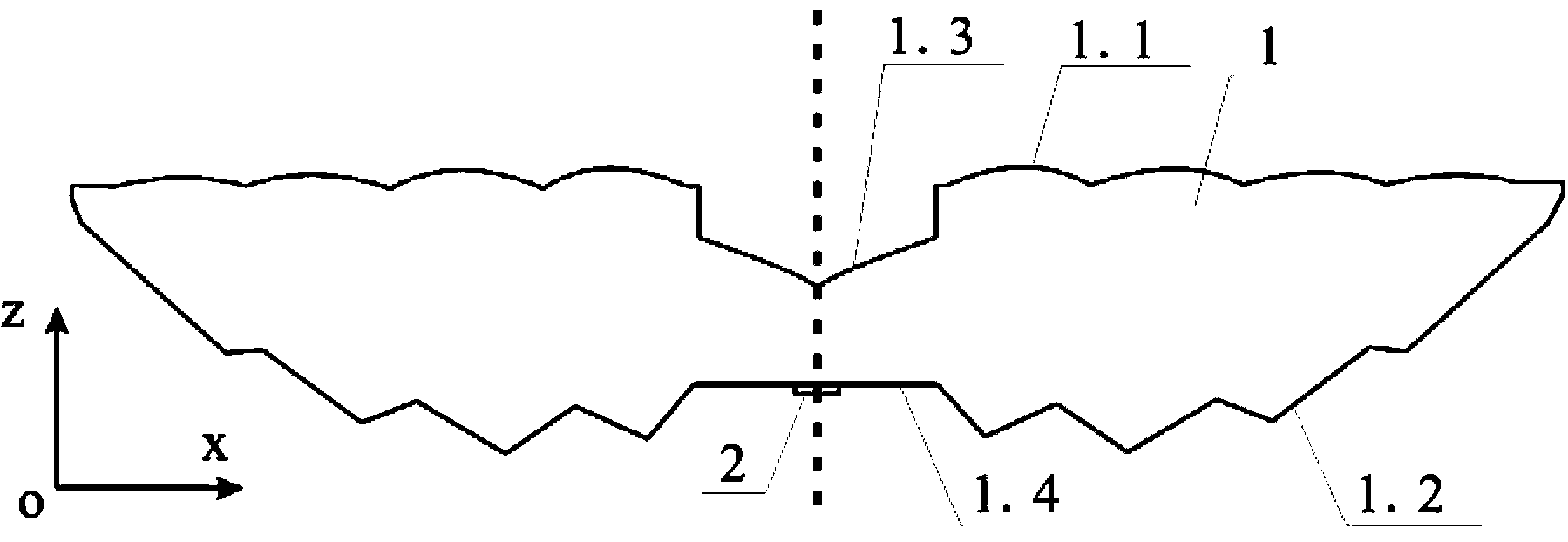

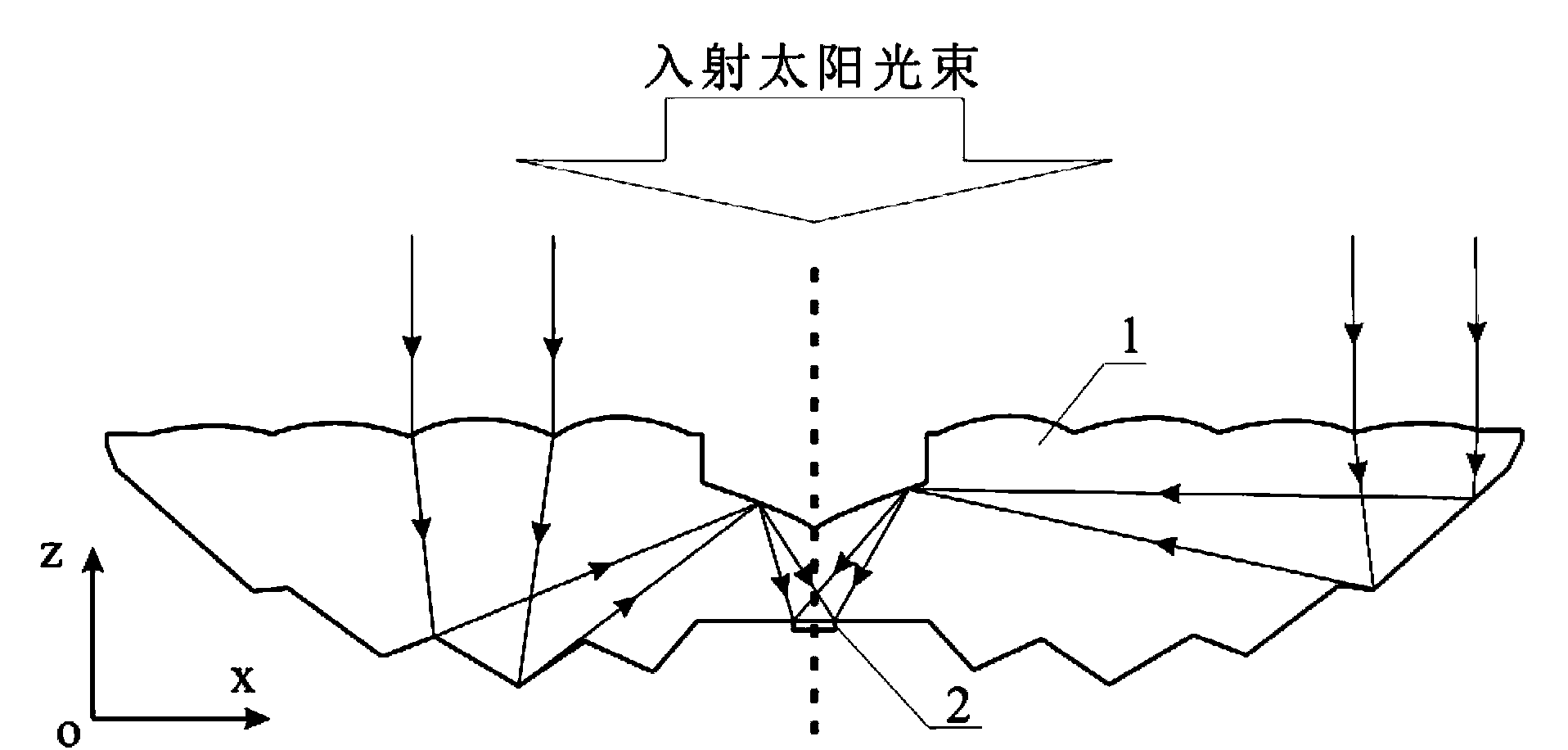

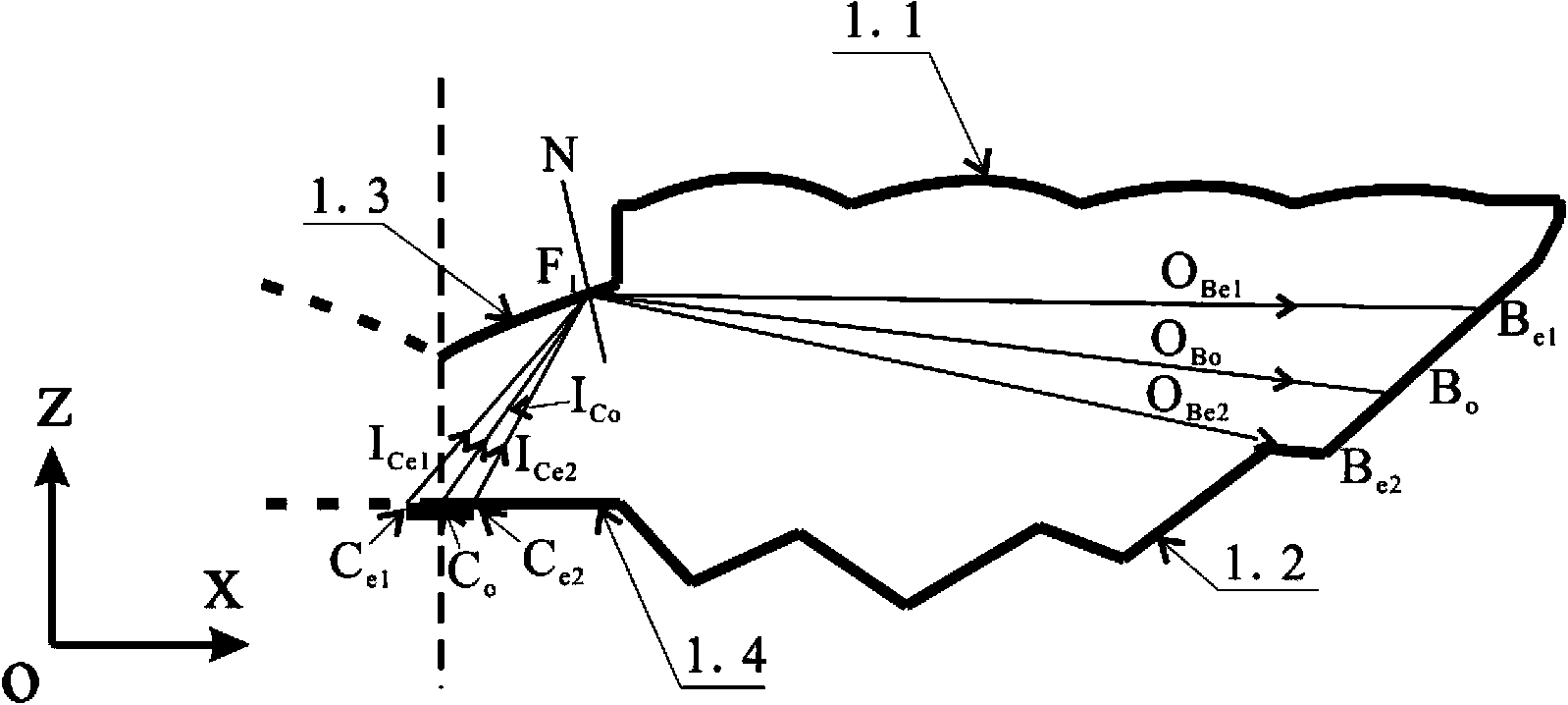

InactiveCN103441178AUniform illuminationImprove photoelectric conversion efficiencyCondensersPhotovoltaic energy generationPolymethyl methacrylateEngineering

The invention relates to the photovoltaic power generation technology, and aims at providing a compact double reflection-type photovoltaic condenser based on compound eyes. The compact double reflection-type photovoltaic condenser based on the compound eyes comprises a photovoltaic cell and an optical collector, wherein the upper surface of the optical collector comprises a free curved surface and a refraction curved surface, the lower surface of the optical collector comprises a transmission plane and a reflection plane, the center of the refraction curved surface and the center of the reflection plane are positioned at the same vertical position, the center of the free curved surface and the center of the transmission plane are positioned at the same vertical position, and the free curved surface is arranged at a focal position of the refraction curved surface; and the photovoltaic cell is arranged outside the optical collector and adjoins to the transmission plane, the photovoltaic cell is positioned at a focal position of the free curved surface, and the aperture of the transmission plane is larger than that of the photovoltaic cell. The compact double reflection-type photovoltaic condenser has the advantages that the photovoltaic conversion efficiency of the photovoltaic cell is improved, the service life of the photovoltaic cell is prolonged, an optical plastic PMMA (polymethyl methacrylate) is adopted and is prone to injection molding and processing, light in weight and applicable to large-scale processing, and the processing cost is reduced.

Owner:ZHEJIANG UNIV

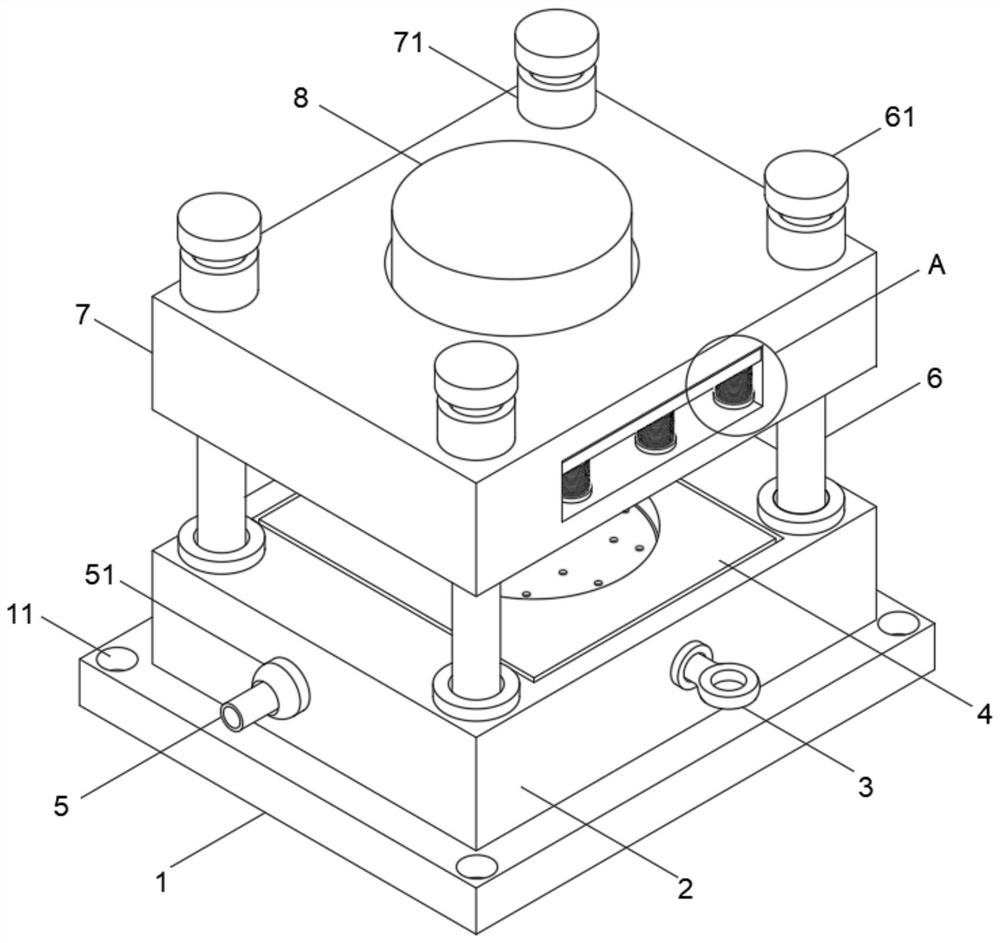

Plastic injection mould for mobile phone shell

InactiveCN103707465AEasy for injection moldingSimple mold opening processDomestic articlesEngineeringMechanical engineering

The invention relates to a plastic injection mould for a mobile phone shell. The plastic injection mould comprises a movable mould side machine fixing plate, a fixed mould side machine fixing plate, a male mould plate and a female mould plate, wherein the male mould plate and the female mould plate are encircled to form a cavity; the male mould plate is fixedly provided with a first inverted hook matched with an inverted buckle at one end of the mobile phone shell, the lower end of the first inverted hook is connected with an ejector rod, a fixed plate is fixedly provided with a second inverted hook matched with another inverted buckle at the other end of the mobile phone shell; the fixed plate is fixedly provided with a first inclined stretching tip and a second inclined stretching tip; the female mould plate is provided with a first sliding block and a second sliding block; and a first avoidance hole matched with the first inclined stretching tip is formed in the first sliding block, and a second avoidance hole matched with the second inclined stretching tip is formed in the second sliding block. According to the plastic injection mould for the mobile phone shell disclosed by the invention, mutually matched avoidance mechanisms are arranged on the male mould plate and the female mould plate, so that the plastic injection processing of the inverted buckle parts of the mobile phone shell becomes feasible and simple; and moreover, the plastic injection mould is simple in mould opening working procedure and high in processing efficiency.

