Upper and lower cover plastic mold with mold closing positioning anti-deviation structure

A plastic mold and mold technology, which is applied in the field of upper and lower cover plastic molds, can solve the problems of reducing the service life of the mold, waste, deformation of the mold clamping part, etc., and achieve the effects of reducing friction, preventing collision damage, and preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

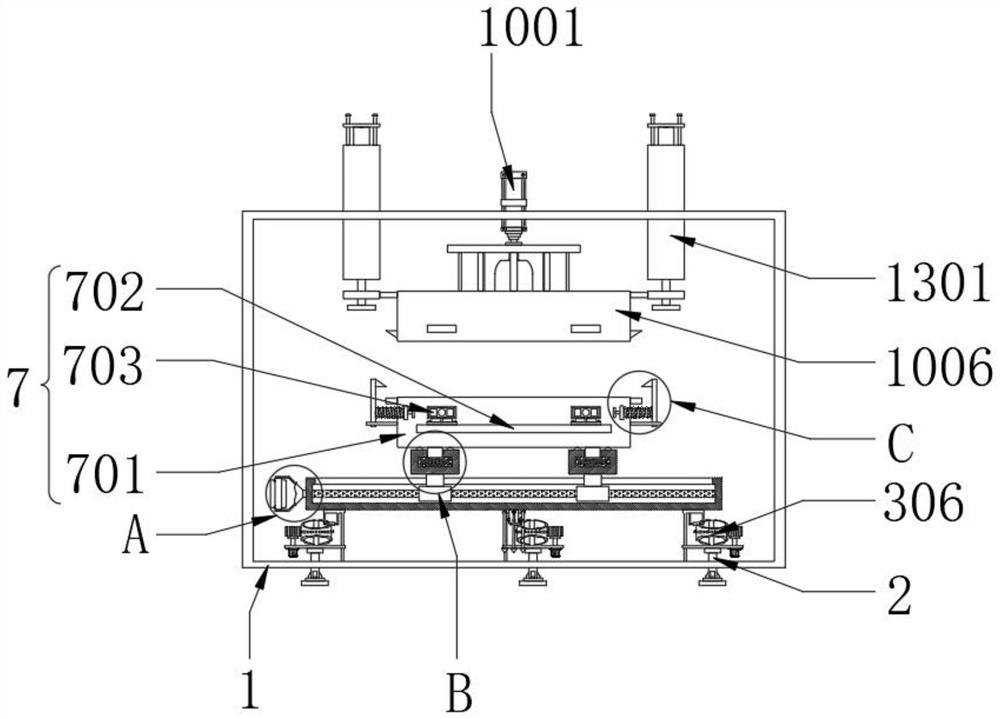

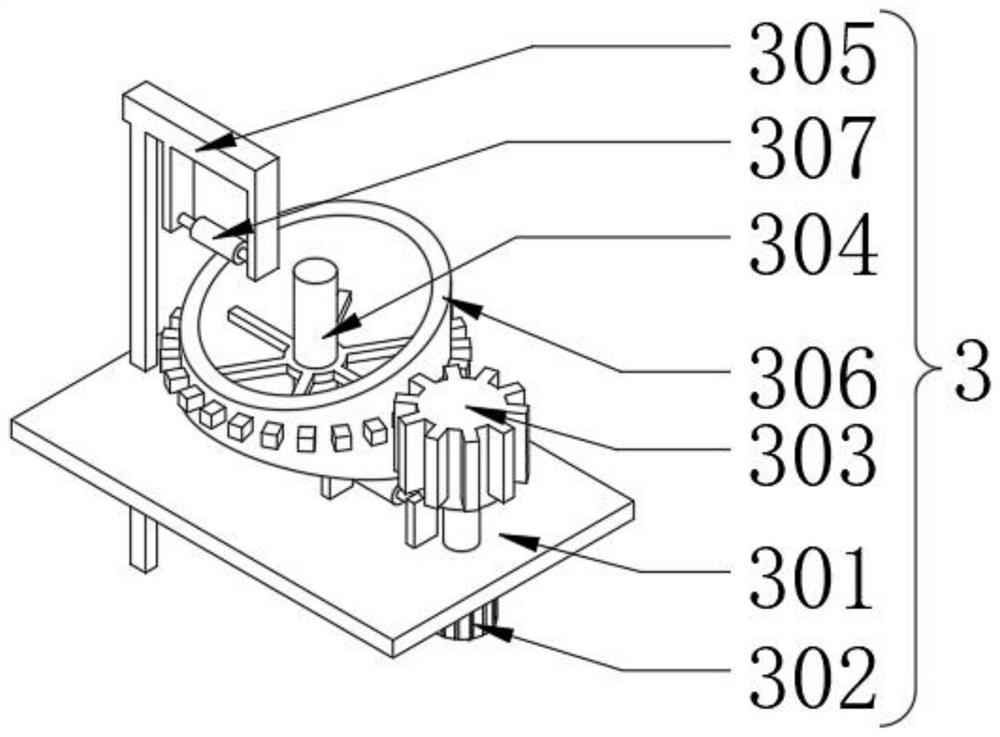

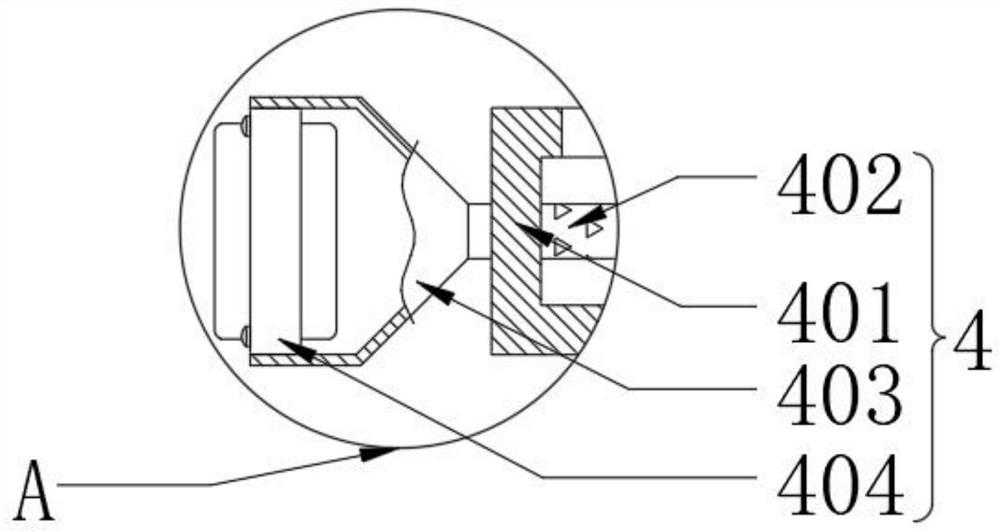

[0031] Such as Figure 1 to Figure 8 As shown, the present invention provides a technical solution: an upper and lower cover plastic mold with a mold clamping positioning anti-deviation structure, including a casing 1 and a permanent magnet 11, a support 2 runs through the lower wall of the casing 1, and the upper end of the support 2 is provided with a The lifting adjustment assembly 3, the upper end of the lifting adjustment assembly 3 is provided with a left and right translation assembly 4, and the central axis of the left and right translation assembly 4 is provided with a detection assembly 5, and the upper end of the left and right translation assembly 4 is provided with a front and rear translation assembly 6, and the front and rear translation assembly 6 is installed with a lower mold assembly 7, and the left and right sides of the lower mold assembly 7 are sequentially provided with a self-locking assembly 8 and a limit block 9 from bottom to top. The front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com