Drying tobacco drying shed and drying device and tobacco leaf clip

A drying device and drying shed technology are applied in the fields of tobacco, tobacco preparation, application, etc., which can solve the problems of easy falling, affect the quality of tobacco leaves, easy to produce mildew, etc., achieve smooth changes in elasticity, improve drying efficiency, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

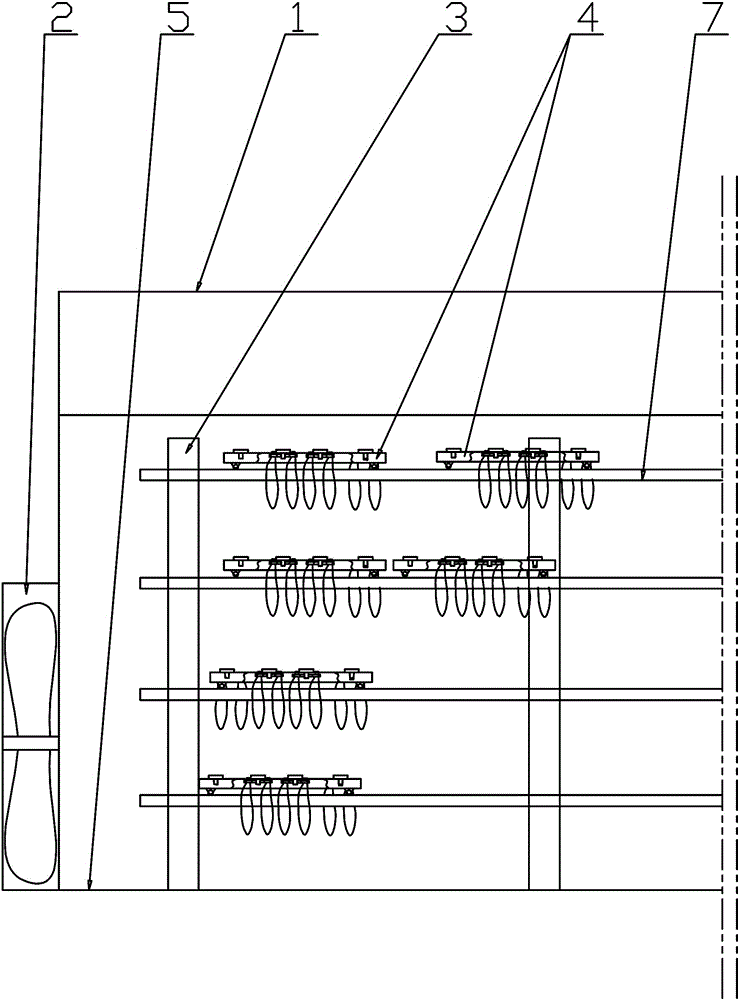

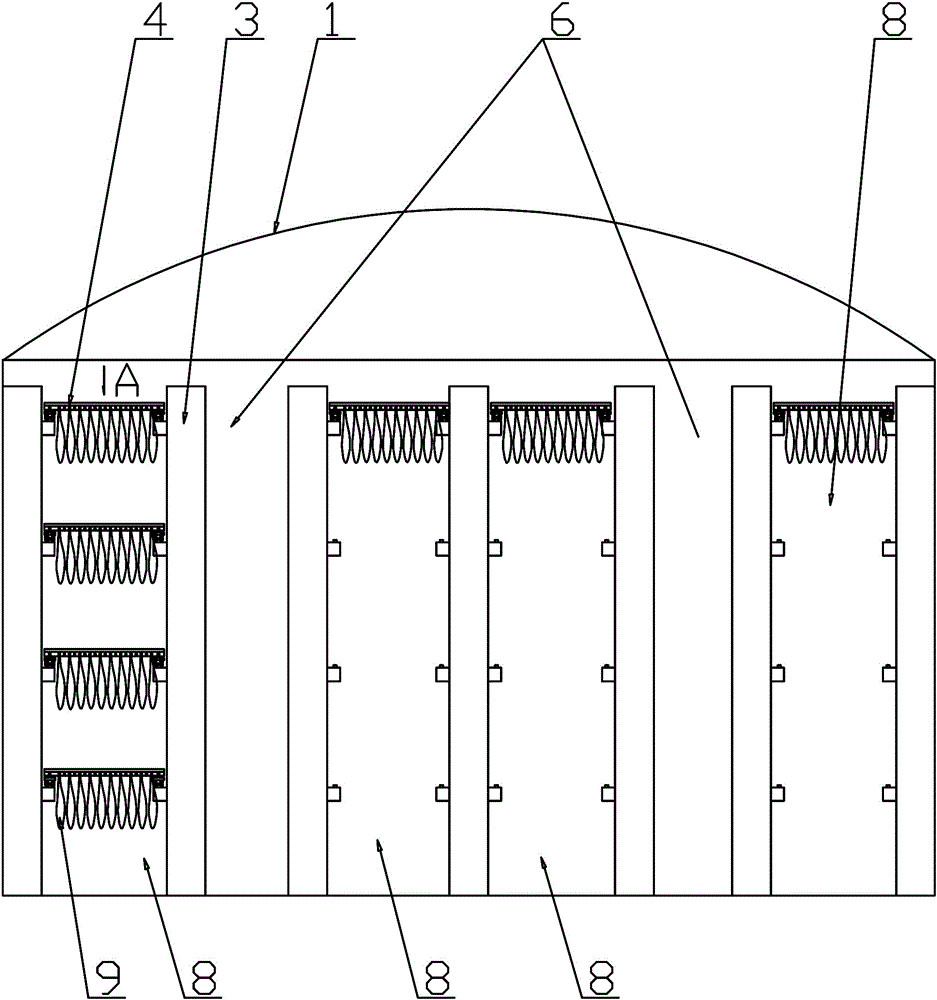

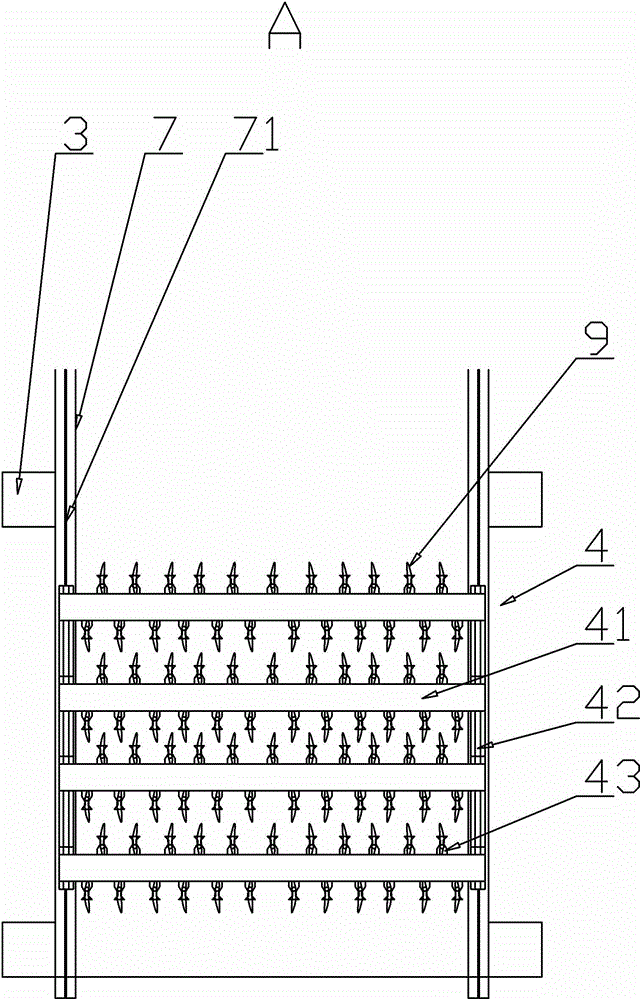

[0034] Such as Figure 1~3 Among them, a tobacco drying shed for drying tobacco, comprising a shed body 1, a multi-row drying unit 8 is arranged on the shed body 1, and a transverse channel 5 is provided at the end of the drying unit 8; preferably, between the drying units 8 are also provided Longitudinal channel 6, so that the operator can walk around. Further preferably, a plurality of blowing devices 2 are also provided in the shed body 1 to enhance the flow of air.

[0035] In the drying unit 8, a plurality of columns 3 are arranged on both sides of the drying unit 8, and a plurality of slide rails 7 are arranged from top to bottom on the opposite side of the column 3, and slide rails 7 on the same floor are provided with A drying device 4 that can slide along the slide rail 7; in this example, 4 slide rails 7 are arranged from top to bottom, and the distance between each slide rail 7 is 1 meter to 1 meter 4, due to the adoption of the drying device 4 and The combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com