Owner:SHENGYANG PRECISION MOLD KUSN

Glass fiber reinforced polycarbonate composite, preparation method thereof and application

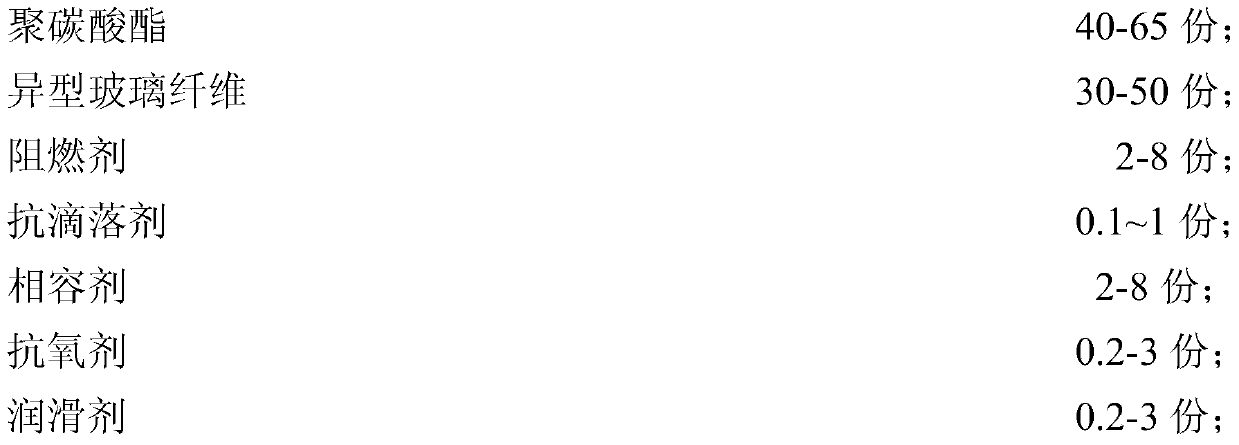

The invention discloses a glass fiber reinforced polycarbonate composite, a preparation method thereof and application of the glass fiber reinforced polycarbonate composite in preparation of a laptop shell. With 100 weight parts in total, the composite is prepared from, by weight, 40-65 parts of polycarbonate, 30-50 parts of special-shaped glass fiber, 2-8 parts of fire retardant, 0.1-1 part of anti-drip agent, 2-8 parts of compatilizer, 0.2-3 parts of antioxidant and 0.2-3 parts of lubricant. Non-alkali flat short-cut glass fiber serves as the special-shaped glass fiber, and the special-shaped glass fiber has the width of 30-40 microns, the thickness of 2-5 microns and the length of 350-450 microns. The composite has the advantages of being ultrahigh in modulus, less in warping, high in fire retardant performance, high in impact property, good in coating performance and the like, and meanwhile the composite is easy to inject, low in cost and quite suitable for preparing the laptop shell.

Owner:CGN JUNER NEW MATERIALS +1

Special material for injection grade non-halogen flame-retardant wire plug and preparation method thereof

ActiveCN101161719AGood physical and mechanical propertiesFlat surfaceCouplings bases/casesHalogenSmooth surface

The invention discloses special material and preparation method for injection molding level halogen-free flame retardation wire plug. The special material adopts elastic body and polyolefin resin as base material with expansion type flame retardant, flame retarding synergist, compatilizer, antioxidant and processing agent added. After intensive mixing, the special material is obtained through extrusion and pelleting by a BUSS mixing roll with autoweighing blanking device. The method has good mixing effect, stable compounding formula and high processing efficiency and the particles prepared via the method have even size and bright appearance. The flame retardation rating of produces prepared via the method reaches UL94V-0 level, the tiptop fusion index reaches 55g / 10min, and Shore hardness is from 65A to 95A in case of qualified flame retardation level and high fusion index. The composite material provided by the invention is environmental-friendly material which completely meets current international environmental requirements on halogen-free material. The material which not only has good flame retardation performance and flowing property but also enables smooth surface and good felt of products is suitable for manufacturing various injection molding level wire plugs with high flame retardation requirements.

Owner:SHANGHAI KINGFA SCI & TECH +1

Vertical greening modularization assembly wall hanging device

InactiveCN101268745BEasy to storeVertical assembly is beneficialReceptacle cultivationModular compositionStructural engineering

The invention relates to a packaged modularized wall hanging device for vertically reforesting. The device is characterized in that each basic module comprises a wall hanging backboard, vertical frames, a top partition board, a bottom partition board, at least two vertical partition boards are arranged between the vertical frames, at least two horizontal partition boards are arranged between the top partition board and the bottom partition board, and an implantation cabin forms after being divided by the vertical and the horizontal partition boards, wherein, the wall hanging backboard is at least provided with a horizontal hanging groove; the top and the bottom partition boards are parallel to the horizontal partition boards, and the included angle Alpha among the top and the bottom partition boards, the horizontal partition boards and the wall hanging backboard is less than 80 DEG; the outer edges of the top and the bottom partition boards for forming the implantation cabin are all provided with notches used for circulatory perfusion.

Owner:南京怡爱迪景观园林技术开发有限公司

Injection-molded wire harness and molding method

PendingCN111478060ANo mutual wearThe relative positioning size is accurateContact member assembly/disassemblyCoupling contact membersElectrical conductorInjection moulding

The invention relates to an injection-molded wire harness and a molding method. The wire harness comprises a terminal and at least one conductor, wherein one end of the terminal is connected with an electrical loop of an electric device, the other end of the terminal is connected with the conductor, and the wire harness is provided with a protection layer which is formed by injection molding and wraps the conductor, and at least one positioning device which is formed by injection molding and is used for fixing the position of the wire harness or / and a sealing device for water prevention. According to the invention, manual operation can be reduced, the consistency of wire harness products is improved, the production cost of the wire harness products is reduced, and the service life of the wire harness is prolonged.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

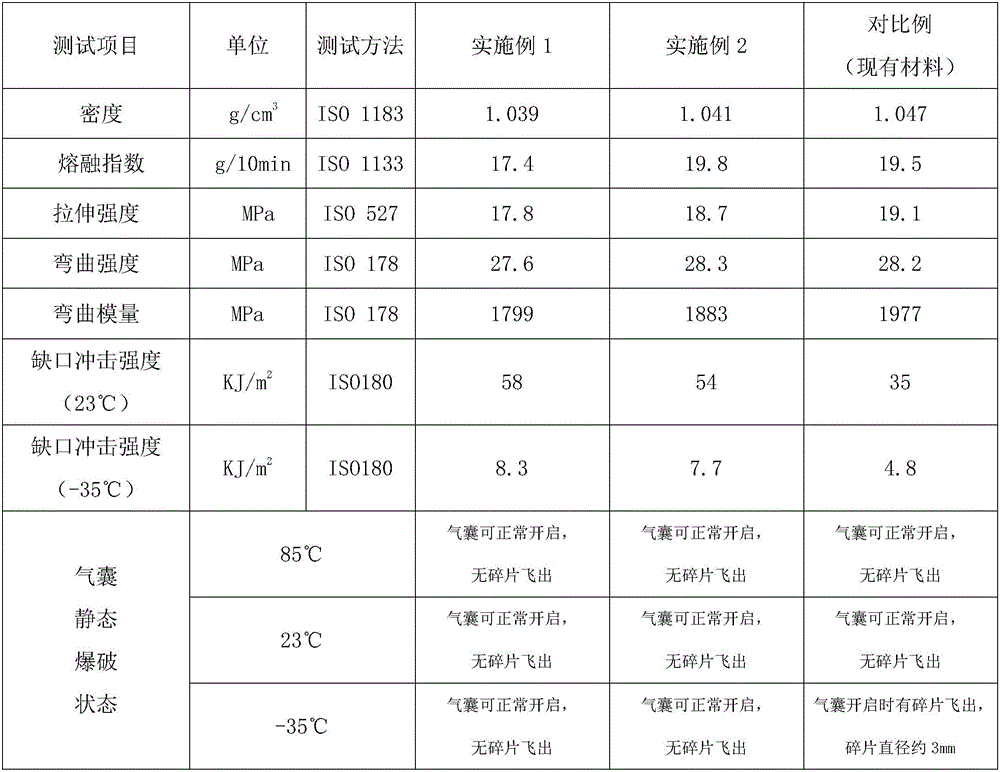

ABS alloy with low-temperature resistance, oil resistance, acid resistance, alkali resistance and high impact, and preparation method thereof

The invention discloses ABS alloy with low-temperature resistance, oil resistance, acid resistance, alkali resistance and high impact. The ABS alloy is characterized by being prepared from the following components in parts by weight: 40 to 60 parts of ABS, 8 to 15 parts of PC, 15 to 30 parts of PBT, 3 to 6 parts of styrene-acrylonitrile-glycidyl methacrylate, 1 to 2 parts of methyl silicone oil, 5 to 15 parts of an MBS toughening agent, 1 to 3 parts of triphenyl phosphate and 0.5 to 1 part of other processing aids. ABS alloy resin produced by a formula and a process of the ABS alloy with low-temperature resistance, oil resistance, acid resistance, alkali resistance and high impact has high mechanical property, higher heat resistance compared with that of common ABS, high low-temperature notch impact strength, obviously improved oil resistance and resistance to moderate-strength acid and alkali soaking, and obviously improved anti-ageing degree.

Owner:TAIZHOU SPRING BRIGHT PLASTICS TECH

Weather-resistant matt polycarbonate regenerated material and preparation method thereof

The invention provides a weather-resistant matt polycarbonate regenerated material and a preparation method thereof. The weather-resistant matt polycarbonate regenerated material is prepared from thefollowing raw materials in percentage by mass: 3 to 15 percent of first polycarbonate recycled crushed materials, 60 to 83 percent of polycarbonate recycled crushed materials, 3 to 10 percent of thirdpolycarbonate recycled crushed materials, 10 to 25 percent of matte surface agents, 0.2 to 1.0 percent of antioxidants, 0 to 0.6 percent of light stabilizing agents and 0.1 to 1.0 percent of ultraviolet absorbents. Through the addition of the matte surface agents, the antioxidants, the light stabilizing agents and the ultraviolet absorbents, the weather resistant performance of polycarbonate is improved; the processing performance is improved; the modified material with stable melt index is obtained; the performance is similar to that of a new material.

