High-performance plastic injection molding machine with cooling device and injection molding method

A high-performance plastic and cooling device technology, applied in the field of high-performance plastic injection molding machines and injection molding, can solve the problems of not meeting the production needs of enterprises, the cooling effect of the cooling device is not good, and the surface of the finished product is uneven, and the structure design is compact and reasonable. , High qualified rate of finished products, good effect of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

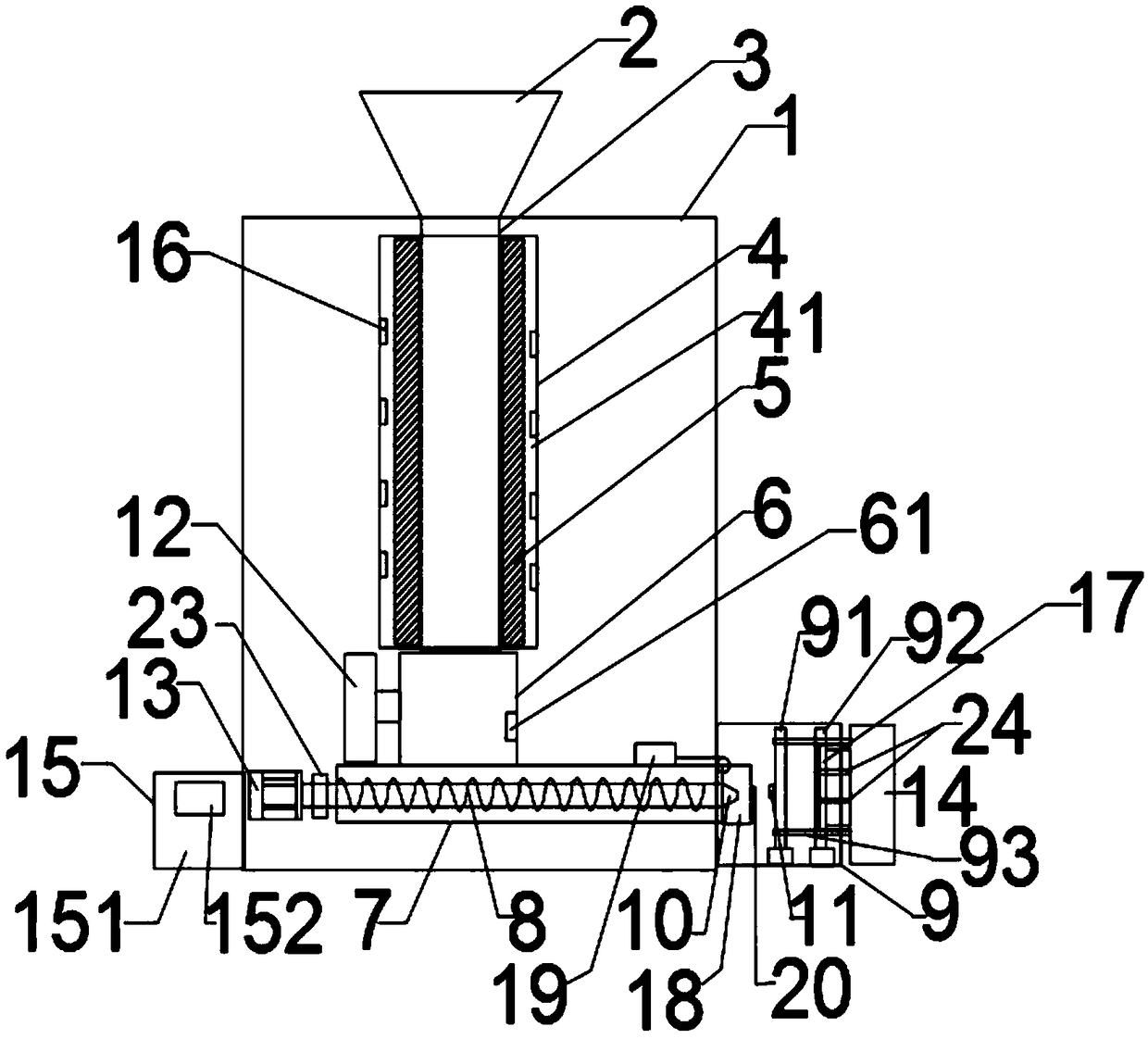

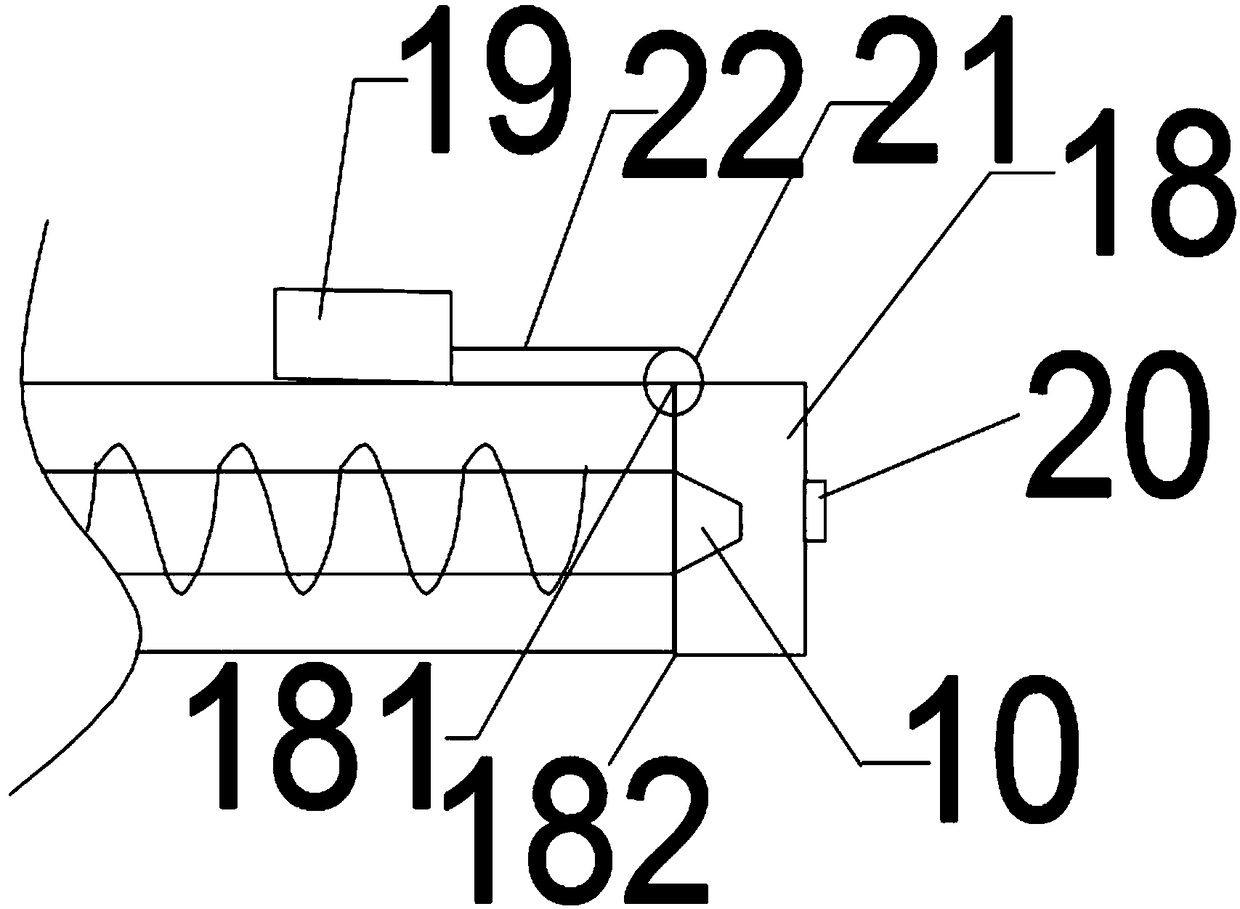

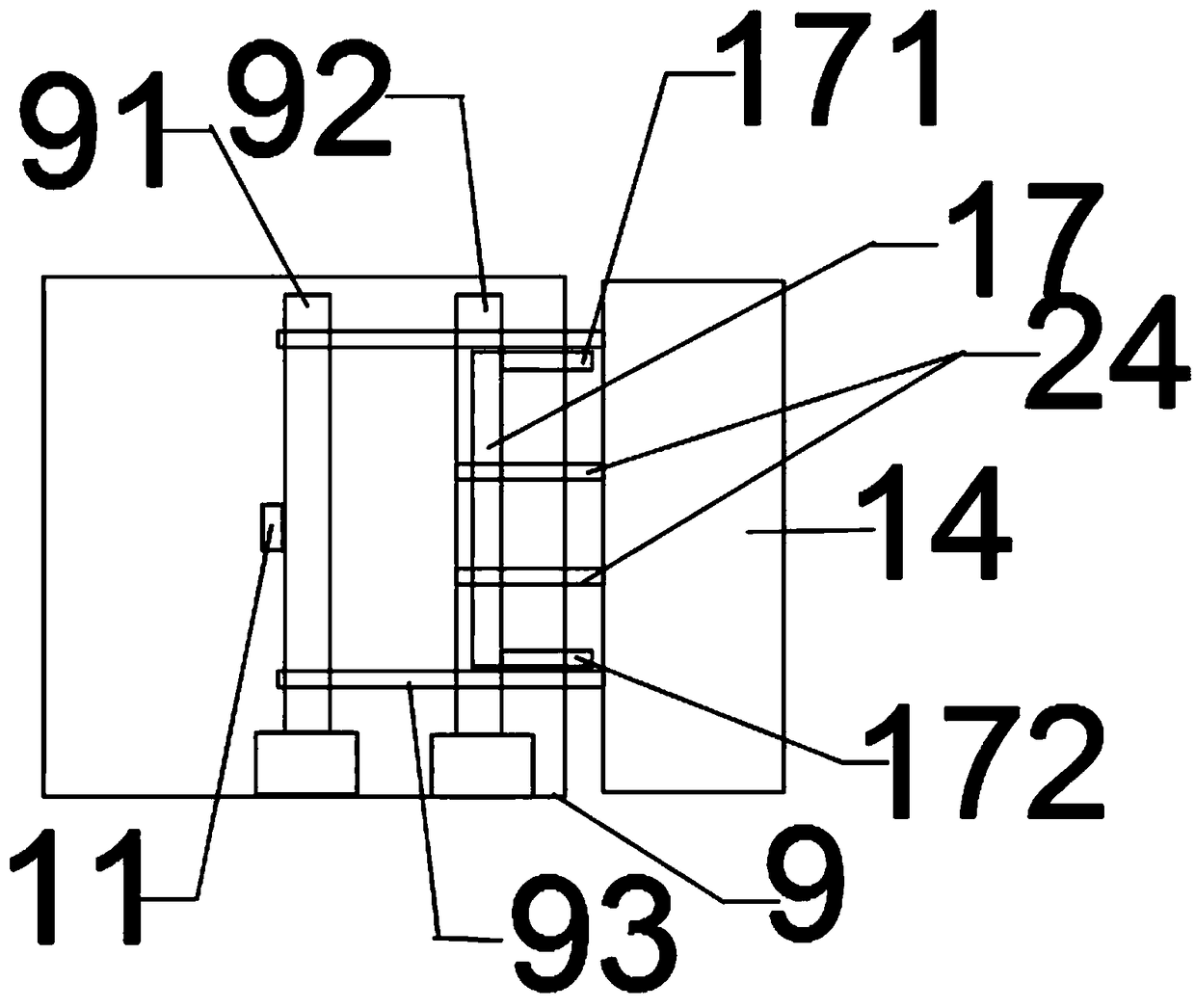

[0035] like Figure 1-4 As shown, a high-performance plastic injection molding machine with a cooling device includes an injection molding machine body 1, a material inlet 2, a first material delivery channel 3, a heating pipeline 4, a buffer warehouse mechanism 6, a second material delivery channel 7, Injection molding mechanism 9, cooling device 17, ejection mechanism 24,

[0036] The feed port 2 is arranged on the top of the injection molding machine body 1, and the feed port 2 is tapered, with a large upper end and a small lower end;

[0037] The first delivery channel 3 is vertically arranged inside the injection molding machine body 1 and the upper end of the first delivery channel 3 is connected to the lower end of the feed port 2;

[0038] The heating pipe 4 is arranged on the outside of the first material delivery channel 3 and concentrically arranged with the first material delivery channel 3 , and a heating pipe 4 is arranged in the cavity 41 between the first mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com