Halogen-free flame-retardant PC/ABS alloy material and preparation method thereof

A technology of alloy material and polycarbonate, which is applied in the field of halogen-free flame-retardant PC/ABS alloy material and its preparation, can solve problems such as buckle fracture, performance retention decline, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

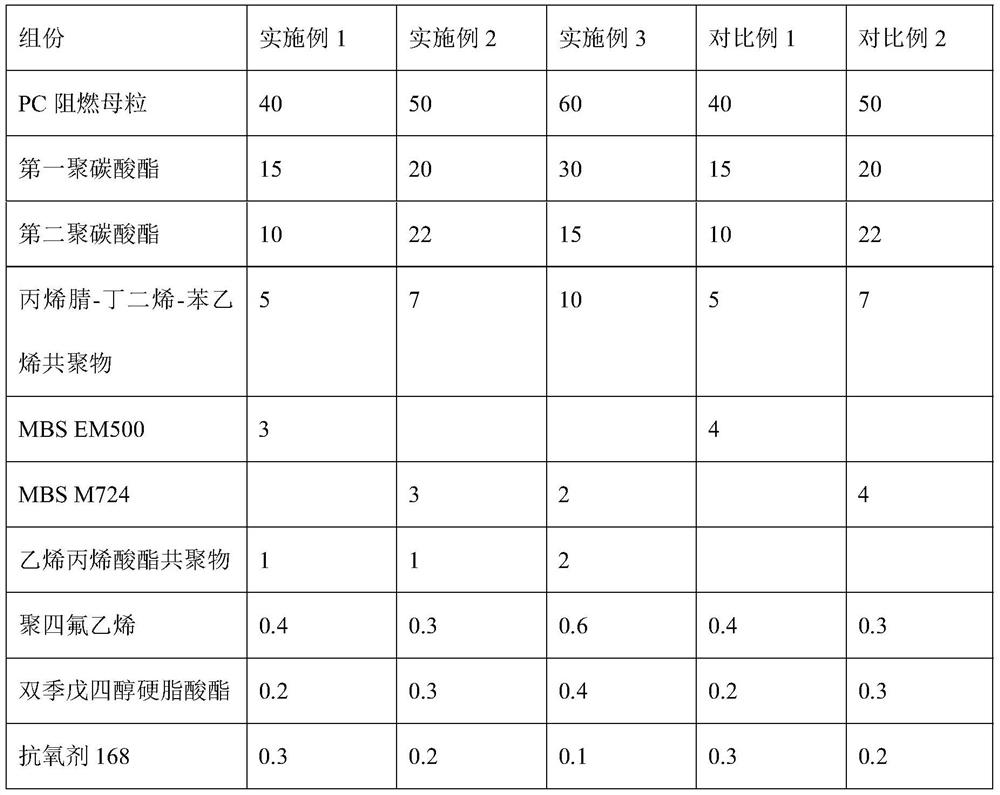

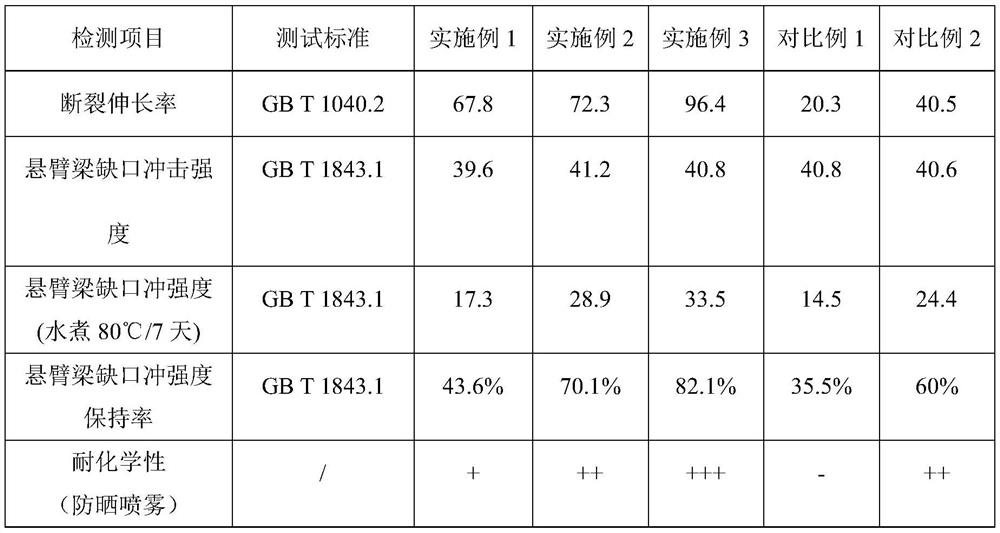

Embodiment 1

[0033] According to parts by weight, 40 parts of the flame-retardant PC masterbatch, 15 parts of the first polycarbonate, 10 parts of the second polycarbonate, 5 parts of acrylonitrile-butadiene-styrene copolymer, 3 parts of MBS EM500, ethylene After 1 part of acrylate copolymer, 0.4 part of polytetrafluoroethylene, 0.2 part of dipentaerythritol stearate and 0.3 part of 168 antioxidant are mixed uniformly, they are put into the twin-screw extruder through the main feeding port, and passed through the twin-screw extruder. The halogen-free flame-retardant PC / ABS alloy material is obtained by shearing, melting and plasticizing, extruding and granulating in a screw extruder, and homogenizing. The barrel temperature of the twin-screw extruder from zone 1 to zone 9 and the machine head are as follows: 180°C, 250°C, 250°C, 250°C, 250°C, 240°C, 240°C, 230°C, 210°C, 240°C ℃; main engine speed 400r / min, vacuum -0.08MPa.

Embodiment 2

[0035] According to parts by weight, 50 parts of the flame-retardant PC masterbatch, 20 parts of the first polycarbonate, 22 parts of the second polycarbonate, 7 parts of acrylonitrile-butadiene-styrene copolymer, 3 parts of MBS M724, ethylene After 1 part