Owner:SHANGHAI AUSELL CHEM TECH

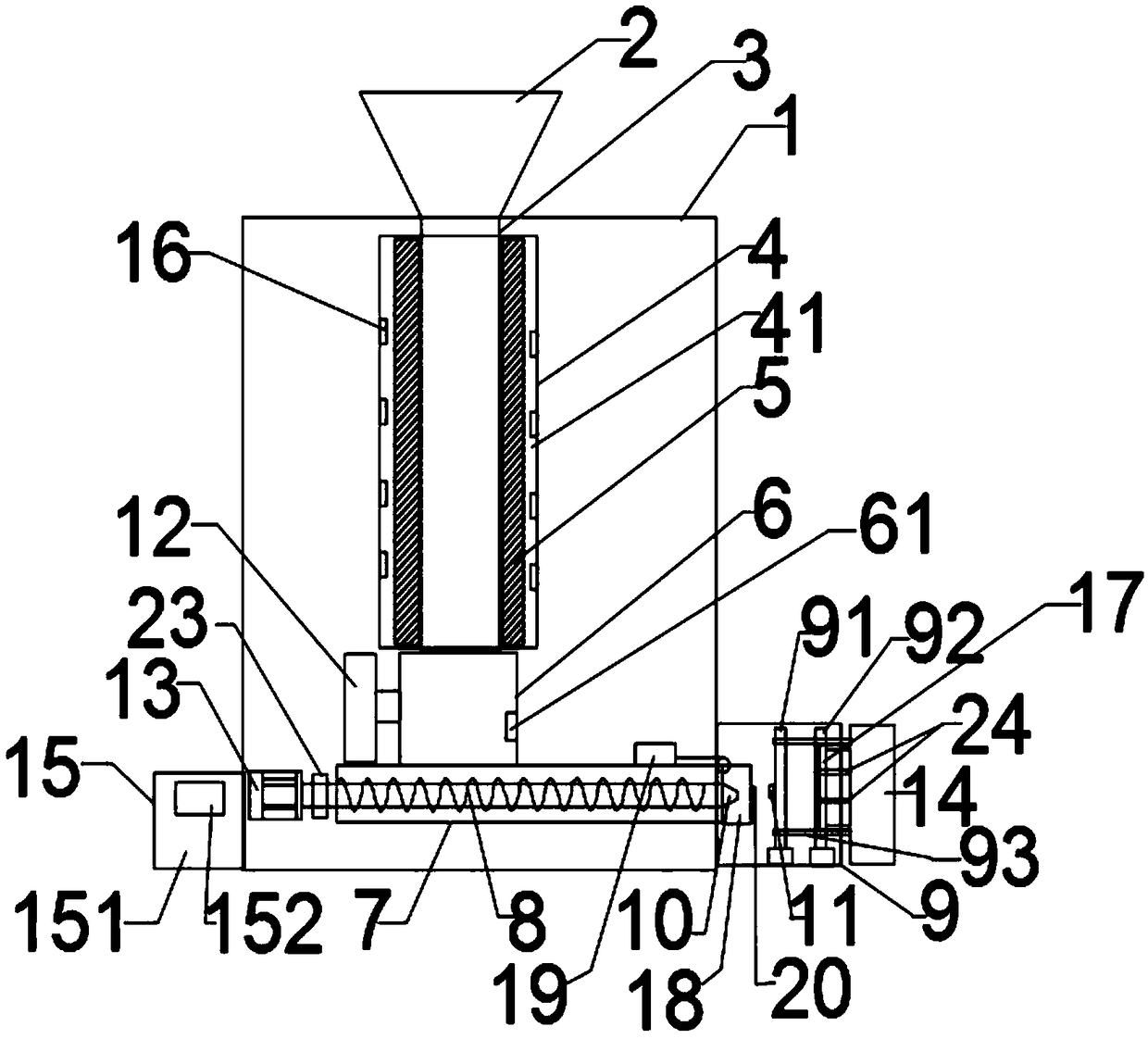

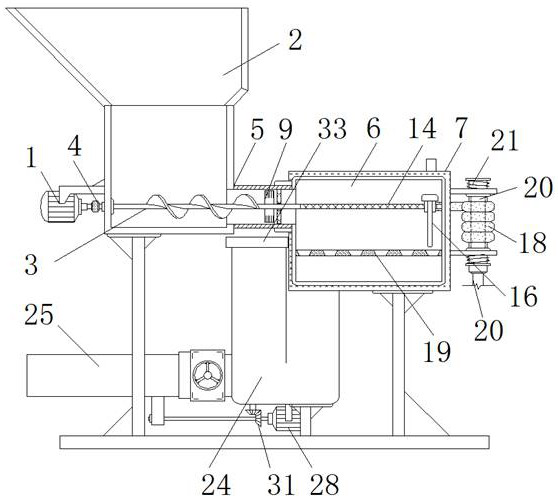

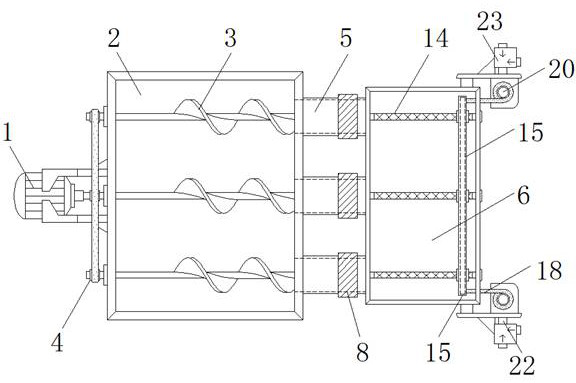

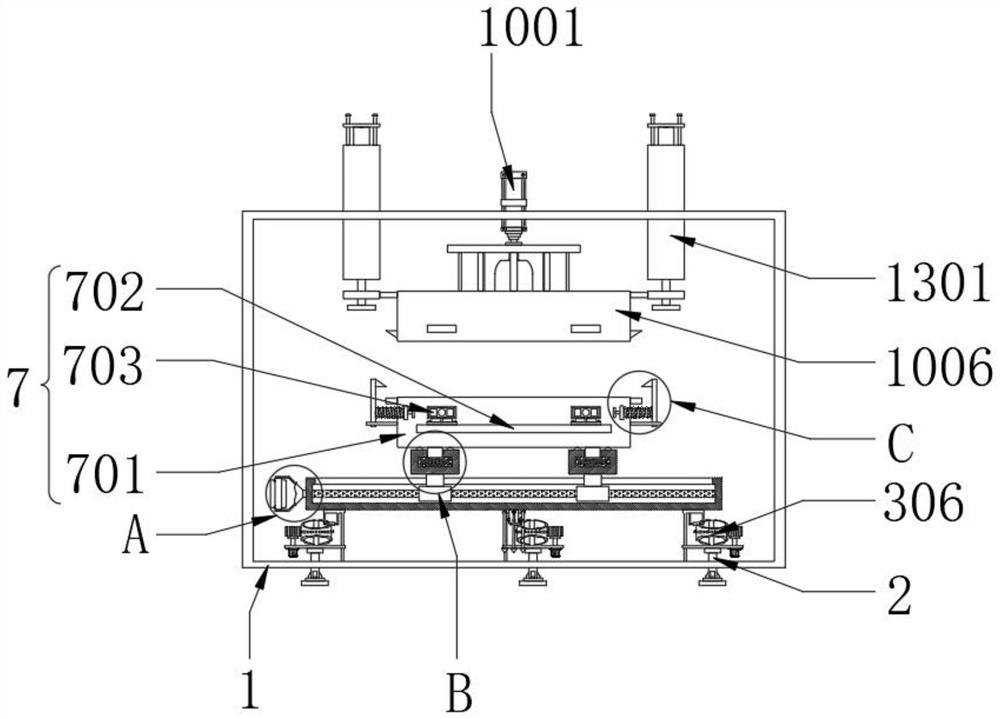

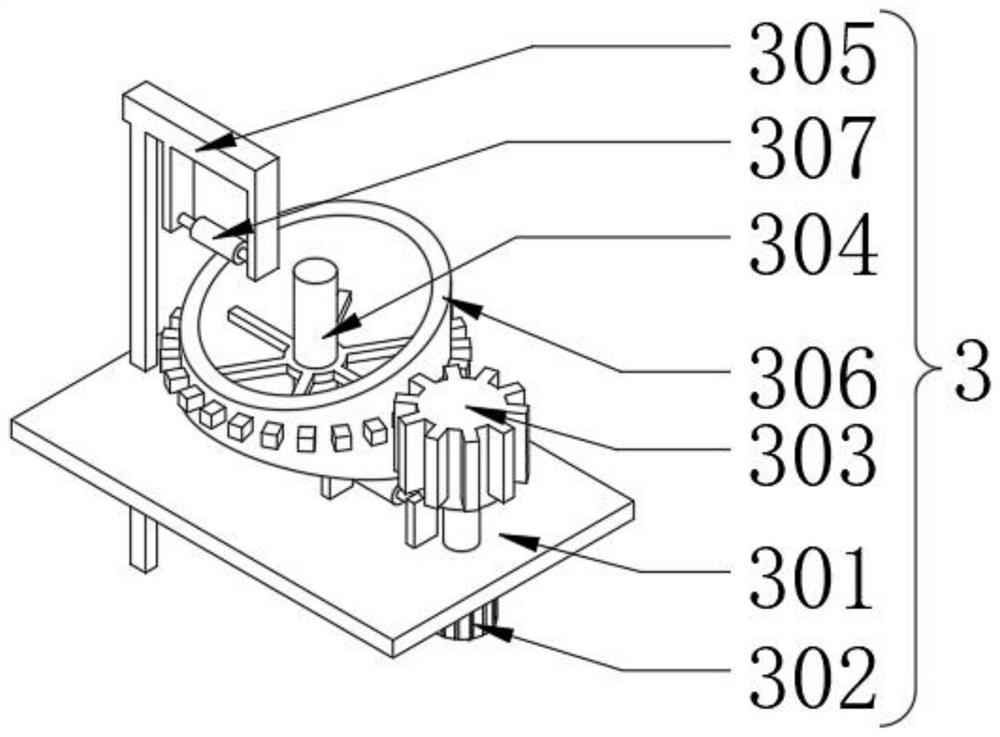

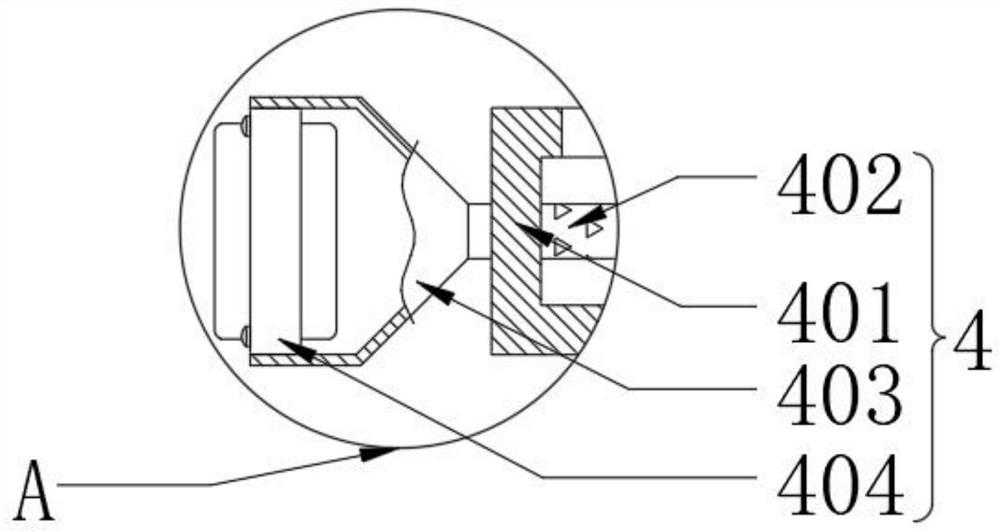

High-performance plastic injection molding machine with cooling device and injection molding method

The invention relates to the field of plastic production equipment, in particular to a high-performance plastic injection molding machine with a cooling device and an injection molding method. Heatingdevices are uniformly arranged on the outer wall of a first conveying channel in the circumferential direction and extend from the upper end to the lower end of the first conveying channel; materialis uniformly heated in the first conveying channel; a buffering cabin mechanism is arranged to ensure feeding continuity; a fixed die and a moving die are arranged in an injection molding mechanism; afeeding runner opening is formed in the fixed die; material enters an injection molding die through a nozzle and the feeding runner opening sequentially; a first transverse air cylinder drives the moving die and the fixed die to be splitted and assembled so as to finish circulation of injection molding production; the cooling device is arranged in the moving die, is excellent in cooling effect, accelerates cooling of a finished injection molding product and improves the working efficiency; a thermal insulating cover is arranged to carry out excellent thermal insulation on molten fed materialat the nozzle and facilitates following injection molding processing; and during the injection molding process, the injection molding effect is excellent, the surface of the finished product is uniform, the yield of the finished product and the production efficiency are high, and the production demand of an enterprise is met.

Owner:太仓曌信金属制品有限公司

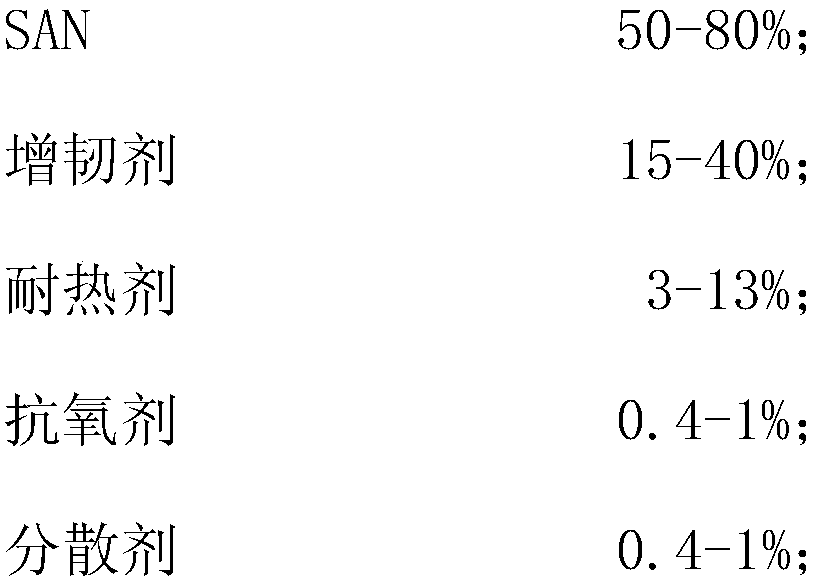

High-flowability and low-internal-stress electroplated ABS (acrylonitrile butadiene styrene) material and preparation method thereof

