Environment-friendly polyvinyl chloride elasticizer and method of preparing the same

A technology of polyvinyl chloride and plasticizer, applied in the field of environment-friendly plasticizer composition, can solve the problems of poor transparency of PVC film, increase the amount of epoxy vegetable oil added, increase the difficulty of injection molding processing, etc., and achieve low Viscosity, reduced viscosity, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

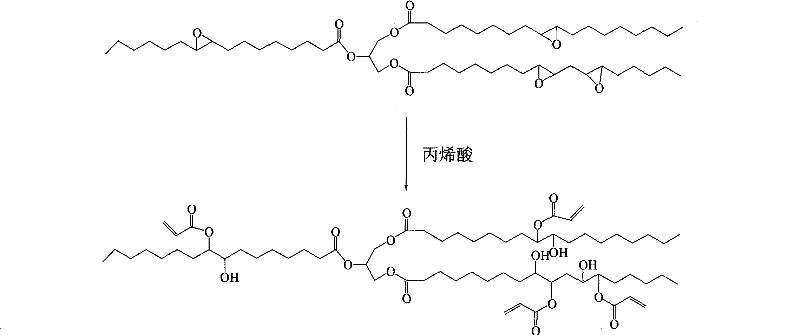

[0029] The preparation method of this environment-friendly plasticizer comprises the steps:

[0030] (1) Modification treatment of epoxy soybean oil: when the epoxy soybean oil oil bath is heated to 90°C, add dropwise The mixed solution of acrylic acid, epoxidized soybean oil: triphenylphosphine: triethylbenzylamine bromide: triethylamine: hydroquinone: acrylic acid is 100:0.1:0.5:0.1:1.0:20 by mass ratio. Control the rate of addition to complete the dropwise addition of the mixed solution within 60 minutes. After the dropwise addition of the mixed solution is completed, the oil temperature is raised to 135° C., and the reaction is stopped after continuing the constant temperature reaction for 3.5 hours. Firstly, the product was washed with 50° C. pure soda water until the pH value was 6, and then the product was washed with saturated saline and soft water successively until the pH value was 7.

[0031] (2) Dehydration treatment: the modified epoxy soybean oil obtained in ste...

Embodiment 2

[0039] The preparation method of this environment-friendly plasticizer comprises the steps:

[0040] (1) Modification treatment of epoxy soybean oil: when the epoxy soybean oil oil bath is heated to 65°C, dropwise add Mixed solution of diphenol and acrylic acid, epoxy soybean oil: triphenylphosphine: didodecyldimethylammonium bromide: triethylamine: hydroquinone: acrylic acid in a mass ratio of 100:2.0:3.5: 3.0:0.02:20. Control the rate of addition to complete the dropwise addition of the mixed solution within 20 minutes. After the dropwise addition of the mixed solution is completed, the oil temperature is raised to 95° C., and the reaction is stopped after continuing the constant temperature reaction for 1.5 hours. Firstly, the product was washed with 50°C soda water until the pH value was 5, and then the product was washed with saturated saline and soft water successively until the pH value was 7.

[0041] (2) Dehydration treatment: the modified epoxidized soybean oil obt...

Embodiment 3

[0044] (1) Modification treatment of epoxy soybean oil: when the epoxy soybean oil oil bath is heated to 85°C, dropwise add triphenylphosphine, tetraoctyl ammonium chloride, ethylenediamine, hydroquinone and acrylic acid Mixed solution, epoxy soybean oil: triphenylphosphine: tetraoctyl ammonium chloride: triethylamine: hydroquinone: acrylic acid in mass ratio of 100:1.0:1.5:1.0:0.02:5. Control the rate of addition to complete the dropwise addition of the mixed solution within 40 minutes. After the dropwise addition of the mixed solution is completed, the oil temperature is raised to 95° C., and the reaction is stopped after continuing the constant temperature reaction for 3.5 hours. Firstly, the product was washed with 50° C. pure soda water until the pH value was 6, and then the product was washed with saturated saline and soft water successively until the pH value was 7.

[0045] (2) Dehydration treatment: the modified epoxidized soybean oil obtained in step (1) is transferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com