of acrylate copolymer, 0.3 part of polytetrafluoroethylene, 0.3 part of dipentaerythritol stearate and 0.2 part of 168 antioxidant are mixed uniformly, they are put into the twin-screw extruder through the main feeding port, and passed through the twin-screw extruder. The halogen-free flame-retardant PC / ABS alloy material is obtained by shearing, melting and plasticizing, extruding and granulating in a screw extruder, and homogenizing. The barrel temperature of the twin-screw extruder from Zone 1 to Zone 9 and the machine head are as follows: 180°C, 250°C, 250°C, 250°C, 250°C, 240°C, 240°C, 230°C, 210°C, 240°C ℃; main engine speed 400r / min, vacuum -0.08MPa.

Embodiment 3

[0037] According to parts by weight, 60 parts of the flame-retardant PC masterbatch, 30 parts of the first polycarbonate, 15 parts of the second polycarbonate, 10 parts of acrylonitrile-butadiene-styrene copolymer, 2 parts of MBS M724, ethylene After 2 parts of acrylate copolymer, 0.6 part of polytetrafluoroethylene, 0.4 part of dipentaerythritol stearate and 0.1 part of 168 antioxidant are mixed uniformly, they are put into the twin-screw extruder through the main feeding port, and passed through the twin-screw extruder. The halogen-free flame-retardant PC / ABS alloy material is obtained by shearing, melting and plasticizing, extruding and granulating in a screw extruder, and homogenizing. The barrel temperature of the twin-screw extruder from Zone 1 to Zone 9 and the machine head are as follows: 180°C, 250°C, 250°C, 250°C, 250°C, 240°C, 240°C, 230°C, 210°C, 240°C ℃; main engine speed 400r / min, vacuum -0.08MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com