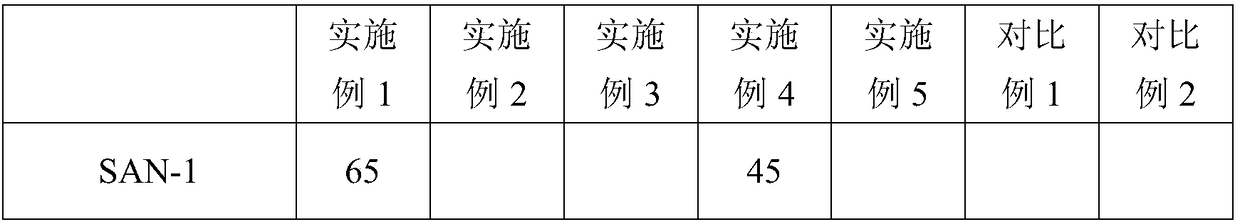

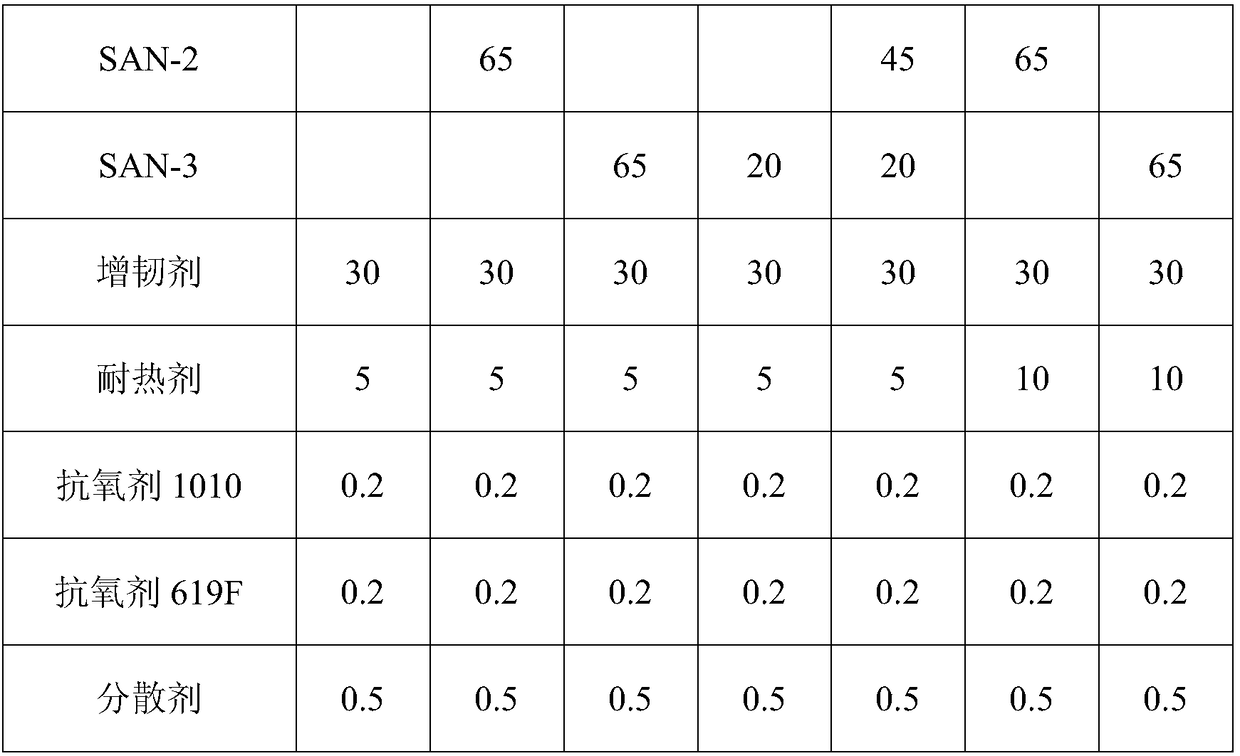

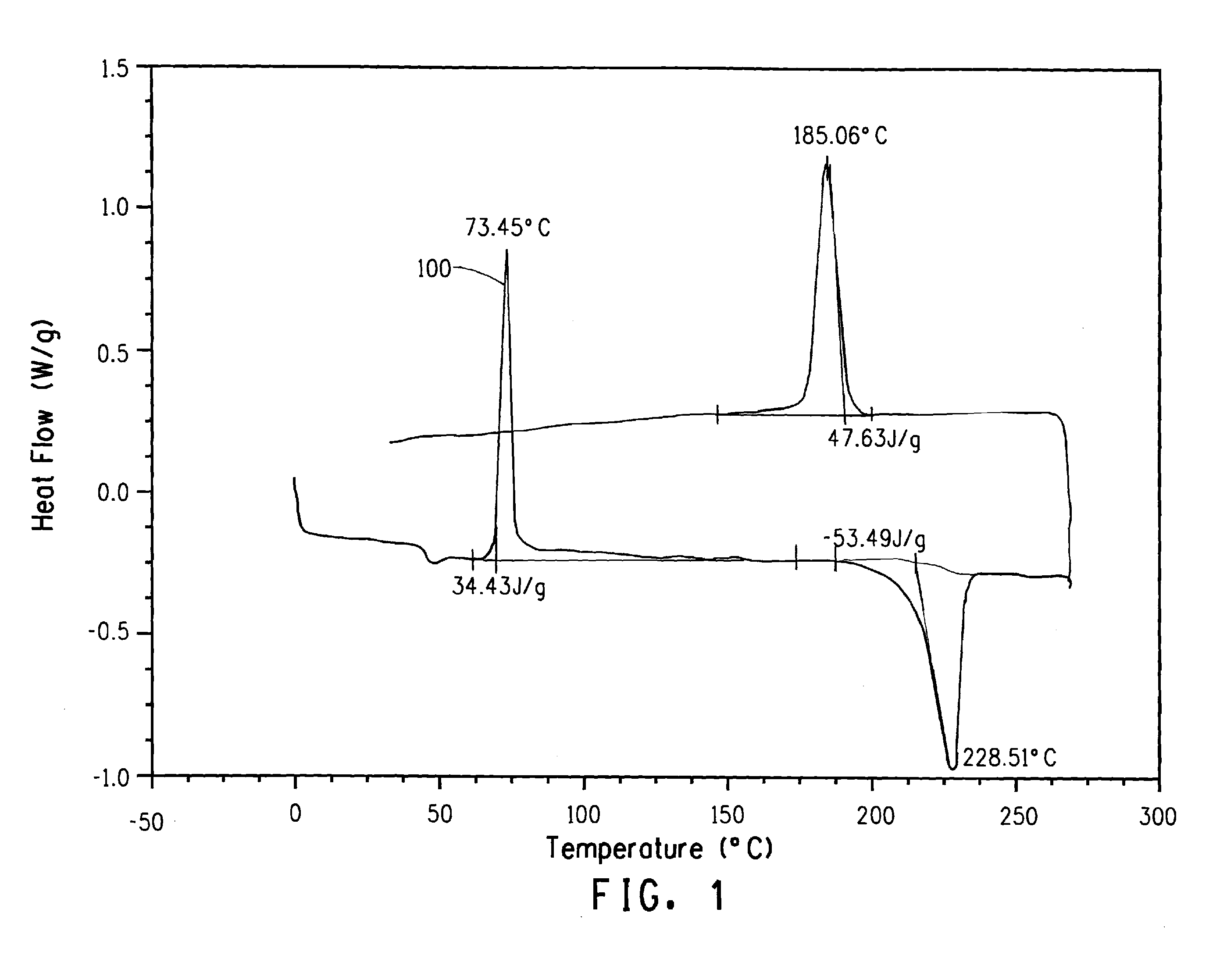

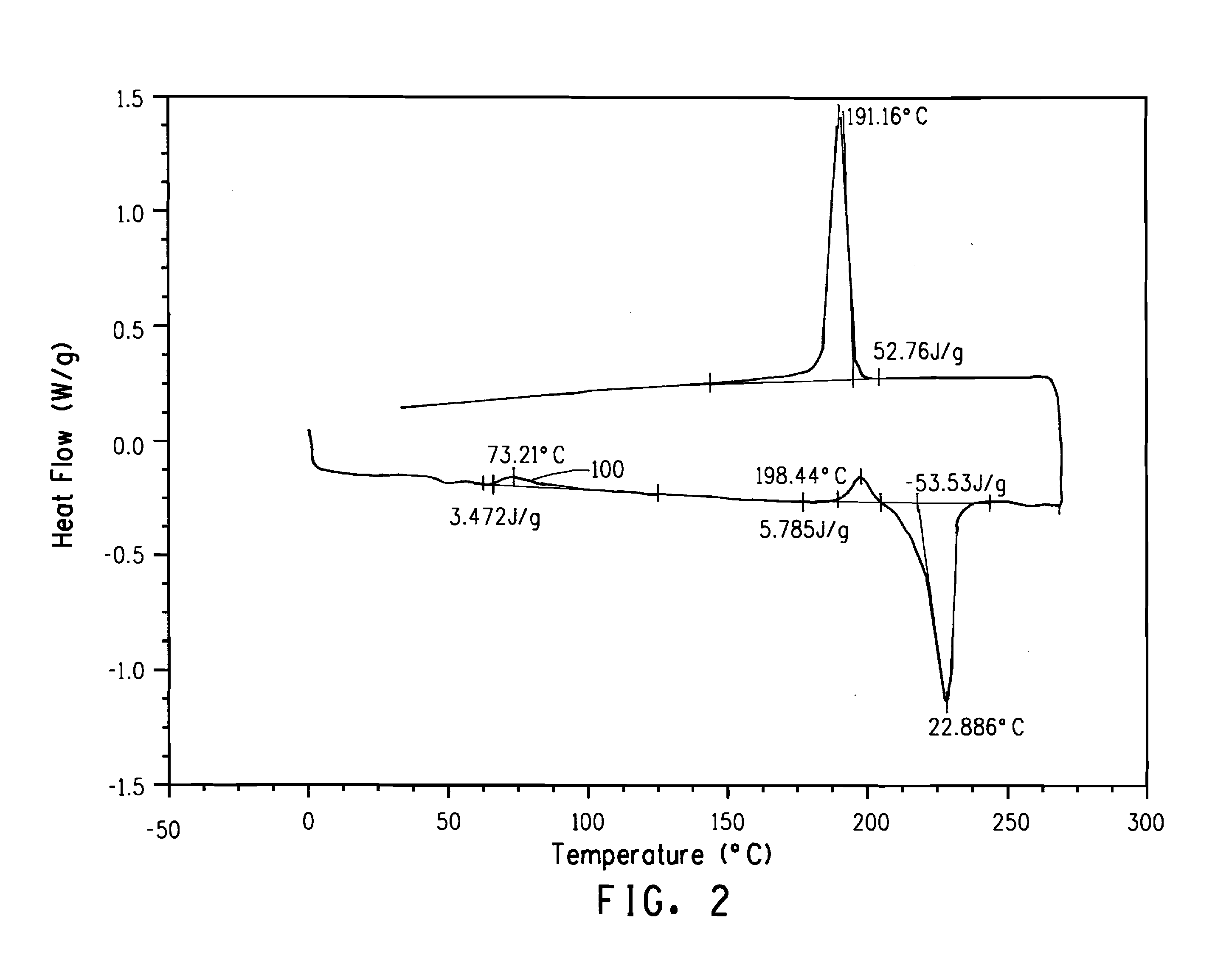

The invention discloses a high-flowability and low-internal-stress electroplated ABS (acrylonitrile butadiene styrene) material and a preparation method thereof. The material is prepared from the following raw materials in percentage by weight: 50 to 80 parts of a styrene-acrylonitrile copolymer, 15 to 40 parts of an impact-resistant modifier, 3 to 13 parts of a heat-resistant modifier, 0.4 to 1 part of an antioxidant and 0.4 to 1 part of a lubricating agent. The high-flowability and low-internal-stress electroplated ABS blended material prepared with the technical scheme has the characteristics of high flowability, low internal stress to an injection-molded part and the like, and can be applied to slender electroplated products such as an automobile grill decorative bar and a door decorative bar.

Owner:ZHEJIANG PRET NEW MATERIALS +4

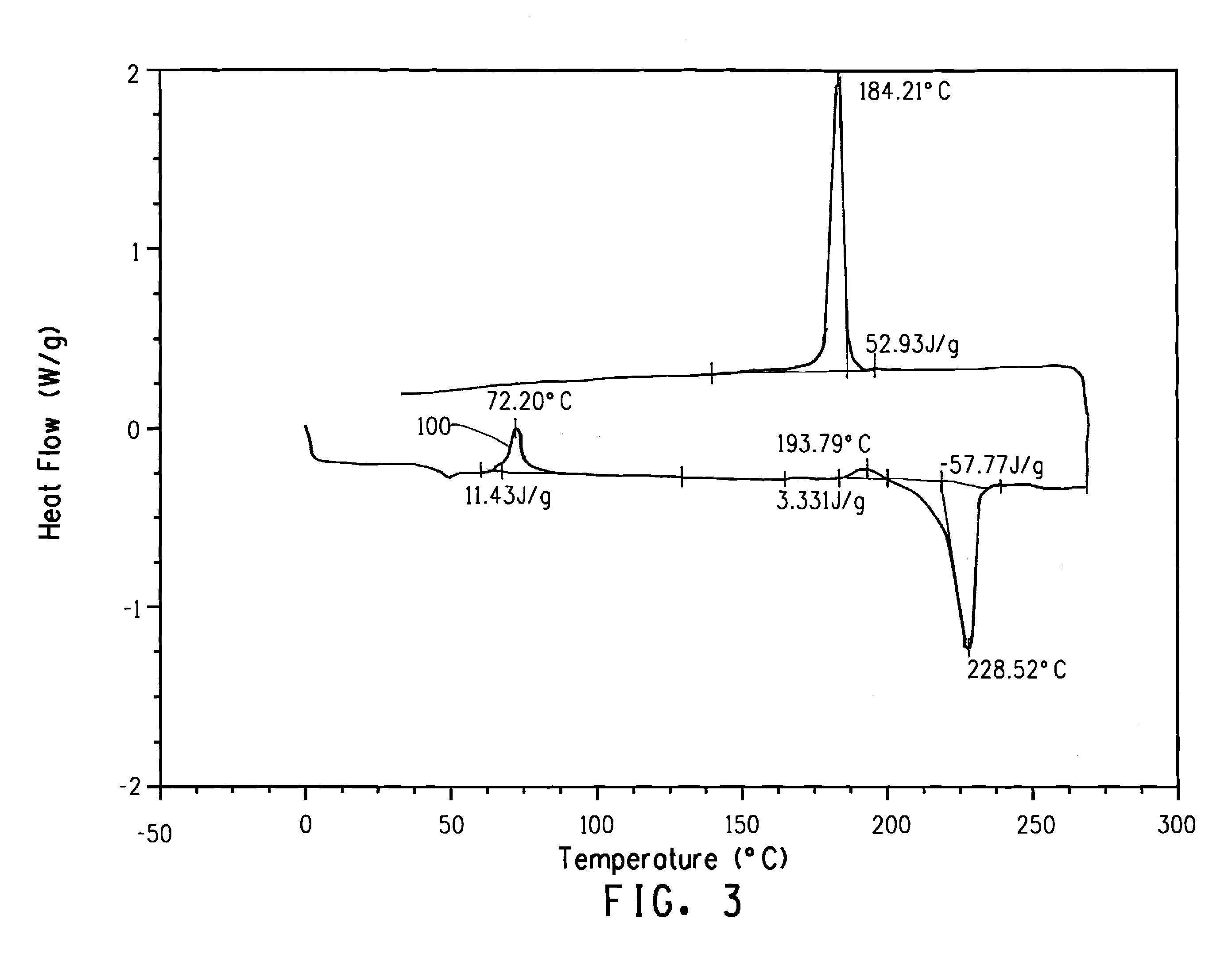

Toughened poly(trimethylene terephthalate) molding resins and molded articles therefrom

InactiveUS20110105644A1Easy for injection moldingLiquid surface applicatorsAlkaline-earth metal silicatesRepeat unitIonomer

Owner:EI DU PONT DE NEMOURS & CO

Plastic injection mould for mobile phone shell

InactiveCN103707469AEasy for injection moldingSimple mold opening processMechanical engineeringMobile phone

The invention relates to a plastic injection mould for a mobile phone shell. The plastic injection mould comprises a male mould plate and a female mould plate, wherein the female mould plate and the male mould plate are encircled to form a cavity; a fixed plate is fixedly provided with a first inclined stretching tip and a second inclined stretching tip, the female mould plate is provided with a first sliding block and a second sliding block, a first avoidance hole matched with the first inclined stretching tip is formed in the first sliding block, and a second avoidance hole matched with the second inclined stretching tip is formed in the second sliding block; the male mould plate is provided with a third sliding block, a wedge-shaped hole is formed in the third sliding block, and the female mould plate is fixedly provided with a guide post with a wedge-shaped end. According to the plastic injection mould of the mobile phone shell, mutually matched avoidance mechanisms are arranged on the male mould plate and the female mould plate, so that the plastic injection processing of inverted buckle parts of the mobile phone shell becomes simple and feasible. Moreover, the mould is simple in mould opening working procedure and high in processing efficiency.

Owner:SHENGYANG PRECISION MOLD KUSN

Copolyamide binder for metal powder injection molding and preparation method thereof

ActiveCN110437443AEasy to processImprove solubilityTransportation and packagingMetal-working apparatusPolymer scienceAlcohol

The invention discloses a copolyamide binder for metal powder injection molding and a preparation method, and relates to the technical field of copolyamide binders. The adhesive comprises the following components in percentage by mole: 30%-45% of aliphatic dimer acid, 6%-20% of aliphatic dicarboxylic acid, 45%-49% of aliphatic diamine and 1%-5% of aliphatic diol with carboxyl polar groups on sidechains. The copolyamide binder is easy to dissolve, especially easy to dissolve in an alcohol solvent, has good compatibility with metal powder, and is high in powder bearing capacity, small in volumeshrinkage, low in melt viscosity and easy to carry out injection molding processing.

