Polypropylene composite material with high toughness under ultralow temperature and preparation method and application thereof

A composite material, polypropylene technology, applied in the field of preparation, polypropylene composite materials, can solve problems such as difficulty in obtaining rigidity and toughness, low temperature brittleness, large shrinkage rate, poor impact resistance, etc., achieve good processing fluidity and improve compatibility Sex, easy injection molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

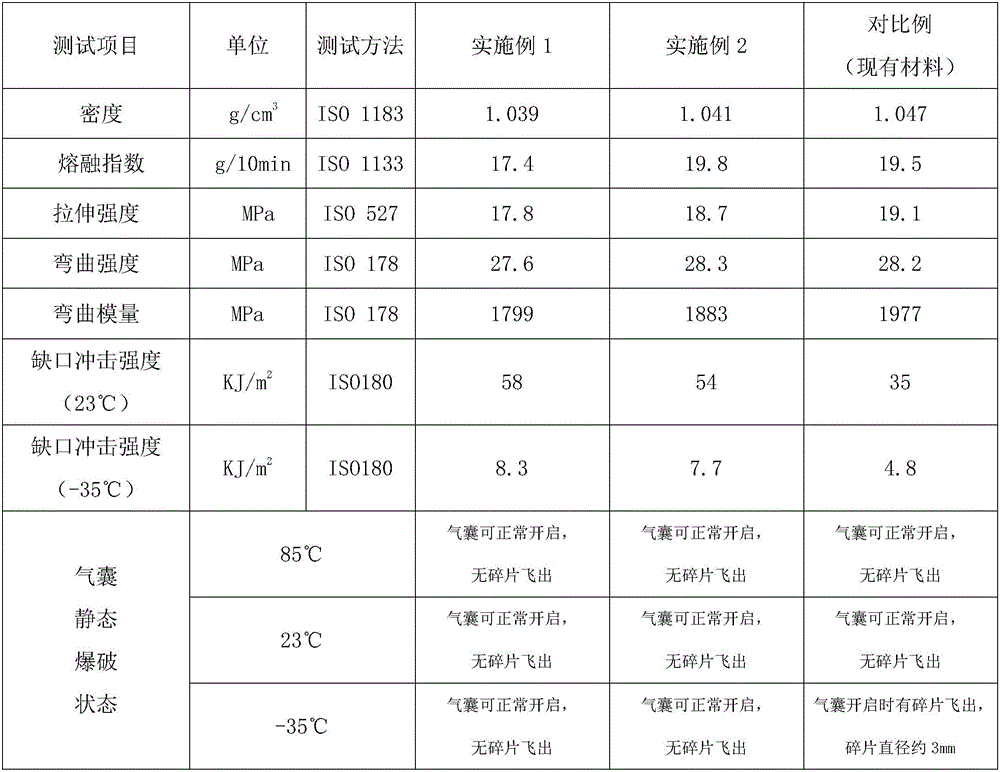

Examples

Embodiment 1

[0025] A polypropylene composite material with high toughness at ultra-low temperature, comprising the following raw materials in weight percentage: 37.3wt% polypropylene (PPM1600), 29.9wt% pre-made modified polypropylene, 12wt% toughening agent (POE, 5030S), 20wt% Pretreatment ultrafine talcum powder, 0.3wt% antioxidant (antioxidant 1010: 0.1%, antioxidant 168: 0.2%), 0.5wt% lubricant (EB-FF).

[0026] A method for preparing a polypropylene composite material with high toughness at ultra-low temperature, comprising the following steps:

[0027] (1) In the pretreatment ultrafine filler system, 100 parts by mass of 1500-mesh ultrafine talc powder and 1.2 parts by mass of aluminum-titanium composite coupling agent were mixed and stirred under a high-speed mixer for 8 minutes to obtain pretreated ultrafine talc powder.

[0028] (2) In the pre-made modified polypropylene system, add 7 parts by mass of POE model: 5030S, 6 parts by mass of molecular weight regulator (peroxide master...

Embodiment 2

[0033] A polypropylene composite material with high toughness at ultra-low temperature, including the following raw materials in weight percentage: 33.5wt% polypropylene (AP03B), 33.5wt% pre-made modified polypropylene, 12wt% toughening agent (POE model is 670), 20wt% % pretreatment ultrafine filler, 0.3wt% antioxidant (1010: 0.15%, 168: 0.15%), 0.7wt% lubricant.

[0034] A method for preparing a polypropylene composite material with high toughness at ultra-low temperature, comprising the following steps:

[0035] (1) In the pretreatment superfine filler system, 50 parts by mass of 3000 mesh ultrafine talc powder, 50 parts by mass of muscovite powder of 2000 mesh, and 1.5 parts by mass of rare earth coupling agent were mixed and stirred under a high-speed mixer for 8 minutes to obtain a pretreated ultrafine filler system. fine filler;

[0036] (2) In the pre-made modified polypropylene system, add 5 parts by mass of POE (preferably POE model is 5030S), 6 parts by mass of pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com