Shirt collar type mold machine with multi-directional core pulling mechanism and implementation method thereof

A core-pulling mechanism and multi-directional technology, applied in the field of mold machines, can solve the problems of easy-to-adhesion injection molding parts, many core-pulling mechanisms, and poor use effect, and achieve the effect of convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

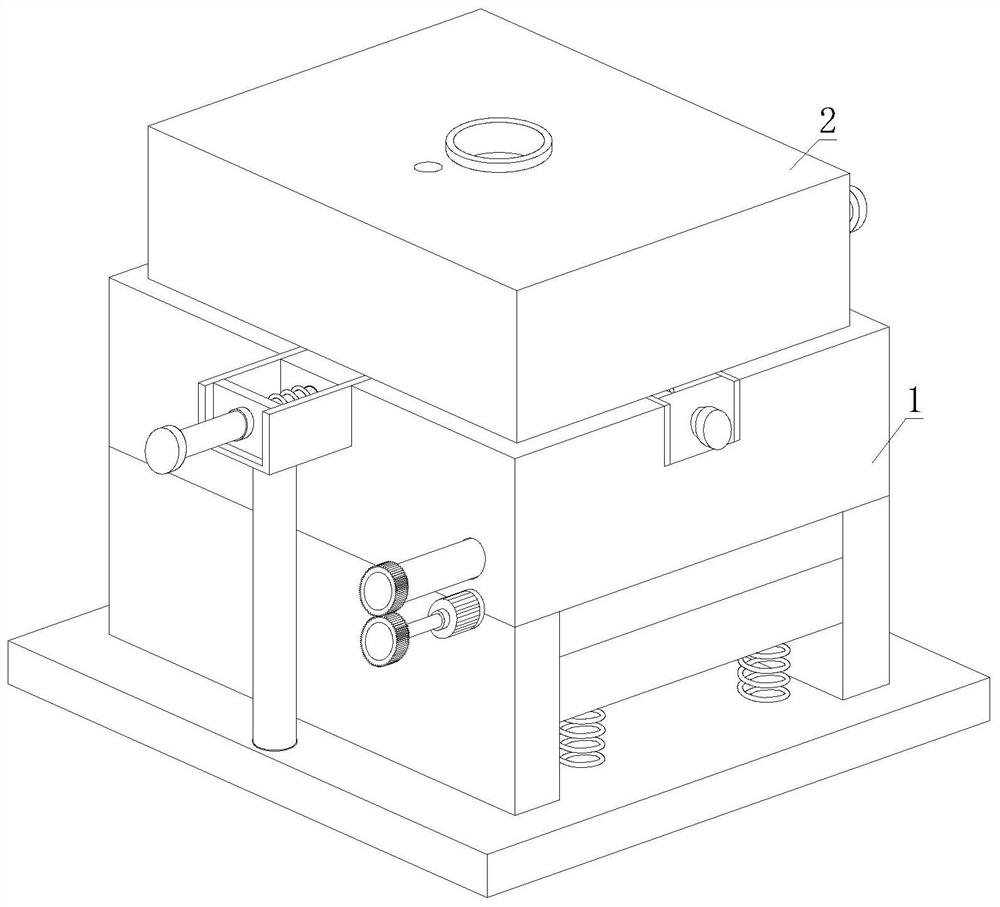

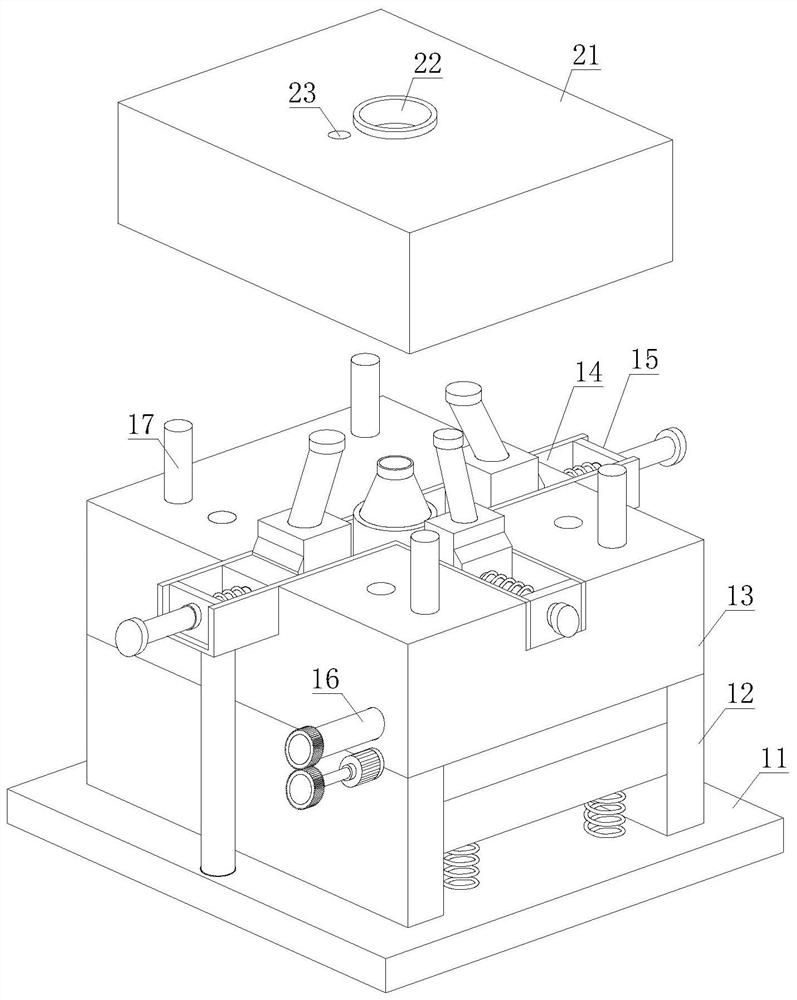

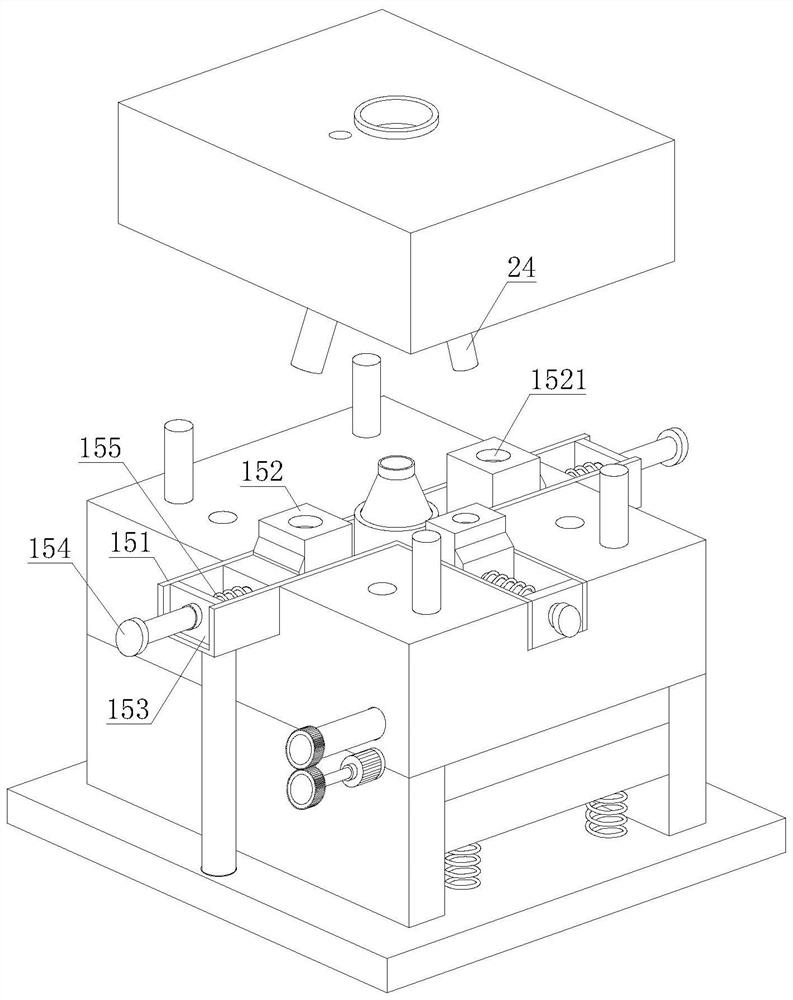

[0037] see figure 1 , figure 2 and image 3, a shirt collar mold machine with a multi-directional core-pulling mechanism, comprising a lower mold 1 and an upper mold 2, the upper mold 2 is movably installed on the upper end of the lower mold 1, and the lower mold 1 includes a base 11, a support 12, and a mold base 13 , Groove 14, upper core-pulling mechanism 15, lower core-pulling mechanism 16 and positioning column 17, the support 12 is arranged on the upper end of the base 11, the mold base 13 is fixedly installed on the upper end of the support 12, and the groove 14 is arranged on the mold base 13, there are three groups of upper core-pulling mechanisms 15, and the upper core-pulling mechanisms 15 of the three groups are all arranged on the upper surface adjacent to the mold base 13, and the lower core-pulling mechanism 16 runs through the mold base 13 and is arranged on the The lower end of the upper core-pulling mechanism 15; the upper mold 2 includes a pressing plate ...

Embodiment approach

[0042] For a better presentation, this embodiment now proposes an implementation method of a shirt collar mold machine with a multi-directional core-pulling mechanism, including the following steps:

[0043] Step 1: inject lubricating oil into the lubricating port 231 so that it flows into the card groove 133 through the lubricating pipe 232 and is completely absorbed by the sponge layer 233;

[0044] Step 2: The operator clamps the positioning groove 211 at the lower end of the pressure plate 21 with the positioning column 17 at the upper end of the mold base 13, the first core 24 penetrates the core-pulling hole 1521 and engages with the clamping groove 133, and the pressure plate 21 is tightly connected to the mold base 13 fit;

[0045] Step 3: Injection molding by injecting injection molding fluid into the injection port 22;

[0046] Step 4: Lift the pressing plate 21 after forming, and when the first core 24 moves upward, when passing the scraper 15222, the lubricating o...

Embodiment 2

[0049] see figure 1 , figure 2 and image 3 , a shirt collar mold machine with a multi-directional core-pulling mechanism, comprising a lower mold 1 and an upper mold 2, the upper mold 2 is movably installed on the upper end of the lower mold 1, and the lower mold 1 includes a base 11, a support 12, and a mold base 13 , Groove 14, upper core-pulling mechanism 15, lower core-pulling mechanism 16 and positioning column 17, the support 12 is arranged on the upper end of the base 11, the mold base 13 is fixedly installed on the upper end of the support 12, and the groove 14 is arranged on the mold base 13, there are three groups of upper core-pulling mechanisms 15, and the upper core-pulling mechanisms 15 of the three groups are all arranged on the upper surface adjacent to the mold base 13, and the lower core-pulling mechanism 16 runs through the mold base 13 and is arranged on the The lower end of the upper core-pulling mechanism 15; the upper mold 2 includes a pressing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com