Owner:安徽泰合新材料科技有限公司

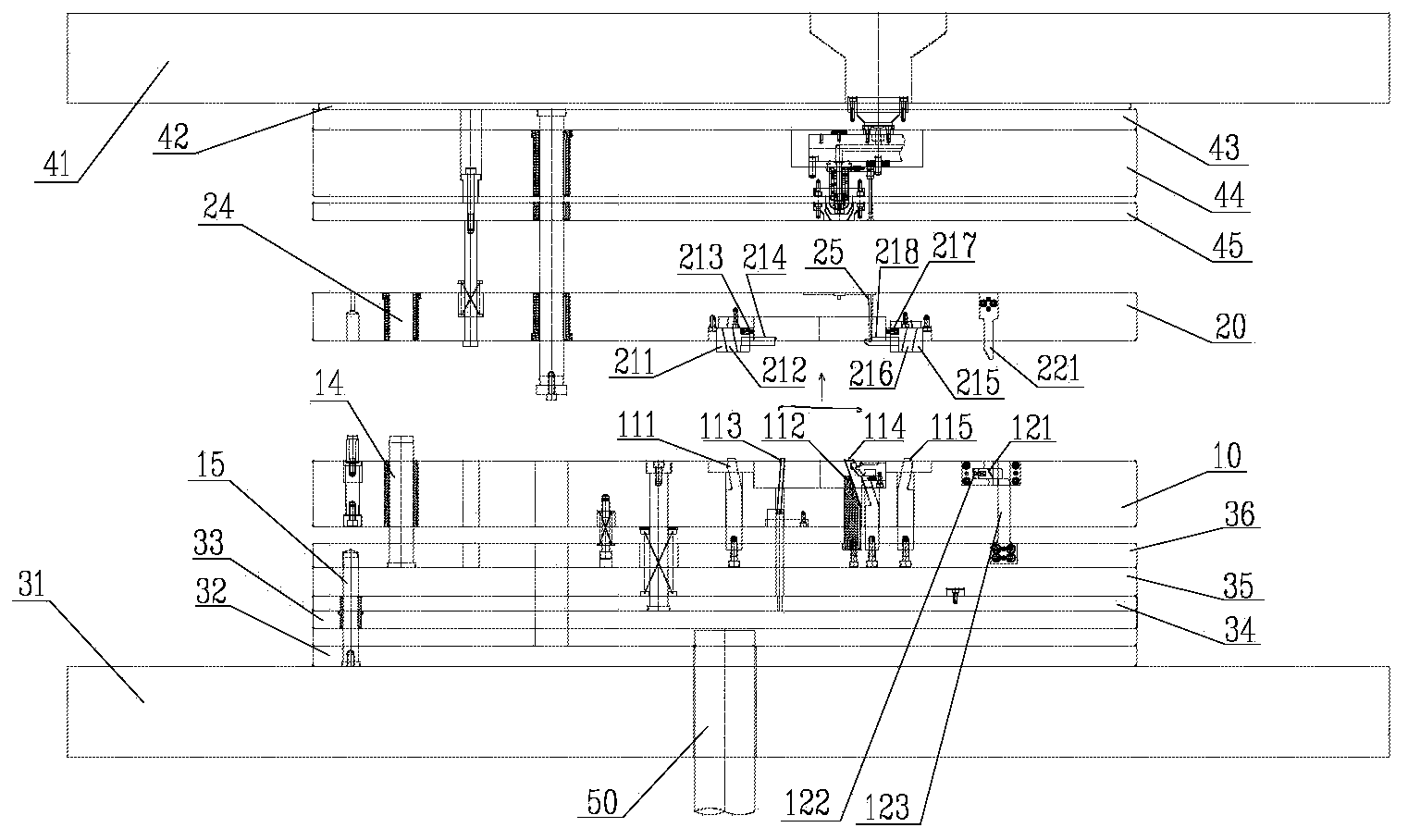

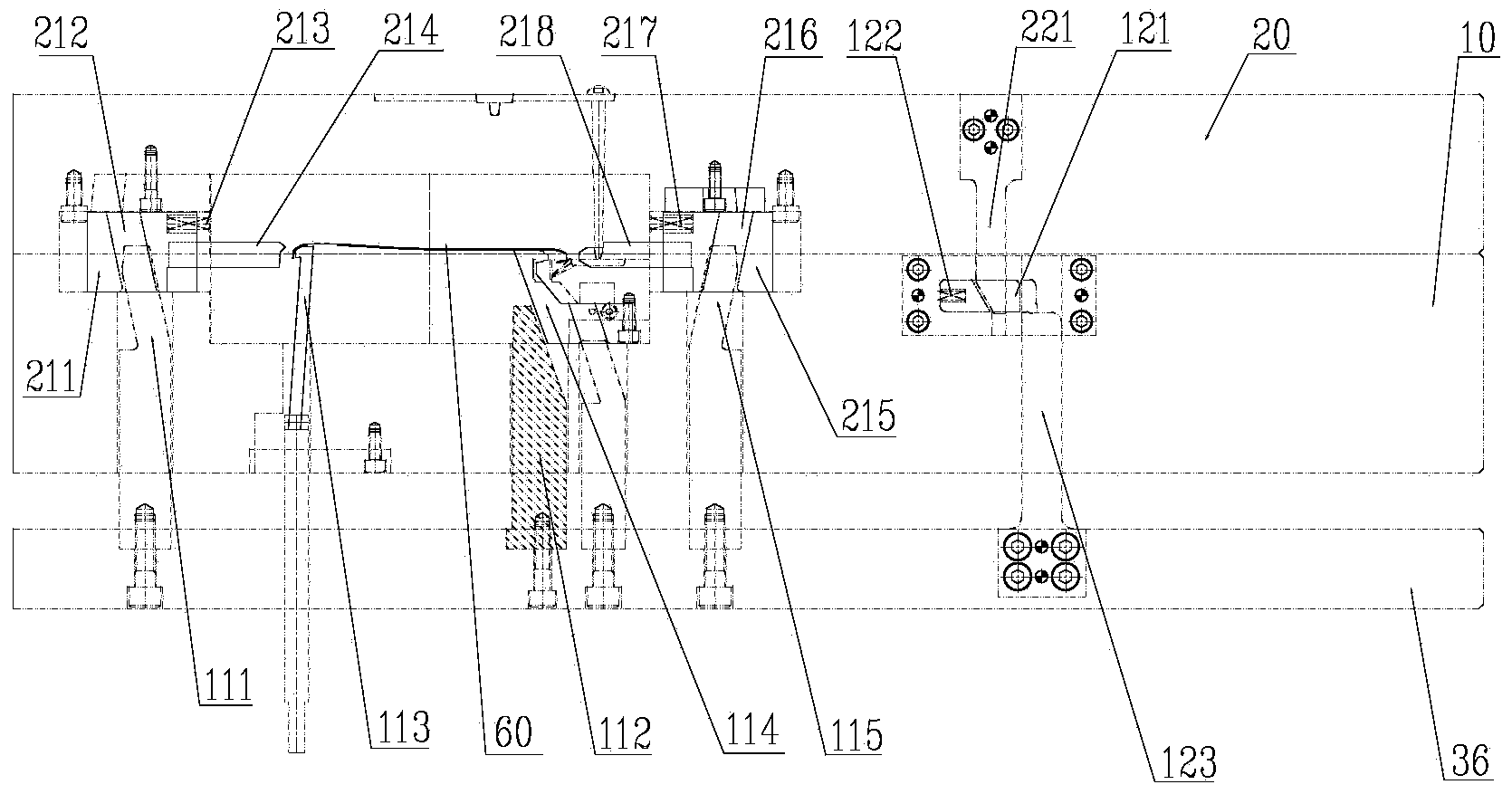

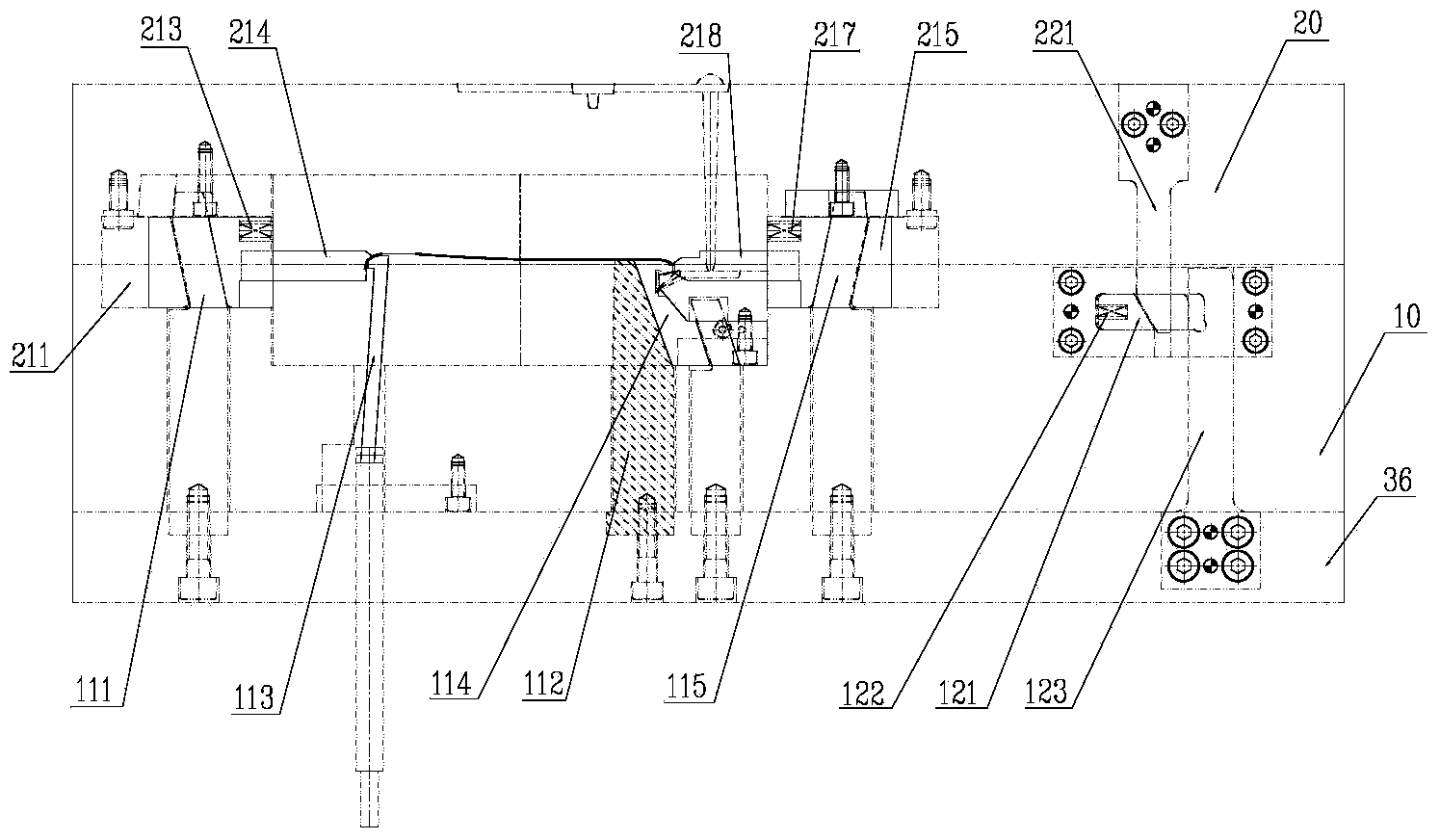

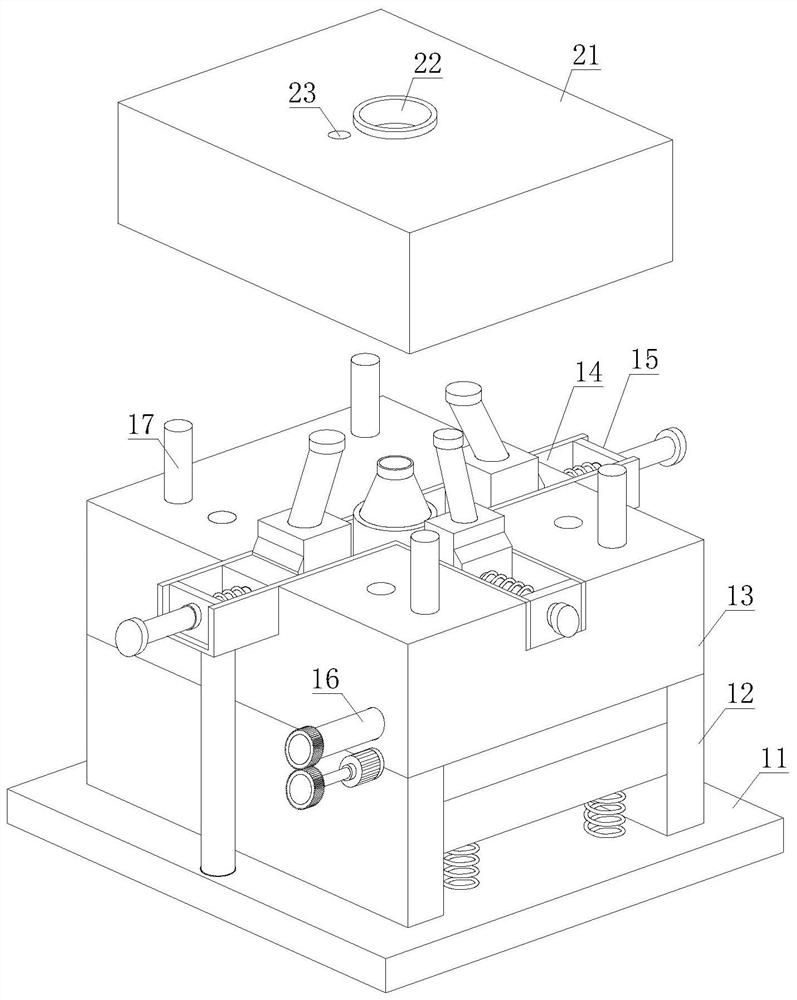

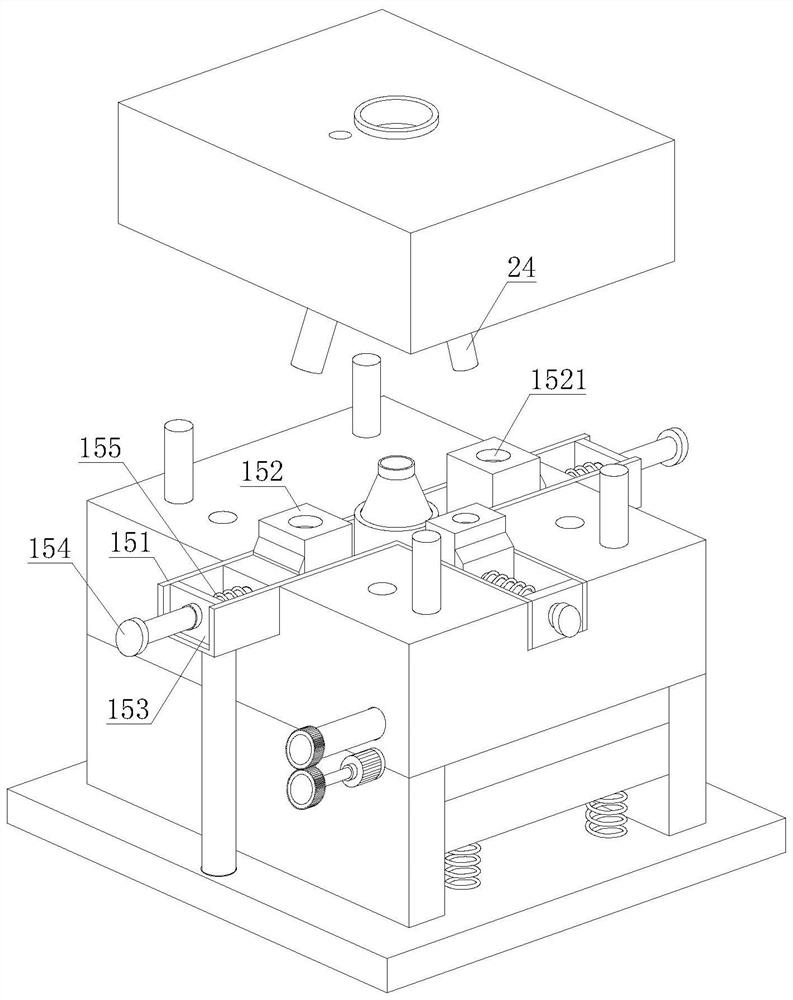

Shirt collar type mold machine with multi-directional core pulling mechanism and implementation method thereof

The invention discloses a shirt collar type mold machine with a multi-directional core pulling mechanism. The shirt collar type mold machine comprises a lower mold and an upper mold, wherein a slidingsleeve is a component made of stainless steel materials and is arranged inside a groove, so that sliding of a sliding block is facilitated; the sliding block is arranged inside the sliding sleeve, afixing block is fixedly arranged inside the sliding sleeve, a pull rod penetrates through the fixing block and is fixedly connected with the sliding block, a spring is fixedly arranged on the outer surface of the pull rod, and the two ends of the spring are connected with the sliding block and the fixing block respectively; and a pressing plate is lifted after forming, a first mold core drives thesliding block to move towards the two sides along the sliding sleeve in the upward moving process, the spring is compressed, a clamping ring is fixedly arranged on the inner wall of a core pulling hole, and a scraper is fixedly connected with the inner wall of the clamping ring. According to the shirt collar type mold machine, the lower end of the first mold core is wrapped by lubricating oil ofa sponge layer, then the first mold core is brought into the core pulling hole, when the first mold core passes through the scraper, the lubricating oil and burrs are scraped off by the scraper, the deburring effect is good, the lubricating oil is left in the core pulling hole, and the effect of lubricating the first mold core can be achieved conveniently.

Owner:河北万发服装纺织集团有限公司

Polypropylene composite material with high toughness under ultralow temperature and preparation method and application thereof

The invention provides a polypropylene composite material with high toughness under the ultralow temperature and a preparation method and application thereof.The polypropylene composite material comprises, by weight, 25-53% of polypropylene, 12-35% of pre-self-made modified polypropylene, 10-20% of flexibilizer, 10-30% of preprocessed super-fine filler, 0.3-0.5% of antioxygen and 0.5-1.5% of lubricant.Compared with the prior art, the super-fine filler (the average particle size is 5-15 microns) is processed with a composite coupling agent so as to improve rigidity of the composite polypropylene material, meanwhile the fracture mode of the material can tend to ductile fracture, and great significance is achieved in preventing debris from being splashed out in the explosion process; in addition, the polypropylene of the pre-self-made performance and the flexibilizer are adopted to jointly modify the polypropylene, and compatibility among materials is improved, so that low-temperature toughness is improved, and good processing fluidity is provided.

