High-flowability and low-internal-stress electroplated ABS (acrylonitrile butadiene styrene) material and preparation method thereof

An ABS material and internal stress technology, which is applied in the preparation of blended materials and the field of styrene-acrylonitrile-butadiene materials, can solve the problems of low fluidity of electroplated ABS, improve flow performance, reduce internal stress, and flow sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

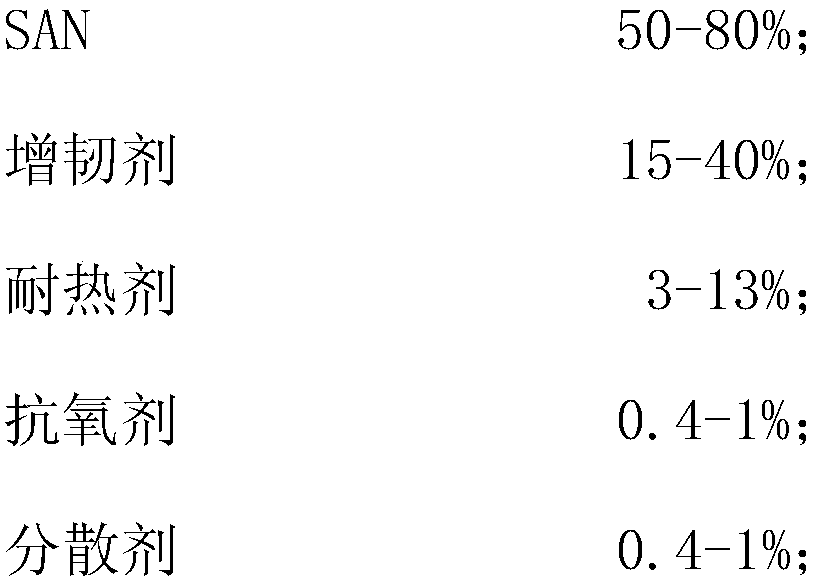

Method used

Image

Examples

Embodiment Construction

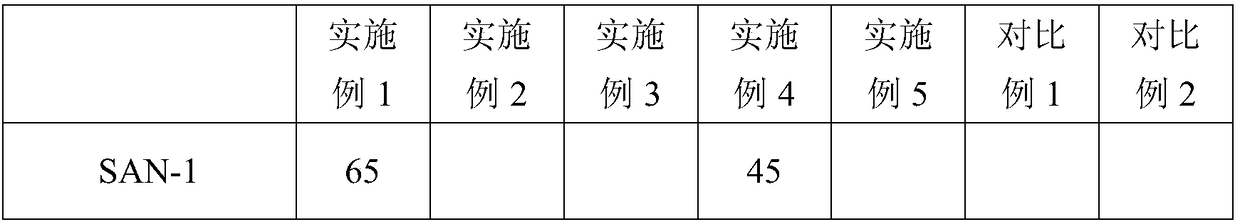

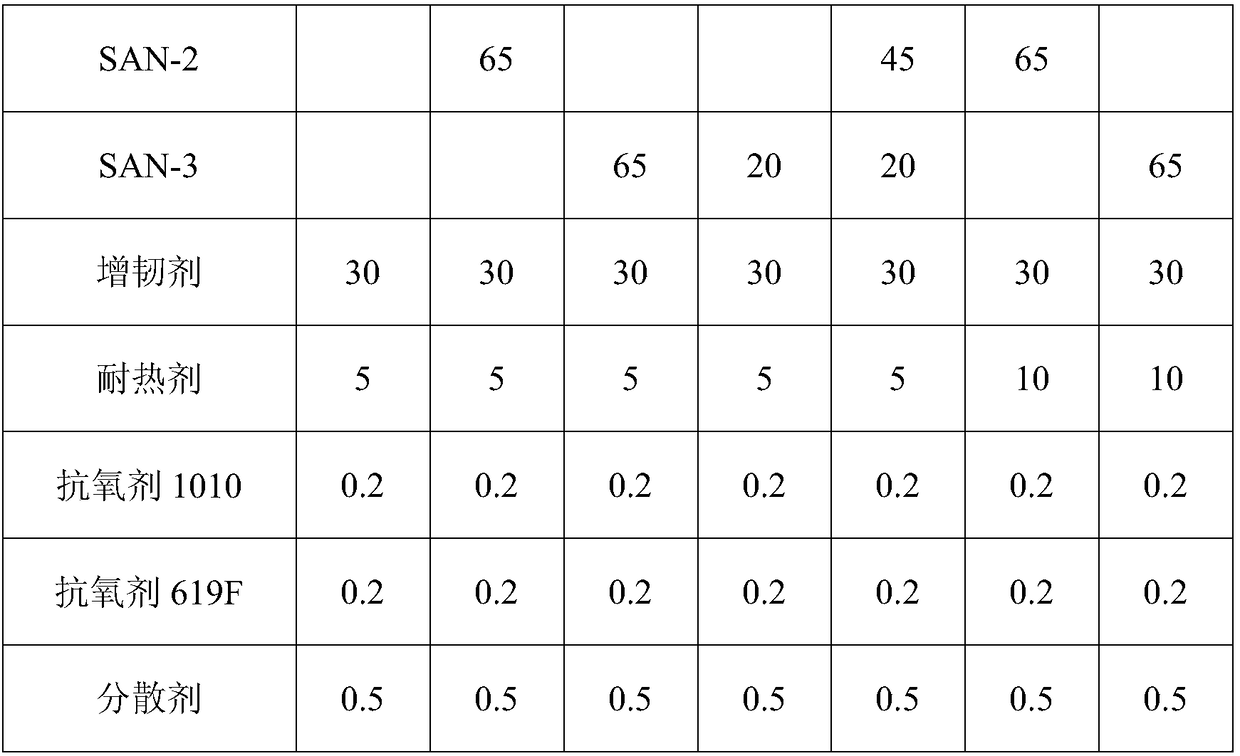

[0020] The present invention will be further described below through specific examples, but the examples are only used to illustrate the present invention rather than limit the present invention.

[0021] Raw materials used in the present invention:

[0022] SAN-1: produced by Zhenjiang Chimei, PN-138H;

[0023] SAN-2: produced by LG Chemical Company, PN-80HF;

[0024] SAN-3: Zhenjiang Chimei, PN-108L;

[0025] Toughener: ABS high-glue powder, model HR-181, 60% glue content, Korea Kumho;

[0026] Heat-resistant agent: DENKAIP heat-resistant modifier, MS-NIP granular, Denki Chemical Industry (Shanghai) Trading Co., Ltd.;

[0027] Antioxidant 1010: hindered phenolic antioxidant, produced by DOUBLE BOND CHEMICAL IND. Co., Ltd.;

[0028] Antioxidant 619F: phosphite auxiliary antioxidant, produced by Chemtura;

[0029] Dispersant: ethylene bis stearic acid amide;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com