Owner:安徽纽麦特新材料科技股份有限公司

Mobile phone shell injection mould with safety hook

InactiveCN103753776AEasy for injection moldingSimple mold opening processDomestic articlesEngineeringMobile phone

The invention relates to a mobile phone shell injection mould with a safety hook. The mobile phone shell injection mould comprises a male template and a female template; the female template and the male template form a cavity in an encircling manner; a first inclined extension tip and a second inclined extension tip are fixedly installed on a fixed plate; a first sliding block and a second sliding block are arranged on the male template; a first avoidance hole matched with the first inclined extension tip is formed in the first sliding block; a second avoidance hole matched with the second inclined extension tip is formed in the second sliding block; a third sliding block is arranged on the male template; a wedge-shaped hole is formed in the third sliding block; a guide column, the end part of which is wedge-shaped, is fixedly installed on the female template; the safety hook is arranged on the female template; a fifth spring is installed on the female template; a fourth sliding block is arranged on the male template; and a support column, the end part of which is wedge-shaped, is installed on the fixed plate. According to the mobile phone shell injection mould disclosed by the invention, mutually matched avoidance mechanisms are arranged on the male template and the female template, therefore, injection processing of a mobile phone shell reverse buckling part is viable and simple; furthermore, the mobile phone shell injection mould disclosed by the invention is simple in mould-opening process and high in processing efficiency.

Owner:SHENGYANG PRECISION MOLD KUSN

Flexible LED SMD lamp belt

ActiveCN102788283BEasy for injection moldingPoint-like light sourceElectric circuit arrangementsWhole bodyLeading line

The invention relates to a flexible LED SMD lamp belt, which includes a core line, at least one flexible belt circuit board, and a covering layer, wherein the core line is a strip body made of flexible plastic through extrusion molding and is preset in length, a guide line is embedded in the core line, and the guide line is distributed in the length direction of the core line and is equal in length with the core line; a plurality of LED SMD are arranged on the flexible belt circuit board, the flexible belt circuit board is provided with a leading line, the leading line is electrically connected with the guide line so as to supply power to the LED SMD on the flexible belt circuit board; the covering layer is made of flexible plastic through extrusion molding, is equal in length with the core line, allows light to transmit, and covers the core line and the flexible belt circuit board; the flexible belt circuit board is coiled on the core line, and extends spirally in the length direction of the core line. The flexible LED SMD lamp belt has benefits as follows: the flexible LED SMD lamp belt is coiled on the core line spirally, LED are distributed on the whole peripheral surface of the core line, the 360-degree illumination on the peripheral surface can be realized, and the whole body emits light for illumination.

Owner:ZHONGSHAN MLIGHT PHOTOELECTRIC

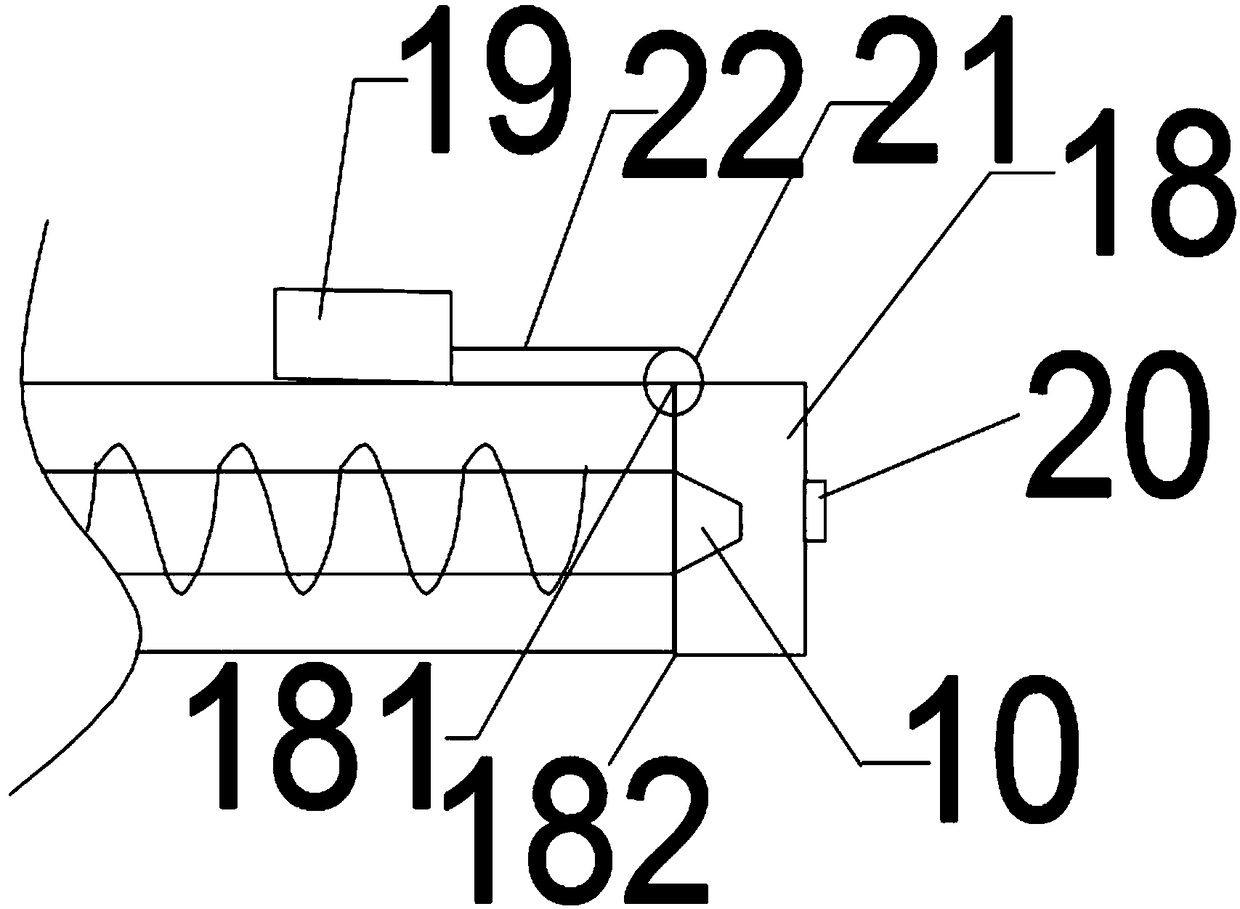

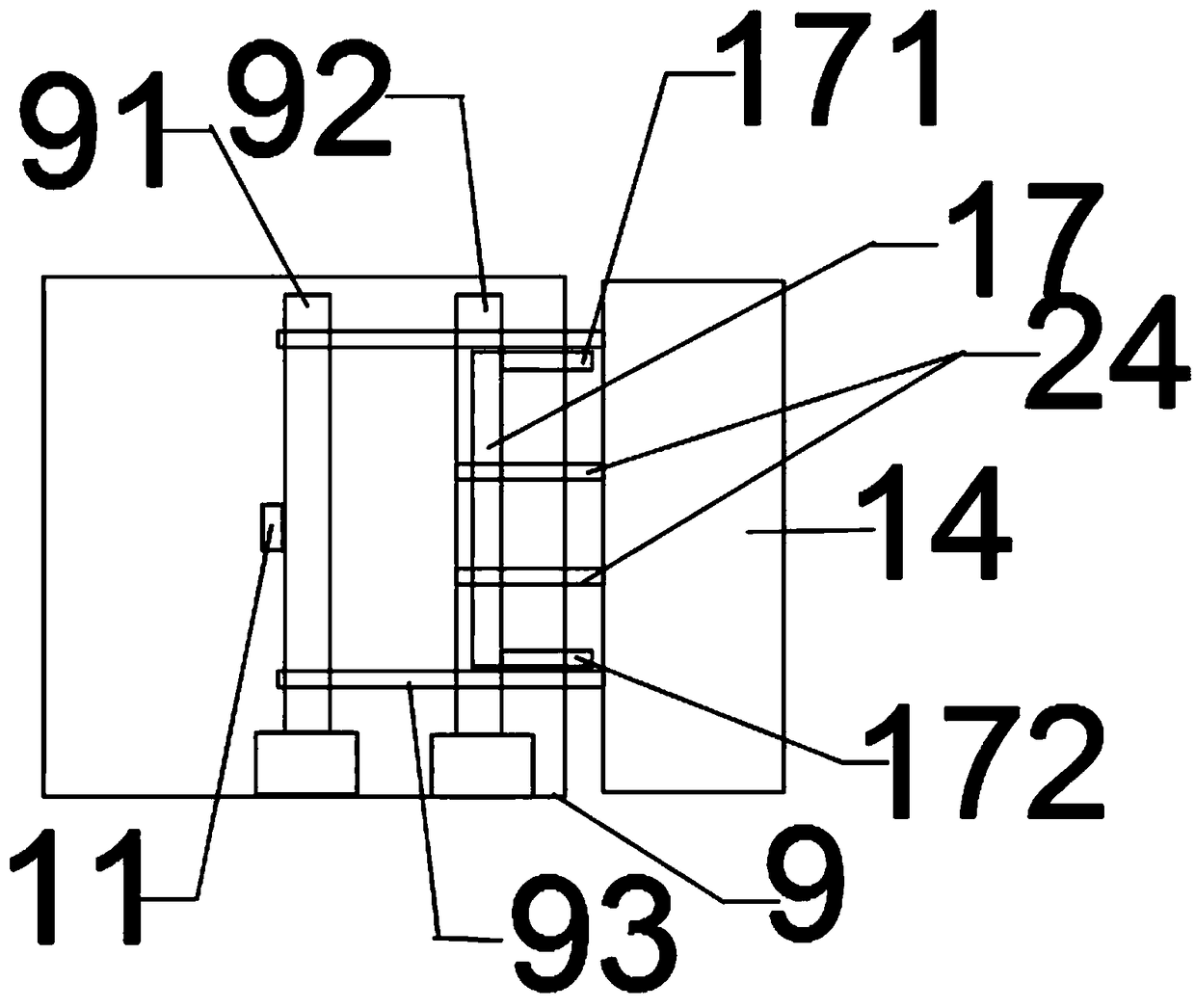

Intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine

The invention discloses an intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine. The intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine comprises a first motor, a material containing tank, a heating cavity and a material storage cavity, wherein the first motor is fixedly installed at the bottom of the left side of the material containing tank, and a conveying auger shaft is rotatably installed in the material containing tank; and an output shaft of the first motor is fixedly connected with the end of the middle conveying auger shaft in the material containing tank, the heating cavity is connected to the bottom of the other side of the material containing tank through a communicating pipe in a penetrating manner, a reciprocating lead screw is fixedly connected to the portion, located at the end of the conveying auger shaft, of the communicating pipe, and a threaded hose is connected to the edge of the end of the inner hollow rod in a penetrating manner. According to the intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine, the injection molding frequency can be changed according to different specifications of injection molding parts, and meanwhile, the melting efficiency and stability of injection molding raw materials can be improved, subsequent injection molding machining is facilitated, the injection molding quality is improved, and molding deformation damage to the injection molding parts is effectively reduced.

Owner:赵秉辉

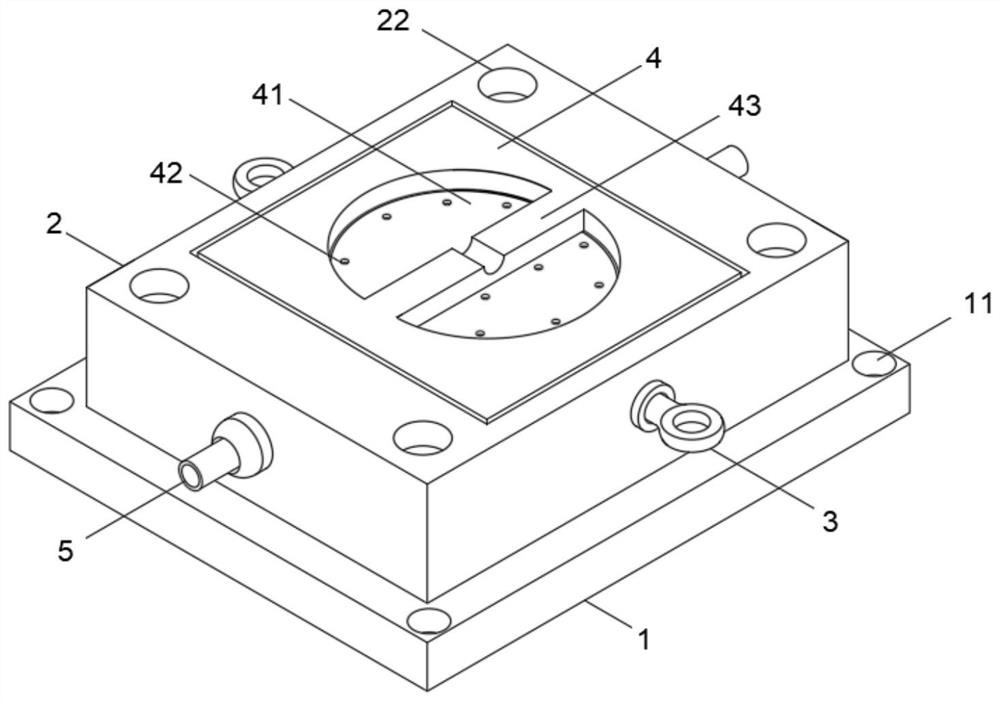

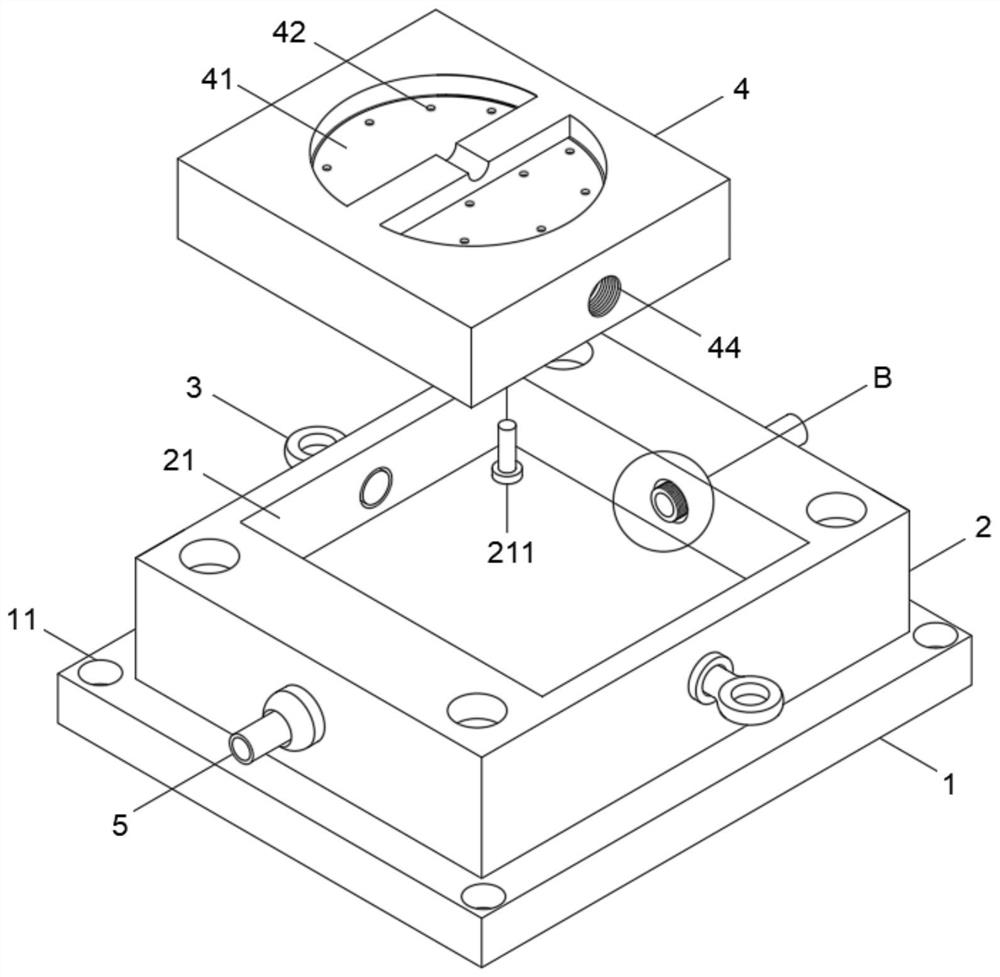

Forming die of injection molding machine

The invention discloses a forming die of an injection molding machine. The forming die comprises a base, mounting holes are formed in the four corners of the base, a lower die is fixedly connected to the upper end of the base, a mounting cavity is formed in the middle of the upper end of the lower die, limiting rods are mounted at the four corners in the mounting cavity, penetrating holes are formed in the four walls in the mounting cavity, and limiting holes are formed in the four corners of the top end wall of the lower die. Fixing bolts are installed on the left side wall and the right side wall of the lower die, air pipes are mounted on the front end wall and the rear end wall of the lower die, fixing rings are mounted at the roots of the two air pipes, an inner die is mounted in the mounting cavity, a plurality of forming cavities are formed in the inner die, and a plurality of air holes are formed in the inner bottom end walls of the multiple forming cavities. A lower die seat is composed of two parts, and the inner die is mounted in the lower die through fixing blots in a pin tensioning mode. When in use, the inner die can be taken out and mounted at will and is convenient to take out, subsequent replacement of dies of different sizes for injection molding is facilitated, the whole lower die does not need to be replaced, convenience and rapidness are achieved, and the practicability of the forming die is improved.

Owner:昆山安亿齐电子科技有限公司

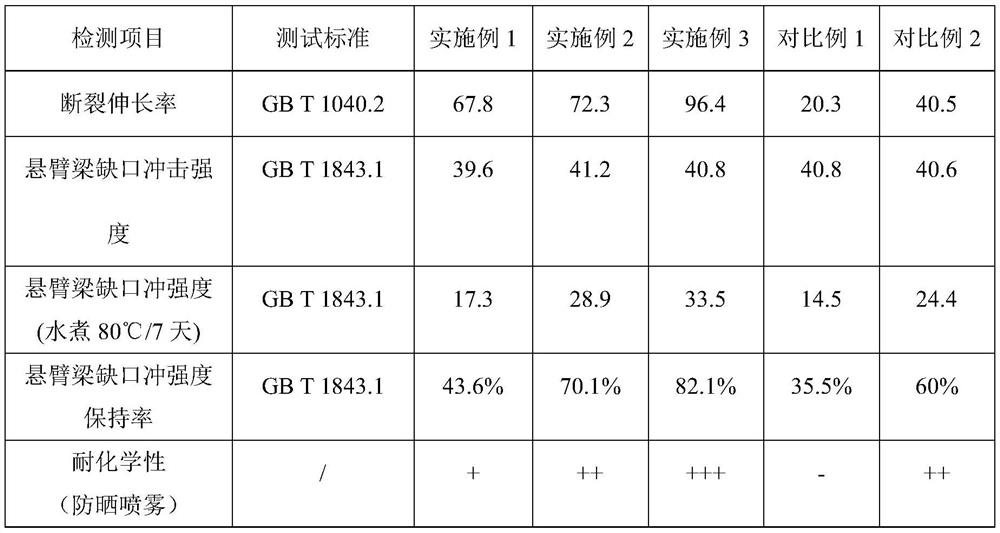

Antistatic glass fiber reinforced PBT/ASA composite material and preparation method thereof

InactiveCN109836783AGood physical propertiesBroad market spacePolytetramethylene terephthalateGlass fiber

The invention provides an antistatic glass fiber reinforced PBT / ASA composite material and a preparation method thereof. The composite material comprises the following ingredients (by weight): 20-30 parts of polybutylene terephthalate, 15-25 parts of ASA resin, 10-20 parts of glass fiber, 5-10 parts of a compatilizer, 1-5 parts of an anti-oxidant, 1-5 parts of a dispersant, 1-5 parts of an antistatic agent and 1-5 parts of a liquid additive. Under the precondition of guaranteeing excellent properties such as high strength, good electrical property, dimensional stability, good heat resistance,low water absorption and easy forming, the antistatic property of the composite material is enhanced. The invention brings greater profit margins for the application of PBT / ASA plastic alloy.

Owner:太仓市华鼎塑料有限公司

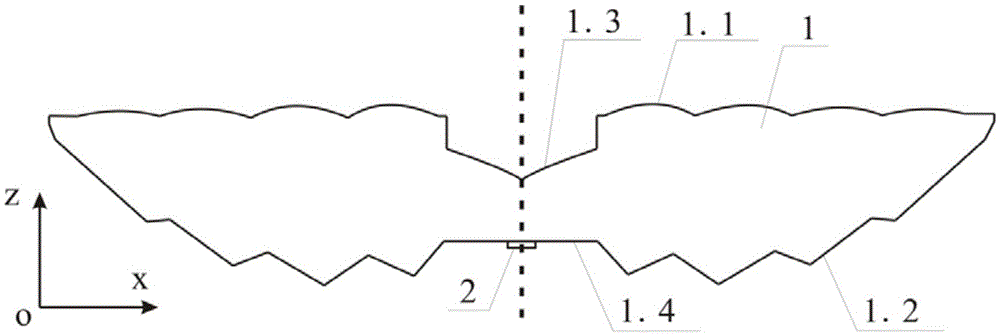

Flexible light-emitting diode (LED) surface mount device (SMD) lamp belt

InactiveCN102840492AEasy for injection moldingPoint-like light sourceElectric lightingWhole bodyFlexible circuits

The invention relates to a decorative illumination device, in particular to a flexible light-emitting diode (LED) surface mount device (SMD) lamp belt. The LED SMD lamp belt comprises a core wire, at least one flexible circuit board and a coating layer. A lead wire is buried inside the core wire and arranged along the length direction of the core wire, and the length of the lead wire is the same as that of the core wire. A plurality of LED SMDs are arranged on the flexible circuit board, the flexible circuit board is provided with a leading wire, and the leading wire is in electric connection with the lead wire to provide power for the LED SMDs arranged on the flexible circuit board. The coating layer coats outside the core wire and the flexible circuit board. The flexible circuit board comprises a belt-shaped body which is arranged along the length direction of the core wire, two long edges of the belt-shaped body are provided with several wing-shaped auxiliary boards in protruding mode, and the wing-shaped auxiliary boards are arranged at intervals and extend along the circumference direction of the core wire. All LED SMDs or some LED SMDs of the flexible circuit board are arranged on the wing-shaped auxiliary boards. The wing-shaped auxiliary boards extend along the circumference direction of the core wire, and therefore the whole circumference surface of the core wire can be provided with LEDs, illumination of 360 degrees can be achieved, and the whole body can emit light and illuminate.

Owner:ZHONGSHAN KESHUN ANALYTICAL & TESTING TECH

Compound-eye-based compact double-reflective photovoltaic concentrator

InactiveCN103441178BUniform illuminationImprove photoelectric conversion efficiencyPhotovoltaicsCondensersPolymethyl methacrylateEngineering

The invention relates to the photovoltaic power generation technology, and aims at providing a compact double reflection-type photovoltaic condenser based on compound eyes. The compact double reflection-type photovoltaic condenser based on the compound eyes comprises a photovoltaic cell and an optical collector, wherein the upper surface of the optical collector comprises a free curved surface and a refraction curved surface, the lower surface of the optical collector comprises a transmission plane and a reflection plane, the center of the refraction curved surface and the center of the reflection plane are positioned at the same vertical position, the center of the free curved surface and the center of the transmission plane are positioned at the same vertical position, and the free curved surface is arranged at a focal position of the refraction curved surface; and the photovoltaic cell is arranged outside the optical collector and adjoins to the transmission plane, the photovoltaic cell is positioned at a focal position of the free curved surface, and the aperture of the transmission plane is larger than that of the photovoltaic cell. The compact double reflection-type photovoltaic condenser has the advantages that the photovoltaic conversion efficiency of the photovoltaic cell is improved, the service life of the photovoltaic cell is prolonged, an optical plastic PMMA (polymethyl methacrylate) is adopted and is prone to injection molding and processing, light in weight and applicable to large-scale processing, and the processing cost is reduced.

Owner:ZHEJIANG UNIV

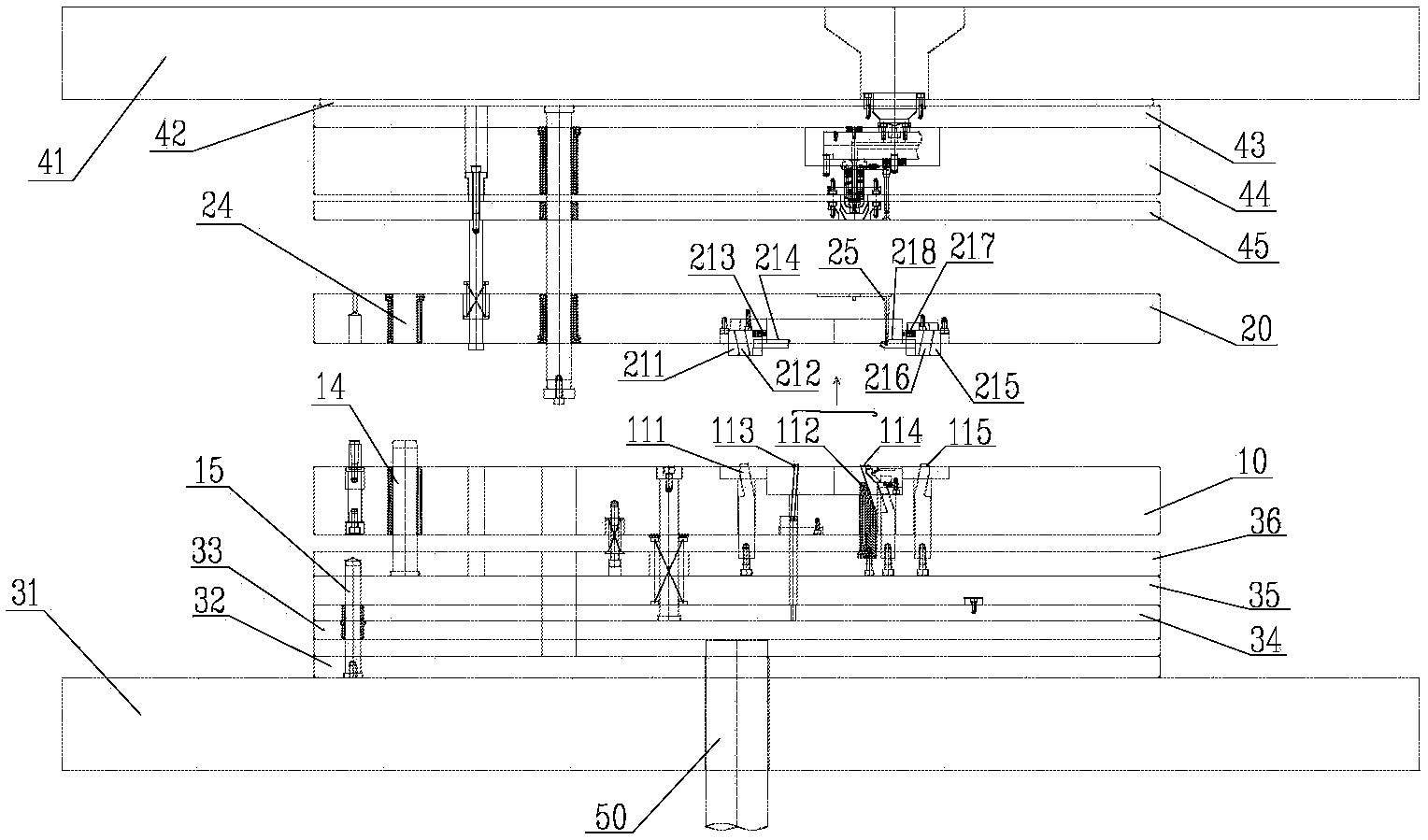

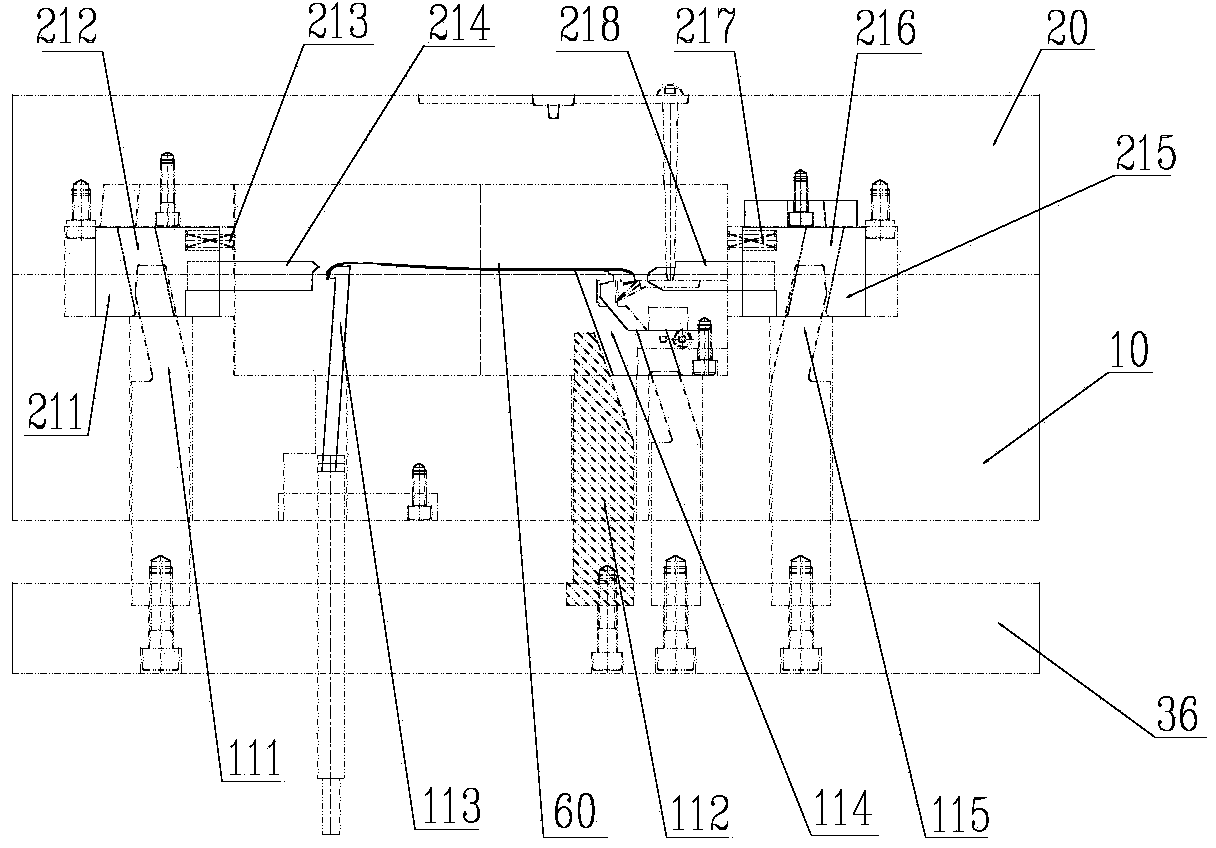

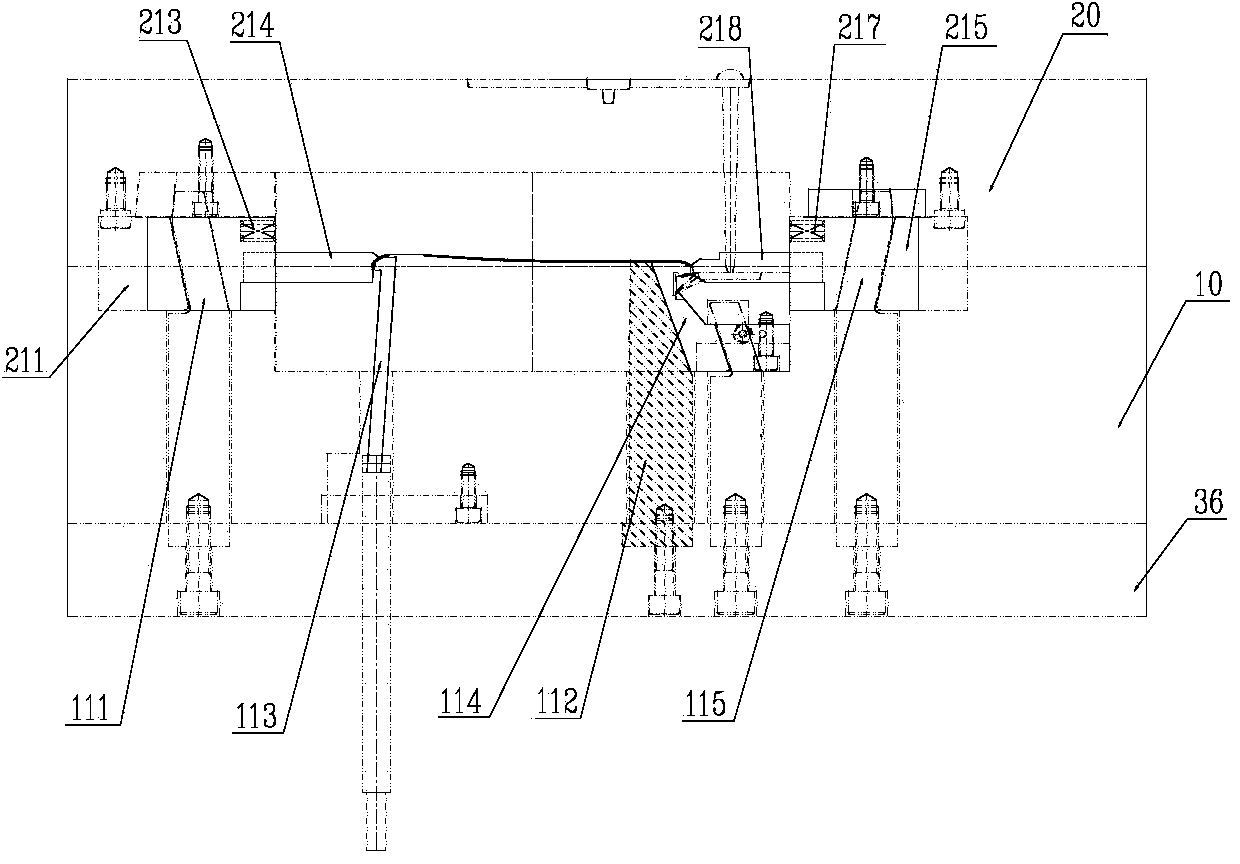

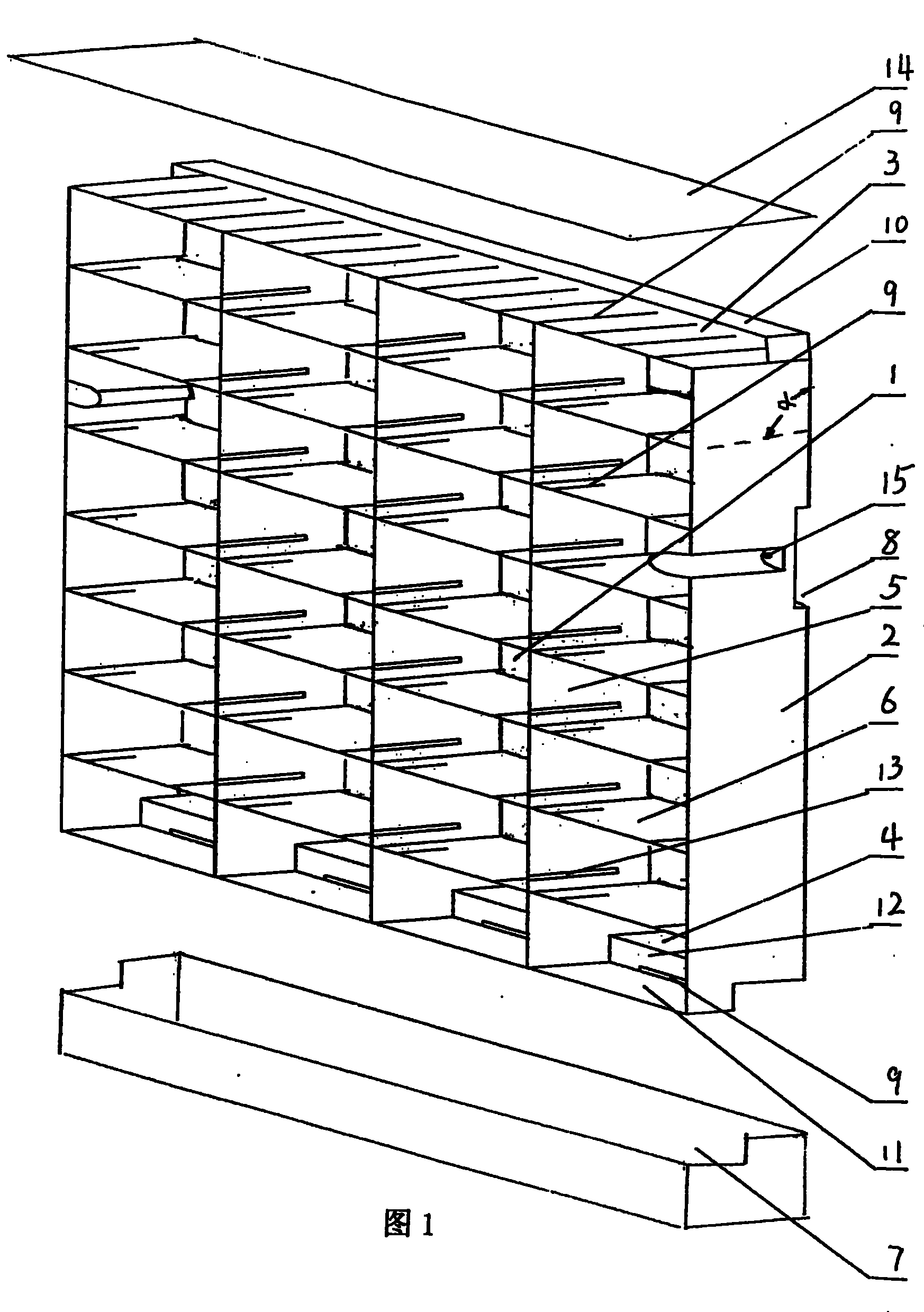

Drying tobacco drying shed and drying device and tobacco leaf clip

InactiveCN103404958BOvercoming drapeRealize cluster dryingTobacco preparationEngineeringUltimate tensile strength

The invention discloses a sun-cure shed for sun-cured tobaccos, sun-cure devices and tobacco clips. The sun-cure shed comprises a shed. The shed is provided with a plurality of rows of sun-cure units, and transverse channels are arrange at the ends of the sun-cure units; a plurality of upright columns are arranged on two sides of each sun-cure unit, a plurality of slide rails are arranged on opposite sides of the upright columns, and the corresponding sun-cure devices are arranged on the slide rails on each same layer and can slide along the slide rails; the multiple tobacco clips used for clamping the tobaccos are arranged on the sun-cure devices. The sun-cure shed, the sun-cure devices and the tobacco clips have the advantages that the sun-cure shed is provided with the sun-cure devices and the tobacco clips used for clamping the multiple tobaccos, and the tobaccos can be subjected to sun-cure in a clustered manner by the aid of the sun-cure devices; the sun-cure devices can slide along the slide rails, so that the tobaccos can be fed mechanically and can be cured in an industrialized manner; the shortcoming of draping of tobacco braiding ropes is overcome, accordingly, the tobacco sun-cure density is increased as compared with a tobacco sun-cure mode implemented by the aid of the tobacco braiding ropes, and tobaccos of 82 tobacco plants can be cured in each square meter of the steel-structured shed while only tobaccos of 33 tobacco plants can be cured in each square meter of an existing standard cure shed; the production efficiency is improved, the integral cost is lowered, and the labor intensity is reduced.

Owner:湖北省烟草公司宜昌市公司

Glass fiber reinforced polycarbonate composite material and its preparation method and application

The invention discloses a glass fiber reinforced polycarbonate composite material, its preparation method and its application in the preparation of notebook casings. The composite material is made of the following raw materials in parts by weight: polycarbonate 40-65 parts; special-shaped glass fiber 30-50 parts; flame retardant 2-8 parts; anti-dripping agent 0.1-1 part; compatibilizer 2-8 parts; antioxidant 0.2-3 parts; lubricant 0.2- 3 parts; the special-shaped glass fiber is an alkali-free flat chopped glass fiber, the width of the special-shaped glass fiber is 30-40 μm, the thickness is 2-5 μm, and the length is 350-450 μm. The material of the invention has the characteristics of ultra-high modulus, low warpage, high flame retardancy, high impact performance, and good coating performance, and at the same time, the injection molding process is simple and the cost is low, and it is very suitable for preparing the notebook shell.

Owner:CGN JUNER NEW MATERIALS +1

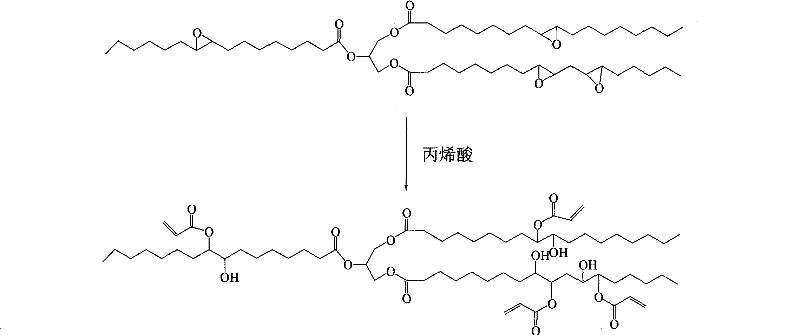

Environment-friendly polyvinyl chloride elasticizer and method of preparing the same

InactiveCN101367958BMeet environmental protection requirementsImprove plasticityContour matchingVegetable oil

Owner:SOUTH CHINA UNIV OF TECH

Halogen-free flame-retardant PC/ABS alloy material and preparation method thereof

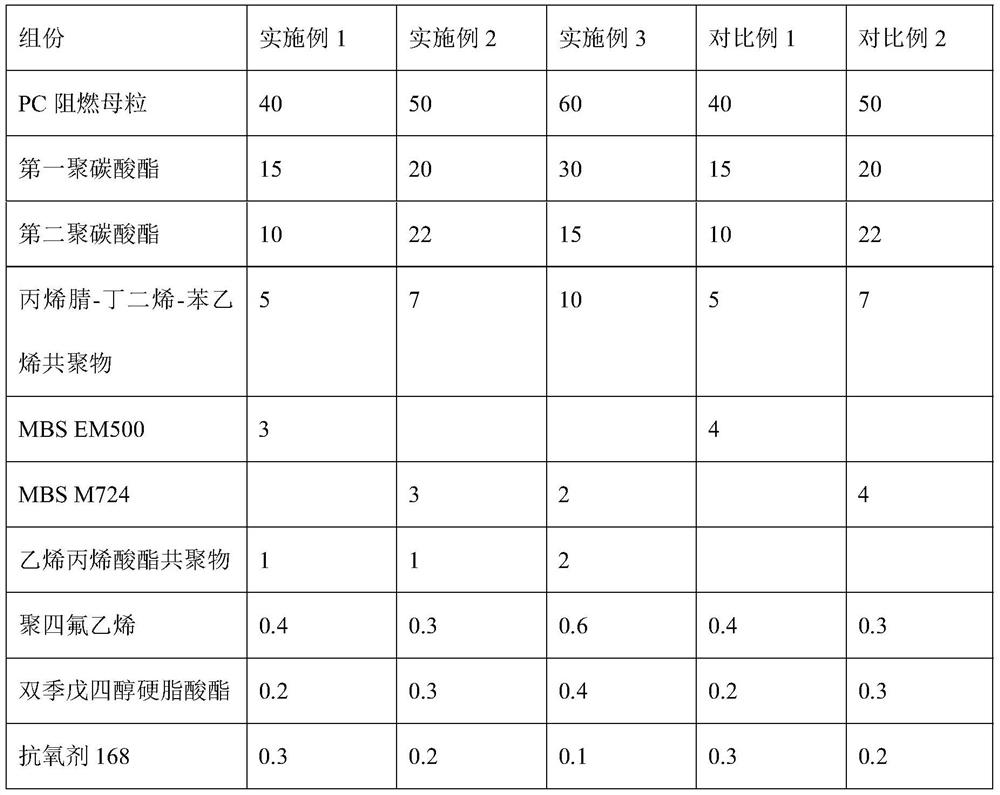

The invention discloses a halogen-free flame-retardant PC / ABS alloy material, which is prepared from the following components in parts by weight: 40 to 60 parts of flame-retardant PC master batch, 15 to 30 parts of first polycarbonate, 10 to 22 parts of second polycarbonate, 5 to 10 parts of acrylonitrile-butadiene-styrene copolymer, 2 to 4 parts of methacrylate-butadiene-styrene copolymer, 1 to 2 parts of ethylene acrylate copolymer, 0.3 to 0.6 part of polytetrafluoroethylene, 0.2 to 0.4 part of stearate and 0.1 to 0.3 part of antioxidant. According to the halogen-free flame-retardant PC / ABS alloy material and the preparation method thereof provided by the invention, the halogen-free flame-retardant PC / ABS alloy material has relatively high elongation at break, high performance retention rate under high temperature and high humidity, and strong chemical reagent resistance, and can improve the problems that the PC / ABS is easy to break when being applied to a screw stud and a buckle on an electronic and electrical appliance shell, the performance is severely degraded under high temperature and high humidity, and the PC / ABS alloy material is easy to induce cracking when being in contact with a chemical reagent and the like, so that the PC / ABS material can be widely applied in the field of electronic and electrical appliances and under severe environment requirements.

Owner:ORINKO NEW MATERIAL CO LTD

Upper and lower cover plastic mold with mold closing positioning anti-deviation structure

The invention relates to an upper and lower cover plastic mold with a mold closing positioning anti-deviation structure. The upper and lower cover plastic mold comprises a shell and a permanent magnet. An upper mold assembly penetrates through the upper wall of the shell, and the permanent magnet is located at the front end of the upper mold assembly. A buffer assembly comprises a sleeve, a piston, a cushion head, second guide rods, a second spring, a slender rod, a movable block and a connecting rope. The second guide rods are arranged on the left side and the right side of the cushion head, and the lower end of the piston is connected with the slender rod. The upper and lower cover plastic mold with a mold closing positioning anti-deviation structure has the beneficial effects that equipment can be kept horizontal to facilitate injection molding machining of the equipment; the equipment can realize automatic aligning and mold closing, and the situation of position deviation during mold closing of the equipment is prevented; the equipment can be fixed during mold closing and prevented from being jacked open by pressure; the equipment can still perform accurate butt joint mold closing when a mold deviates; and the equipment can perform buffering during mold closing, so that the mold is prevented from being collided and damaged.

Owner:深圳市赛雨易昊科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com